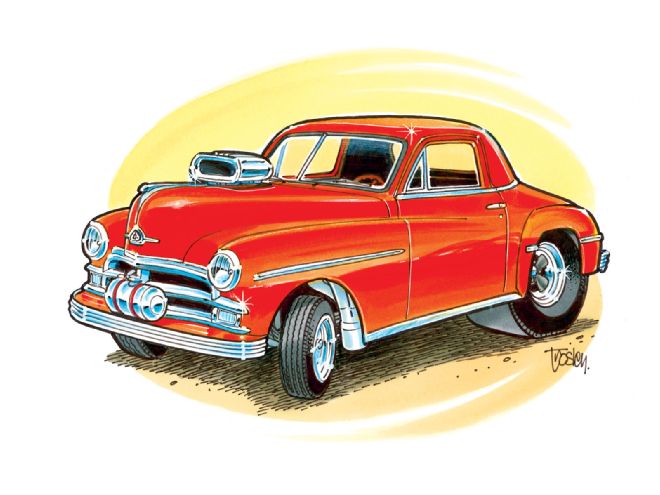

There are times when looking at something from a different angle gives you a fresh perspective-in more ways than one. So it was while sitting on a creeper in front of our project RamRodder. We were kicking around options for a radiator when, from our low-angle position, it struck us that the grille opening was much wider than it was tall. The stock radiator was tall, had a narrow downflow design with a good deal of the core hidden behind the hood. From our vantage point it appeared as though a short, wide crossflow radiator was the way to go.

Thumbing through the Speedway Motors catalog we came across a variety of AFCO universal fit crossflow aluminum radiators. The one we settled on was 25-1/2 inches wide and 19 inches tall. To fit this cooler between the framerails would require some modifications, and although we could have gone with a slightly smaller unit that would have fit easily, we decided our blown Chrysler should have all the cooler we could cram in and opted for the largest available with a shroud and electric fan.

The AFCO crossflow radiator takes better advantage of the Plymouth's grille opening than the stock downflow design.

The AFCO crossflow radiator takes better advantage of the Plymouth's grille opening than the stock downflow design.

When discussing our radiator requirements with Jay Miller of AFCO, he agreed that the crossflow design had advantages for our application. He also pointed out some other facts to take into consideration when selecting a radiator. At one time the rows of tubes in a radiator was a big selling point. The theory was the more the better and three or four rows were thought to offer the optimum in cooling. However, the multiple rows of tubes (particularly when they were staggered) and a high fin count (which was also thought to be beneficial) actually impeded airflow through the core. Today it's known that fewer rows of larger tubes are more effective. The goal with both the rows of tubes and the number of fins per inch is to provide the maximum surface area with the least amount of resistance to airflow; our AFCO radiator has two rows of 1/2-inch tubes and 14 fins per inch.

While aluminum radiators work well there are some precautions that go along with their use. While this sounds out of place, always make sure the engine is properly grounded to the frame-if it isn't, the possibility exists that the electrical system will try to ground through the coolant and the resulting electrolysis will destroy the radiator in short order. Another precaution is to use the recommended pressure cap. Aluminum radiators will stand steady high pressure but sudden bursts from a percolating cooling system can cause damage-a 16-18 psi cap will prevent such problems. Finally, Miller recommends a fifty-fifty mix of water and antifreeze for coolant.

AFCO radiators from Speedway Motors are beautifully built. They're available in direct fit and universal configurations.

AFCO radiators from Speedway Motors are beautifully built. They're available in direct fit and universal configurations.

It took a little tweaking and trimming to get the radiator in place as the Chrysler and blower drive fills the engine compartment with little room to spare, but we're confident that going with the biggest crossflow radiator will help us keep our cool.