In the world of chemistry, FE is the atomic symbol for iron, a basic building block in the construction of our universe. FE is also a symbol of early-1960s Ford horsepower, a building block in the universe of hot rodding. As the universe in space expanded and became more complex, the usefulness of our friend iron, FE, did not diminish. And as the universe of engine building expands and becomes more complex, the venerable Ford FE engine continues to prove its usefulness. In fact, the elegant simplicity of its design has been mimicked time and again as an unconscious tribute to those engineers at FOMOCO who, so long ago, set out to build a machine that would convert gasoline into horsepower.

Every car, every engine, has its group of devoted fans and experts. If you were building a big-block Mopar, you'd probably call Ron at Indy Cylinder Heads. Slapping together a big-inch mountain motor? Jon Kaase has a fairly good grasp of the concept. Building an FE engine? Barry Robotnick and his crew at Survival Motorsports are hard to beat. Barry is one of those "long-term, overnight success" stories that we hear about. His business has been quietly building engines, specifically FE Ford engines, for a number of years, and he's carved out his place in that niche market. In the last three years as a competitor in the Jegs Engine Masters Challenge, his horsepower-producing skills have ramped up quickly, and he's steadily gaining notoriety outside the nice little world of big-block Fords.

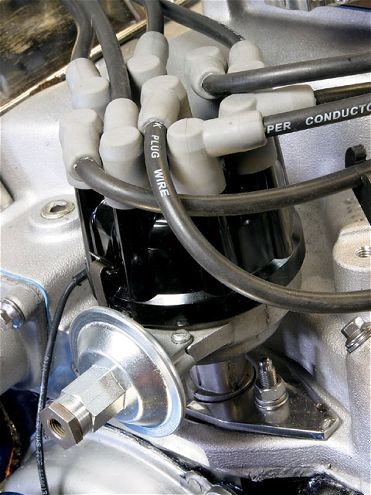

Keeping with the retro theme, Robotnick modified this period-correct factory distributor to utilize late-model Ford Duraspark guts. What looks like a single thin wire actually contains the shielded dual wires necessary to trigger the MSD ignition box.

Keeping with the retro theme, Robotnick modified this period-correct factory distributor to utilize late-model Ford Duraspark guts. What looks like a single thin wire actually contains the shielded dual wires necessary to trigger the MSD ignition box.

Barry was selected again as a competitor for the 2007 Engine Masters Challenge, and as in years past, he chose to build his favorite-an FE. Specifically, a 427 side oiler. Like any engine build, when approaching the Engine Masters Challenge, Barry took a good look at the application and the constraints of the build. In this case, the application would be a dyno challenge pitting some of the best engine builders in the country against each other using stock-configuration engines in an rpm range comparable to what most street cars and hot rods see. The constraints, well, there were many, but the basic gist was that the engine had to be 10.5 compression or less, run a flat-tappet cam, and drink 91-octane pump gas. How hard could it be?

A quick glance at the last several years of Challenges reveals a steady increase in the levels of torque and horsepower produced at these events. A winning combination-even with unlimited compression and a solid-roller cam-from just a few years ago might not make it into the Top 3 in 2007. Have the engines gotten more high tech? No. In fact, a concerted effort has been made to reduce the amount of big-dollar modifications and ultra-inaccessible parts in order to bring out the best in common-sense approaches to engine building. In other words, getting back to the basics like good heads, the right cam, and attention to detail. The things that Barry specializes in.

When constructing this engine in his head, Barry decided he wanted a theme to go along with it. His goal was to make it look like it just came out of an old hot rod. "Cosmetically, we made that engine look as much as we could like an original '64 Ford 427 motor that would have been in somebody's Galaxie back in the day," Barry says.

Indeed, at first glance it looks like a bone-stock, yet clean and pristine example of a survivor. It's when you look beyond the spit-shine and pop off the valve covers that you start to understand that this is not the same engine that came out of grandpa's cruiser. As hard as it is to believe by looking at it, about the only "factory" Ford items used are the distributor housing, timing cover, and crankshaft! Aftermarket support for the FE engines has slowly grown through the years with companies like DOVE, Blue Thunder, and Genesis Performance Castings providing a substantial inventory of new and replacement parts.

Barry is thankful for the quality of the aftermarket support for FE engines. These stunning valve covers with the Thunderbird decal are perfect repros and not just cheap junk. Survival Motorsports offers them for $269.50 per set.

Barry is thankful for the quality of the aftermarket support for FE engines. These stunning valve covers with the Thunderbird decal are perfect repros and not just cheap junk. Survival Motorsports offers them for $269.50 per set.

The foundation of Barry's engine began with a Genesis 427 block. There have been a number of different OEM versions of the FE block available throughout the years with minor variations in bore size, oiling system, and main-cap designs. Genesis took the best of the factory designs and improved on them. The most important feature that they replicated was the oiling system of the famed 427 side oiler. Although it is a staple in hot rod nomenclature like "Hemi" or "ZL1," not many outside the big-block Ford world know the intricacies that make up the 427 side oiler's namesake. The most obvious feature is an oil galley that runs along the driver side of the block with passages supplying oil directly to the main bearings prior to the cam and heads. The more common FE variants like the 360/390/428 versions run oil to the cam first, then down to the mains, significantly reducing the oil available at this key area. The '61-63 high-performance 390, and the often-forgotten 406 and the 427 were all designed specifically for solid flat-tappet cams, and as such, had no provisions to run oil to hydraulic lifters should one want to swap cams. The Genesis block allows this provision, as many street-driven car owners now prefer the low maintenance of a hydraulic cam. Another feature of the original side oiler that is replicated is the pressure relief valve at the rear end of the main oil galley, allowing the engine builder to alter oil pressure with different springs or shims. Something to keep in mind if you find yourself building a combination like Barry's is that the side oiler blocks use a different set of cam bearings, as oil travels to the top end through grooves in the second and fourth cam journals, then up through passages in the block and heads before ending up at the rocker shafts.

The FE block is a "Y-block" design similar to big-block Mopars. Where the standard Mopar blocks had two-bolt mains, the race-inspired Hemis had cross-bolted four-bolt mains. The FE engines followed suit with the "normal" blocks having two-bolt mains, but the side oilers (and now Genesis blocks) came standard with cross-bolted mains. Additionally, the Genesis block has the benefit of allowing up to a 4.440-inch bore size. Couple that with a possible 4.375-inch stroke crank, and the thought of a 532ci monster looks tempting.

Barry's crankshaft was decidedly more old school than the brand-new block. "The crankshaft was a 391 truck crank, originally out of a garbage truck or a dump truck," Barry reveals. Most FE engines came with cast-iron cranks, and save for the '65-67 427 engine with the "LeMans" steel cranks, the easiest way to get a forged steel crank is to pluck one from one of the heavy-duty truck versions of the engine family. Officially known as FT engines (Ford/Truck) instead of FE engines (Ford/Edsel), the 361/391 engines all used steel cranks, and all shared the same journal and stroke dimensions as their passenger-car brothers. The only modification necessary to use the truck crank is to turn down the snout of the crank, as the passenger cars and light-duty pickup trucks used a smaller inside diameter on the harmonic dampers. A trip to the machine shop quickly fixes that issue. Barry's choice when it came to modifying his crank was to send it off to fellow Engine Masters Challenge competitor and crankshaft guru Adney Brown of Performance Crankshaft for some serious updating. He did the usual stuff, grinding and indexing the crank to the factory 3.780-inch stroke, but after lightening, bull-nosing the leading edges, and knifing the trailing edges of the throws, the crank looked and performed as good as any NASCAR piece. Barry praised Adney openly: "What he did to that crankshaft was nothing short of stunning."

The classic FE valve covers don't have any provisions for breathers, so at the rear of the intake, a crankcase breather (in place of the classic "road draft tube") is fitted to allow the release of any pressure buildup.

The classic FE valve covers don't have any provisions for breathers, so at the rear of the intake, a crankcase breather (in place of the classic "road draft tube") is fitted to allow the release of any pressure buildup.

Attached to the crankshaft is a set of Scat 6.490-inch H-beam connecting rods. Though they sound like really long rods, they are the factory length. Barry points out: "It's one of the weak points on the FE for parts, because in aftermarket support, although they're getting much better, there are no long rods for an FE on the market. The only rod choice is the 6.490-inch factory-dimension rod." That is not to say that it's a short rod when compared to the stroke, it's just that when compared to the deck height of the block, it forces the engine builder to use a tall, heavy piston. Always one to find the good elements in what he is forced to deal with, Barry points out that the tall pistons actually do a very good job of stabilizing the lightweight Speed-Pro rings and keeping the piston from rocking back and forth.

The pistons Barry chose for this combination are made by Diamond, and use a spherical dish to achieve the final 10.5:1 compression ratio. "It's a full round dish, where the center is deeper, like if you took a baseball and pushed it into the top of the piston." When choosing his pistons, his thought process brought him to consider that when the combustion process occurred, he wanted to center the pressure over the middle of the wristpin instead of wasting energy rocking the piston over as he envisioned with a traditional D-shaped inverted-dome design. "It seems to work pretty good. The motors don't need a lot of timing, the mixture seems to work out real well, and they make good power that way. I think it works well in concert with the location of the cylinder head on the block." The final portion of Barry's comments refers to the massive relocation of the cylinder head in relation to the bores. The dowel pins on the block remained the same, but the dowel locating holes in the heads were welded up and moved to shift the head closer to the lifter valley. He moved the head so much that a portion of the locating dowel is visible beyond the edge of the head. The combination of the dish design and efficiency of the relocated combustion chamber allowed him to make best overall power with a mere 32 degrees of total timing.

Barry points out that the move to a spherical dish is not a total stab in the dark. "This is out of the LS1 world as much as anything else." Referring to the Ford Modular motors and new 5.7 Hemi engines, Barry says: "Those all have spherical-dish pistons in them from the factory. None of them have a D-shaped cup or anything like that in them anymore. We're mirroring factory stuff there. We're not leading-edge, we're just applying leading-edge stuff to an old motor." He adds, laughing: "They worked really hard developing that, we might as well steal it."

Finally able to quantify the effects of an electric water pump, Barry was surprised it only made about 6 hp; not quite the 20 or 30 that some claim. In a street application, Barry prefers the loss of a few a horses for the peace of mind that comes with a beltdriven water pump.

Finally able to quantify the effects of an electric water pump, Barry was surprised it only made about 6 hp; not quite the 20 or 30 that some claim. In a street application, Barry prefers the loss of a few a horses for the peace of mind that comes with a beltdriven water pump.

The oiling system was not as high-tech as the pistons, but as it has been refined for a number of years, it did not need to be high-tech. "We blend from the oil pump into the block, we match where the oil enters the main bearings and blend those passages a little bit, and we restrict the oil to the cylinder heads." Barry used a Melling oil pump, and found this setup to be totally reliable. He admits to having the same problems as the Chrysler guys when it comes to windage, though. "The Hemi guys, to get the benefits of the kick-out-style pan on their motors, they mill windows on the sides of the block. I think that is the same issue I have. The Y-block minimizes the benefits of a good pan." He ended up using an out-of-the-box Milodon pan, surprised at its performance. "I've run really cool, swoopy pans on these things in the past, and that Milodon one actually made more horsepower, by about 3, compared to a billet-aluminum, swinging-trapdoor wild pan. I'm sure the cool pan was better in the car at controlling oil, and the way oil behaves, but because of the nature of the FE, it didn't have any advantage on the dyno, which was totally surprising and disappointing."

As for the ever-popular windage trays, he claims that he's tried with and without trays of different styles, and hasn't seen any real benefit or loss. "I normally end up running a tray on it just because I'd feel guilty not doing it, but I can't attribute it to a single bit of horsepower."

With the foundation prepared, Barry worked on the top end of the engine: the side where the real power is made. In years past, there were not a great number of choices when it came to cylinder heads for the FE. Medium-riser heads were plentiful and made good power. High-riser heads made better power, but with their height forcing the carb to sit a solid 2-3 inches higher than any other design, they were impractical without a hoodscoop. Tunnel-port heads, with their massive runners designed with pushrod tubes going straight through them, made incredible power, but were hard to come by, even in years past. Today they are almost extinct. Enter the Blue Thunder FE head. Similar in design to a medium-riser head, Barry acquired a pair of these jewels in bare form and had his friends at E/T Performance do their computer-enhanced magic on them. For those unfamiliar with the name, E/T Performance is most commonly known throughout the LSX world as a leader in CNC head-porting technology. Looking closely at the ports and chambers, they don't look anything like the early Ford designs. In fact, they look just like an LS1. "They tried to put an LS head into an FE head," said Barry.

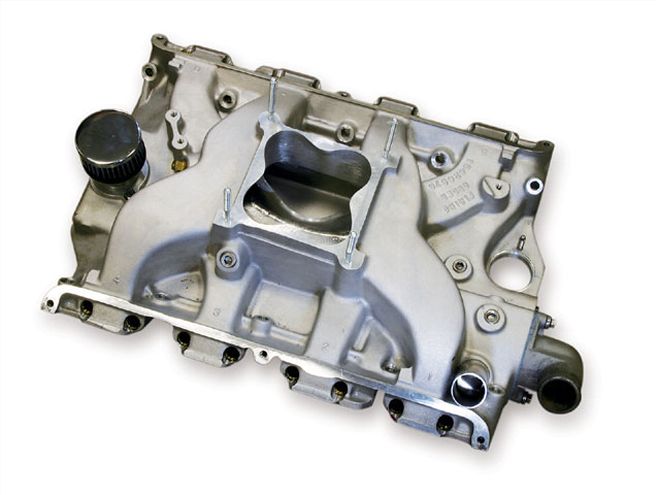

This is the Twilight Zone of intake manifolds; E/T Performance did some major plenum modifications to allow the cylinder to draw equal amounts of air and not be restricted. You can also see how the FE intake has the unique characteristic of running the pushrods through the intake manifold, forcing the removal of the rockers and pushrods, and relashing the valves for any manifold changes.

This is the Twilight Zone of intake manifolds; E/T Performance did some major plenum modifications to allow the cylinder to draw equal amounts of air and not be restricted. You can also see how the FE intake has the unique characteristic of running the pushrods through the intake manifold, forcing the removal of the rockers and pushrods, and relashing the valves for any manifold changes.

As Barry was not overly concerned with high-mileage durability, they installed 5/16-inch-stem lightweight valves and performed a 50-degree competition valve job to work with some serious porting. In comparison to a traditional 45-degree valve job, the 50-degree valve job tends to kill a small amount of low-lift airflow. When using a cam with a good amount of overlap and lots of lift and duration, that can actually be beneficial, as it allows the intake valve to pop open a little bit without contaminating the intake charge with exhaust gasses. The downside of using 50- or 55-degree valve jobs is that it beats in the valve seats and valves much sooner than the 45-degree seats.

"Within the legal boundaries of the rules, we angle-milled the heads 1 degree. There's nothing in the rules talking about the location of the head on the block, so yeah, we moved the head around the block a little bit and that seemed to help. It's hard to say how much each of the individual changes helped because we never checked it out that way; we just keep on moving in directions where the package gets better. I know it's not the scientific method, but I don't have the budget to employ the scientific method all the time."

Operating the valves was the job of the T&D shaft rocker system. Barry is totally sold on the design. The key benefit he points out is that the burden of supporting the rocker arms was moved from a single long shaft with several individual support stands to a single long steel support structure with four paired rocker shafts. That change eliminates the fairly common failure of rocker stands and shafts breaking. And with an aggressive solid flat-tappet cam like the one from COMP Cams he's got thumping in this engine, he needs all the stability he can get.

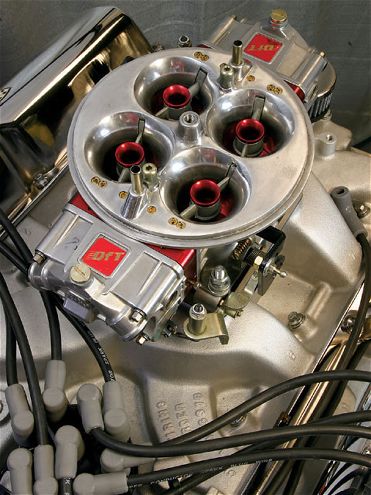

Marvin at Quick Fuel built this Dominator for Barry a few years ago, and it has been on Barry's last three Engine Masters Challenge entries. The QFT is extremely responsive, and takes changes well. A carb that produces predictable and expected results to jet and bleed changes is a valuable piece when dialing in an engine.

Marvin at Quick Fuel built this Dominator for Barry a few years ago, and it has been on Barry's last three Engine Masters Challenge entries. The QFT is extremely responsive, and takes changes well. A carb that produces predictable and expected results to jet and bleed changes is a valuable piece when dialing in an engine.

Barry's first choice of intakes was to use his tried-and-true Edelbrock Victor that he had from the previous year's Challenge. As a comparison, he decided he'd give a second intake a shot. "Early on, Martin, from Blue Thunder, wanted me to try his dual-plane." At first, the fully tricked-out Edelbrock beat it handily, but he thought he'd let his pals from E/T take a shot at the more street-oriented dual-plane intake. John and the guys at E/T were leery about the Blue Thunder intake performing at the same level as the Victor, but they took it in like a puppy out of the rain, and fed it plenty of carbide and cartridge rolls. Barry recalled his reaction when he got the intake back. "He brought me back an intake a few weeks later that when you took the carburetor off and looked down it, it was like something out of the Twilight Zone." Barry asked John whether he thought the intake would perform, and his response was: "It's either going to work good, or it'll be a turd." Barry says: "If you look at the dual-plane, the plenum shape in there and the interior layout is unlike any dual-plane intake I've ever seen. He's onto something. I don't know if it's truly revolutionary, but it's certainly different." Normally, the plenum divider would run front to back in a straight line, and sometimes there would be a notch milled into it to increase the plenum area. In this case, they shaped the plenum divider into an inverted rainbow shape and continued the runners, allowing their lengths to be closer to the same, and also creating a larger plenum from which to breathe.

They ended up installing the heavily modified Blue Thunder intake on the engine for final testing not long before it was to be shipped. They got their ignition, cam, and carb dialed in, assuming that afterward, they would just swap out to the "good" single-plane intake and make even more power. In back-to-back testing, it turned out the dual-plane-the "street" intake-beat the single-plane across the board. Barry was amazed. Time didn't allow individual exhaust probe testing to check fuel distribution, but based on the overall fuel curve and the amount of fuel needed to make the power, he felt it was definitely a great working design.

As a test to see how close he could get the engine to perform in real-world conditions, he ran his testing sessions with an electric water pump and a set of Hooker headers against the same engine with a belt-driven water pump and a rare set of cast-iron headers from a '63 Galaxie. As you'd expect, the tubular headers and electric water pump helped the engine make a good deal of grunt, to the tune of 659 hp. What you might not expect is that with the beltdriven water pump and cast-iron exhaust, the engine still made an amazing 606 horses! Imagine, this flat-tappet-cammed, pump-gas engine could be dropped straight into an early Ford luxo-barge and eat late-model Camaros alive!

When that first FE engine exploded on the scene a good 50 years ago, its designers might not have realized at the time how its fallout would affect the rest of the engine building world, or how long its half-life would be. The universe of hot rodding has evolved into an array of overhead-cammed, fuel-injected, and computer-driven technologies. Nonetheless, Barry Robotnick and his thriving business, Survival Motorsports, have proven that the FE engines can still inflict some serious damage in the battle for torque and horsepower.

BY THE NUMBERS SURVIVAL MOTORSPORTS 427 FE FORD Bore: 4.250 inches Stroke: 3.{{{780}}} inches Displacement: 429 actual cubic inches Compression ratio: 10.5:1 Camshaft: COMP solid flat-tappet Cam duration: 252/252 degrees at .050-inch tappet rise Valve lift: .640/.640-inch Rocker arms: T&D shaft-type, 1.75 ratio Lobe separation: 110 degrees Installed centerline: 106 degrees Top ring: .043-inch Speed-Pro Second ring: .043-inch Speed-Pro Oil ring: 3mm Speed-Pro Piston: Diamond spherical-dish Block: {{{Genesis}}} Performance Castings Crankshaft: OEM forged 391 Rods: Scat 6.49-inch H-beam Cylinder head: Blue Thunder medium riser Intake valve diameter: 2.{{{200}}} inches Exhaust valve diameter: 1.710 inches Intake manifold: Blue Thunder dual-plane Carburetor: Quick Fuel modified Holley Dominator Header: Hooker Super Comp 2-inch primaries Ignition: MSD 6AL Damper: Professional Products ON THE DYNO {{{DTS}}} DYNO DATA SURVIVAL MOTORSPORTS