With all the interest in aftermarket electronic fuel injection, carburetors are often the forgotten form of induction. But when it comes to effectiveness per dollar spent, reliability, and ease of installation, carburetors are hard to beat.

One of the most innovative manufacturers in the carburetor business is Quick Fuel Technology (QFT). After opening their doors in 1998 the firm rapidly built a reputation for quality and performance in motorsports. Then in 2005 QFT introduced their very successful Super Street line of carburetors. Not a company to rest on its laurels, QFT recently introduced the RaceQ small flange drag race carburetor and the Hot Rod series, which is said to be the most affordable and tunable carburetor on the market today.

Carb 101 with QFT

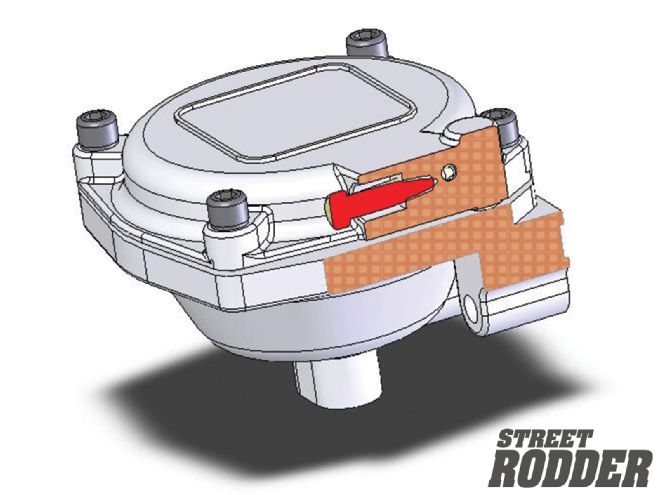

The first thing required for a carburetor to function properly is atmospheric pressure. Pressure is the most important variable tied to a carburetor's performance, and without it one simply will not run! Most carburetors will have a vent tube that provides the carburetor with atmospheric pressure and forces the fuel to move through the metering passages as required based on engine demand.

A carburetor supplies fuel to the engine by something referred to as draw. Draw is essentially what the engine wants from the carburetor in terms of air and fuel. When an engine increases in rpm range, draw will increase. As draw increases a carburetor must react to properly mix the air and fuel together. Basically as more air passes through the carburetor, more fuel is drawn from the float bowl(s) and an atomized mixture is created.

If you've ever looked in a carburetor and seen the small diameter portion of the barrel, that's the venturi. The Italian physicist, Giovanni Venturi discovered that when air passes through a restriction two things happen: air speed increases and pressure decreases. Basically what happens in a carburetor is this: air passes through the restricted area(s), as there is atmospheric pressure acting on the fuel in the float bowl(s) the low pressure created draws atomized fuel into the airstream and sends it along to the intake runners.

It should be pointed out at low speeds and throttle settings airflow through the venturi is not sufficient to draw fuel from the main system, instead fuel is delivered through the idle ports below the throttle valves, which when almost closed create a venturi effect at the idle fuel port. As the throttle blades open vacuum at the idle ports decreases and fuel is now drawn from an intermediate, or transfer port. When the throttle blades open even further, airflow is sufficient to draw fuel from the main system.

Thinking out of the Carburetor Box

A question frequently asked of the tech team at QFT is how to properly install and set up a new carburetor.

While installing a carburetor is a simple procedure the QFT crew points out that there are a few crucial items needing special attention. A carburetor is designed to precisely meter fuel and air; if the sealing surface is damaged or obstructed the carburetor will essentially have an uncontrolled source of air—the dreaded vacuum leak!

A common mistake that can also lead to trouble is over tightening. Moving in a crisscross pattern will evenly distribute the torque of your wrench and ensure that the mounting flange of the carburetor is not damaged. Once the carburetor is properly mounted, take a few moments to move the throttle linkage. For your own safety it is imperative that the throttle returns to the closed position on its own and moves freely.

After the carburetor is mounted on the engine and everything else works properly the initial tune-up can be dialed in. Float level is very important to the overall performance; there are noticeable side effects if you deviate from this crucial step. Once the fuel bowls are filled and the engine starts, the float levels are set with the engine running at idle. Normally, a QFT carburetor will have the fuel level halfway up the sight window with 6.5-7 psi of fuel pressure.

The next step will be to set the idle mixture. Most four-barrel carburetors have adjustable idle mixture screws; some may have just two, while those for higher horsepower often have four, one for each barrel. The ideal method for setting idle mixture is with a manifold vacuum gauge. Setting the mixture screws to attain the highest vacuum reading is the standard method of adjustment, but that may not be the procedure for every engine combination. Performance engines often require more fuel at idle. Idle mixture is often a process that takes experimentation. Make mixture adjustments, slowly turning the screws half a turn at a time, keeping in mind that not all four screws need to be turned in or out the same amount.

Once the float level and idle mixture are set the next step is adjusting idle speed. Many carburetors have a transfer slot that aids the carburetor in its transition to wide open. If the throttle plate position is too far up (and into the transition slot) idle quality will be poor and the car might stumble off idle. The plate position can be corrected by adjusting the mixture screws (again something you will have to experiment with). The goal of a proper idle speed and mixture is to have an engine with a suitable idle while in neutral or in gear.

A carburetor that is adjusted properly during installation will give a solid baseline for fine-tuning to achieve maximum performance. When it comes to selecting jetting the most accurate means is with an air/fuel meter, however performance is a good indicator as well. Drag racers often use the best mph in a quarter-mile to determine proper jetting for best power. The procedure is to change jet size and record how it impacts mph. An increase indicates the engine needs more fuel; a decrease means the engine needs less fuel. Continue to go up or down with jetting until the mph drops below the peak, then simply return to that jetting combination that produced the best mph.

Air Bleeds

Perhaps one of the most misunderstood carburetor tuning elements are the air bleeds. Playing a vital role in the operation of a carburetor, air bleeds are responsible for determining the amount of air that will mix with each circuit in the metering block. Virtually every carburetor has air bleeds, however they are not always changeable, as they are in QFT's carburetors.

The number of air bleeds a carburetor will have is dependent on the number of throttle bores and circuits the carburetor has. Most racing-style carburetors will have either 8 or 12 air bleeds, depending on whether they are two- or three-circuit as each barrel will have one bleed per circuit.

Idle Air Bleed: The idle air bleed could be the hardest working one of them all. Air to be mixed with idle fuel is provided by the idle air bleed. The idle mixture screws rely on air provided by this bleed. Often engines with poor idle quality and no response to adjustment of the mixture screws have incorrect idle bleeds. Many idle issues can be addressed by simply adding or taking air away from the idle system.

Intermediate Bleed: The intermediate bleed is found on three-circuit carburetors; it provides air for the third, or intermediate circuit, which is only adjustable externally by the air bleed. On most large-flange carburetors this would be the bleed found in the middle. To lean out the intermediate system so the engine will come off idle cleaner, increasing the size of the intermediate bleed will lean out that circuit. Just remember that too much of a good thing can get you into trouble. Before fine-tuning a carburetor you should take note of the stock spec so you can always come back to where you started.

High-Speed Bleed: The high-speed air bleed, also referred to as the main bleed, is part of the main system. The high-speed air bleed control how much air is fed to the emulsion channels of the metering block. The high-speed air bleed is generally located closest to the accelerator pump squirter.

Tuning with air bleeds is often easier than anything else on a carburetor. Air bleeds often resemble a main jet only slightly smaller. Tuning is simple in that you just need to remember the size of the hole determines how much air is coming into the carburetor. If you want to richen up the idle, simply replace your idle air bleed with a smaller one (less air in the system equals more fuel and a richer idle), this will help get the mixtures screws within the one-two turn range.

High-speed bleeds not only affect the mixture, they also impact the fuel curve. As an example, if the mixture gets richer at high rpm, a larger bleed will help.

While electronic fuel injection is high tech, carburetors remain a viable alternative to complicated and expensive electronic fuel-injection systems. Carburetors like those from QFT are reliable and infinitely adjustable, and they're affordable too. What else can you ask for?

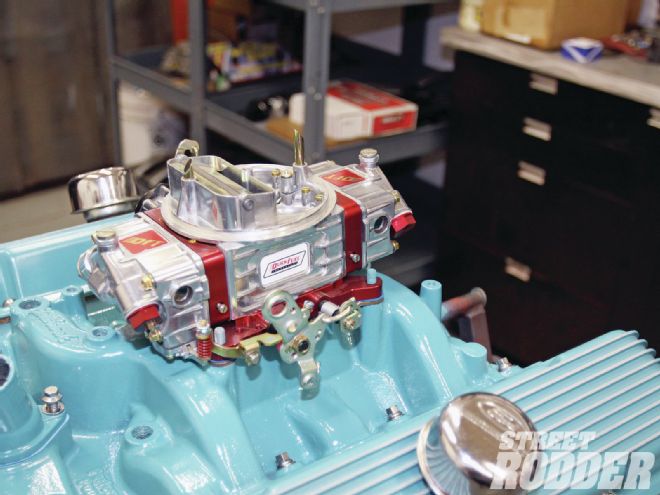

1. John Beck at Vintage Hot Rod/Pro Machine freshened our 389 Pontiac then bolted on a new Quick Fuel Technology 750 SS carburetor. These carbs not only look great but they work that way as well.

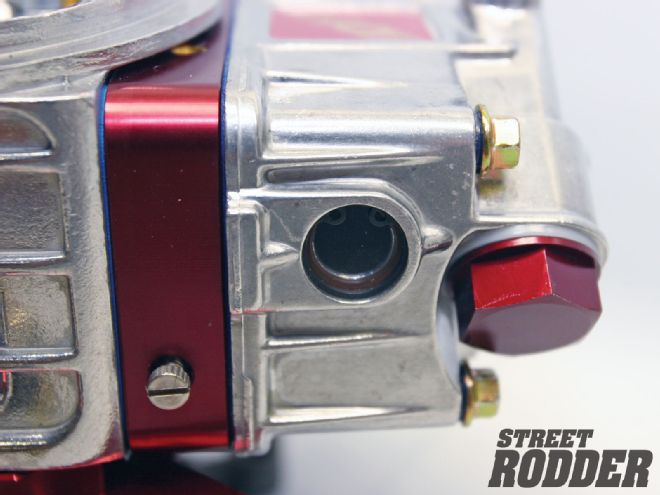

2. One of the most basic, and often overlooked, carburetor adjustments is float height. On QFT carbs the adjustment is external.

3. Floats are adjusted by loosening the lock screw and then turning the adjustment nut clockwise to lower the float, counterclockwise to raise it.

4. A sight glass in each bowl makes setting the floats easy and it's much safer than having to remove a plug to see the fuel level and running the risk of spilling gas on a hot engine.

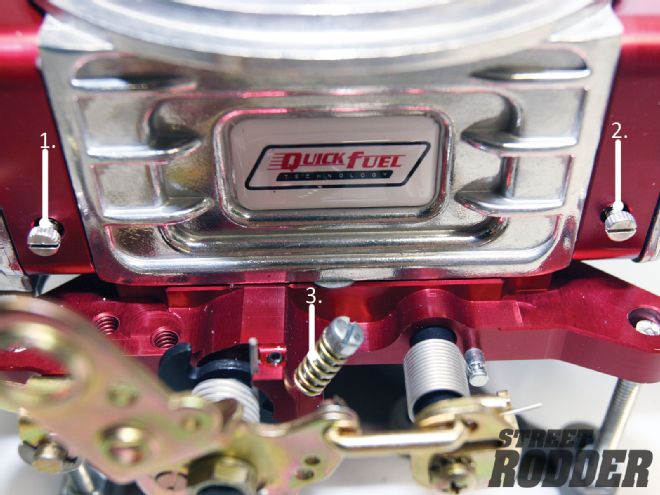

5. Vacuum secondary carburetors will have idle mixture screws on the primary side (1), mechanical secondary carbs often have them on the secondary side as well (2). The spring-loaded screw (3) is used to hold the primary throttle valves slightly open for idling.

6. This QFT 750-cfm carburetor has an adjustment screw to hold the secondary throttle valves open to add additional air and fuel at idle.

7. QFT uses a unique vacuum-operated secondary system. On carbs so equipped, adjustments to opening timing and rate are made with an adjustment screw rather than disassembling the unit and changing springs.

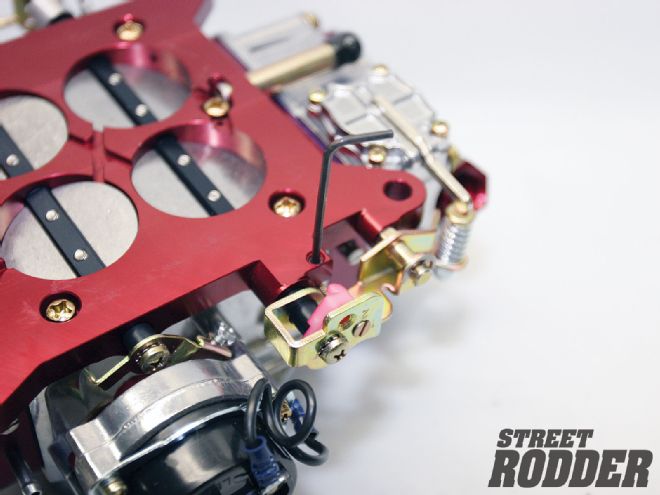

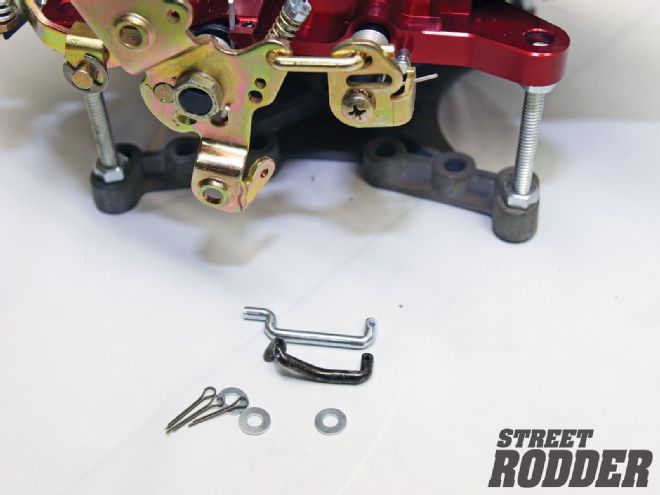

8. On mechanical carbs changing links alters the secondary opening rate. Options are: black link, secondary opens when primaries are 60 percent open; gold link, 40 percent; silver link, 1 to 1.

9. Accelerator pumps are operated by cams operating on actuating levers (vacuum secondary carbs have one pump, mechanicals have two). Various cam profiles are available. QFT advises that engines that have more load generally require more initial pump shot while combinations with less load (e.g. high stall torque converters) can benefit from less pump shot.

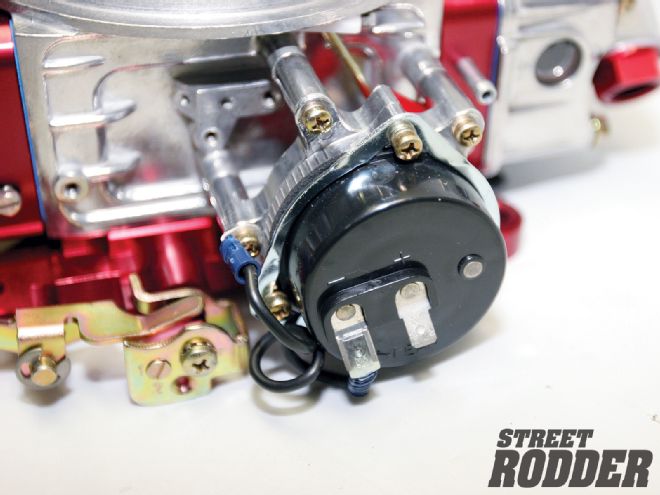

10. For quick starts and to reduce stumbling during warm up, an electric choke is used. One 12V supply wire is all that is required.

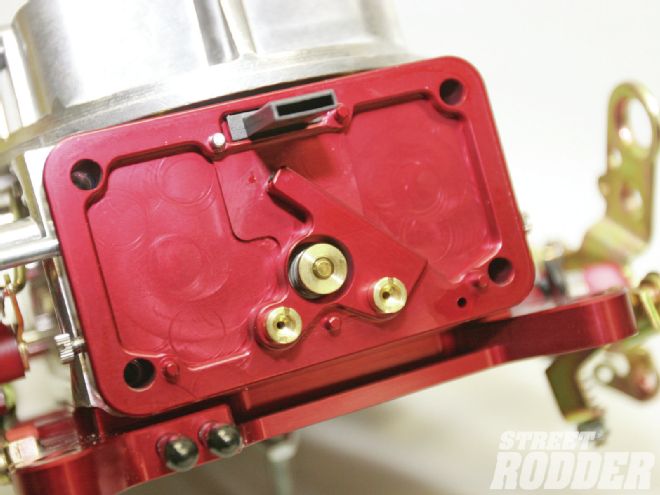

11. Quick Fuel metering blocks are machined from billet aluminum for precise fuel metering. Note the two changeable jets and the power valve between them.

12. This is the side of the power valve exposed to vacuum. For tuning purposes valves that open at various vacuum levels are available.

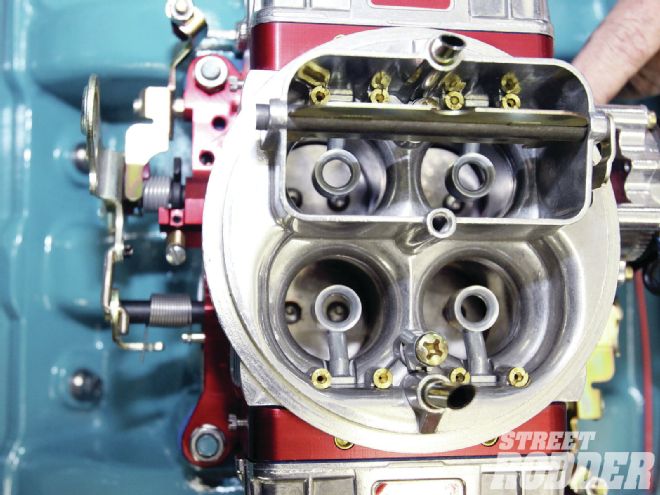

13. The jet-like orifices adjacent to each venturi are air bleeds. This carburetor allows you calibration of the idle and high-speed systems for more performance and or fuel economy.

14. Quick Fuel's newest offering is the Black Diamond Series. These new carbs introduce QFT's high-temperature coating technology for select performance and street carburetors.