Let's face it, 400M Ford owners get no respect. Sure, mention the word Cleveland and watch everyone's eyes light up, but the fire dies right out when you try to include the Modified or Midland family in the discussion. This seems odd since the two motors share so many components. In fact, it can be argued that the 400M motors are nothing more than a tall-deck, stroker Cleveland. Think about it-that's all that separates the legendary 351 Cleveland from its torque-oriented 400M (try running that statement by a Cleveland fan some time). Run with the same combination of parts (heads, cam, and intake), the 400M will always make more power than a 351 Cleveland, making it a readily available and ideal classic truck powerplant. Nonsense you say? They key to the statement is that fact that one truck motor measures 400 ci and the other fancy race motor displaces just 351 ci. It doesn't take a rocket scientist to realize that if both have the same head flow, cam timing, and induction system, the bigger motor will always make more peak and average power. The key is selecting the right components for your intended application.

More power and torque for your Ford 400M is a simple intake swap away.

More power and torque for your Ford 400M is a simple intake swap away.

How many Clevelands out there are running around with 568 hp and how may of those make 542 lb-ft of torque? These 400M motors are capable of some serious power, but for now we will stick with some basic mods, namely the induction system. Unfortunately for 400M owners, Ford saw fit to offer the motor with only a two-barrel manifold and carburetor. True enough, the motor was designed as a workhorse, but why limit the power and torque potential with a restrictive induction system? Heck, even the tiny 289 and 302 Windsor motors came with four-barrel carbs and intakes. If any motor could take advantage of the benefits of a four-barrel carb, it was the comparatively larger 400M. In fact, it can be argued that a proper four-barrel induction system would not only improve towing power, but might improve mileage as well, providing a spread-bore carb design was employed to allow cruising on the smaller primaries. Regardless of their reasoning, the factory deuce (two-barrel intake and carb) are restrictive even on a stock motor.

The test motor started out life as a wrecking yard find, pulled from the engine bay of a '76 F-250.

The test motor started out life as a wrecking yard find, pulled from the engine bay of a '76 F-250.

To illustrate the gains offered by dropping the deuce, we rebuilt a stock 400M yanked from the engine bay of a '76 F-250. The motor was in running condition, but we found a couple of bent pushrods and other evidence of abuse, so we took Demon Engines up on their offer to perform the necessary rebuild. Working with L&R Automotive (machine shop) and Probe Racing, the guys from Demon Engines were able to transform the tired 400M into a healthy stocker. In fact, the motor was treated to a piston upgrade in the form of a set of forged flat-top pistons from Probe Racing. The .030-over forged slugs were originally designed for a 351 Cleveland application, but fit perfectly in the freshly machined bores on our 400 block. The reciprocating assembly was balanced using a new 28-ounce balancer from Pro Comp. Additional changes included new rings and bearings, a new (stock) hydraulic flat-tappet cam from Elgin, and upgrading the factory connecting rods with ARP rod bolts. Care must be taken when rebuilding a motor equipped with a flat-tappet cam. The cam was liberally coated with assembly lube, ditto for the bottom of the lifters. We also added a container of high-zinc break-in lubricant from Lucas Oil before pre-lubing the 400M with a drill motor. Never start a dry engine.

Though the motor was likely a runner, we decided a rebuild was in order before running the motor on the engine dyno. The crank had been turned some time in its long life but checked out perfectly at .010/.010.

Though the motor was likely a runner, we decided a rebuild was in order before running the motor on the engine dyno. The crank had been turned some time in its long life but checked out perfectly at .010/.010.

All 400M combinations came equipped with factory 2V heads and matching intakes. Demon Engines and L&R treated the stock heads to a new valve job and a light surface before adding a fresh coat of Ford Blue paint. Since these heads were eventually going to be replaced by a set of aluminum Cleveland heads from Pro Comp, they were given only minimal care to bring them up to factory specs. Were we retaining these heads, we would certainly upgrade the tired and weak factory valvesprings as well as perform some minor porting to further improve the power output. The heads were installed using Fel-Pro head and intake gaskets with the factory half-inch head bolts. The factory 2V intake was installed using a stock-style gasket designed to shield the bottom of the manifold from the heated engine oil. Additional components employed by Demon Engines on this build up included a stock electronic distributor (with Pro Comp plug wires), Meziere electric water pump and a set of Hooker headers. Ideally we'd run this combination with 13/4-inch headers, but all we had at our disposal was a set of 17/8-inch Hooker Super Comp headers designed for a Boss 302 application. Since both the 2V and 4V induction systems were run with the same header configuration, the power gains offered would be the same with the smaller headers. The final component employed on the 400M was a 500-cfm Holley two-barrel carb. Someone managed to snag the factory Autolite carb off our 400M before we pulled it from the wrecking yard, so we borrowed the Holley two-barrel from the guys at Westech. This is a much better carb than the factory piece, so the gains offered by the four-barrel would likely be even greater than illustrated here.

The guys at L&R performed a valve job and a light surface on the stock 2V heads. Nothing fancy, just bringing them back up to factory specs. We reused the factory valvesprings and retainers, though new seals were installed.

The guys at L&R performed a valve job and a light surface on the stock 2V heads. Nothing fancy, just bringing them back up to factory specs. We reused the factory valvesprings and retainers, though new seals were installed.

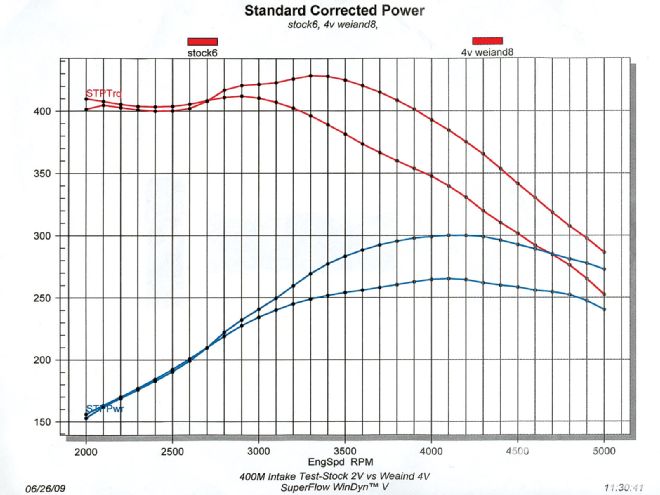

Before running the motor in anger, we provided the new components plenty of time to get acquainted, especially the rings and bearings. After running through two complete computerized break-in procedures, the motor was loaded with impressive results. Equipped with the stock two-barrel intake and Holley carb, the 400M produced peak numbers of 265 hp at 4,100 rpm and 412 lb-ft at 2,900 rpm. Torque production from the 400M exceeded 400 lb-ft from below 2,000 rpm (we didn't load it lower than 2,000 rpm) to 3200 rpm. Obviously the stock cam and induction system were not designed with high-rpm power in mind. After confirming the baseline numbers, we replaced the stock 2V induction with the Weiand Action-Plus intake and 750 Holley carb. Since Westech had it jetted and ready to rock, we ran their Holley 750 HP Street carb, but know that this combination would work equally well with something as small (and inexpensive) as a 600-cfm vacuum secondary Holley. Equipped with the Weiand/750 Holley combination, the peak numbers jumped to 301 hp at 4,100 rpm and 429 lb-ft of torque. We certainly expected to improve the power output with the four-barrel set up (to say nothing of the weight savings over the hefty stock intake), but what was really amazing was the fact that these gains came with no penalty in the lower rev ranges. From 2,000 to 2,700 rpm, the two induction systems produced nearly identical power, but from there out to 5,000 rpm, the Weiand pulled away and never looked back.

The stock 2V heads featured large 79cc combustion chambers. Though they helped keep the static compression ratio down on the 400-inch motor, the lack of a proper quench area increased the sensitivity to detonation.

The stock 2V heads featured large 79cc combustion chambers. Though they helped keep the static compression ratio down on the 400-inch motor, the lack of a proper quench area increased the sensitivity to detonation.

What is most impressive about the results is not that the four-barrel Weiand combination made more power (that was expected), but that the combination never lost out to the stock intake and Holley two-barrel. The Weiand intake not only improved the peak numbers from 265 hp and 412 lb-ft to 301 hp and 429 lb-ft, but even matched the torque production of the 2V setup down at 2,000 rpm. The two induction systems produced near-identical power from 2,000 to 2,700 rpm, where the Weiand/four-barrel setup started marching away. Measured peak to peak, the four-barrel set up improved torque production by 17 lb-ft, but offered an additional 48 lb-ft at 3,700 rpm. The Weiand intake and Holley four-barrel are definitely the hot set up for even a stock 400M. This intake swap was only the first of many tests run on this 400M.