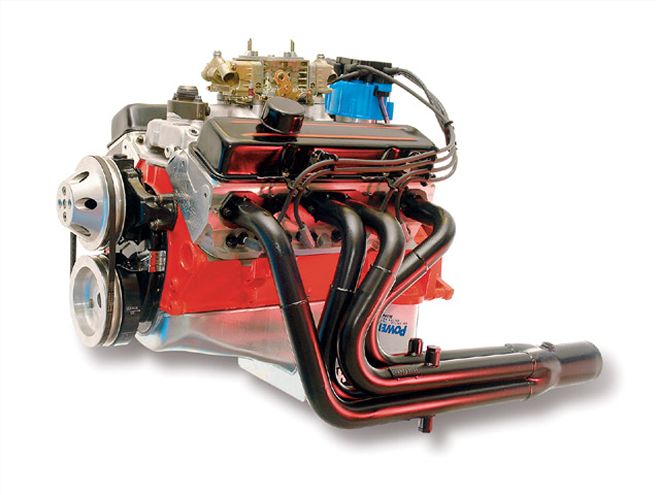

Back in the day, when our replica Cup car Laguna was a current NASCAR entry, Talladega engines were unrestricted, and depending on whether they were early or late in the era, made between 560 and 585 hp. That's about 110 or so more than a restrictor-plate engine currently makes at Talladega, NASCAR's largest and fastest venue, but with the aerodynamically more blunt bodies of the '70s, the straight-line speeds where not too different from today's. For our Laguna, we wanted comparable power from a 350-based engine, but with everyday driving street manners and reliability. Also, all this had to be achieved without the use of a blower, nitrous, or a dry sump system. Another stipulation is that this engine had to be a bolt-it-together deal-in other words, all easily available off-the-shelf parts that sold for street car prices, not Cup car prices.

If the foregoing sounds like a tall order, it was-but certainly not out of reach if we add one factor into the equation: as many extra cubes as possible from a 350 block. The road to success with any engine build (where performance is the prime consideration) is the overall combination. In our case, since we're looking for a lot of power, everything gets just that much more critical. The carb must have sufficient flow capacity, as well as good mixture preparation qualities. The intake must flow well, as must the heads. The cam must open and close the valves at the right time to suit the combination (very important). Lastly, the exhaust system must be tuned to the rpm range, and the mufflers must not defeat the pipe length tuning. What this means is we have to pay attention to every aspect of the build from where the air enters, to where it leaves. A while back, we built a 408 stroker with T&L Engines in Stanfield, North Carolina, that was a great success on a moderate budget. (T&L's entry-level 408 makes better than 510 lb-ft and 505 hp, and sells turnkey for about $5,850.) We decided this should be our starting point.

Short-Block Assembly

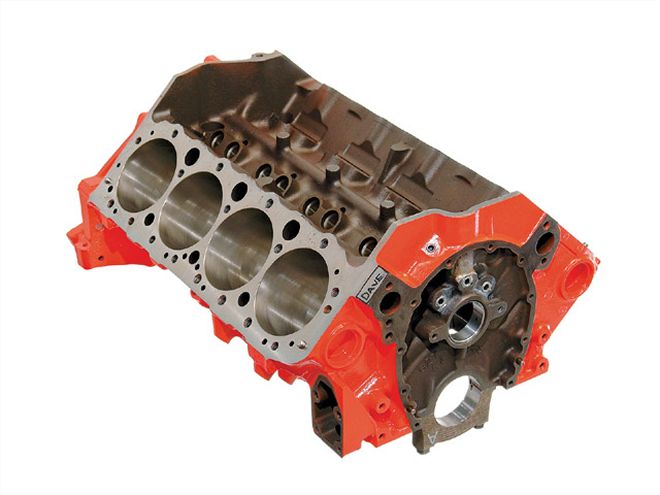

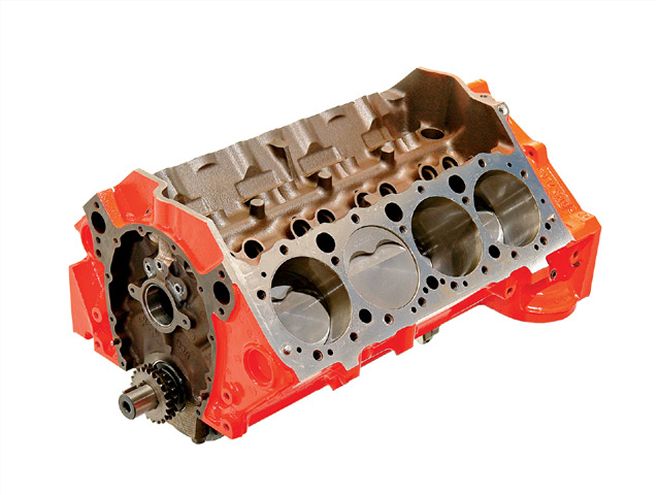

The foundation of our T&L 408 was a sonic-tested late-model 880 hydraulic roller block of about 1995 vintage. These blocks have the advantage of being stronger, higher quality, and more consistent from block to block than the earlier pre-'87 blocks. Also, they come roller cam ready in stock form with a thrust plate to control the roller cam's end float.

Our block was given all the usual prep in terms of boring, decking, etc. After that, it was clearanced for the longer four-inch-stroke rotating assembly that was to be used. The clearancing of the 350 block is a critical issue. It takes the right combination of parts to accommodate 0.520 inch of extra stroke. Just diving in and grinding the block clearance without the right know-how will land you in the block's water jacket for sure, so here's how it's done.

After selecting an appropriate block, the next move to generating 408 inches is to go with the right rotating assembly, and the key component within this is the connecting rods. To get the job done, we went with a Scat forged rotating assembly, which uses their budget (about $290 a set) forged six-inch stroker rods (PN 2-ICR6000-7/16). Why this rod, and no other? It's all about bolt-head and rod-shoulder clearance. With a four-inch stroke, the bolt head of a typical rod will need so much clearance to be cut into the block that it will be well into the water jacket. The bolt head on the Scat rod is set way lower than usual, and thus requires far less clearance to be cut into the block. Also, the rod's shoulder where the bolt end is situated is more compact, and with minimal grinding, gives the extra clearance necessary for it to miss the cam when a four-inch stroke is used. It is because of the extra clearance afforded by the Scat rod that we can, with greater certainty, put a four-inch stroke into a 350 block without finding water. A point worth noting is that this rod, in a post-'87 roller block, will often allow the rotating assembly for 383 inches (3.75 stroke) to be done as a simple "drop in" procedure. That's a plus for the home builder for sure.

The piston for our 408 is an off-the-shelf Mahle item. For a stroker motor, piston and ring selection is more important to the engine's final output than it is with a shorter-stroke motor. The reason is piston-to-bore wall friction. The use of a longer stroke not only means a greater distance for friction to operate over, but also a piston-to-wall side-loading penalty because of greater rod angularity. All this means that some of the advantage of the extra cubes can be easily squandered to the evils of friction. The Mahle piston seeks to offset frictional losses, and past experience with these pistons shows they do just that. The most obvious move to reduce friction is the skirt coating, but that's only the start. The main deal is the ring pack used by Mahle. Instead of the usual 1/16-1/16-3/16 rings, these use a 1.5mm-1.5mm-4mm ring pack that installs into a much shallower ring groove. The result is not only a ring pack that weighs about 55 percent of the usual, but also a ring pack that requires less radial pressure on the cylinder walls to get the job of sealing done. I haven't done any back-to-back tests, but I have heard some engine builders talking a 15hp improvement with these pistons over a piston with a regular ring pack. The other nice thing is by the time the rings are figured into the price, (they come with the pistons), these Mahle pistons work out to be a good deal for what is essentially a real high-performance item.

The late-model block we selected is roller lifter ready, but due to the taller lifter bores it requires a 0.300-inch taller lifter (Comp Cams Endure-X PN 871-1).

The late-model block we selected is roller lifter ready, but due to the taller lifter bores it requires a 0.300-inch taller lifter (Comp Cams Endure-X PN 871-1).

The last item on the agenda for the bottom end is the pan. Stroker motors are a lot more sensitive here than a stock stroke build. With a four-inch stroke, the rotating assembly can more easily pick up and entrain oil, as well as hit the pan rail. To avoid this, a suitable Moroso pan is essential. Fortunately, Moroso has a variety of pans that will work with most chassis, so a phone call is all that's needed should you want to duplicate this 408 in any way.

Camshaft

Now here's something different. The cam for our 408 was from a new range that I've been working on with Comp Cams. So often, you can look through a catalog and the application given for any particular cam is really vague if you just go by what the catalog describes. (As if a cam described for a 262-inch small-block is equally ideal for a 400-plus-inch small-block!) It could be said that 99 percent of catalog cams are semi-generic. On top of this, it can easily take 20-30 minutes of studying the catalog to come up with a cam that, unless you are well-versed in the art of cam selection, may, at best, only be a passable selection. For those with less than professional experience, there is always a degree of uncertainly with the selection process.

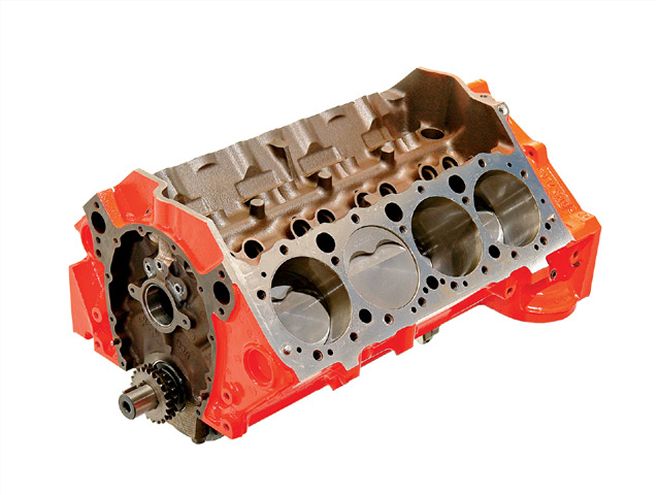

Here is our finished block prior to assembly by T&L. The precision applied to the bores, decking, and align honing is the same that T&L uses for top-series NASCAR engines. Block prep for a production 350-inch cylinder block-a late-model 880 casting in our case-takes on added importance when it's being taken out to 408 cubic inches. We detailed that process in our May 2008 issue (search "Stretching The Limits" at popularhotrodding.com).

Here is our finished block prior to assembly by T&L. The precision applied to the bores, decking, and align honing is the same that T&L uses for top-series NASCAR engines. Block prep for a production 350-inch cylinder block-a late-model 880 casting in our case-takes on added importance when it's being taken out to 408 cubic inches. We detailed that process in our May 2008 issue (search "Stretching The Limits" at popularhotrodding.com).

Let me ask a question: How would you like to make a cam selection for your engine at least as good as Jon Kaase or Warren Johnson? Also, how would you like to select it in 30 seconds or less? The new V range from Comp allows just that. The way the catalog is structured means that, in essence, you have a top pro engine builder in your corner working exclusively for you. This allows you to select a cam that is very specific to your engine, not just a generic grind for a small-block Chevy engine. To give you an idea as to how easy and accurate this new selection method is, try this for size. My 12-year-old daughter selected this 408's cam in under 20 seconds. The outstanding torque and horsepower results we got amply demonstrate just how effective that cam proved to be.

So what exactly was this "wonder" cam from Comp? The part number was V280-05RSX. All these numbers actually mean something. The "280" signifies the duration at 0.020-inch lift (at 0.050, it was actually 242 degrees). The "05" signifies the last two numbers of the lobe centerline angle (105), and the RSX signifies a Roller, Solid, and Xtreme. This cam is very specific to our requirement. It's intended for a small-block Chevy of 400 to 420 inches in displacement, with cylinder heads having an intake valve between 2.02 and 2.08, and a compression ratio of 9 to 10.5:1. In addition, it also assumes a decently flowing intake and exhaust system. Now if my 12-year-old daughter can pick a cam for an engine that will have its results shown in a national magazine, just think how smart you can look by using this new catalog selection system. (By the time you read this, it will hopefully be up on Comp's website.)

For the rest of the valvetrain, we used a set of Comp's new Gold rockers having a 1.65 ratio. These, when the lash was figured in, delivered the necessary big lift number of 0.600 inch so as to allow the filling of those big, stroked cylinders. The pushrods where Magnums, and the solid roller lifters where Comp's Endure-X design. All this made for a dynamically sound and reliable valvetrain. One last point here is that many hot rodders are shy about using a solid roller on the street. Here you need to know that the opening and closing ramps on Comp's street rollers are such that they will often go as much as 80,000 miles before needing relashing. On top of that, they are way quieter than the roller cams your father used.

Here is our Scat four-inch stroker kit that turned our 350 into a 408 (Scat PN 1-40576; $2,358.95, Summit price). This kit features Mahle high-tech pistons and Scat's stroker-friendly rods, which offer far greater internal clearance than most rods. This kit comes complete with rings, and as an option from Scat, can be had as a balanced assembly for $250 extra.

Here is our Scat four-inch stroker kit that turned our 350 into a 408 (Scat PN 1-40576; $2,358.95, Summit price). This kit features Mahle high-tech pistons and Scat's stroker-friendly rods, which offer far greater internal clearance than most rods. This kit comes complete with rings, and as an option from Scat, can be had as a balanced assembly for $250 extra.

Heads, Intake, And Carb

To make power, it's necessary to have heads that flow a lot of air and have good wet flow and combustion properties. Give up anything on any of these counts and the results will be less than you hoped. The heads we wanted to use for our 408 were the 210 Comp Eliminators from Air Flow Research. Part of the rationale driving this choice was the fact that one of my more advanced students from UNC-C built a 350 and achieved nothing short of outstanding results on pump gas using the smaller 195cc runner version of these heads. So working on the premise that reinventing the wheel is somewhat futile, the 210 heads from AFR seemed like the obvious choice. Since there is a lot more to these heads than just another CNC port job, the info for it and our flow tests was gathered together and put in sidebar form, so read all about it there.

After installing the heads with ARP six-point head bolts, the rockers were installed. The Gold rockers are a new line for Comp, with supposedly superior trunnion bearings, pushrod, pivot point, and roller geometry. They are available in the usual 1.5, 1.6, and 1.65 ratios. The ones we used with our single-pattern cam were 1.65:1 ratio, which delivered the 0.600-inch valve lift we sought.

When used correctly, the current crop of air-gap-style intakes are nothing short of highly effective, and the grand daddy (and one of the top players) of them all is the Edelbrock RPM Performer Air-Gap two-plane intake. When fed to full carburetion capacity (which most often it is not), these intakes will deliver some really great street performance figures. But that's not all they do. Allowing for the less-than-direct route the airflow must take, this Performer Air-Gap does exceptionally well. The end result is a top-end not far behind a race intake. But the key to making it all work as we did here is a carb that delivers both at low speed, and has sufficient flow to make full use of this great intake manifold. The carb we used was an AED carb based on the Holley 950-series race carb. With boosters built expressly to deliver a strong signal for good low-speed calibration and mixture atomization (which also helps mileage), our AED carb flowed a wet 900 cfm. The carb was ordered from AED specifically for our application, and came with the jetting so close to ideal (on the dyno), that it defines the real meaning of plug-and-play.

Exhaust

All our efforts toward building power will be to no avail unless the exhaust system is up to scratch. Remember, this is a street motor, and therefore will need to be muffled. For headers, we used a dyno set that T&L's boss, Lloyd McCleary, had previously found ideal for a similar spec 408. This proved to be a stepped header as follows: primary 1 3/4-inch diameter by 9-10 inches in length to the step. From there it was 1-7/8-inch diameter by 22-24 inches to a 3.5-inch collector. Using this as a starting point, our plan was to get the secondary length (the most critical) tuned on the dyno. So that all this length tuning would not be overridden by the effect of a muffler, which the exhaust might see as additional tuned length, it was decided that we would go with a big pair of Flowmasters (PN 953541-10). These 3.5-inch-diameter mufflers have sufficient open volume for the exhaust pressure waves to act as if they have hit open atmosphere. What this means is the header/collector length tuning sees almost no impact, so the engine largely responds as if the muffler was not there. This, combined with a respectably high muffler flow, means the engine can produce near open exhaust power with noise levels more commensurate with street requirements. And since we'll be building a custom side-exit exhaust NASCAR style, we won't really have to deal with snaking a 3.5-inch pipe over the rear axle.

Here is our Scat four-inch stroker kit that turned our 350 into a 408 (Scat PN 1-40576; $2,358.95, Summit price). This kit features Mahle high-tech pistons and Scat's stroker-friendly rods, which offer far greater internal clearance than most rods. This kit comes complete with rings, and as an option from Scat, can be had as a balanced assembly for $250 extra.

Here is our Scat four-inch stroker kit that turned our 350 into a 408 (Scat PN 1-40576; $2,358.95, Summit price). This kit features Mahle high-tech pistons and Scat's stroker-friendly rods, which offer far greater internal clearance than most rods. This kit comes complete with rings, and as an option from Scat, can be had as a balanced assembly for $250 extra.

Dyno Testing

We did our dyno testing on T&L's primary dyno in phases. First a "safe and conservative" tune-up was done to act as a provisional baseline. This basically consisted of an ignition setting that was a little retarded, and carb calibration that we anticipated was just a shade too rich, along with a secondary tuned length too short. At this point, we swapped intakes from the two-plane Air-Gap to a single-plane Super Victor to see what it would do. After that the Super Victor was changed out for a Dominator Super Victor to establish what that would do to our 408's power curve. After these exploratory tests, the Air-Gap was reinstalled, and the final detailed tune was done to extract every last ounce of power. Check out the sidebars for the results of our manifold tests. For some applications, you may find it suits you better to go single-plane on one of these powerhouse 408s. Remember, we are on pump gas with a compression ratio of only 10.5:1. Just check the power curves: This street driver cranked out, through the mufflers, a very creditable 551 lb-ft of torque and just a shade over 560 hp. But the best part is the cost: T&L will build you a replica, minus headers, water pump and mufflers, for $7,685, and that includes a video dyno test.

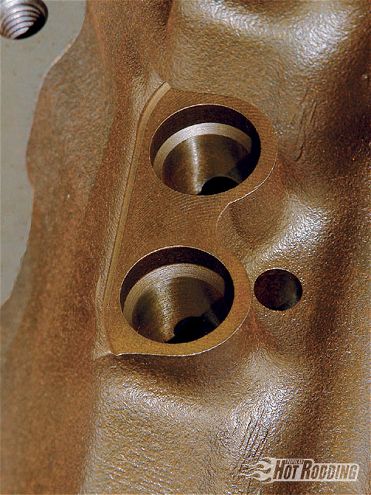

Wet Flow Intake Ports

There's a lot more to these AFR Comp Eliminator heads than meets the eye. Unlike most small-block Chevy heads within this price range, the AFR heads have some very worthwhile performance features not found on other heads. For starters, the valves are a lightweight design that come in at about 15 percent less than you will find on most other heads. Also, the springs on the AFR heads are more like the upgraded springs we see on most of the competition. All this goes to make a better valvetrain package, and it shows in terms of valvetrain control and higher rpm limits. Nevertheless, to the untrained eye, these assets might just pass unnoticed. Pull an intake valve out of the port and what you see in the bowl will most certainly catch your attention. Alongside the guide on the cylinder wall side of the runner is a fuel-shear ramp. The intent is to reduce or eliminate the heavy fuel wash normally seen on the chamber wall immediately adjacent to the spark plug. This wash drastically increases bore wear and negatively impacts power, economy, and emissions.

Two questions need to be asked here: Does the presence of the ramp in the port compromise flow, and does it improve wet flow characteristics as intended? Well, there was not time to run wet flow tests, but we went one step better and removed the heads after testing to check the burn pattern. It proved to be very uniform with no visible signs of fuel wash, so on that score, yes, the ramp apparently works great. As for compromising flow, our dry flow tests indicated that if the ramp did compromise flow, the amount was more than offset by the top-notch wet flow characteristics. From the result achieved on the dyno, we would have to say that the AFR Comp Eliminator looks to be one hot ticket.

Here's the finished short-block. Due to the lower piston friction of the Mahle piston/ring assembly, static turning torque was measurably lower than with a more conventional piston/ring assembly.

Here's the finished short-block. Due to the lower piston friction of the Mahle piston/ring assembly, static turning torque was measurably lower than with a more conventional piston/ring assembly.

More Manifold: What's It Worth?

For its displacement, our 408 has not got a particularly big cam, but 408 inches and high-flowing heads make it a deep breather. This combination puts a lot of emphasis on manifold flow capability. Although the air-gap design is a great deal for a two-plane, we asked ourselves what this 408 could do given more intake flow in the form of a single-plane Super Victor. Before looking at the results, remember that this test was done prior to optimizing the timing and exhaust, so the numbers are down on what we achieved in our final round of testing. Nevertheless, the "before" and "after" results are totally indicative of what happens when the air-gap intake is replaced with a Super Victor. A check of the graph curves shows that our 408 was still a low-speed torque monster, but to a lesser degree. A duplicate of our 408 build, but equipped with a Super Victor, can be expected to net better than 575 streetable horsepower.

Let It Eat! It's Dominator Time

Since our 408 responded to the tune of 20 horses when given the better-breathing Super Victor, we speculated that it might just like even more induction flow. Even if it didn't, it would be an interesting experiment to see what effect a lot more intake flow would have on the engine's power curve. To this end, we had the almost ideal intake and carb setup. T&L was in the middle of building a 454 small-block for a customer, and the heads and manifold were already complete. A check of the intake showed it matched the ports of our 408's AFR heads perfectly. The only downside was the port size of the Dominator-equipped manifold for an engine nearly 50 cubes larger, and one that would utilize a race cam instead of a street cam. Knowing that, we decided to go ahead anyway, as the test would still give us a ballpark indication of the pros and cons of using a bigger manifold with a 1,150-cfm Dominator. Another angle was that AED was claiming to have improved the low- and part-throttle driveability of their Dominators to the extent they can be used on much smaller engines than previously thought practical. Here was a test of both power and part-throttle behavior at low speed. Check out the graph, and you'll see power up by as much as 25 horses. The good news is that low-speed manners were as good as the 900-cfm 4150 this AED Dominator replaced.

A point worth noting is that had we spent the time at this point (instead of after the final manifold change) to tune the exhaust, the engine would undoubtedly have topped the 600hp mark by as much as 10 horses. Not bad for an engine that still has street manners.