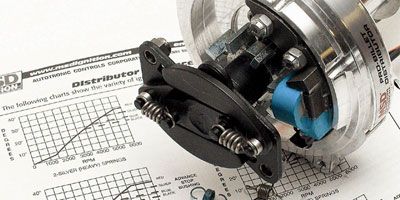

The MSD distributor comes with springs and bushings that can allow a tuner to easily tailor the mechanical spark advance to the needs of the engine.

The MSD distributor comes with springs and bushings that can allow a tuner to easily tailor the mechanical spark advance to the needs of the engine.

Tuning a carburetor-equipped engine to perform its best with the reformulated unleaded gasoline of today can prove to be a challenge for many kit car owners and builders. Back in the days of leaded gasoline a tuner would tune the ignition spark timing and the carburetor's jetting by "reading" the spark plugs, but quite often the reformulated unleaded gasoline of today does not leave any "color" on the spark plug unless the air/mixture is very rich. The unleaded reformulated gasoline of today is blended for a modern computer-controlled, electronic fuel-injected engine with the goal of the lowest possible exhaust emissions.

Modern gasoline is composed of hundreds of different hydrocarbons blended together to provide the engine with a fuel that hopefully will allow the engine to perform its best from the moment you start your engine. There are complicated differences between the reformulated unleaded gasoline of today and the leaded gasoline of years past. The following changes are the ones most important to tuners. Removal of the lead that was used as an octane enhancer from the gasoline is the clearest difference, but the distillation profile of the gasoline has also been changed to help reduce evaporative emissions from the fuel. The fuels also have density differences, as well as flow changes. This means the fuel burns at a different rate during the combustion process and the fuel even flows differently through the jets of a carburetor when compared to the leaded gasoline of days past.

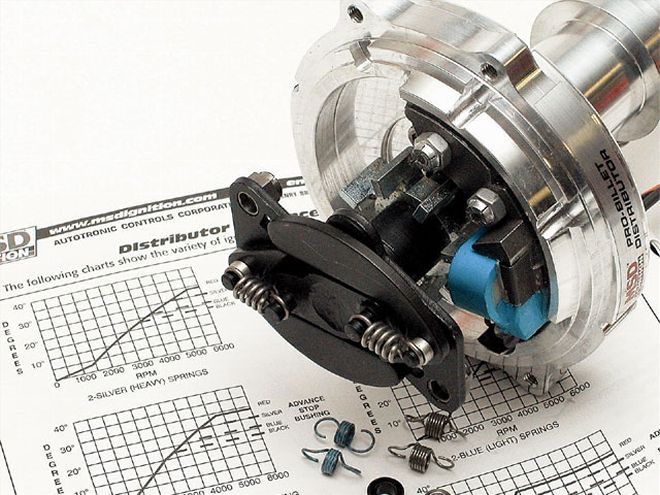

The map on the previous page shows different blends of gasoline mandated in the United States. Many areas of the country are voluntarily adding oxygenates such as ethanol to their gasoline.

A dial-back timing light can allow a tuner to read the ignition timing spark advance from the distributor.

A dial-back timing light can allow a tuner to read the ignition timing spark advance from the distributor.

There are at the least 14 different government-mandated blends of conventional, reformulated, and oxygenated gasoline that are available at your local gas station depending on the part of the country where you live. The formulation of gasoline available at your local petrol station will also vary by the season of the year and the predicted temperatures in that part of the country. Gasoline in many parts of the country may also contain oxygenates such as ethanol. This is true even in areas of the country where there is not yet a government mandate for its use.

The new fuel-injected cars of today have an onboard computer that is continually adjusting the air/fuel mixture and ignition spark advance to match the formulation of the gasoline and the engine's needs. When you use this modern unleaded reformulated and/or oxygenated gasoline in an engine that was designed and tuned for leaded gasoline, it changes the air/fuel mixture the engine is getting from its carburetor. The burn rate of modern gasoline is also different from the leaded gasoline of days past, so the ignition spark-timing advance needs of the engine are also different than they were. This means the air/fuel mixture the engine is getting from its carburetor and the ignition spark advance curves from its ignition distributor must be tuned to match the needs of the engine and the blend of gasoline you are using.

In this tuning article we are going to show you how we tuned the ignition and carburetor systems on two Cobra replica kit cars to solve the driveability problems their owners were experiencing. Hopefully, you should also be able to do this for yourself. The first Cobra has a high-end 427ci Ford crate engine that was rated at 550 hp, while the second Cobra has a 347ci Ford engine that has since been dyno tested to show that it has over 350 hp at the rear wheels. The first Cobra with the 427 crate engine had a very bad stumble off idle. When you drove it at 2,200 rpm on the highway, the engine would almost shut off even though the engine was "hot tested" and "dyno tested" at the factory before they shipped it to the customer. The second Cobra with the 347 engine had a hesitation on acceleration, a surge at part throttle, and it did not have the power the owner expected from the engine he built.

U.S. Gasoline RequirementsThis map shows different blends of gasoline mandated in the United States, but many areas of the country are voluntarily adding oxygenates such as ethanol to their gasoline."> <br><strong>U.S. Gasoline Requirements</br></strong>This map shows different blends of gasoline mandated in the United States, but many areas of the country are voluntarily adding oxygenates such as ethanol to their gasoline.

<br><strong>U.S. Gasoline Requirements</br></strong>This map shows different blends of gasoline mandated in the United States, but many areas of the country are voluntarily adding oxygenates such as ethanol to their gasoline.

Ignition Spark TimingThe first step in the process of tuning an engine to use today's reformulated unleaded gasoline is to tune the ignition spark advance curve(s). The proper tuning of the initial and the ignition spark timing advance curve(s) may be the easiest and lowest-cost way to unlock the power that was built into an engine.

The distributor ignition advance curve that is in most new aftermarket distributors is a very conservative advance curve for a generic engine. It is up to the person installing this new distributor to set the amount and rate of ignition spark advance curve of the distributor and how much initial spark timing the engine needs. The variables that need to be taken into account when you pick an ignition advance curve are: the vehicle's weight, how the driver will operate the engine (the rpm range of engine operation, or if the driver tends to lug the engine), the fuel octane, the engine compression, altitude of the vehicle's main usage, and the heat of the air. The distributor's mechanical and vacuum advance curves must be correct for the engine and the fuel being used or the engine's performance will suffer-and there's also the possibility of engine damage from detonation.

Ignition Spark Advance Curves

The ideal ignition timing for power and fuel economy is just short of the point where detonation or pinging occurs. The correct ignition timing (the initial timing plus the advance from both mechanical and vacuum advance mechanisms) will cause the pressure created by the fuel being burned in the combustion chamber that is pushing the piston down to be at its peak/maximum when the piston is at about 12 and 15 degrees ATDC (after top dead center). If the peak cylinder pressure is reached too soon, the engine will lose power as the piston fights to compress the burning air/fuel mixture. Detonation may also be experienced, which can lead to engine failure. If peak cylinder pressure is reached too late, the engine will just be wasting the energy the combustion process creates as wasted heat out through the exhaust system.

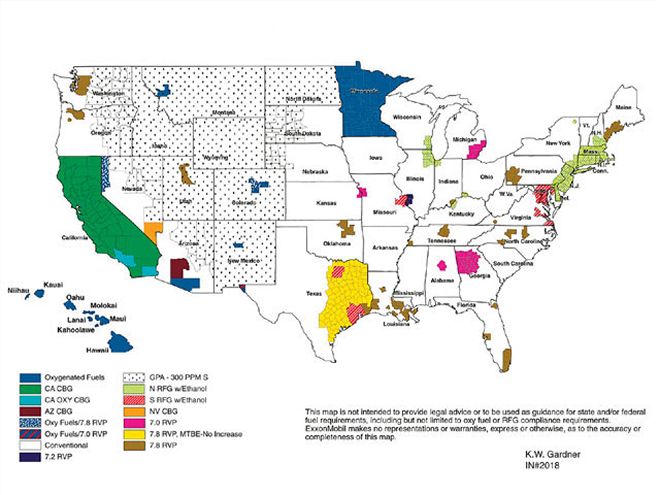

Here's an initial timing guideline chart from Barry Grant.

Here's an initial timing guideline chart from Barry Grant.

The amount of ignition advance needed changes with engine speed, engine load, engine temperature, air temperature, compression ratio, the fuel octane being used, and the air/fuel mixture. When an engine is operating with a rich (power) air/fuel mixture for maximum power, it needs less ignition spark advance than it does when it is operating with a lean (cruise) air/fuel mixture. A distributor with a vacuum advance adds a little more ignition spark advance during a low-load highway cruise condition, so the engine can more completely burn the slower-burning, leaner air/fuel mixture that is seen at part-throttle conditions. A 12.5-13.5:1 air/fuel mixture burns the fuel faster and will make more power, but a leaner air/fuel mixture of 14-15:1 is better for fuel economy.

If an engine does not have enough ignition spark advance, the engine may lack power, plus the engine may tend to run hot or overheat. If the engine has too much ignition spark advance, the engine will also want to run hot and lack power. If excessive pinging or detonation is present, you are also risking engine damage. Any distributor, whether it is original or performance replacement, should have the mechanical and vacuum advance curves checked to confirm they are correct for use with your driving style, engine package, and today's reformulated unleaded gasoline.

The best way to check both the vacuum and mechanical advance curves of a distributor is in a distributor test stand; this is because you can check the spark advance curve at any rpm without fear of over-revving the engine. Back in the 1960s and 1970s almost every automotive repair shop had a distributor test stand so they could check the advance systems of a distributor. In current times, it's getting hard to find a shop that has one.

A distributor test stand is the best way to check the advance curve of a distributor.

A distributor test stand is the best way to check the advance curve of a distributor.

If you don't have access to a distributor test stand, an optional method to check the vacuum and mechanical advance curves is a dial-back timing light. A dial-back timing light allows you to read the advance curve of an engine at different engine speeds even if it doesn't have a degreed vibration dampener. Just take care not to over-rev the unloaded engine. The vacuum advance curve can also be checked with a hand vacuum pump to vary the vacuum supplied to the vacuum advance. Use the timing light to read the amount of advance given by the vacuum advance at different amounts of vacuum from 1 to 23 inches.

Ignition Spark Advance GuidelinesThe "hot-rod" advance curve used most on a typical 9.5:1 compression engine with a mild camshaft (duration less than 220 degrees at 0.050 inch) is 10-12 degrees initial timing plus 22-24 engine degrees of additional advance from the mechanical advance mechanism. In most cases, full advance (32-36 degrees) is in by 3,500 rpm. An engine with camshaft duration above 220 degrees at 0.050 inch will like more initial timing; however, the total timing will stay the same (32-36 degrees).

Any original or high-performance aftermarket replacement distributor must have the ignition spark advance curve(s) tuned for your engine and the gasoline you will be using. Most of the high-performance replacement ignition systems, such as an MSD distributor, come with a very conservative ignition advance curve installed in the distributor. A new MSD distributor comes with a selection of advance springs and bushings so you can set the advance curve you want. However, most vacuum-advance-equipped distributors have too much advance for the reformulated gasoline of today.

These are the primer electric fuel pumps in the trunk of a 427SE Shelby Cobra used to feed the mechanical pump on the engine. The photo provides a great idea of how well this Shelby Cobra was built.

These are the primer electric fuel pumps in the trunk of a 427SE Shelby Cobra used to feed the mechanical pump on the engine. The photo provides a great idea of how well this Shelby Cobra was built.

The mechanical advance should not start advancing until just above the base idle speed. Too much advance with the engine speed too low may cause a ping or detonation problem, which can lead to engine damage. The guideline we have found for determining what initial timing is best for a gasoline engine is in the Barry Grant Inc. catalog and/or Web site in the Demon carburetor selection guide. The booklet recommends 10 to 12 degrees of initial timing when the camshaft duration is less than 220 degrees @ 0.050 valve lift, 14 to 16 degrees of initial timing with less than 240 degrees @ 0.050, and 18 to 20 degrees of initial timing with a cam with less than 260 @ 0.050 valve lift. The total ignition mechanical advance from the distributor must be reduced when you increase the initial timing because engine damage will result if the total advance is excessive for the engine compression and fuel being used. A modern 9.5:1 compression Chevrolet, Ford, or Chrysler engine will in most cases like 34-36 degrees of total mechanical ignition spark advance, including the initial timing with the reformulated gasoline of today.

An engine with a high-performance camshaft designed to create power above 3,000 rpm will respond well to 18 degrees of initial timing because the air/fuel mixture is not uniformly mixed together at lower engine speeds. The additional initial timing allows more time for this air/fuel mixture to burn in the cylinder (the same theory also applies to an engine with a race-designed intake manifold or an air-gap intake manifold). A high-performance cam and/or intake manifold will decrease the velocity of the air/fuel mixture at low rpm. This low velocity causes the fuel to separate from the air at lower engine speeds.

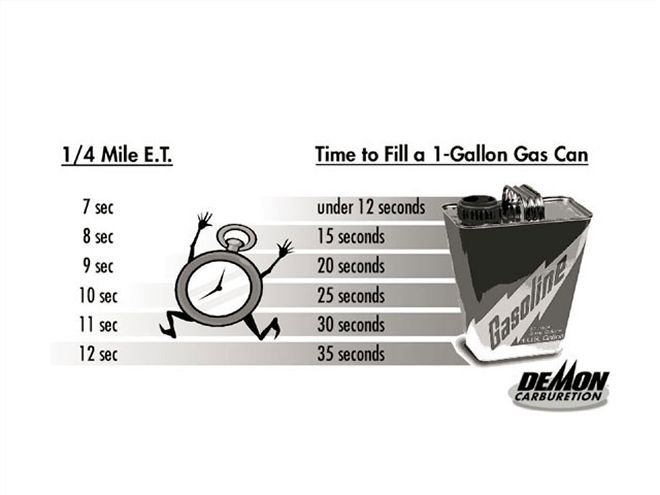

The following Barry Grant chart shows the fuel needs of an engine based on the vehicle's 1/4-mile E.T.

The following Barry Grant chart shows the fuel needs of an engine based on the vehicle's 1/4-mile E.T.

Tuning The Ignition Spark Advance For Fuel EconomyThe ignition spark advance curve an engine needs for maximum power with the rich air/fuel mixture the engine has during wide open throttle acceleration is different than the ignition spark advance it needs for the leaner air/fuel mixture the engine has when you are cruising at 65-75 mph on the highway. The vacuum advance curve we use most will provide the engine with an additional 10 to 12 degrees of spark advance when the engine vacuum is above 10 inches. This way the engine has the extra spark advance it needs to burn the leaner cruise air/fuel mixtures it sees at part throttle.

Tuning The Cobras AdvanceWhen we referenced the Barry Grant initial timing guide, we decided that 18 degrees of initial timing would work quite well with the camshafts that are in both of the high-performance engines in the Cobras we are working on. We then recurved the distributor so it would give us 16 degrees of mechanical advance that starts advancing at 800 rpm and is all in by 3,000 rpm to give us 34 degrees of total mechanical advance that the 427 engine manufacturer recommended. We set the total mechanical advance on the 347 Ford engine at 36 degrees since this engine did not have the same fast burn cylinder heads as the 427 engine.

This Holley electric fuel pump can supply enough fuel for an engine with as much as 900 hp.

This Holley electric fuel pump can supply enough fuel for an engine with as much as 900 hp.

The changes improved the engines' performance. The idle quality was much improved on both engines, and both engines had more power at low- and mid-range rpm driving conditions. Now that the ignition system is tuned for the reformulated unleaded gasoline it's using, it's time to look at the fuel system.

Fuel Supply Systems

The fuel supply system in every gasoline-powered vehicle must supply the carburetor with an adequate volume of fuel delivered at the correct fuel pressure during every operating condition the engine will be driven at. The job of keeping fuel pressure constant on a high-performance engine may not be as simple as it seems. Everything from the fuel tank vent system to the point where the fuel is delivered to the carburetor's needle and seats must be designed to flow enough fuel for the needs of the engine.

If the fuel pressure supplied to the carburetor by the fuel pump drops below the ideal fuel pressure as measured at the carburetor's needle and seat, even within a second, the engine may run out of fuel. If the air/fuel mixture shifts too lean, engine performance will suffer, and/or if you run too lean for too long engine damage may result.

A vented gas cap is not as simple as it looks from the outside.

A vented gas cap is not as simple as it looks from the outside.

Fuel Tank VentingFuel tank venting is an often ignored area that can cause quite a few fuel volume and pressure-related driveability problems. As the fuel pump pulls fuel from the fuel tank, outside air must be allowed in to replace the fuel. The fuel tank gets this outside air through the vent in a vented gas cap, a fuel tank vent hose, or the evaporative canister system, depending on what fuel tank vent system that was installed on your kit car. A vented gas cap has a vent restriction that is in the 0.080-inch range. This small of a fuel tank vent may be OK for normal driving, but if you drive at high speeds for an extended length of time, it could lead to low fuel volume and pressure-related problems. If your kit car has a sealed gas tank with an evaporative canister system, the fuel tank vents through the canister. The evaporative canister has a filter system built into it. As this filter gets dirty, it will restrict the flow of outside air into the gas tank.

The next critical component in the tuning process is tuning the air/fuel mixture the engine is getting from its carburetor for both power and fuel economy. Stay tuned for part two, tuning the air/fuel mixture, in the next issue of KIT CAR magazine.