The Pontiac division of General Motors met an untimely demise in 2010, but in the glory days of American muscle, the marque defined an era. Pontiac was a brand synonymous with performance, climaxing with the breakout GTO intermediate that launched the muscle car era, a position reinforced by worthy Firebirds, Bonnevilles, Catalinas, and Gran Prix model variants through those years. Unlike the products of the corporate era, Pontiac muscle was propelled by distinct Pontiac engines. Those engines were known for outstanding street power and helped build a legacy that lives on today. While the last true Pontiac engine was cast in 1981, these engines retain a dedicated following, and aftermarket parts support has never been better.

Mike Semchee is one of those loyal Pontiac enthusiasts, and for our annual engine-building competition, the AMSOIL Engine Masters Challenge, he represented the faithful with a true Pontiac entry in the Street Division of competition. Although in today's world it is entirely possible to build a high-performance Pontiac engine combination with all aftermarket parts, Semchee looked to base his build on traditional Pontiac iron. The result is a stout street Pontiac that makes use of an authentic Pontiac foundation, while upping the ante on modern-era horsepower.

The Build

Semchee started with a production base, beginning with an OEM Pontiac engine as the core. The basis is a factory 400 block typical of those fitted to an original muscle Pontiac. As Semchee jokes, the 1972 casting is considered a late-model piece in the Pontiac world, "I tell everyone I used my ‘new' block; it is a 1971 GTO block. These have a factory bore of 4.125 inches. I just gave it a standard overbore, but over the years of freshening it up, it grew a little to the current bore size of 4.157 inches."

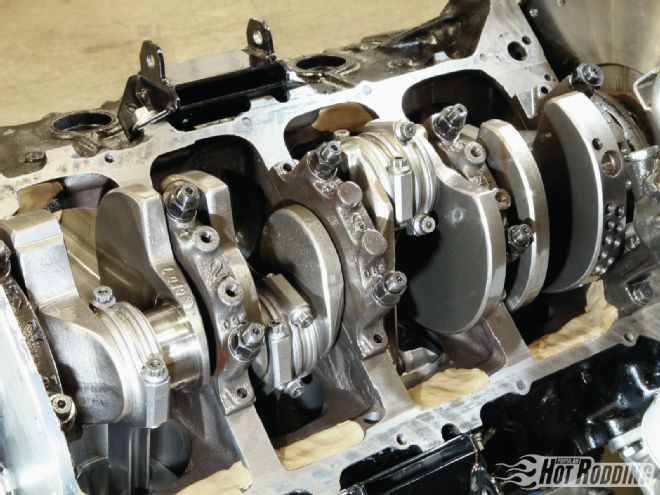

Although Semchee modified the factory block for increased strength, it retained most of its OEM content. As Semchee explained: "The Pontiac blocks are strong. I did fill it, but they are very strong. I filled the block to the bottom of the water pump hole. This keeps the cylinders more stable and stronger. The block has the factory two-bolt mains. I put a lifter bore brace in it because the bores are in the open and if you run a really aggressive cam you can bust them out, so I made my own lifter bore brace. I machined four individual pieces that fit under the plates and epoxied them in and put the bars on top to hold them. I had my block machined at Crank and Sleeve Shop in Girard, Ohio. They do what I ask them to do. They do excellent, perfect stuff."

To go along with the factory block, Semchee looked no further than OEM equipment for the crankshaft: "The crankshaft is a factory unit, in fact, it is the original crank that came out of this block. I sent it to Lunati to have it Magnafluxed, shot-peened, and ground. The OEM cranks are good and strong. I've never had a problem with the crankshaft. It is a nodular iron unit, and is the original crank for this block."

Things altered from OEM include the rods and pistons, as modern aftermarket pieces provide the durability and performance that the stock parts cannot match. The rods are Scat H-beams in the OEM 6.625-inch length. As Semchee tells us: "They are bulletproof. You'll never have a problem with those in a Pontiac motor, at least for what we are doing." The pistons are from JE, but received substantial modification from Semchee for this specific application: "I could not get what I needed for the piston shape, so what I did was I ordered the pistons as flat-tops with valve reliefs, and machined the shape of the combustion chamber and made it a spherical dish. When the fuel burns in a spherical dish configuration it requires less timing and makes more power." The rings are also from JE, with .043-inch compression rings and a 3mm oil ring. Semchee notes: "The JE piston pins are much lighter than those from Pontiac; the Pontiac pins were very heavy. With the lighter pins it revs quicker and makes more power, and there is a lot less strain on the rotating assembly."

The bottom end of the engine was sealed with a full-length "bathtub" style oil pan from Charlie's Oil Pans. The odd choice of pan configuration was to take advantage of the liberal rules in effect for the 2012 EMC competition, though as Semchee tells us, the majority of the oiling system is OEM Pontiac: "I used the huge pan to keep the windage from the crank down and prevent wrapping all the oil up. I was advised by Charlie's not to use a windage tray with that pan, but I filled the pockets in the block at the pan rail to keep the oil from splashing back into the crank. The only thing I do to the factory oiling system is take the top half of the main bearing and machine it to match the oil passages in the block. I have never had a problem with the OEM oiling system—there really is no trick there. I just put a little .030-inch hole in the screw-in plug at the back of the motor near the distributor gears to help to keep them oiled."

Building strong street performance from a Pontiac does not require starting over with aftermarket components. For power in the mid-500hp range, this engine uses a factory block, mains, and crankshaft. Mods here include ARP studs and stuffing the recesses in the pan rails with epoxy to relieve the windage trapping pocket.

Building strong street performance from a Pontiac does not require starting over with aftermarket components. For power in the mid-500hp range, this engine uses a factory block, mains, and crankshaft. Mods here include ARP studs and stuffing the recesses in the pan rails with epoxy to relieve the windage trapping pocket.

Filling the bores are a set of JE forged pistons hanging from Scat H-beam rods. The pistons were modified by engine builder Mike Semchee with a dish matching the combustion chambers. The effect of the volumes involved tally to a pump-gas friendly compression ratio of 10.4:1.

Filling the bores are a set of JE forged pistons hanging from Scat H-beam rods. The pistons were modified by engine builder Mike Semchee with a dish matching the combustion chambers. The effect of the volumes involved tally to a pump-gas friendly compression ratio of 10.4:1.

With the open lifter bores of a Pontiac block, side loading from a roller cam can induce stresses that can potentially result in breakage. Semchee buttressed this area with custom aluminum supports bedded in epoxy.

With the open lifter bores of a Pontiac block, side loading from a roller cam can induce stresses that can potentially result in breakage. Semchee buttressed this area with custom aluminum supports bedded in epoxy.

For the AMSOIL Engine Masters Challenge, Semchee had Charlie’s Oil Pans build this full-length bathtub-style oil pan, which was run without a tray or scraper. The huge pan woks with a Melling pump and an otherwise stock oiling system.

For the AMSOIL Engine Masters Challenge, Semchee had Charlie’s Oil Pans build this full-length bathtub-style oil pan, which was run without a tray or scraper. The huge pan woks with a Melling pump and an otherwise stock oiling system.

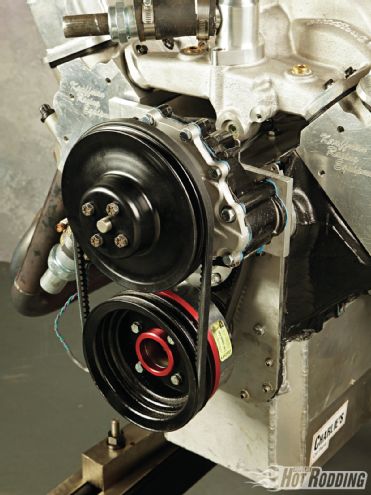

At the front, a BOP beltdrive spins the cam in time with the crank. The hydraulic roller cam from Bullet Cams is a very quick hydraulic roller, measuring 240/248 degrees duration at .050-inch lift, and delivering .685-inch valve lift. The beltdrive speeds cam timing changes, helping zero-in on the optimal setting.

At the front, a BOP beltdrive spins the cam in time with the crank. The hydraulic roller cam from Bullet Cams is a very quick hydraulic roller, measuring 240/248 degrees duration at .050-inch lift, and delivering .685-inch valve lift. The beltdrive speeds cam timing changes, helping zero-in on the optimal setting.

Heads and Cam

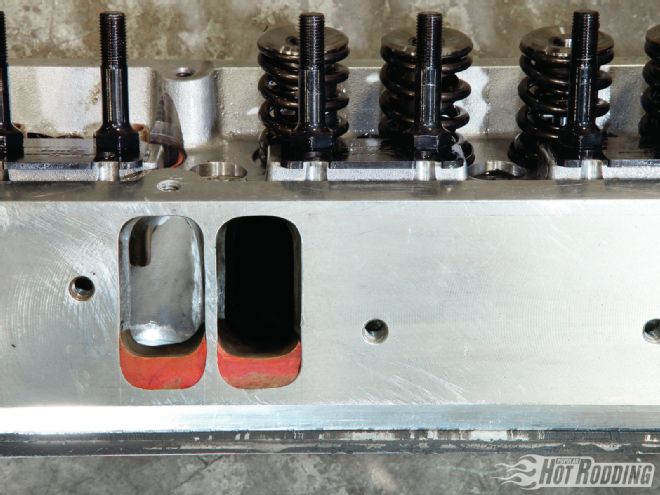

In contrast to the heavily production-biased bottom end, the top end of the engine takes advantage of aftermarket products and significant modifications. Semchee details the cylinder heads: "I used the Kauffman high-port heads, and I had Darrin Morgan port them. We added the epoxy to get the port velocity up, and above the epoxy the heads were widened and raised. The intakes flowed 400 cfm at .900-inch lift, but of course we are not lifting the valves that much. The flow adds up to horsepower, but you have to consider the velocity too; you have to consider the two together. I wanted to keep the heads as small as possible. Just by comparison, the heads are smaller than the large Pontiac Ram Air IV iron castings, but flow a lot more."

To operate the valves, Semchee relied on the expertise of Bullet Cams: "We kind of had an idea of what we wanted and talked to John Partridge at Bullet and had him finalize the cam specs. We were a little tight on time, so we couldn't experiment much on the cam. The cam measures 240/248 degrees duration, ground on a lobe separation angle of 106 degrees. We use a mixed set of Crower and COMP rockers at 1.7/1.65:1 ratio because we had to slow the exhaust down a little. It was scavenging too much and losing power, so we reduced the ratio. We made the change and picked up around 20 hp."

Semchee continued on the valvetrain: "The lifters are Scorpion limited-travel hydraulic rollers. Whether you need them depends on the profile of the cam. If it is not that radical, you can use the regular lifters, but if you lose stability, it will be very hard on the valvetrain. With the high spring pressure and the radical cam we used a stud girdle to stabilize the valvetrain. We also went with a beltdrive system, which is a real benefit in a higher powered engine. With the beltdrive, it is just a five-minute job to alter the cam timing without having to tear the motor apart. It makes it very easy to tune, and you can pull the cam easily without having to do as much disassembly to the front of the engine."

Induction Equation

Semchee disclosed that the fuel delivery system was one area where the engine build plan strayed off course: "We were originally going to run an EFI combo on a single-plane intake manifold, but we ran into problems. With time running out to prepare the engine for competition, we threw the carb on it with a two-plane intake. We probably lost 60-70 hp compared to the big intake on the EFI system, but as it turned out the control box was bad. The Edelbrock Performer RPM manifold was nearly box-stock, other than filling the bottom of the ports to match the heads. We really did not have much time to work on it. We did have a very good Holley carburetor on the engine. The carb was done by the late Keith Dillard, and it was pretty extensively reworked. We had used the carb in the past and found that it worked much better than one out of the box."

A set of custom headers was fabricated with a stepped primary configuration featuring 1¾ - 1⅞-inch primary tubes. The headers were fitted with a pan evacuation system drawing crankcase pressure into the collector. Semchee disclosed: "The crankcase ventilation makes some more power. The shape of that tube in there is very critical, as is the angle it is on, and the length it is in there. Ray Clayton did extensive testing on the flow bench to find the placement, angle, and shape, and it made a difference. Overall, to put a number on it, we found around 5 hp with this system."

To The Dyno

The engine was dressed with a full MSD ignition system including an MSD 7AL-2 Plus control box, which is programmable, but it was set for a straight 36 degrees advance for total timing. Bolted to the DTS Powermark engine dyno at the University of Northwestern Ohio, this hot Pontiac combination had the opportunity to prove its worth. Running on VP unleaded fuel, the Poncho showed a power curve right on target for serious street action. With just 408 ci, the torque curve displayed tire-frying twist, with 436 lb-ft on tap at a lowly 2,500 rpm, and a peak of 535 lb-ft at 4,700-4,900 rpm. That's torque in abundance in an rpm range where you can really use it. Power came in at a healthy 546 hp at a modest 5,800 rpm, again just in the range for usable street output.

As Semchee tells us: "What is great now is all the aftermarket support with the heads and other parts. Years ago we had to run the factory iron heads and you'd pay a lot for a set of iron Ram Air IV heads. For a street/strip car, you might not even want to run the high-port head, but for an application like this the high-port heads improve the flow and allow more top end horsepower." The combined efforts of a vibrant aftermarket and the unwavering enthusiasm of Pontiac specialists like Semchee assures us that Pontiac's legacy will indeed live on!

Topping the engine is a set of Darrin Morgan–ported Kauffman high-port heads fitted with Ferrea 2.250-inch intake valves and 1.750-inch valves on the exhaust side. The valvetrain consists of Scorpion limited-travel hydraulic roller lifters, Trend pushrods, and Bullet springs.

Topping the engine is a set of Darrin Morgan–ported Kauffman high-port heads fitted with Ferrea 2.250-inch intake valves and 1.750-inch valves on the exhaust side. The valvetrain consists of Scorpion limited-travel hydraulic roller lifters, Trend pushrods, and Bullet springs.

The extensively reworked cylinder heads feature significant filling on the intake port floor, looking to achieve the maximum flow from the smallest cross-section. The efficient port form delivers an impressive peak flow of 400 cfm.

The extensively reworked cylinder heads feature significant filling on the intake port floor, looking to achieve the maximum flow from the smallest cross-section. The efficient port form delivers an impressive peak flow of 400 cfm.

The stud-mounted valvetrain features both COMP and Crower rockers, as testing showed a slightly reduced ratio on the exhaust side improved power. The intake ratio specs at 1.7:1, while the exhaust is 1.65:1. The Kauffman stud girdle ties the valvetrain together for improved stability.

The stud-mounted valvetrain features both COMP and Crower rockers, as testing showed a slightly reduced ratio on the exhaust side improved power. The intake ratio specs at 1.7:1, while the exhaust is 1.65:1. The Kauffman stud girdle ties the valvetrain together for improved stability.

Topping the engine is an induction featuring a street-oriented Edelbrock Performer RPM two-plane intake manifold and a Holley 4150 HP-series carb. The carb was custom tuned by Lone Star Motorsports.

Topping the engine is an induction featuring a street-oriented Edelbrock Performer RPM two-plane intake manifold and a Holley 4150 HP-series carb. The carb was custom tuned by Lone Star Motorsports.

Modifications to the Edelbrock intake manifold were minimal, other than significant reworking at the port exits to match the modified intake ports of the heads.

Modifications to the Edelbrock intake manifold were minimal, other than significant reworking at the port exits to match the modified intake ports of the heads.

By The Numbers 408ci Pontiac Bore: 4.157 inches Stroke: 3.750 inches Displacement: 408 ci Compression ratio: 10.4:1 Camshaft: Bullet hydraulic roller Camshaft duration: 240/248 degrees at .050-inch tappet rise Valve lift: .685/.685-inch Rocker and ratio: COMP/Crower 1.7/1.65 Piston rings: JE .043/.043/3mm Piston: JE forged Block: OEM Pontiac production Crankshaft: OEM Pontiac production Rods: Scat H-beam, 6.625-inch Cylinder head: Kauffman Intake valve diameter: 2.250 inches Exhaust valve diameter: 1.750 inches Intake manifold Edelbrock Performer RPM Carburetor: Holley 4150 Header: CHE 1¾-1⅞-inch stepped Ignition: MSD Damper: PRW

On The Dyno 408ci Pontiac RPM: TQ: HP: 2,500 436 208 2,700 450 231 2,900 444 245 3,100 458 270 3,300 475 299 3,500 487 324 3,700 495 349 3,900 497 369 4,100 507 396 4,300 521 427 4,500 531 455 4,700 535 479 4,900 535 499 5,100 529 513 5,300 520 525 5,500 512 536 5,700 501 544 5,800 494 546 5,900 485 545 6,100 467 542 6,300 444 533 6,500 421 521

A set of Fel-Pro gaskets illustrate the radically raised port position. Note the re-punched fastener location and the altered port floor.

A set of Fel-Pro gaskets illustrate the radically raised port position. Note the re-punched fastener location and the altered port floor.

MSD met the requirements of the complete ignition system, including the programmable 7AL-2 Plus ignition box and HVC-2 coil. Semchee tells us the MSD components deliver reliability and performance.

MSD met the requirements of the complete ignition system, including the programmable 7AL-2 Plus ignition box and HVC-2 coil. Semchee tells us the MSD components deliver reliability and performance.

Much experimentation with the header led to the final configuration of a stepped 1¾ - 1⅞-inch primary by CHE. Semchee noted that the pan evac system efficiency was sensitive to the angle and position of the scavenging tubes.

Much experimentation with the header led to the final configuration of a stepped 1¾ - 1⅞-inch primary by CHE. Semchee noted that the pan evac system efficiency was sensitive to the angle and position of the scavenging tubes.

Up front we see a production-style mechanical water pump, with an MSD crank trigger wheel hidden behind the drive pulley. Cooling on the street is well handled by the capacity of this system.

Up front we see a production-style mechanical water pump, with an MSD crank trigger wheel hidden behind the drive pulley. Cooling on the street is well handled by the capacity of this system.

On the dyno at the 2012 AMSOIL Engine Masters Challenge, this stout production-based Pontiac delivered impressive output with a minimum of fuss, belting out a peak of 546 hp at a modest 5,800 rpm.

On the dyno at the 2012 AMSOIL Engine Masters Challenge, this stout production-based Pontiac delivered impressive output with a minimum of fuss, belting out a peak of 546 hp at a modest 5,800 rpm.

Pontiac performance is what it is all about for these individuals. Pictured from left to right are John Albert, Bruno Jacobs, Ray Clayton, and Mike Semchee.

Pontiac performance is what it is all about for these individuals. Pictured from left to right are John Albert, Bruno Jacobs, Ray Clayton, and Mike Semchee.