For the past several months HOT ROD and Duttweiler Performance have been evaluating the performance potential of the widely available 6.0L LS-series truck engine. Beginning with a stock 355hp/396 lb-ft baseline output on a GM Performance Parts (GMPP) LQ9 crate truck motor, it first received basic intake and exhaust enhancements ("Hopping GM's 6.0L LS-Series Small-Block," Oct. '07) before being treated to GM's new L92 performance cylinder heads and a progressively more aggressive series of Crane Cams ("6.0L Hop-Up, Part II," Nov. '07). We left off last month with the engine still normally aspirated, making 510 hp and 462 lb-ft with electronic fuel injection (EFI) on the GM Holden Australian L76 car EFI manifold, and 539 hp and 452 lb-ft with a 750-cfm carburetor on GM's single-plane carburetor-style intake.

Bear witness to the awesome potential of an LS-series 6.0L truck engine. Equipped with a Crane hydraulic roller cam, GMPP L92 heads, Magnuson Products' new high-helix 1900-series supercharger, and alcohol injection, the engine-still running the stock short-block-pounded out 751 hp and 621 lb-ft on 91-octane Chevron pump gas.

But we weren't done yet. Not by a long shot. The previous tests hinted at yet untapped potential, even with the existing normally aspirated combination. So far the best numbers had been achieved with computer-friendly cams utilizing fairly wide lobe separation angles. A narrower LSA cam had the potential to perform better with a carburetor. Also, the EFI and carburetor tests were run using two completely different intake manifolds-a long- runner, production factory- type intake with EFI, and a classic short-runner/single-plane configuration with the carburetor. That was like comparing apples and oranges. We wondered how EFI would stack up in a head-to-head showdown with the carburetor on the same intake manifold. Then, too, the 750-cfm carb was pulling vacuum on the top end, indicating that a bigger carb might perform better on the dyno. So we decided to tie up these loose ends before finally bringing out the big guns: Magnuson Products' new high-efficiency supercharger, backed by alcohol injection. Get ready for some serious power output, well over 700 hp.

750 VS. 950 Carb

Duttweiler wanted to try a bigger carburetor, as last month's 750-cfm Bill Mitchell unit had been pulling vacuum of about 131/44 inches of mercury (in-Hg) on the top end. He bolted on a Holley Ultra 4150 HP 950-cfm carb, Holley's trickest 4150-flanged offering. But in this instance, although the big carb pulled just 11/44-in-Hg vacuum at 7,000, it performed only marginally better, adding just 0.8 hp and 4.5 lb-ft of torque at the peaks.

In terms of overall average numbers, the 950 was worth 1.9 lb-ft and 1.3 hp compared to the 750. Still, the 950's peak 541.5 hp and 461.5 lb-ft represent the high-water mark for our normally aspirated tests. If there was more development time available, we could have played with the Ultra's adjustable bleeds, but realistically at this performance level the pricey carb is probably overkill.

Wide Vs. Narrow LSA

On cams with otherwise identical lift and duration specifications, theory holds that increasing the overlap between the intake and exhaust lobes by narrowing the lobe separation angle (LSA) can help pull more fuel through a carburetor installed on a single-plane, short-runner intake. This should at least help pick up the low and midrange, although not necessarily the top end. To evaluate this, Crane took last month's best power profile but reground the lobes with a 110-degree LSA in place of the previous 115-degree spec.

Running with the same 750-cfm double-pumper carb, Wilson 1.5-inch-tall tapered spacer, GMPP single-plane intake, and MSD timing/rev-control unit used on last month's best power combo, the new cam improved the overall curve significantly, with the engine up 5-10 numbers below 6,600 rpm. On average, the tight-LSA cam was worth 7.3 lb-ft and 9.3 hp. The engine's new peak 540.7hp and 457.0-lb-ft output represented a gain of 1.9 and 4.8 numbers, respectively. The power peak was also raised 200 rpm (from 6,700 to 6,900-7,000 rpm). Duttweiler did not want to spin the engine past 7,000 with the stock factory rods and rod bolts.

Carb VS. EFI

Prevailing wisdom holds that although EFI may not make as much peak power as a well-tuned carburetor, with EFI the overall area under the curve should be broader, the torque curve smoother, and the low and midrange better. Muddying the waters on most street-oriented tests is the usual long-runner design of the EFI intake, while the best carburetor configurations are typically high-rise, short-runner, open-plenum types.

GM's carbureted single-plane intake (PN 25534401) is cast with residual bosses that can be drilled and tapped for EFI nozzles and fuel rails. Duttweiler sent the intake to the experts at Hogan's Racing Manifolds for the conversion. Hogan's forte is custom sheetmetal intakes, but it also can do a simple job like adding EFI capability to existing castings.

Duttweiler sent the GM carb intake tested last month out to Hogan's Racing Manifolds to receive EFI bosses and fuel rails. That let us conduct a direct head-to-head comparison using 30-lb/hr fuel injectors, an ACCEL/DFI 1,000-cfm throttle body, and the same GM factory computer recalibrated with the HP Tuners VCM software suite used in our previous EFI Part I and II tests.

Compared to the best previous fuel-injection test (using the GM Holden L76 car-type EFI intake, a 90mm FAST throttle body, and the 115 LSA camshaft), fuel injection on the short-runner intake lost about 20 lb-ft of peak torque, and the peak occurred 300 rpm higher (462 lb-ft at 5,300 rpm for the Holden compared to 442 lb-ft at 5,600 for the single-plane). On the other hand, EFI's power output was higher on the single-plane (516 hp at 7,000 rpm compared to 510 hp at 5,200 for the Holden). In terms of overall average output, torque was about even (406 lb-ft for the single-plane, 404 lb-ft for the Holden), but the single-plane made much more average power (352 hp compared to 330 hp). Nevertheless, in the so-called midrange area-between 3,200 and 5,300 rpm-the GM Holden intake and wide-LSA cam beat the single-plane EFI and narrow-LSA combo in both power and torque.

On comparing the EFI single-plane setup to the carburetor on the same intake, the results were downright disappointing. The 950-cfm carb proved superior to EFI at every point in the rpm scale in both torque and power output. At the peaks, EFI managed only 516.1 hp and 541.5 lb-ft, a loss of 25.4 hp and 19.1 lb-ft compared to the numbers developed by the 950-cfm carb. EFI was also down big overall across the board.

To be fair, we only had several hours available to play with the EFI system. Days of development time may be warranted-going way beyond fuel- and spark-calibration issues and actually addressing the system's physical layout. For example, as is typical on most conversions of existing (as opposed to custom-built) carbureted intakes, the injectors were placed close to the runner exits for ease of installation and fuel-rail interface. The new L92 heads and single-plane intake may prefer a more upstream nozzle placement. Given enough time, one could experiment with moving the nozzles progressively upstream closer to the plenum and/or changing their intersection angle relative to the axis of the runners. With the single-plane's short runners, the injector spray initiation timing may require alteration to achieve optimum fuel sequencing in comparison to the long-runner factory intakes. This option is not available with the stock factory computer and would require a sophisticated aftermarket ECU like those offered by MoTeC.

Blower Vs. Blower

Normally aspirated, our 6.0L engine was up to 540 hp using a carburetor. That's impressive on the stock short-block, but at this point the car's street manners were starting to go away. But the combination of EFI and a state-of-the-art supercharger designed to work with modern electronics provides the ability to go fast without sacrificing driveability. So it was time for a radical departure: Shove in a milder cam, namely Crane's 144HR00118 with 216/224 degrees at 0.050 on 118-degree lobe separation, as evaluated last month. Those specs may not seem very impressive, but our strategy now was to bolt on a high-efficiency Magnuson supercharger, an eminently suitable application for this camshaft.

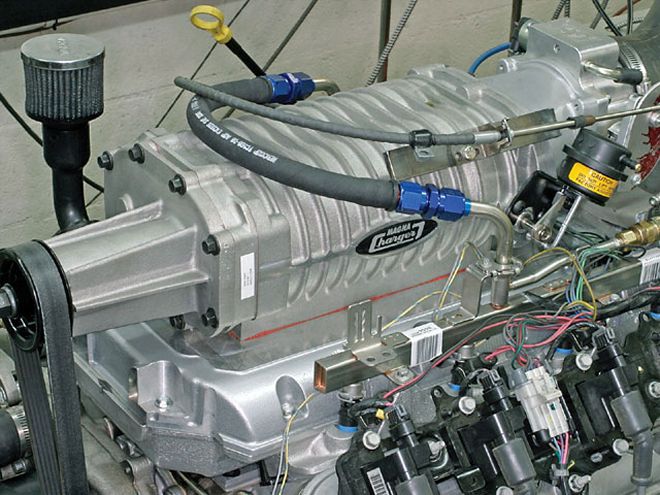

Here's the model 122 bolted to Magnuson's L92 head-compatible intake. Magnuson blowers are based on the modern Eaton superchargers found on many OEM applications. Magnuson's kits include the blower, an intercooler, a voltage enhancer for the stock fuel pump (which speeds it up for additional output under boost), and higher-capacity injectors.

Based on current Eaton OEM technology, Magnuson superchargers are designed primarily for late-model engines. They make gobs of power, many kits are 50-state smog-legal, and they're happy on premium pump gas. The basic Magnuson blower is based on a 112ci-displacement Eaton supercharger, but we moved right up to the larger 122 (we certainly had the cylinder-head flow to support it). At the time of these tests Magnuson had just come out with an L92 head-compatible intake manifold, and we received one of the first prototypes. Once again, Duttweiler ran the blower off the stock GM computer (recalibrated as necessary via HP Tuners VCM software suite), using the same 90mm FAST production-style throttle body as in our normally aspirated Part I and II EFI tests.

With the standard 3.1-inch-od top drive pulley, the Magnuson 122 was worth 130 hp and 95 lb-ft over the best previous normally aspirated combination (the Holley 950-cfm Ultra HP carb on the GM single-plane intake), making just shy of 10 pounds of boost, still on Chevron 91-octane unleaded gas. Detonation was kept under control with judicious computer recalibration, so Duttweiler decided to up the ante with a smaller 2.9-inch-od upper drive pulley. Spinning ever faster to make 11.5 pounds of boost, power jumped to 683.3 hp at 6,600 rpm, with a whopping 581.7 lb-ft of torque from 5,200 to 5,300 rpm. The engine made over 500 hp from 4,600 rpm on up and over 600 hp at over 5,500 rpm. Torque numbers exceeded 500 lb-ft from 2,300 rpm on up. At this point some incipient detonation was noted, indicating the 122 was just about done on pump gas at around 12 psi of boost.

As good as the 122 is, Magnuson has come up with something even better: its next-generation TVS four-lobe supercharger. We were able to get our hands on one of the first of these 1900-series blowers. Although it's slightly smaller than the 122, the paper specs make the 1900 out to be much more efficient. However, because it is smaller, the blower needs to spin faster to make the same boost. On the 1900,,it required a 2.7-inch pulley (the smallest available) to make about the same 10 psi of boost as a 3.1-inch pulley did on the 122.

On a mechanically driven blower, when you run out of smaller top-pulley options the usual solution is a larger crank pulley. This isn't easy on an LS-series engine, as the serpentine belt pulley is cast integrally with the harmonic damper. Normally Magnuson gets around this with an intermediate driveshaft setup, but one wasn't yet available for the new TVS series. Duttweiler feels this blower should be stable on pump gas at up to 14 psi once the driveshaft option comes online.

But even with the 2.7-inch pulley running at 10 psi, the 1900 generally outperformed the 122 with its 2.9-inch pulley at 11.5 psi. The 1900 gained 11 more horsepower and 23 lb-ft at the peaks, as well as generating better numbers under most of the curve. Only between 5,200 and 6,300 rpm was the 122/11.5-psi combo slightly better. Now making 694.2 hp with the 1900 blower, our 6.0 was up over 200 hp compared to the normally aspirated EFI combo running the same Crane cam (see "6.0L Hop-Up, Part II," Nov. '07). It still idles at 18 inches of vacuum and should fit under the hood on most late-models.

Alcohol Injection

After all this flogging, the stock short-block was still together, so we crossed our fingers and decided to try one more bolt-on: an aftermarket alcohol-injection system. Today's alky kits work with modern electronics, allowing you to run nearly race-gas ignition-timing numbers on pump premium gas. You can inject methanol, ethanol, or even windshield-washer fluid through these units for a significant power boost. (In fact, some kits use the stock windshield-washer fluid reservoir.) Alcohol-particularly methanol-has higher knock resistance than gasoline, plus it provides some additional charge-air cooling when injected ahead of the blower in the inlet duct. Supplementary alcohol injection may also alleviate the need for upgrading a production-based fuel system to huge injectors, a bigger fuel pump, and increased-diameter fuel lines when moving up to high boost levels. That in turn minimizes ECU-recalibration issues and avoids low-speed idle quality and driveability woes.

Duttweiler has tried a bunch of alky-injection kits and says that when dialed in they all add about the same power. Use the one that best suits your needs. Here are three representative kits, from left: Snow Performance's Boost Cooler includes a pump, reservoir, and control components; it's a good choice for medium- to low-boost setups. Alkycontrol uses the stock windshield-washer-fluid reservoir and has a sophisticated control that tailors injection volume to boost pressure by varying the amount of voltage delivered to its supplementary pump. Alcohol Injection Systems' strap-on kit easily mounts in the trunk or other convenient location.

Bolting on the alcohol-injection system and filling the reservoir with methanol, Duttweiler dialed in 24 degrees of total advance, the same amount run with EFI in the normally aspirated configuration. Methanol requires a different air/fuel ratio from gasoline, so to maximize the gains Duttweiler also leaned out the ECU's power-enrichment tables by approximately 17 percent.

With the timing and fuel curves optimized, the engine was drunk with power, thundering to 751.4 hp at 6,700 rpm and 621.1 lb-ft at 4,700. Average output between 2,500 and 6,700 rpm was in excess of 522 hp and 585 lb-ft! It made over 600 hp from 5,100 rpm on up and over 600 lb-ft from 4,000 to 6,500 rpm.

And that's a heck of a long pull from what the stock LQ9 crate motor started out with back in Part I. We're looking at 400hp and 225-lb-ft gains on a stock short-block that still retains daily driveability. That shows the awesome potential of the LS-series engine, but there's no doubt we were pushing it with the stock powdered-metal rods and cast pistons. For repeated abuse under real-world, in-car conditions, we'd strongly recommend a forged bottom end. Once you bulletproof that bottom end and obtain either a custom damper with a bigger lower drive pulley or an intermediate driveshaft for the TVS, you are looking at a potential 800 streetable horsepower.

Test Description

Letters below correspond to the test designators in the adjacent tables and graphs. Test designation sequence continues from the Part II tests (Nov. '07).