This is for all the guys who are addicted to super sizing. You know, the largest soda at the 7-11, the Camaro with the widest rear tires on the planet, and a Rat motor that must displace at least 500 ci. While the small-block has enjoyed plenty of attention when it comes to displacement enhancement, the Rat continues to be King of the Street.

So this got us thinking about what kind of street-driven, pump-gas, normally aspirated big-block we could build that would automatically be branded Neolithic by the tree-huggers and blasted as anything but cost-effective by the monetarily challenged. If you are either of these and are considering firing up your poison pen, save yourself the trouble because we'll ignore your bleating. This is an in-your-face Rat that we wanted to build mainly because we could.

OK, so our pal Tim Moore stumbled across a good deal on a Gen VI 502 iron-block at a swap meet, so right away we were off to a good start. That led to the selection of a Scat 4340 steel crank with a 4.250-inch stroke to add a quarter-inch arm to a stock 454's swing. Since this had to be a pump-gas motor, we went with Sportsman Racing Pistons' (SRP) streetable forged aluminum-alloy pistons with a flat top to keep the compression realistic. With a 4.500-inch bore allowed by the 502 block and the coffee-can-sized pistons, we ended up with Max the Rat at 540 cubic inches.

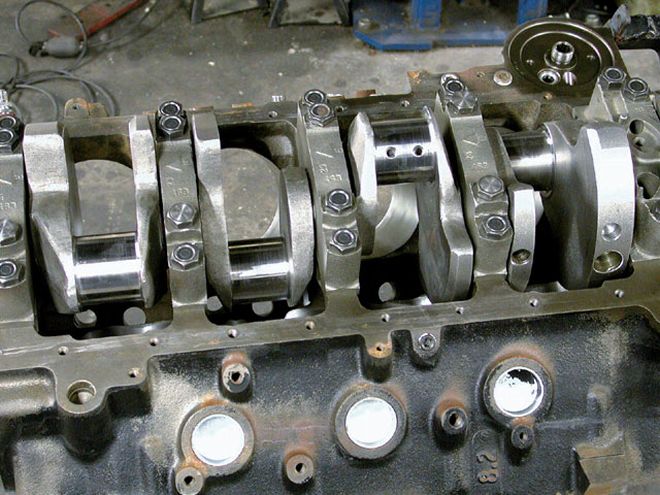

To begin our 540ci buildup, we started with a used Gen VI Bow Tie block that Tim discovered at a swap meet. After Jim Grubbs Motorsports completed the machine work, Tim dropped in the Scat one-piece rear-main-seal stroker crank with Federal-Mogul bearings.

To begin our 540ci buildup, we started with a used Gen VI Bow Tie block that Tim discovered at a swap meet. After Jim Grubbs Motorsports completed the machine work, Tim dropped in the Scat one-piece rear-main-seal stroker crank with Federal-Mogul bearings.

Flow Chart

The key to power with any engine, from the lowliest four-cylinder to the manliest supercharged Top Fuel engine, is cylinder head flow. But while ultimate flow is always attractive, there are other considerations that often become critical. The most important for us was to retain the street nature of the cylinder head. Many good Rat heads raise the exhaust ports to improve the exhaust flow. While this is an excellent plan for power, it requires very expensive custom headers-something we wanted to avoid.

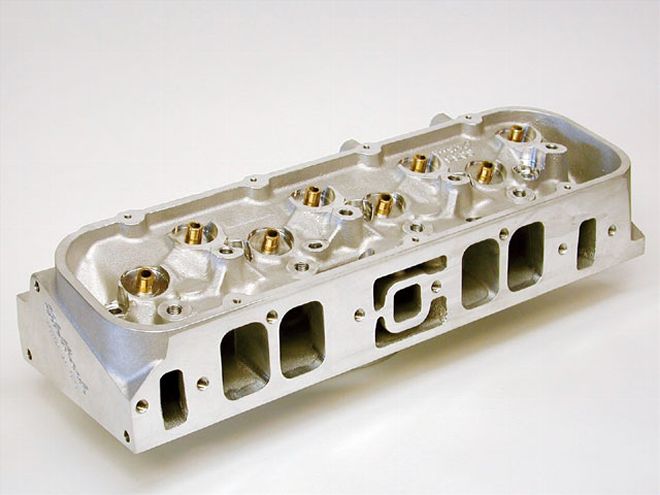

This led us to Edelbrock's Victor Jr. Chapman CNC heads. These heads feature a stock-location exhaust port, yet sport a healthy 320cc intake-port volume and a fully CNC-machined 112cc chamber. The valve sizes come in at a manly 2.250/1.90 inches. The heads are shipped with valves but without springs, because Edelbrock realizes that a head like this will require custom springs to match the cam.

Next it was time for a camshaft. Tim is good buddies with Flowmaster's Kevin McClelland, who also did us the favor of helping spec the camshaft. The idea was that we didn't want to worry about detonation, but we also didn't want to short-change the heads with a wimpy cam. Tim was also smart enough to realize that the cam would have to be ground on a Gen VI-style cam blank in order to properly mate with the Gen VI block. We ended up with a custom grind from Crane. This may sound expensive and time-threatening, but the truth is that Crane handles custom orders like this every day and got us the cam in a few days. You can find the specs in the accompanying spec chart, but needless to say, it's a thumper.

A 540 creates its displacement not only from the 4.25-inch-stroke increase but also from the monstrous 4.500-inch bore. This called for SRP forged pistons featuring a Total Seal 1/16-inch ring package with a 3/16-inch oil ring. Tim pinned the pistons to a set of Scat 4340 forged H-beam 6.135-inch rods to complete the rotating assembly.

A 540 creates its displacement not only from the 4.25-inch-stroke increase but also from the monstrous 4.500-inch bore. This called for SRP forged pistons featuring a Total Seal 1/16-inch ring package with a 3/16-inch oil ring. Tim pinned the pistons to a set of Scat 4340 forged H-beam 6.135-inch rods to complete the rotating assembly.

We also lined up a Victor Jr. 4500-style intake along with a Demon 1,090-cfm Race Demon carburetor-a big-inch motor like this wouldn't be happy with an 850- or 900-cfm square-bore carburetor. We also acknowledge that it will take some effort to ensure that this big Dominator gets a little attention when it comes to part-throttle tuning for the street.

Along with the induction system, we also added a complete MSD billet-aluminum distributor, wires, and an MSD-6A box to boldly light the fire. On the exhaust side, we chose a set of Dynatech 2 1/4-inch headers to vent the exhaust along with a Flowmaster 3-inch exhaust system and a pair of matching mufflers. After Ed Taylor bolted all these parts in place on Ken Duttweiler's dyno, and after gently warming up and breaking in Max the Rat, we were ready to make some noise.

The key power point of any buildup has to be the cylinder heads. For our fat Rat, we chose a set of Edelbrock Victor Jr. CNC'd rectangle-port heads. With 320cc Chapman-ported intake ports, the Victor Jr. CNC'd heads are based on the Performer RPM casting. In addition, the casting has been rolled 1.5 degrees before machining to decrease the chamber size and unshroud the valves.

The key power point of any buildup has to be the cylinder heads. For our fat Rat, we chose a set of Edelbrock Victor Jr. CNC'd rectangle-port heads. With 320cc Chapman-ported intake ports, the Victor Jr. CNC'd heads are based on the Performer RPM casting. In addition, the casting has been rolled 1.5 degrees before machining to decrease the chamber size and unshroud the valves.

WOT Fun

Big-inch Rats have a sound all their own. This motor doesn't thump at idle like some you've heard mainly because with a big cam and only 9.5:1 compression, the cylinder pressure's not overpowering. But the cam matched nicely with the rest of the package, and this allowed Ed to pull this rotund rodent all the way down to 2,500 rpm. If you've ever wondered why many dyno-tests start at 3,500 or 4,000, it's often because the cam is so rowdy that the engine literally won't hold a wide-open-throttle (WOT) load at that low of an engine speed. Tim's super-sized Rat, on the other hand, was more than happy at 2,500, so our test data starts at 2,600.

The first minor difficulty our gallant testers ran into was that Max wanted a bunch more fuel. Even using the largest jets we had in the 1,090-cfm Demon, our Innovate air/fuel-ratio meter reported a lean 13.5:1. This necessitated increasing the power-valve feed restrictors in the primary as well as increasing the restrictor size in the Demon's intermediate fuel-delivery circuit. This was worth sufficient fuel to bring the air/fuel ratio closer to 12.9 to 13.0:1, where we felt the engine would be safe and also make the best power.

And power is what we had. We ran Max both with open headers and with 3-inch Flowmasters, but we'll deal with the muffled exhaust numbers for the sake of our street intentions. Our big-stick big-block started out at 2,600 rpm with over 500 lb-ft of torque and then pushed peak torque up to 632 lb-ft at 4,900 rpm, with peak horsepower coming in with 711 hp at a reasonable 6,200 rpm. That's a 1,300-rpm powerband, which is a little narrower than we would have liked-but hey, we're talking about 711 big ones here.

The fully CNC-machined chambers measure a mere 112 cc's but are crammed with monstrous 2.250/1.90-inch valves. To keep the weight down, they use smaller 1 1/32-inch versus 3/8-inch stems. The heads come complete with Serdi-machined ductile iron seats.

The fully CNC-machined chambers measure a mere 112 cc's but are crammed with monstrous 2.250/1.90-inch valves. To keep the weight down, they use smaller 1 1/32-inch versus 3/8-inch stems. The heads come complete with Serdi-machined ductile iron seats.

For fun, we plugged that power into the Quarter Pro simulation for a 3,500-pound body style with a TH400 automatic and a conservative 3,500-rpm stall, 5 percent slippage, a 3.91 gear pushing sticky 18-inch tall slicks that are 10.5 inches wide on a decent 72-degree-F day at sea level with a 29.00 barometer. The simulation spit out a 10.55/132-mph number using a 1.60-second sixty-foot time while shifting at 6,500 rpm. That's a great effort from a heavy car, but certainly achievable-and that's without any power adder. Imagine pumping a 150 or 200hp shot on top of that! Yahoo!

Conclusion

So what have we learned here? Max the Rat isn't cheap and it isn't conservative. But it does make excellent power, and since it only spins to 6,500 rpm, it should be dead reliable. With 500 lb-ft of torque on demand at 2,600, traction will be difficult to achieve. But that's the kind of problem that every car crafter dreams of. So there you have it-a Rat for all seasons, because it's never too hot or too cold to go fast.

Test Numbers

Test 1: The 540ci Rat complete with 2-inch primary tube headers with an open exhaust system

Test 2: The same as Test 1 except the addition of a complete 3-inch exhaust system and Flowmaster mufflers

RPM TEST 1 TEST 2 TQ HP TQ HP 2,{{{600}}} 503 249 488 241 2,800 522 278 508 271 3,000 538 307 535 306 3,{{{200}}} 595 362 581 354 3,400 627 406 618 400 3,600 618 424 609 417 3,800 602 436 609 440 4,000 600 457 617 466 4,200 616 493 622 493 4,400 631 529 623 526 4,600 643 563 625 553 4,800 638 583 635 570 5,000 644 613 632 598 5,200 645 639 630 623 5,400 643 661 630 647 5,600 637 679 623 664 5,800 630 696 615 679 6,000 619 707 609 696 6,200 608 718 602 711 6,400 584 711 580 706 6,600 573 {{{720}}} - - 6,800 547 709 - - 7,000 523 697 - - Avg. 607 525 599 518Note: Averages were calculated only between 2,600 and 6,400 rpm.

Flow Results

Edelbrock Victor Jr.

CNC Head

2.250/1.90-inch valves

112cc Chamber

320cc Intake Port

E/I @ 0.400: 87%

Note: This head was flowed on a 4.250-inch bore fixture. Our 540 sports a much larger 4.50-inch bore that unshrouds the intake valve considerably. This is why our flow numbers are smaller than Edelbrock's published flow numbers.

Cam Specs

The cam we used was a Crane custom mechanical roller with the following specs, installed 3 degrees advanced at a 109-degree intake centerline.