Some people are never satisfied; ordinary just won't do. For most, simply owning a nice '67 GTO would be great. Getting to drive around in a fully restored one would be a dream come true. Not so for Jeff Hutchens of Springfield, Missouri. If it looks fast, it had better be fast.

Following a lead from a previous MCR customer, Jeff looked up the guys at Muscle Car Restorations (MCR) in Chippewa Falls, Wisconsin. MCR is known for restoration work, but it's also no stranger to building ground-up race cars. Jeff owned a '67 in high school and he didn't want to mess with that classic GTO look, but he also had to have the state-of-the-art performance to run with the high-dollar exotics. We'll begin with the powerplant and get to the chassis in later issues.

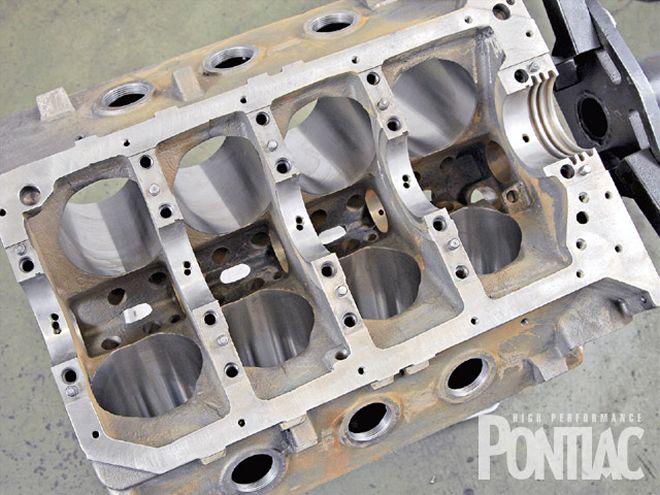

The IA II block is very beefy and is claimed to be good for up to 3,000 hp. This 3.00-inch main-block is made from ASTM-class cast iron and has Siamesed cylinder bores, 4-bolt mains, thicker main webs and deck surfaces, and wider pan rails than a stock Pontiac block. It also has threaded freeze plugs, a redesigned cooling system, and improved oiling. With a 5-bolt motor-mount pattern, it will fit in any Pontiac, and it has bellhousing bolt patterns to accept BOP and Chevy transmissions.

The IA II block is very beefy and is claimed to be good for up to 3,000 hp. This 3.00-inch main-block is made from ASTM-class cast iron and has Siamesed cylinder bores, 4-bolt mains, thicker main webs and deck surfaces, and wider pan rails than a stock Pontiac block. It also has threaded freeze plugs, a redesigned cooling system, and improved oiling. With a 5-bolt motor-mount pattern, it will fit in any Pontiac, and it has bellhousing bolt patterns to accept BOP and Chevy transmissions.

How much performance does Jeff desire? How about a twin-turbo pump-gas IA II engine in excess of 500 ci? Sure this combo will produce lots of power, but it has to be smooth, controllable power that uses real pump gas from any corner station. It also has to be new-car-with-a-warranty reliable.

To that end, MCR told Butler Performance the customer's desires; Butler scienced out the combination and supplied many of the parts to build it. Wheeler Dyno Service performed the assembly, and MCR fabricated the turbo exhaust.

An IA II iron-block provides a solid foundation; this one received a 4.350-inch bore and will run a 4.250-inch-stroke forged crank. It could have been built bigger-4.400 x 4.75 is the absolute max-but by leaving a few cubes on the table and building the engine a little "under square," it will rev quicker than a "maximum-inch" beast and retain thick walls to better contain cylinder pressure. Besides, 505 ci under boost is more than enough to test Jeff's nerve.

The forged 4.250-inch stroke crank is spun by a set of Ross custom-forged pistons by way of Scat 6.700-inch forged rods and Ferrea pins. The bearings are Sealed Power, and Jeff Fiala at Wheeler, who assembled the engine, custom-filed the Total Seal classic rings. A custom street, hydraulic roller from Comp Cams with 258/248-degrees of duration at 0.050, 0.541/0.541 lift, a 111-degree centerline, and a 115-degree LSA was chosen for this engine.

A cam that works well with a normally-aspirated combination won't work as well on a turbo engine because too much overlap will blow boost out the exhaust. The last thing Jeff wants is a peaky power curve. Besides, a proper cam will improve exhaust gas velocity, which will help the turbos to spool up more quickly. Since there are two turbos, they'll still be able to push the top end into the "too much" category. An added benefit is a relatively smooth idle that will allow easy around-town cruising, just hinting at what's inside.

It has fully ported, closed-chambered Edelbrock heads with 2.11 and 1.66 valves. Traditionally, opening up the intake port would reduce port velocity, which affects low-end power. In this case, the early onset of boost compensates for it, and Jeff will definitely feel the extra rush on the top side. The intakes flowed 304 cfm and the exhaust managed 232 cfm (both at 0.600-inch valve lift). Static compression ratio works out to be a boost-friendly 7.96:1.

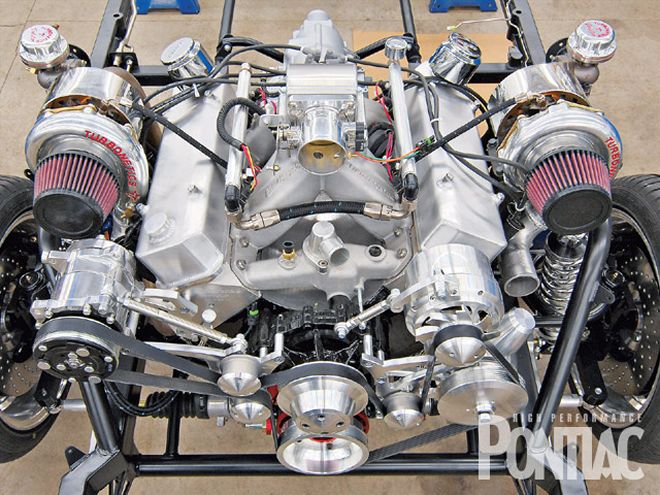

Here's where things start to get really fun. MCR did an absolutely masterful job of building a pair of stainless steel, 2-inch turbo headers that mount 70mm Turbonetics units, with Evolution 35mm mechanical wastegates keeping each of them under control. They, along with a 2.5-inch Bell intercooler and a 3-inch exhaust, fit beautifully inside the stock '67 GTO profile. A 70mm Accufab throttle body gives Jeff total control of the entire operation by way of his right foot.

The heads received the full porting treatment on the intake and exhaust sides.

The heads received the full porting treatment on the intake and exhaust sides.

Ignition is fairly straightforward: an MSD crank trigger distributor, which was modified for a cam sync sensor so a FAST computer can sequentially control the 83-lb-hr injectors. We'll go into more detail about the FAST box and how it makes this project possible when we get to the dyno session in Part II.

Assembling something like this is mostly straight forward, but there are a few things you need to know to avoid making the wrong kind of history and reputation for yourself. However, since we want to provide all the information we can on the combination and how the parts work together, we won't detail all the clearances and torque specs that are normally contained in an engine build-up article as they don't vary significantly from a typical high-performance buildup.

Next month, we'll bolt this monster to Wheeler's dyno to see how much power it makes.