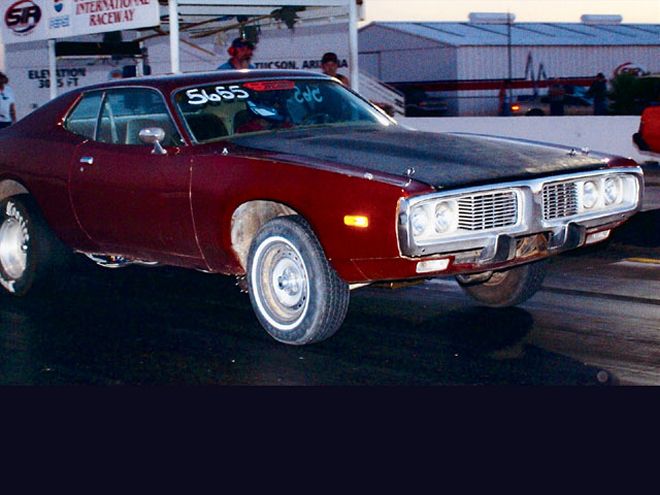

Our first attempt to compare the performance of 91-octane, pump premium gasoline to E-85 was at Southwest International Raceway in Tucson, Arizona. The Charger weighed in at a hefty 4,256 pounds, but ran 11.60s at 118 mph with a 5,250-foot density altitude. We were impressed with the power, but it was consistent results we were after, and three problems emerged. The Charger is a street car with no line-lock for consistent tire heating; it has a production shifter that occasionally goes from first to third, not first to second to third; and we were running entirely too close to the NHRA limit of 11.50 seconds without a rollbar. We were at risk of being barred from the track if we happened to make a really good run. So it was off to the dyno.

Our first attempt to compare the performance of 91-octane, pump premium gasoline to E-85 was at Southwest International Raceway in Tucson, Arizona. The Charger weighed in at a hefty 4,256 pounds, but ran 11.60s at 118 mph with a 5,250-foot density altitude. We were impressed with the power, but it was consistent results we were after, and three problems emerged. The Charger is a street car with no line-lock for consistent tire heating; it has a production shifter that occasionally goes from first to third, not first to second to third; and we were running entirely too close to the NHRA limit of 11.50 seconds without a rollbar. We were at risk of being barred from the track if we happened to make a really good run. So it was off to the dyno.

We believe the current world situation will force the U.S. to fully develop our own energy supply in the not-too-distant future, and that E-85 will play a huge part in that transformation. So until hydrogen, or whatever it is that comes along to answer everyone's dreams, let's further look at E-85's possible benefits for the high-performance enthusiast.

We're sure everyone already knows what E-85 is, or at least has heard of E-85, and what it's made from, but just in case, we will begin with a short quiz. Is E-85:

A: 85-percent moonshine liquor poisoned with 15-percent gasoline so we won't drink it?

B: A lower-cost race and high-performance street fuel?

C: An alternative new car, SUV, and pickup truck pump premium? (flex fuel)

D: A small first step for the United States towards independence from foreign oil?

E: All of the above?

There are no wrong answers to this quiz, but (E) is the most correct.

The United States is taking a small first step towards independence from foreign oil. E-85 is 85-percent plant-based ethanol and 15-percent unleaded gasoline. It appears that E-85 will be readily available and relatively inexpensive across the entire U.S. within the next couple of years. In southeastern Arizona, E-85 is 30 cents a gallon less than 87-octane regular, and about one-third the cost of 100-octane race fuel. True, we will use about 25- to 30-percent more E-85 than gasoline per application, but do the math and it still comes out to be a great value for a 105-octane fuel. That's right, E-85 carries a 105-octane rating.

On a comparative cost basis, E-85 sounds favorable, so let's look into it a little further. A downside to E-85 is that you need about 20- to 30-percent more fuel running through your carburetor for the vehicle to run properly. If you just try and run E-85 in a vehicle and not compensate with larger jets and whatnot, the vehicle will run lean. Another problem that may arise if you are running old fuel lines is alcohol fuels are more corrosive on some rubbers, plastics, and even some metal parts. We have also heard rumors that the uncombusted ethanol (especially during rich, cold-start conditions) may migrate past the piston rings, resulting in cylinder-wall washing, which reduces cylinder-wall lubrication and could run down into the crankcase, diluting the engine oil. While such occurrences are unsubstantiated and unlikely, there are some special engine oils that add an additional degree of protection until more field experience can be accumulated. If you are, or plan to, run E-85, you may want to look into an engine oil designed to handle such issues. After a quick search, we found an oil called Lubrilon. It's a specialty automotive oil that was specifically formulated for use with all ethanol-blended fuels. Lubrilon multi-viscosity motor oils are SAE and API licensed for use in all gasoline engines, and are engineered to help combat the acids formed when burning any modern ethanol fuel blend, including gasoline and E-85.

On the good side, as we said earlier, E-85 is rated at 105-octane. This is definitely a benefit, but E-85 also burns cooler than traditional gasoline. While that is great for your engine, it also means it may not burn completely if your ignition isn't set up for it, which means you aren't getting all the energy available and are just wasting fuel. So your ignition, including your spark plugs, better be up to the task. If you are planning to run E-85, your engine will benefit remarkably by changing to a colder range spark plug. The reason is that E-85 is prone to cause pre-ignition. If you are converting to an E-85 fuel, we recommend dropping your heat range at least two numbers cooler than your stock setting.

From a performance standpoint, the next obvious questions are: will E-85 cut the mustard in terms of performance, and how difficult is the changeover? The answers are: yes, it is a great high-performance fuel, and the changeover is pretty straightforward. So if you are struggling with today's pump premium in your street car, or interested in a lower cost race fuel, or even contemplating adding forced induction to your higher compression ride, read on.

We wanted to know what happens if we take a car that we are driving today-one that is working just fine on readily available 91-octane-and change it over to run on E-85.

To find the answer, we took The Supercharger Store's test mule-a '73 Dodge Charger with an F-1 Procharger mounted on a 440-and added a complete second fuel system. This allowed us to make rapid changeovers and do back-to-back testing with two different fuels. This particular Charger also has some useful instrumentation onboard, which will be handy when we try to sort out what is going on as we change between the two fuels. We will measure intake temperatures above and below the carburetor, exhaust temperatures, and where differences occur.

We enlisted the help of Eddie and Ron at Performance Carburetors in Ontario, California, and Robbie at Magna Fuel in Colorado Springs, Colorado, to put together proper blow-through carbureted fuel systems for our tests. We were concerned about obtaining consistent results, and consistency at the strip is a tough game, so we also enlisted the services of Tim at Xact Dyno in Tempe, Arizona. Xact Dyno utilizes a Dynapack hydraulic chassis dyno. The Dynapack is unique in that it uses hydraulic load units that bolt directly to the axles. Obviously, there is no tire slip here. Also with the Dynapack, you can conduct steady-state pulls and a number of other tests that are not practical with roller chassis dynos.

Test day arrived, and it was a typical September afternoon in the Phoenix area: sunny and about 98 degrees Fahrenheit. While Tim bolted the Charger to the Dynapack, we checked to make sure the E-85 fuel system was ready to go. We made two quick pulls with E-85, and recorded rear wheel torque, rear wheel horsepower, lambda values (rich/lean), supercharger boost in the intake manifold, maximum air temperature above the carburetor, and maximum temperature of the fuel/air mix in the intake plenum. The two E-85 pulls felt strong, and we had a lot of data to study later, so we set about changing the fuel system over to 91-octane pump premium fuel. We made two quick pulls with pump premium, and again, they felt good. despite the fact we lost the lambda readings on one pull, we had the data we desired.

We were convinced the Charger would be running lean in Phoenix because the carburetors were jetted for 4,600 feet above sea level, and Xact Dyno is in Tempe, which is around 1,300 feet above sea level. We didn't take time to study the data we had just gathered, but immediately changed to larger jets, thereby making what turned out to be an already rich mixture even richer. We did this for both the E-85 carburetor and the 91-octane pump gas carburetor. Subsequent pulls for both fuels were not as good as the earlier pulls and, for all practical purposes, a waste of time.

By now we were out of dyno time, so we removed the Charger from the dyno and headed for home. We were later told by Eddie and Ron at Performance Carburetor that properly calibrated blow-through carburetors are not sensitive to altitude changes.

Our E-85 fuel conservatively made 25 more horsepower than the 91-octane fuel, across the entire power spectrum. We didn't change anything except the fuel, so why did this occur? One very noticeable difference was the maximum temperature in the intake plenum ran 55 to 68 degrees cooler with E-85 than with the 91-octane. We were vaporizing 25- to 30-percent more fuel, with nearly twice the latent heat of vaporization of gasoline, and it cooled the charge. Cooler intake plenum temperatures mean more power. The difference will naturally be less on naturally aspirated engines, but it should still be there. The air temperature above the carburetor and the exhaust temperature was nearly identical with both fuels, so nothing to talk about there.

Could we gain even more with E-85? We think so. Cooler intake plenum temperatures in combination with E-85's 105-octane should allow more compression, more boost, or even more timing than 91-octane without encountering detonation, and this should yield more power.is E-85 a viable option for you? That's a hard question to answer. First, is E-85 readily available in your area yet? Are you willing to change your engine's current tune to efficiently run E-85? There are a lot of factors that have not been explored yet and will come to light with long-term usage, but for now, E-85 does sound like it will be a viable choice in alternative fuel sources that our musclecars will be able to live with.

For the comparative 91-octane pump gas versus E-85 dyno pulls shown in the subject article, the 4150 HP Holley carburetors were jetted as follows:

Editor's note: There are a couple of concerns about E-85 fuel that we felt our readers should also be aware of. One concern involves the fact that E-85 is generally blended with 15-percent unleaded gasoline at the pump, and this could invariably affect the consistency of the fuel from station to station. This variation may not affect you if you're not eeking out every last bit of horsepower available, but if super-tuning, the difference could mean that some timing changes may need to be made as blending differences could be affected by the content properties of the unleaded fuel being used in the mixture. The second concern with E-85 is the price. While this fuel seems less expensive than gasoline, it actually costs more to produce. The low price of E-85 is partially due to the federal government subsidizing the fuel at a rate of some 51 cents per gallon. Once E-85 is generally accepted and used, we wouldn't be surprised if this subsidy goes away, and E-85 may soon be taxed as a motor fuel, making it somewhat more expensive than gasoline

Test Vehicle Particulars

Procharged '73 Dodge Charger with blow-through carburetion and water injection