With a world of affordable parts available for the 383, it shouldn't take much convincing to build a stroker small-block instead of a plain-Jane 355. Better yet, build a 383 and tell the street rats out there it's just a 307.

With a world of affordable parts available for the 383, it shouldn't take much convincing to build a stroker small-block instead of a plain-Jane 355. Better yet, build a 383 and tell the street rats out there it's just a 307.

If the small-block Chevy is the most predominant powerplant in the musclecar world, the 383 could very well be the most popular displacement. In a world where cubic inches are king, it doesn't make much sense to build a 350ci small-block when you can build a 383 for virtually the same price. In the old days, car crafters pillaged unsuspecting 400ci engines for their cranks and connecting rods. Today, the aftermarket is bulging with ridiculously affordable cast cranks. When you can buy a brand-new, fully machined, and ready-to-install cast 3.75-inch stroker crank for $175, there's no reason to build a plain vanilla 350. This giant section is devoted exclusively to the design, creation, building, and testing of the 383ci stroker small-block Chevy.

The essential component of the stroker swap is the crank. Adding an additional 0.270 inch of stroke means that the crank and rod swing also increase, making the crankcase a very tight place on a small-block Chevy.

The essential component of the stroker swap is the crank. Adding an additional 0.270 inch of stroke means that the crank and rod swing also increase, making the crankcase a very tight place on a small-block Chevy.

The Origin Of The Species

First of all, Chevy never built a production 383. Secondly, the 383 did not just fall out of the sky one bright, clear summer afternoon. Sometime roughly 30-odd years ago, a creative small-block engine builder realized that if he machined the main journals of a 400ci small-block crank to fit in a 350 block, the longer arm would add roughly 28 ci to a 0.030-overbored small-block Chevy. This happens because the 400 small-block uses a 3.75-inch stroke compared with the 350's 3.48-inch stroke. Add in a 0.030-inch overbore and the displacement formula spits out 382.6 ci, which car crafters have conveniently rounded off to 383.

While the standard 383 is the most common form of stroker small-block, there are several variations to this theme. The first question might be: Why not just build a 400ci small-block and take advantage of the additional cubic inches? In the early days of the 383, many enthusiasts were under the mistaken impression that the 400 small-block was prone to overheating, so using a 350 block was considered a better way to go. Today, finding a 400ci standard-bore production block is becoming increasingly difficult, which is why the 383 has remained popular. The following is a selection of the variations on the stroker small-block concept.

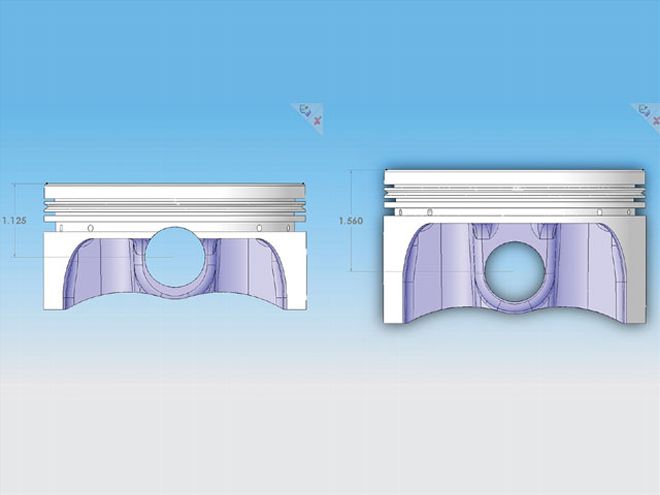

DISPLACEMENT BORE STROKE NOTES 377 4.155 3.48 400 block (+0.030), 350 crank 377 4.000 3.75 350 block standard bore, 400 crank 383 4.030 3.75 350 block (+0.030), 400 crank 388 4.060 3.75 350 block (+0.060), 400 crank 395 4.030 3.875 350 block (+0.030), custom crank 401 4.060 3.875 350 block (+0.060), custom crank These engineering drawings from SRP illustrate the difference in compression height (CH) of a typical 350 piston with 1.560-inch CH (right) versus a 383 piston using a 6.00-inch connecting rod, requiring a much shorter 1.125-inch CH (left). Note how the shorter compression height pushes the wristpin into the oil ring, requiring an oil ring support rail.

These engineering drawings from SRP illustrate the difference in compression height (CH) of a typical 350 piston with 1.560-inch CH (right) versus a 383 piston using a 6.00-inch connecting rod, requiring a much shorter 1.125-inch CH (left). Note how the shorter compression height pushes the wristpin into the oil ring, requiring an oil ring support rail.

Stroke Stuffing

All production small-block Chevys share the same deck height of 9.025 inches. Stroke, connecting-rod length, and block deck height are the variables the engine designer must play with when creating a new engine. In the case of the stroker small-block Chevy, it comes down to squeezing a bigger arm into a standard small-block. The original 265ci small-block used a 3.75-inch bore and a 3.00-inch stroke. When the time came to design the 400, Chevy engineers had to stuff a 3.75-inch stroke into the 265's same block architecture. Bumping the stroke required changing a few other details as well. Instead of moving the piston's wristpin location upward, they shortened the connecting rod. All stock small-block Chevy connecting rods measure 5.70 inches, except for the 400, which measures 5.565 inches. The difference is 0.135 inch, which just happens to be exactly half of the added stroke at 0.270 inch. Let's add up the numbers to see how this works. The formula is simple: Half the stroke, plus rod length, plus piston compression height needs to fit within the block deck height. To define everything, the deck height is the distance from the crank centerline to the head surface of the block. Compression height is the measurement from the wristpin centerline to the flat portion of the piston. The numbers lay out as follows:

Reciprocating component height: 1/2 stroke + rod length + piston compression height350ci component height: (3.48/2) + 5.70 + 1.56 = 9.00 inches400ci component height: (3.75/2) + 5.565 + 1.56 = 9.00 inchesThe small-block Chevy standard deck height is 9.025 inches.Production small-block Chevys are built with the piston roughly 0.025 inch below the deck.

Based on this information, the earliest 383s were built using stock 5.565-inch-long connecting rods because this combination allowed using a 350 compression height piston. However, this creates a severe rod-length-to-stroke relationship (rod length divided by stroke), producing a ratio of 1.48:1 on a 400, while the 350 uses both a shorter stroke and a longer rod to produce a ratio of 1.64:1. This may not sound like a big deal, but it was clear from these early engines that the short 400 rod pushed the piston into the cylinder wall pretty hard and was not happy at engine speeds more than 6,000 rpm.

This led to the better idea of combining the longer 5.70-inch 350 rod with the 3.75-inch stroke crank, which made the rod angularity much gentler on the cylinder wall. Of course, this requires a custom piston with a shorter compression height. For example, a typical 383 piston intended for a 5.7-inch-long connecting rod will have a compression height of 1.425 inches to create that same 9.00 deck height. This allows up to 0.025 inch of room to mill the deck to create a zero deck height between the top of the piston and the deck of the block. As the length of the connecting rod increases, the piston's compression height shortens and the wristpin moves closer to the ring package. At some point, adding a longer rod will push the wristpin too far into the ring package, which reduces piston stability at higher engine speeds. While there are many custom pistons with the wristpin in the ring pack, there are limitations to the minimum piston compression height. Many engine builders will limit minimum compression height to 1.00 inch. For example, a small-block Chevy with a 4.00-inch stroke and a 6.00-inch rod will require a very short 1.00-inch compression height to squeeze it all into a standard-deck-height small-block. SRP makes a very short piston for this specific application, although the pin most definitely intrudes into the oil ring land.

Most 383 stroker cranks are designed to use external weights on the balancer and the flexplate/flywheel. Many aftermarket balancers now come with bolt-on external weights for these applications, like this Professional Products balancer.

Most 383 stroker cranks are designed to use external weights on the balancer and the flexplate/flywheel. Many aftermarket balancers now come with bolt-on external weights for these applications, like this Professional Products balancer.

Internal Vs. External Balance

Here's where it gets fun. When Chevy engineers pulled out their slide rules and put their pencils to the drawing board in the late '60s to design the 400ci small-block, it meant adding counterweight to the crankshaft to properly offset the longer stroke. There wasn't room in the crankcase to move the crank counterweights away from the crank centerline because the weights would hit the block. Instead, the designers added weight at the flywheel/flexplate and harmonic balancer ends of the crankshaft, creating an externally balanced engine. The 400 is the only Gen I small-block that requires offset balance weights on both ends of the crank. This means that most standard 383 rotator packages use an externally balanced crank that requires a 400-style offset weight balancer and flywheel/flexplate.

While externally balanced engines have survived for decades, heavy external weights are more likely to put a twist in the crank at higher engine speeds. To minimize this, many 383 cranks are also offered internally balanced. This requires Mallory, or heavy metal, to be added to the crank throws to offset the amount of weight normally added to the balancer and flywheel/flexplate. This is a more expensive process, but internal balance does offer durability advantages. Several crank manufacturers offer an internal balance option for 383 stroker packages either as separate cranks or complete rotator packages.

One-piece rear main seal stroker cranks also demand attention to a critical balance issue. A two-piece rear main seal crank has a small offset weight incorporated into the flywheel/flexplate flange that does not exist on one-piece rear main seal cranks. As a result, most one-piece rear main seal crankshafts require offset weight on the flywheel/flexplate. But since one-piece cranks have a unique flange bolt pattern, all one-piece flywheels/flexplates come with the required offset weight.

This is fine until you realize that several crank companies also offer internally balanced, one-piece rear main seal 383 stroker cranks. Balancing them requires eliminating the offset weight from the flywheel/flexplate. For flexplates, this means removing the weight that is usually welded in place. For flywheels, weight is not added but instead removed from the opposite side of the flywheel. Zero-balancing a one-piece flywheel means drilling holes 180 degrees from the original holes to zero-balance the flywheel and prevent vibration.

Two-Piece Vs. One-Piece Seals

From 1955 to 1985, all small-block Chevys were built with two-piece rear main seals. Unfortunately, this seal design is prone to leaking, so in 1986, GM redesigned the small-block with a one-piece rear main seal. This changed the rear crankshaft flange design to accommodate the one-piece seal. At first, no crankshaft companies were building one-piece performance stroker crankshafts, which required an adapter. However, all the major crank companies now offer 383 crankshafts in two-piece and one-piece rear main seal versions.

While the older two-piece crankshaft can be adapted for use in a newer one-piece block, the one-piece crank cannot be retrofitted to the two-piece block. That's just as well because there are some real advantages to using the one-piece rear main seal blocks to build a 383. We'll run through a quick version of a buildup of one of these engines, but the one-piece seal combined with the advantages of using a hydraulic roller cam in these same blocks is well worth the effort. It's important to know the one-piece crank also uses a smaller flywheel bolt pattern compared with the early two-piece design, so flywheels and flexplates do not interchange between these two flange designs.

Many aftermarket stroker rods convert to capscrews (as opposed to bolts and nuts) that can be contoured on the top side to clear the camshaft.

Many aftermarket stroker rods convert to capscrews (as opposed to bolts and nuts) that can be contoured on the top side to clear the camshaft.

Internal Clearancing

Stuffing a 3.75-inch stroke crank into a block designed for a 1/4-inch-shorter arm requires minor trimming. The first area for attention is where the rods swing by the base of the block just inboard of the oil-pan rail. If you are building a 383 for the first time, mock up the crank and rods with dummy pistons so the rods swing in their proper orientation. The rod bolt nuts (or bolt heads for capscrew rods) will probably either hit the block or come extremely close, requiring clearancing with a die grinder and a carbide cutter designed for cast iron. The key is to remove as little iron as possible because there is a water jacket directly beneath the area you will be grinding. Most blocks will require clearancing at the base of each cylinder, and many will also need a slight amount of grinding just on the inside edge of the pan rail. The extent of the grinding will depend on the rod design and position of the rod bolts. The pan rail may not always need to be clearanced.

Some budget engine kits grind too much material away from the rod bolt head, as in this situation. The semicircle mark was created when torque began to pull this bolt apart. Had this bolt been used in a running engine, it would have failed immediately and caused major damage.

Some budget engine kits grind too much material away from the rod bolt head, as in this situation. The semicircle mark was created when torque began to pull this bolt apart. Had this bolt been used in a running engine, it would have failed immediately and caused major damage.

There's a second and equally important internal clearance issue on 383s between the camshaft and the connecting rods. Because of the additional stroke, the upper portion of the big end of the connecting rod swings very close to the camshaft. Using stock 5.7-inch rods in a 383 requires grinding the leading edge of the rod near the bolt on rods 1, 2, 5, and 6. One way to help with this clearance to use a new rod bolt from ARP (PN 134-6027, $65.88, summitracing.com), which offers additional bolt head clearance for the camshaft. Small-base-circle cams are another suggestion when building a 383 stroker motor. The base circle is the starting point for any lobe lift. Since maximum lobe height on any cam cannot be larger than the diameter of the cam journals, one way to gain lift with a cam is with a smaller base circle. Big-lift roller cams often present the biggest clearance problems with a 383, so this is something that should certainly be checked when trial-fitting your next 383. Cam phasing is also critical to this effort, so when test-assembling the engine, the cam should be accurately degreed to ensure proper clearance between the cam lobes and the rods. Our friends at Jim Grubbs Motorsports (JGM) recommend a minimum clearance of 0.020 inch that can be measured using a long feeler gauge. Using clay doesn't really work because it tends to smear rather than cut cleanly.

The staff at JGM also told us they prefer I-beam over the H-beam rods for all small-block Chevy stroker applications because the H-beams often require radical block clearancing. In fact, JGM's Jeff Latimes says that they've had to clearance a block using H-beam rods with a standard 3.48-inch stroke crank. In that same area, internally balanced cranks place the additional mass on the rear counterweight, which often creates clearance issues right at the oil-pan rail. This sometimes requires reshaping the inside edge of the oil pan to clear the counterweight. The procedure is to mount the pan on the pan rail with the crank in place and rotate the crank for clearance without the gasket. If the pan clears, it will have the same or more clearance with the gasket. JGM also prefers the Fel-Pro one-piece molded pan gasket not only for ease of installation, but also for its additional clearance.

The best dished piston design (left) retains the quench portion of the piston to create better cylinder mixing as the piston approaches top dead center (TDC). This better quench design usually results in an engine that is less detonation sensitive and that also doesn't need as much ignition timing to make best power. SRP calls this an inverted-dome-style piston.

The best dished piston design (left) retains the quench portion of the piston to create better cylinder mixing as the piston approaches top dead center (TDC). This better quench design usually results in an engine that is less detonation sensitive and that also doesn't need as much ignition timing to make best power. SRP calls this an inverted-dome-style piston.

Compression Lessons

One way to squeeze every last ounce of power out of your engine is by carefully selecting the parts and blueprinting the engine. Compression ratio is a great place to enhance power while still using pump gas. The variables that come into play include piston top configuration (flat, dished, or domed), piston deck height, head gasket thickness, and combustion chamber volume. Two other variables are bore and stroke. Let's assume we're building a typical 4.030-inch-bore, 3.75-inch-stroke 383. We'll run through several classic combinations to generate a pump-gas-friendly compression ratio. We won't get into camshaft selection here, but basically with a longer-duration cam with more overlap, you can afford to pump the compression slightly to offset the loss of cylinder pressure at lower engine speeds.

An important point worth mentioning is to keep the piston-to-head clearance as tight as possible. If you can get that clearance to anywhere near 0.040 inch, that's great, especially because most head gaskets come in around 0.042 inch thick. This tight clearance increases mixture activity in the chamber, which improves power and efficiency. We're not going to go through the clumsy math of computing compression. Instead, we'll refer you to the Performance Trends Web site, where you can download a free compression ratio program that is far quicker than doing the math longhand. To keep things simple, we'll limit the combos in these examples to a 4.030-inch bore and a 3.75-inch stroke.

Combo A: Let's do a typical flat-top piston with four valve reliefs (roughly 6 cc for volume) along with a 0.042-inch-thick head gasket and a 76cc chamber, which is typical for a stock iron production head. For piston deck height, let's use 0.005 inch. As the chart shows, the safest package with a mild hydraulic cam is going to be the 9.54:1 version, while the 10.13:1 version would probably make the best power on pump gas but would be sensitive to things like hot intake air temperatures, since hot air can easily make the engine prone to detonation.

Combo B: Let's look at an 18cc dished piston with many of the same variables as above, such as a 0.005-inch deck height, a 0.042-inch-thick gasket, and a smaller combustion chamber. By including other variables, such as a smaller dish or a larger chamber, you can see how the numbers change.

Combo C: Now let's try something different. Let's keep the piston 0.020 inch below the deck and use a 0.015-inch-thick Fel-Pro embossed steel head gasket with a rubber coating (PN 10094, $19.88, summitracing.com). This gasket can be used on aluminum heads. Our goal here is to reduce the piston-to-head clearance to 0.035 inch. Note how this affects compression. This requires that we minimize piston rock with a long rod and tight piston-to-wall clearance. This option does not require decking the block, and the gasket is also less expensive.

Clearly, there are dozens more combinations that we just don't have space to detail here, such as what happens to compression when changing bore and/or stroke. As an example, adding stroke bumps compression because the piston is moving farther down in the bore, creating more volume to compress. The beauty of the Performance Trends program is that you can play around with different variables very quickly to come up with an optimized combination.

ENGINE PACKAGE COMPRESSION RATIO Combo A: Flat-top piston, 76cc chamber, 0.042 gasket, 0.005 deck 9.54:1 Same as above with 70cc combustion chamber 10.13:1 Same as above with 64cc combustion chamber 10.82:1 Combo B: Dished (18cc) piston, 64cc chamber, 0.042 gasket, 0.005 deck 9.54:1 Dished (12cc) piston, 64cc chamber, 0.042 gasket, 0.005 deck 10.13:1 Dished (12cc) piston, 70cc chamber, 0.042 gasket, 0.005 deck 9.54:1 Combo C: Dished (12cc) piston, 70cc chamber, 0.015 gasket, 0.020 deck 9.78:1 Dished (12cc) piston, 64cc chamber, 0.015 gasket, 0.020 deck 10.41:1 Flat-top (6cc) piston, 70cc chamber, 0.015 gasket, 0.020 deck 10.41:1 Flat-top (6cc) piston, 64cc chamber, 0.015 gasket, 0.020 deck 11.14:1Rod Length

There's much more to stuffing a longer-stroke crank into a small-block Chevy than just making sure the crank will clear the block. In the Origin of the Species sidebar, we outlined how the total height of the rotating assembly should compute to be roughly the same height as the engine's deck height. While a short rod like the stock 400's 5.565-inch piece will work, the angularity is rather harsh. A shorter rod pushes the piston into the thrust surface side of the cylinder wall, causing unnecessary friction and wear. Plus, short rods tend to expose more of the piston skirt out of the bottom of the bore at bottom dead center. This can cause durability and piston noise issues. Most 383 small-block stroker packages prefer the stock 5.70-inch-long 350-style rod, but there are also advantages to going with a 6.0-inch rod. A longer rod further reduces rod angularity during the combustion cycle, which reduces the side load on the piston and cylinder wall. But despite all the theories about long versus short rods, there is no solid evidence to suggest that there is significant power to be gained by using a longer rod.

All is not rosy with a long rod combination, however. Longer rods move the wristpin closer to the ring package. In tight situations, the wristpin overlaps the oil ring, requiring a support rail. This reduced compression height also creates less piston stability at higher engine speeds because of a shorter piston skirt length. The following chart outlines the three popular rod lengths and piston compression heights based on a 3.750-inch stroke. All these rod-length and compression-height combos will produce an overall assembled height of 9.008 inches, which allows roughly 0.017-inch piston-to-deck clearance with a stock deck height of 9.025 inches.

In this example, the 6.00-inch rod requires a compression height of 1.133 inches (SRP's 6.00-inch rod pistons use 1.125 inches). The height is close to the bare minimum of 1.000 that most piston manufacturers recommend, which is why the 5.700-inch rod is so popular. Longer rods are also heavier and can affect the overall bob weight of the rotating assembly. When mixing and matching parts, you'll want to avoid spending extra money to balance the system. This means that if you buy the crank individually, make sure the overall bob weight of the rods and pistons match the crank's designed bob weight. If you screw up here, it will cost big bucks to balance the crank.

We've listed several rods from several manufacturers that would work for a 383. This is only a partial list of the rods available from all the manufacturers. As an example, Scat alone offers five grades of connecting rods. Some are designed as stroker rods, while others are stock replacement rods that will need help to clear the camshaft. There's also the question of I- versus H-beam rods. All prices in the following chart are for a package of eight rods.

ROD LENGTH PISTONI Beam Vs. H beam

When you are selecting a rod for your next stroker, piston speed is the issue. With a 3.75-inch stroke the piston is traveling 7.5 inches from the top to the bottom of the bore. At 6,000 rpm, the piston is traveling 45,000 inches or 3,750 feet per minute.

When the piston is at bottom dead center (BDC), the rod is experiencing compression, and when the piston is at TDC, it is experiencing tension. The most violent force for the rod to endure is from the tension created at TDC during overlap where the piston is not cushioned by compressed air. A piston assembly (piston, rings, pin, and pin clip) that weighs 600 grams, for example, will weigh 11,250 pounds at 6,000 rpm during overlap. The rod must hold on to the piston as it reverses direction without stretching, snapping, or distorting causing bearing failure. Heavier pistons make it worse.

Using Scat as an example, the company's Street I-beam rod will withstand a 6,000-rpm pounding with a piston assembly in the 600-gram range. The Pro Comp I-beam will survive a 600-gram piston at 7,500 rpm or a heavier piston at a lower speed. The next step up would be the H-beam that can take whatever you can afford to throw at it. Chances are though, if you are building an engine that requires an H-beam rod, the pistons will be lighter, allowing more rpm and more rod longevity.

DESCRIPTION PN SOURCE PRICE Scat 5.7 stock I-beam, 3/8 35700P {{{Summit}}} Racing $189.95 Scat 6.0 stock I-beam, 3/8 36000P Summit Racing 189.95 Scat 5.7 H-beam, 7/16 6570020 Summit Racing 429.95 Scat 6.0 H-beam, 7/16 6600020 Summit Racing 429.95 {{{Eagle}}} 5.7 I-beam, 3/8 SIR5700BPLW Summit Racing 235.95 Eagle 6.0 I-beam, 3/8 SIR6000BPLW Summit Racing 235.95 Eagle 5.7 H-beam, 7/16 CRS5700B3D Summit Racing 429.95 Eagle 6.0 H-beam, 7/16 CRS6000B3D Summit Racing 429.95 Crower 5.7 Sportsman, 3/8 SP91200B-8 Summit Racing 571.99 Crower 6.0 Sportsman, 3/8 SP91202B-8 Summit Racing 571.99 This happens to be a Lunati rotator package that we have beating on now for more than a year. While the 4340 steel cranks and rod systems are more expensive, the parts are extremely durable and can withstand days of high-rpm thrashings without complaint. The idea is to build the engine once and then enjoy it for years.

This happens to be a Lunati rotator package that we have beating on now for more than a year. While the 4340 steel cranks and rod systems are more expensive, the parts are extremely durable and can withstand days of high-rpm thrashings without complaint. The idea is to build the engine once and then enjoy it for years.

Rotator Packages

For those car crafters who prefer to build their own engine, the quickest path to making power is with a complete rotator package. The most common rotator packages include the crank, rods, pistons, and the rings and bearings. Often, you can also purchase these systems balanced and ready to install. The most important reason to buy a rotator system is because the manufacturer combines the right parts that can be easily balanced. The danger of piecing together a crank, rod, and piston combination is that you must pay strict attention to bob weights. If you end up with a heavy piston, balancing can become extremely expensive since Mallory (heavy) metal has skyrocketed in price lately. The smart move is to carefully lay out your plans for that 383 engine and do your homework before buying anything. Check the prices and go with a system that is designed to work together, and you will avoid many of the classic engine builder blunders.

The great thing about the small-block Chevy is that the volume of parts being produced is so great that manufacturers can offer excellent deals on brand-new parts that make it silly to dig up used parts to build a 383. For the budget-conscious builder, the hot ticket is to go with a cast nodular iron crank, stock-style 5.7 rods, and cast or hypereutectic pistons. Scat offers its Series 9000 rotating assembly, which uses a cast crank, cast pistons, and I-beam rods for less than $500. That's an amazing price for new parts. The Scat rods are replacement-style I-beams made from 4340 steel and fitted with ARP bolts. It's only slightly less expensive to rebuild stock rods compared with what these babies cost, and the stock rods are not nearly as strong. There are several other companies, such as Competition Products, that offer similar kits-so do a little shopping to see what's out there.

For those who are looking to work their 383 a little harder, you might want to step up the quality a little. Eagle offers a cast crank kit for a two-piece rear main seal 383 that is externally balanced and uses Eagle I-beam 5140 steel rods, hypereutectic pistons, rings, and bearings. This kit also comes with a Pioneer balancer and flexplate. If engine speed above 6,200 rpm is what you dream about at night, then stepping up to a 4340 steel crank and good forged pistons is the only way to go. Crower has created the Enduro kit that lists an American-made 4340 steel crankshaft with Sportsman 4340 steel I-beam rods, along with your choice of forged piston. The kit rounds out with rings and bearings, and while the price is steeper, you're getting a package that could live a long time spinning to a 6,800-rpm shift point

The advantage of working with an extremely popular engine package is that you have lots of choices. We've already made our decision. Now all we have to do is save our lunch money for the next two years and that Crower package is all ours!

DESCRIPTION PN SOURCE PRICE Scat 9000 Series rotator 1-92000-1 {{{Summit}}} Racing $489.95 Eagle rotator kit B13405E030 Summit Racing 749.95 Crower Enduro series kit 95502 Summit Racing 2,557.39Mild To Wild Engine Combos

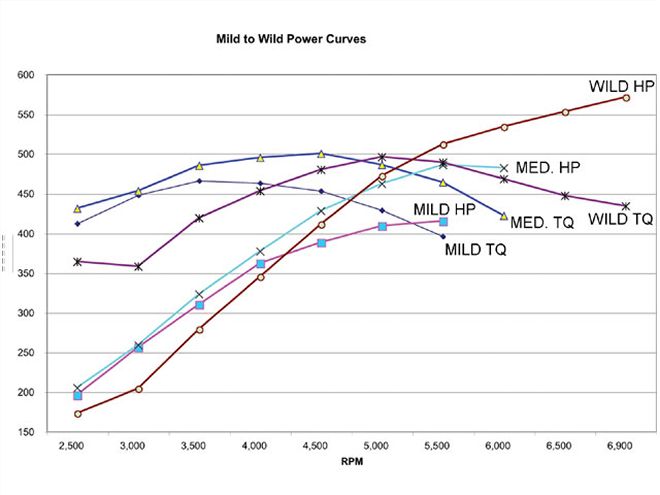

The following is a quick overview of three different engine combinations, all displacing 383 ci with a 5.7-inch-long rod and 23-degree small-block heads. But that's where the similarities end. If you take a look at the three power curves, you'll notice that as the camshaft duration becomes longer, the torque peak moves higher in the rpm scale. The mild engine's peak torque occurs at 3,500 rpm, while the middle engine bumps that up to 5,500 rpm. The wild engine actually lowers the peak torque a little with its better cylinder heads, but you can see how the cam duration slides both the peak torque and peak horsepower up the rpm scale. Also note how the 571hp engine is down 50 lb-ft at 2,500 compared with the mild engine.

Mild-412HP 383

This is a simple and relatively inexpensive combination of a one-piece roller cam block with a stroker crank, 9:1 compression with dished pistons, a tame GM Performance Parts hot hydraulic roller cam, 1.6:1 roller rockers, factory roller lifters, a set of modified Vortec iron heads, an Edelbrock Performer RPM Air-Gap intake, a 750-cfm mechanical-secondary carburetor, and a set of 13/4-inch headers. The only upgrade necessary is some machine work and better valvesprings for the Vortec heads to accommodate the additional valve lift. This combo makes excellent torque with 466 lb-ft at 3,500 and 415 at 5,500 rpm. Even with a stock converter, this is a tire shredder.

Medium-480HP 383

This combination steps up the compression, the heads, and the cam over the mild combo and is rewarded with 70 more horsepower and is still peaking below 6,000 rpm. Overall torque is greater across the board because of the better-flowing TFS 215cc aluminum cylinder heads outfitted with 2.08/1.60-inch stainless valves. This is great overall power because the motor makes more than 450 lb-ft from 3,000 to 5,500. In a 3,400-pound Camaro with an automatic and a 3,000-stall-speed converter, this could run very low 12s, assuming sufficient traction to stick all that torque to the pavement.

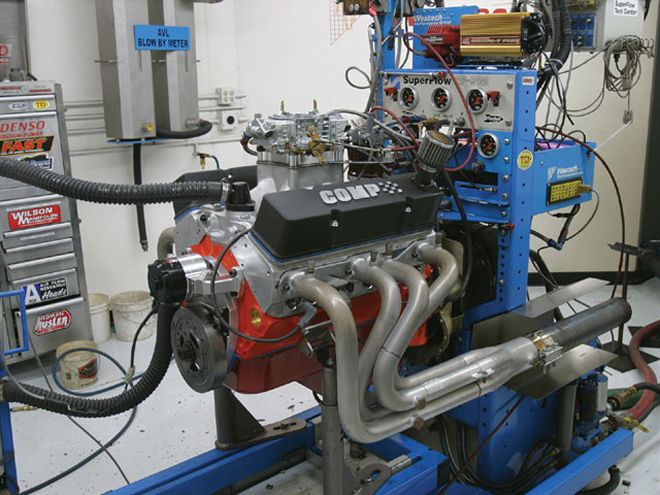

Here is the 570hp engine on the dyno at Westech. Note that the dyno test used a set of Westech's 13/4-inch dyno headers fitted with a set of 18-inch-long, 3-inch-diameter collector extensions. The power numbers would be lower with real 13/4-inch chassis headers and a full exhaust system.

Here is the 570hp engine on the dyno at Westech. Note that the dyno test used a set of Westech's 13/4-inch dyno headers fitted with a set of 18-inch-long, 3-inch-diameter collector extensions. The power numbers would be lower with real 13/4-inch chassis headers and a full exhaust system.

Wild-570HP 383

Here's where the fun really begins. This engine started life as a pedestrian one-piece rear main seal motor that now has a complete Lunati 4340 steel crank rotating package complete with I-beam Lunati Pro Mod rods and forged flat-top Wiseco pistons. We dropped on a set of Dart CNC 227cc heads that helped produce a 10.9:1 compression ratio. Then we added in an aggressive Comp Cams XR-292 mechanical roller cam with (count 'em!) 36 more degrees of duration at 0.050 than the mild combination. Topping off this thumper is a Holley-Dorton single-plane intake and a Holley 750 Street HP carb. Routing the exhaust was the responsibility of a set of Hooker 13/4-inch headers. The final piece was a Wilson 1-inch tapered spacer that on this particular combination was worth a solid 23 hp from 548 to 571 hp. Peak torque occurred at 5,100 rpm. This is a beast in small-block clothing, but with a distinctive idle lope, there's little chance of disguising this small-block as anything less than a contender. If horsepower makes your toes tingle, this is the combo for you. We've actually discussed pushing this beast a little harder to see if we could hit 600 hp. If you like that idea, compose a sell job and convince us this needs to be done. We love it when you talk horsepower.

MILD MEDIUM WILD RPM TQ HP TQ HP TQ HP 2,500 412 196 431 205 364 173 3,000 448 256 453 259 358 204 3,500 466 310 485 {{{323}}} 419 279 4,000 463 362 495 377 453 345 4,500 453 388 500 428 480 411 5,000 429 409 486 462 496 472 5,500 396 415 464 486 489 512 6,000 - - 422 482 468 534 6,500 - - - - 447 553 6,{{{900}}} - - - - 434 571

Cam Specs DURATION

MILD MEDIUM WILD RPM TQ HP TQ HP TQ HP 2,500 412 196 431 205 364 173 3,000 448 256 453 259 358 204 3,500 466 310 485 {{{323}}} 419 279 4,000 463 362 495 377 453 345 4,500 453 388 500 428 480 411 5,000 429 409 486 462 496 472 5,500 396 415 464 486 489 512 6,000 - - 422 482 468 534 6,500 - - - - 447 553 6,{{{900}}} - - - - 434 571

Cam Specs DURATION