Not that long ago—in Car Craft's Jan. 2015 issue, in fact—we documented the build of a pretty potent 351W build that ended up making 505 hp with the stock crankshaft and connecting rods, a set of KB flat-top hypereutectic pistons, a mild Crane hydraulic roller cam, and a pair of Trick Flow Specialties' 190 CNC 11R cylinder heads. Because the engine seemed perfectly happy running up to 7,000 rpm, we suspected that there was more in this combination that could be utilized with a bigger, more aggressive cam. Trick Flow confirmed our suspicions, telling us they routinely run test their valvetrain parts at engine speeds above 7,000 rpm. Well, that's all the incentive we needed. Building on the foundation of our previous build, meet Dirty Harry, the 357ci Windsor that pummeled our eardrums with its 7,500-rpm redline and a whopping 595 hp.

The Short-Block

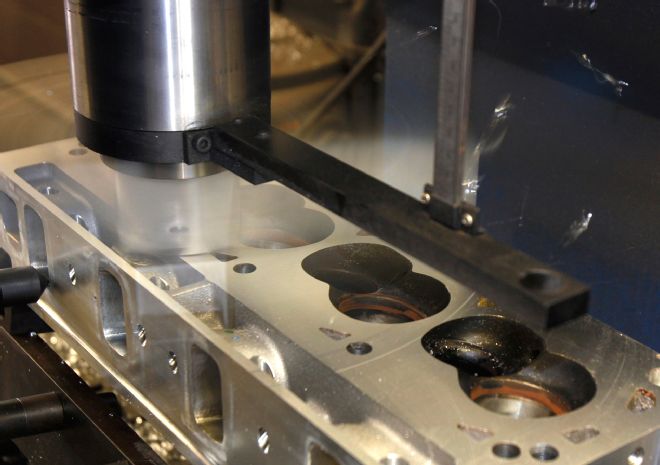

We began fresh with this build, sourcing a core 351 block from a local salvage yard. IMM bored the engine 0.040-inch over, using a BHJ torque plate, and finished the cylinders with a plateau hone with his Sunnen CK10 Power Hone.

We needed a stout bottom end for this build, and Scat delivered with its forged, 4340-alloy Procomp Lightweight crank. This is a high-quality forging with Aero-wing (knife-edge) counterweights, radiused journals, lightening holes in all rod throws, and straight-through oiling for consistent lubrication of the bearing surfaces. In addition, the crank is gun-drilled to help balance internal windage. We decided to stick with the stock stroke (3.500-inch) rather than going straight to a stroker package until we feel we've exhausted the performance potential of this displacement.

We paired the crank with Scat's forged H-beam connecting rods, which are made from 4340 chromoly steel, contain bronze bushings for floating wristpins, and are held together with ARP 2000-series cap screws. We chose these rods for their added strength over comparable I-beam rods, because we will be running nitrous through this engine soon. A naturally aspirated build can use I-beam rods and take advantage of their lighter weight. These are actually Chevy rods, which Brian chose because the big end is wider, but with a smaller diameter than a stock Windsor. They also accept Chevy's 0.0927-inch wristpin. Brian felt that, as a package, these rods could take more power at higher engine speeds than the Ford rods would.

We chose Diamond pistons to match our 4.040-inch bore and added Total Seal's gapless steel 0.043-inch top ring, 0.043-inch ductile iron napier second ring, and a 3mm oil control ring assembly. Had this been a dedicated naturally aspirated build, we would have used moly rings, but with nitrous, the moly coating can break off and damage the engine. These are flat-top pistons with 7.7cc valve reliefs and are based on an existing Diamond piston design, but Brian ordered them with a 1.540-inch compression distance to fit the 6.200-inch Scat connecting rods (stock Windsor rod length is 5.956-inch). The logic behind the decision was to move some of the mass at the top of the rotating assembly (pistons with greater compression distance) and place it closer to the center of the rotating assembly (with slightly longer connecting rods). It's a small point, but it does make a difference at high engine speeds. Scat balanced the rotating assembly for us, but Brian weighed all the components to give us an accurate bob weight. Brian gapped the top and second rings to 0.028-inch, in preparation for nitrous.

The bearing clearances measure 0.003-inch, which Brian verified with his inside micrometer with the bearings installed and the rods and main caps torqued, a procedure he says provides the most accurate measurements.

The Valvetrain

Cam Specs DurationValve liftLobe Separation Angle 250/254 degrees at 0.0500.595-inch (w/ 1.6:1 rocker arms)110 degree

Trick Flow Specialties supplied a set of retrofit hydraulic roller lifters and its Track Max hydraulic roller camshaft. When he degreed it, Brian found the cam to be ground on a 108-degree intake centerline. He decided to leave it as is, thinking the additional advance would increase torque below the peak. The billet steel cam core requires a bronze distributor drive gear or a coated steel gear like the one from Crane that we used. We paired them with a Crane double roller timing set.

Trick Flow's dual valvesprings come from PAC and offer a combined rate of 168 pounds on the seat and 475 pounds of open pressure. A set of titanium retainers cuts some weight off the valvetrain, which, in theory, allows us to run the engine at higher speeds. We've run Ti retainers on other engines in the past and didn't gain any more revs, but that was most likely due to not enough spring rate. We mention this as a warning against the assumption that throwing lightweight components at an engine will always give you the gains you seek.

Trick Flow also supplied a set of 1.72:1 aluminum roller rocker arms, which bumped our lift at the valve to 0.640-inch. They rest on ARP 7/16-inch rocker studs. Behind them are the same set of Manley 5/16-inch pushrods we used in the previous build. Brian set the lifter preload to one full turn with the engine at operating temperature. Trick Flow told us these components have been tested to more than 8,000 rpm on a Spintron without going into valve float, a claim we have no reason to doubt, as we ran this engine to 7,600 rpm in more than a dozen dyno pulls with no problems.

Prep and Assembly

In addition to the overbore and hone, Brian surfaced the block to zero-deck the pistons. He also opened up the oil passage from the oil pump to the filter and cleaned up the radius between the two, as shown by the wire inserted through the oil-filter feed.

Fred and Brian assembled the engine with Clevite H-series bearings and ARP fasteners. The connecting-rod bearings are narrow to fit the crankshaft's radiused journals. Note the "lower" designation stamped on the back of the bearing. Be sure to check for this. If bearings are installed in the wrong orientation, they can contact the crank fillet and cause all kinds of problems.

Brian milled 0.040-inch from the cylinder heads to reduce the combustion-chamber size from 56 cc to 50, which raised the compression ratio to 12.0:1. Other than that, these heads were run as delivered. The final pass on both the block and cylinder heads left a surface finish of 10 to 12 RA, as recommended for our Fel Pro MLS head gaskets.

Fred completed assembly of the bottom end with the installation of a Melling Select high-volume oil pump and a Moroso pick-up tube and pan. We replaced the spindly stock oil-pump drive with a much stronger one from ARP. This combination of parts provided 58-psi oil pressure at idle and a solid 70–76 psi throughout the dyno pulls.

The heads were dropped onto the short-block with a FelPro MLS head gasket sandwiched in between and ARP head bolts providing the clamping force.

The assembled long-block now awaits Trick Flow's R-series single-plane intake manifold, which Brian had to mill the mating surfaces to get the intake ports to line up properly with the milled cylinder heads. Other than that, no porting or port matching was done to the intake. The balancer is from Innovators West, which Brian says, "Works like a friction clutch. It knocks out harmonics and frees up power. I prefer these over other balancers I've tried."

On the Dyno

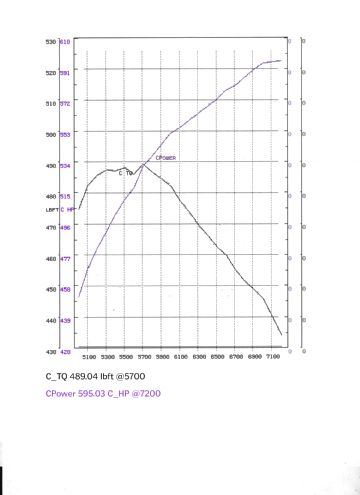

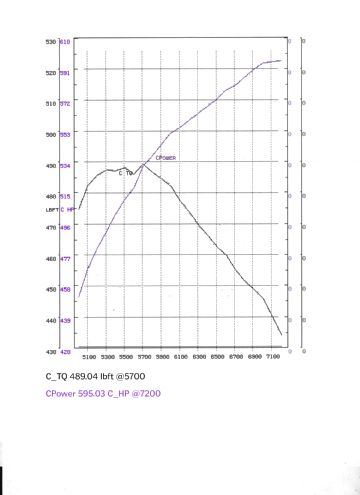

On IMM's DTS dyno, the engine fired immediately. After a short run-in period to bring the fluids up to temperature, Brian made an initial pull—the results were promising, as the power crested 580 hp at 7,000 rpm. Brian and Fred spent some time fine-tuning the engine with timing and jet changes to find that the engine made best power with 90 jets in the front and rear metering blocks of Brian's Holley 1000 HP carburetor, and 29 degrees total timing. Those changes resulted in an increase of power to 587 at 7,100 rpm. Finally, they added a 1-inch open carburetor spacer and reached 595 hp at 7,200 rpm. All dyno testing was done with NGK BCP6ES spark plugs, Torco TR-1 conventional 10W-40 racing oil, a 50/50 mix of pump gas and VP's 110-octane race gas, and both water and oil temperature at 150 degrees. The correction factor was 1.02. Brian specifically chose the pair of Doug's Headers with 1¾-inch diameter, 30-inch long primary tubes and a 3-inch collector. "The primary tube length is shorter than most other Windsor headers available, and they were instrumental in making top end power," he explained.

This engine would be a ton of fun in a sub-3,000 pound street/strip car with a steep rear gear to take advantage of the high-reaching power peak. It runs happily on a pump gas/race gas mix, or get an E85 carburetor and run it solely on "pump gas" if it's available. The best thing is that this engine is built to take some abuse with a power-adder, so throw some nitrous or boost at it with dedicated race gas, and your car will be a contender.

Parts List DescriptionPNSourcePrice Procomp Lightweight crankshaft4-351-3500-6000-2Scat$1,234.00 PistonsCustomDiamond704.95 Piston ringsCustomTotal Seal390.28 WristpinsG927-2750-155Diamond65.98 Main bearingsMS1432HClevite89.97 Cam bearingsSH1321SClevite38.97 Oil-pan gasket1810Fel Pro14.97 Exhaust gaskets (small)1415Fel Pro17.97 Exhaust gaskets (large)1487Fel Pro26.59 Intake manifold gaskets1262RFel Pro14.97 Valve-cover gaskets1684Fel Pro26.39 Oil pan20508Moroso233.97 Oil pick-up24501Moroso46.97 Engine bolt kit554-9703ARP96.49 Intake manifold bolt kit154-2101ARP31.11 Balancer bolt kit154-2501ARP24.91 Cylinder head bolt kit154-3607ARP83 Timing coverSES-5-60-04-201Summit118.97 Cylinder headsTFS-52515601-C01Trick Flow825.00 (each) CamshaftTFS-51403005Trick Flow249.97 Roller liftersTFS-21400006Trick Flow429.97 Rocker armsTFS-51400521Trick Flow289.97 Pushrods25701-16Manley131.97 Intake manifoldTFS-52400114Trick Flow379.97 Harmonic balancer204Innovators West375 HeadersD6672Doug's789.97