Given the current engine technology in the Pontiac hobby, building a big-cube Pure Pontiac engine from a 400 block is easier than ever thanks to the many stroker combo choices for 3.00-inch main engines. When Orwin Middleton of Santa Barbara, California, decided he wanted more power for the street to motivate his rare '61 Royal Pontiac Catalina, he pulled the transplanted '67 400 that sat in its engine bay and paid a visit to Joe Sherman Racing Engines in Santa Ana on the recommendation of storied racer and noted Santa Barbara engine builder, Bob Joehnck.

Coincidentally, Sherman was already in the process of building a Pontiac 455 with an Edelbrock top end featuring its aluminum heads, Performer RPM intake, 800-cfm AFB carburetor, a set of headers, and a street performance roller camshaft from Comp Cams. Sherman is known industry wide for incredibly strong street engines as well as top race engines. He even won the inaugural Popular Hot Rodding Magazine Engine Masters Challenge in 2002!

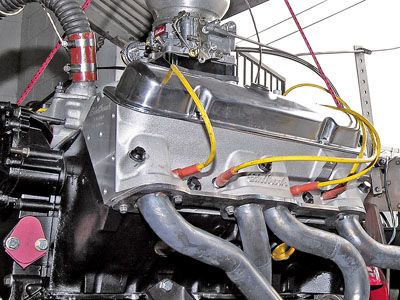

Middleton told him about his '61's proposed combo-a big-inch torquey, yet streetable, engine backed by a 2,500- to 2,800-rpm stall converter, a Turbo 400 and a 3.42 Safe-T-Track rear. With these specs in mind, Sherman devised a plan to have the block machined and bored 0.060 over to 4.181, and to use a 4.210-inch stroke, 3.00-inch main cast crank, stock length rods, 0.030-over 455 KB hypereutectic pistons and a Comp Cams hydraulic roller cam. The top end recipe would duplicate his other customer's 455 with Edelbrock parts.

Sherman explained to Middleton that this 462 cubic inch combination would produce 500-plus horsepower at a livable 5,000 to 5,200 rpm with almost 600 lb-ft of torque. Though we typically see forged rods and pistons in these types of builds, Sherman also said that the hypereutectic pistons and cast rods would be cost-effective as compared to forged pieces, and durable in this application because peak power is made at just 5,200 rpm. Middleton was floored! To his old-world brain, these power figures bordered on Amtrak diesel territory! Sherman suddenly found himself with Middleton's Pontiac engine to build as well. Let's see how it all turned out.

Dyno Results

The engine was dynoed on Joe Sherman Racing Engine's SuperFlow 901 engine dyno. For this pull, the fuel was 91-octane, the timing was set to 39 degrees and the jets were the same as listed in the engine buildup worksheet.

Joe related, "though the carb spacer normally does lean the mixture slightly, the out-of-the-box jetting was nearly perfect for this combo."

Engine Buildup WorksheetDisplacement400/462Bore/Stroke4.181x4.210-inBlock/Crank Combo’67 400/4.210 strokerBore/Stroke Ratio0.993:1Rod/Stroke Ratio1.574:1 Bottom EndBlock’67 {{{GTO}}} 400, code WTPreparationBored and honed 0.060-over Deck Height10.250-inCrankshaftJoe Sherman Racing cast 455 strokerPreparationBalancedBalancerAftermarket replacement, degreedRodsCast, 6.625-in PreparationSize the big and little ends, install new rod bolts, balancedBearingsKingPistonsKB Hypereutectic, 0.030-455 flat-top with valve reliefs Piston to Deck Height0.005-inchPiston PinsKB press-fit Piston RingsHastings moly top, cast-iron secondHead BoltsARPBalancing Spec2,210g bob weight Oiling SystemOil PanReplacement with baffleOil PumpMellings HeadsBrandEdelbrock aluminum, 60579, closed chamberModificationsAs delivered from EdelbrockCombustion Chamber Volume87ccMaximum Flow at 28 Inches of Pressure:Intake275-cfm at 0.700Exhaust185-cfm at 0.700Compression Ratio10.0:1ValvesEdelbrock 2.110/1.660-inAngles Used in Valve Job30-, 45-, 60-degModsNoneRetainersChromolyKeepersSteel 7-degValve GuidesEdelbrock bronzeRocker StudsARP 7/16-inRoller Rocker ArmsPRW full roller, 1.52:1Pushrod Diameter5/16-in CamBrandComp Cams hydraulic rollerGrindXFI 280HRDuration at 0.050230/236-degLift0.540/0.543-inCenterline108-degLobe Separation Angle110-degInstalled Position108-degLiftersComp Cams hydraulic rollerValve SpringsComp Cams dualSeat Pressure145 lbsOpen Pressure395 lbsTiming ChainComp Cams dual-roller InductionIntake ManifoldPerformer RPM ModsPlenum clean-up CarbEdelbrock No. 1412, 800-cfmModsNoneJets/Primary0.113Jets/Secondary0.101Primary Metering Rod Size0.071-0.047Fuel Line3/8-in diameter/No. 6 AN IgnitionDistributorStock-type, Pertronix conversionCoilMSDWiresACCEL 7mm solid coreTotal Timing40-degInitial Advance16-degMechanical Advance24-degVacuum AdvanceNone ExhaustBrandMad Dog Exhaust Products custom Primary Tube Diameter1.875-inPrimary Tube Length30-inCollector Size3 1/2x7-in GasketsBrandEdelbrock