Food For Fuel

Ron Hanisco, Kingston, NH: This is in response to Jeff K.'s little blurb in the Readers' Pages. "Loved the E85 article in the Feb. '07 issue. One hundred and six octane, and a chance to stick it to OPEC; what's not to love! Keep it up. I may subscribe."

Dude, wake up. As soon as E85 investors and manufacturers realize the potential of the fuel, the price will go through the roof, while draining America of its corn supply. Is it worth it to you to pay four or five times the price for every food item containing corn just to spend thousands more on performance parts to make your hot rod E85-compatible for the 106 octane? Don't be stupid. You'll be spending just as much for E85 as petroleum and much, much more for food products containing corn, let alone meat products from animals that consume corn (beef and chicken)! Look past the hot rod and look at the big picture.

Sure, it looks good now on paper, but mark my words, in 10 years you'll be cursing the day E85 was ever invented. Watch what happens to the price as soon as the general public starts consuming the bulk of the fuel and corn supply.

PS: I use a ton of petroleum products to run my race vehicle, but I feel that E85 is just a bad idea for America. We don't have the corn surplus to provide a nation with this fuel and feed us at the same time. I also like to eat-cheaply, if possible.

Jeff Smith: While this isn't really a tech question, I felt that this is a big enough concern, with very little accurate data used to support it, that it would be good to dispel some myths. Foremost among Mr. Hanisco's misgivings is the concept of E85 fuel use as an either/or situation. In other words, people who are opposed to E85 immediately assume that this ethanol-based fuel will totally replace gasoline. Nothing could be further from the truth. The reality is that 2006-based data from U.S. corn production shows that only 18.5 percent of all corn grown in this country is used to produce ethanol, while 50.3 percent is used to feed cattle and other animals. What you may not know is that once ethanol has been distilled from corn, the mash that is left over retains most if not all of its nutrient value. Feedlots then use this mash, called distiller's grain, to feed their animals. This has been going on for years, long before E85 became popular. So when you hear the beef retailers complain that they are forced to raise prices because of the demand for corn to make E85, a small kernel of that statement may be valid, but it doesn't ring largely true. What you may want to consider is the contention that these companies are using increased corn demand for E85 as an excuse to raise prices.

I found a research paper titled "The Impact of Ethanol Production on Food, Feed, and Fuel" written as part of the Ethanol Across America education campaign produced in cooperation with the U.S. Department of Agriculture. One of the most interesting points in this presentation was a cornflakes example. A 14-ounce box of cornflakes costs between $2.97 and $3.50. When corn was $2.00 per bushel, the box contained 2.2 cents worth of corn. When corn prices recently doubled to $4.00 per bushel, the price content of the cornflakes increased to 4.4 cents per box. Yes, that's a 100 percent increase in the cost of the foodstuff, but the price of the corn represents only 1.4 percent of the total cost of the product. A better question might be why the product costs $2.95 when the food you're buying only represents 1.4 percent of the total cost. Either it costs an enormous amount of money to make cornflakes, or there is a mountain of profit built into every box of cornflakes. But that's more of an economics-class discussion we'll leave for another time.

Now that is just one example. Could you come up with some product that probably has seen a radical increase in price based on the demand for corn? We'd be foolish to deny that you could. But it would also be overdramatizing the point (which could also be termed propaganda). What we as car crafters should be concerned with is the notion that there is a fuel out there that offers the equivalent of race-gas octane for the price of pump fuel. It requires some significant changes to the car's fuel-delivery system, and most carbureted guys would benefit from building or buying an E85-specific carburetor. At this year's Car Craft Summer Nationals in St. Paul, Minnesota, we watched Jesse Nelson spin up his 540ci, twin-turbocharged, Rat-motored '70 Chevelle to 1,105 hp on the chassis dyno using E85. If car crafters can use a pump gas fuel to make this kind of horsepower, pay normal pump-gas prices, and not drive up the price of certain foodstuffs, then that's a good thing.

Now, to give the economics of E85 a balanced position, keep in mind that the price of E85 at the pump is also heavily subsidized by the government to the tune of around 50 cents per gallon. That means that without this subsidy, the price of E85 would be higher than regular gasoline. I recently spent a week in Iowa and noticed that many gas stations were selling 89-octane fuel for 8 to 10 cents a gallon cheaper than 87-octane gas. This is because the 89-octane fuel is mixed with a percentage of ethanol that increases its octane rating. The explanation for this higher-octane/cheaper-price dichotomy is that state subsidies offset the additional cost. Once the public accepts the use of fuels like E85, then those government subsidies will gradually disappear when our state legislatures see an opportunity to bring in more money for them to waste. What may alleviate that additional cost will be more efficient ways of distilling ethanol, or perhaps greater production rates of other ethanol-friendly crops that are cheaper and easier to grow.

What all the commotion is really all about is simple human nature. Some people are reacting to this new idea with emotion rather than logic (where is Mr. Spock when we need him?). It's human nature to distrust anything new. It wasn't all that long ago that people thought flying was for the birds. And when computers first began to make an impact on our society, knee-jerk reactionaries said these new machines would put people out of work. The reality is that computers have opened up a worldwide new industry that has put people to work. E85 will not solve all of our energy-use problems, and suggesting that ethanol be the primary solution to fueling all cars in America is ridiculous. But as an additional energy source that can be used in conjunction with gasoline to lessen our dependence on foreign oil, it makes a ton of sense. Even better, this fuel comes from a renewable resource.

My guess is that most of us have delivered harangues about the oil companies and their outrageous profits. So consider that if E85 achieves a significant percentage of total fuel used, the oil companies won't have to build those expensive refineries and use that as an excuse to charge us more for gasoline. Plus, competition from ethanol should be viewed as a positive step toward stabilizing fuel costs, because gasoline will no longer be the only game in town. In a free-market society, competition creates lower prices. Consumers end up the beneficiaries of this competition. Best of all, car crafters can make serious horsepower with an affordable fuel. Hopefully, this short explanation has offered an alternative viewpoint and made the bigger picture clearer. But we'd suggest doing your own research to form your own conclusions. If you see holes in our logic (here come the e-mails), let us know and we'll pass it along.

Gen III Goodies

Rich Wojnar, via CarCraft.com: I am e-mailing you about the past two articles you wrote about the budget Chevy Gen III 6.0L engine build, the latest titled "550 hp for Under $4,900" (May '07).

My reason for this letter is to see if you have performed any additional tests or have any new theories. Just before you guys wrote these articles, I had a 6.0L already sitting in the garage! So I decided to get that project underway. And I am currently researching a head and cam package for it. It will definitely be carb'd, but I would like to choose a good set of heads (really liked the write-up of the L92 heads) and a nasty cam.

To make a long story short, I was hoping that you could share anything you have found out with your trials thus far, or if you have tried any more combos. would appreciate any feedback you are willing to share!

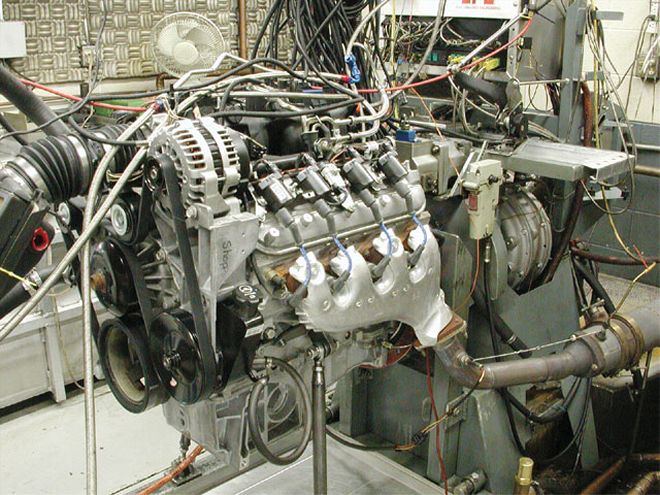

Jeff Smith: Have you been reading our mail, Rich? You're right on target. Our idea is to buy a basic LQ4 or LQ9 Gen III truck engine. We've already been pricing these engines and recently ran across two on eBay that were selling for $700 from an upstate New York recycler. This is a good price, but we didn't go for it because we'd prefer to find an engine a little closer to home that we can check out in person. We dug into the research bin a little deeper to see what it would cost if we started out with a brand-new iron 6.0L Gen III block that's available from GM.

Performance Parts. This block was righteously priced at $700, but by the time we added up all the little parts the engine needed that we don't have, like an oil pan, front and rear covers, and a ton of metric fasteners, it looked like the price would be about the same.

Here's our plan. Buy a used 6.0L iron-block motor, line up a 4.00-inch steel stroker crank, rods, and forged piston assembly from Scat or Eagle that includes a good forged 4.030-inch piston from Diamond, Mahle, or SRP. This will produce a 408-cid package. We bolt all the parts from our last 6.0L engine package onto this larger-displacement engine. The story you mention, "550 hp for Under $4,900," configured our truck LQ4 364ci cast-piston short-block with a Comp Cams XR281HR hydraulic roller cam with 228/230 degrees at 0.050 with 0.571/0.573-inch lift numbers and a 112-degree lobe separation angle. We matched that cam to a set of bone-stock, out-of-the-box L92 production Gen III aluminum heads that just happened to have a 2.16-inch intake valve and flowed 302 cfm at 0.500-inch lift and 332 at 0.600-inch. Yeoowsaaah!

The package in the May story made 551 hp at 6,800 rpm with peak torque of 464 lb-ft at a high 5,400 rpm. The giant L92 heads pushed the powerband way up there where you'd really need a deep gear to take advantage of all that power, but it's there for the taking. We've also heard through our GM contacts that a typical LQ4 cast-piston engine would probably be cracking pistons if it spent too much time at that rpm level. That's why we decided to go with a good steel crank, 4340 I-beam rods, and forged pistons. As for power, I did a little simple math to point us in the right direction. With 551 hp from a 364ci engine, that comes out to an excellent 1.51 hp/ci. We're making some assumptions, but for grins I multiplied 408 ci times 1.51, which gives us a stout 616 hp. Plus, the larger cubic inches will automatically make more torque and should bring the peak-horsepower rpm point down to 6,500. All of this is good, but it's not cheap. The rotator will be around $2,600 because the prices for Gen III engine parts have yet to settle to Gen I levels. The L92 heads are a blessing since a pair of these heads with the rockers and other pieces is a little over $1,000. Get it built and you can expect to have somewhere in the neighborhood of $8,000 invested, including an intake, carb, the MSD ignition conversion for a distributorless ignition system, and a good set of headers as part of the recipe.

Then we started researching crate engines from GM Performance Parts and other sources like Scoggin-Dickey. The cost goes up, but you have the advantage of instant gratification. As an example, Scoggin-Dickey Parts Center (SDPC) sells a 402ci LS2 short-block fitted with either a 14cc dished piston or a -2cc flat-top piston for $4,199 that consists of a block with a crank, rod, and piston assembly bolted together. The advantage of this package is the aluminum block, which automatically saves roughly 75 pounds over the iron 6.0L block. Scoggin-Dickey also offers an L92-based 416ci short-block with a 4.067-inch bore and 4.00-inch Eagle crank for $4,689. Just to add fuel to this fire, Street Legal Performance (SLP) offers a complete 402ci assembled short-block for a very good price of $4,245.95.

To make this even more interesting, we spoke with SDPC's Nicky Fowler, who told us about a small parts kit the company sells, intended for 6.0L bare-block buyers, that includes all the dowel pins and galley plugs, and some of the fasteners needed to complete the short-block. Add the front and rear covers and an oil pump, pickup, and pan, and you're most of the way there. For those on a really tight budget, you could hustle these small parts from a 4.8 or 5.3 iron or aluminum LS1 motor since these parts should interchange.

Most used engines you get from recycling yards also don't come with accessory drives, or if they do, the price is higher. Keep in mind that you can run a 4.8- or 5.3-style truck accessory drive on a 6.0L engine since, again, the parts interchange. This assumes you will be running either the taller truck EFI manifold or a carburetor. Since we plan to run a carb, the truck accessory drive would work just fine. What you cannot do is run a truck accessory drive with an LS1/LS6-style EFI manifold, because the throttle body crashes into a portion of the drive. It's a small point, but one worth knowing when you're mixing and matching.

That's our plan. Now we just have to figure out the best way to launch this whole deal and begin bolting our engine together. This means working with metric fasteners and learning the idiosyncrasies inherent in these new engines, but that's fun too. And anything we learn, we'll instantly pass along.

Swap That Six

Rob Altman, Lakewood, CO: I have recently acquired a '72 Chevy Nova with manual drum brakes and power steering. The car has an inline-six and a Powerglide. However, it also came with a 350 motor and TH350 trans that the previous owner told me was out of a '79 Z28 Camaro with less than 50,000 miles on it. The engine has been sitting for a long time. What should I do prior to installing it in my car? The motor also came with an Edelbrock Performer RPM intake manifold. The Quadrajet doesn't fit the bolt pattern on the Edelbrock manifold, so should I keep the stock manifold or step up to an aftermarket carb? Also, what should I take into consideration when performing the swap? What other budget modifications would you recommend? I have been a subscriber since 2004 when I was in the seventh grade; great magazine!

Jeff Smith: So that makes you a junior in high school, Rob? It's great to hear from younger guys who are into car crafting. You've chosen a great car as your first project, and I think we can help. The biggest issue is managing all the details involved in stuffing a V-8 in place of the inline-six. To begin with, you're going to need V-8 frame mounts and motor mounts just to bolt the engine in. The rear trans position is the same as the Powerglide, and the driveshaft length should also be the same since the Powerglide and TH350 are the same length. If you're going to reuse the Camaro exhaust manifolds, they will work, but it will require an all-new exhaust system. We found a complete single crossflow muffler system in the Classic Industries catalog for $339.95, or you could go with a Flowmaster PN 17104 crossflow system for $369.95. There are certainly other kits that would also work; these are just two examples. The Flowmaster system will be dramatically louder with that distinctive Flow-master resonance, which you might like.

The original six-cylinder radiator will probably not be sufficient for the larger 350 engine, so a new or at least good used radiator will be necessary. Hopefully the small-block came with a complete accessory drive, meaning all the pulleys, brackets, and other components needed to perform the installation. Keep in mind that you'll also need new radiator hoses, heater hoses, clamps, belts, coolant, and a whole bunch of other stuff to complete the engine swap. These little parts are what will drive up the cost of the engine swap. It's entirely possible to spend over $200 just on small items like thermostats and heater hose nipples for the intake manifold and other seemingly insignificant parts. If you're lucky, you can reuse the transmission cooler lines from the original Powerglide since they are similar. That will save you some bucks. Don't forget that the new radiator will need to be configured with an automatic-transmission cooler. Don't try to run the car without a trans cooler.

If the engine has been sitting for a long time, it would be a good idea to pull all the spark plugs out, squirt engine oil into all the cylinders, and turn the engine over by hand several times to help keep everything lubricated. Drain and replace the oil and filter. You might even want to pull the distributor and pressure-lube the engine before firing it. We just did a short story last month in the November issue on how to stab a distributor, if you have never done this before. Use some kind of dummy distributor body to ensure that both sides of the engine get oil up to the rockers. The best move would be to add new plugs and spiral-wrapped plug wires. You will also need to come up with a switched 12-volt power source for the HEI distributor since the early Novas used a resistor wire in the harness to feed power to the coil. The original resistor wire only allows about 5 volts, which won't work well with the HEI. Instead, find a switched 12-volt power source off the fuse box.

As for the intake manifold question, the Edelbrock Performer RPM is a great manifold. I would go with that over the stocker and look for a good used Holley 600-cfm carburetor. The 0-1850 Holley 600-cfm vacuum-secondary is a decent carb and should be easy to find. The part number is located on the driver side of the choke housing. You'll also need to change the throttle linkage to make it work for a V-8.

I'm sure I've probably overlooked one or two parts to this swap, and we haven't even talked about adding stiffer front springs to compensate for the heavier small-block, but that can come later after you get the car running. Good luck.

Brake Talk

Richard Rochelle, Chicago, IL: I've got a '69 Camaro with a 12-bolt rearend and a 350/350 combo. I've heard about putting Ford Explorer brakes on the rear of a Chevy rearend. This sounds like an economical way to go. I've got discs on the front from a Chevelle and an adjustable prop valve. Would this be the way to go or would I be better off with a kit? Saving money would be great and a junkyard crawl is always fun.

Jeff Smith: This is a great question, Richard, and one littered with potential land mines. There are plenty of people out there who are mixing and matching brakes parts on their cars successfully, but we'd hazard a guess that most of them (like us) really just got lucky with the combination. Here's what we've learned. We've seen firsthand what happens when adding a rear disc brake package that is not engineered to work with your front brake combination. We have a friend with a killer '69 Camaro who did a 60-to-0 braking test on his car only to discover that the rear brakes always locked up ahead of the fronts. He backed his adjustable proportioning valve off all the way and the rears still locked up prematurely, which put the car into a dangerous loss of control. What he eventually learned is that the rear Ford Explorer calipers use very large rear caliper pistons. Even minimizing the rear pressure (we'll get to that detail later) did not fix the problem, because the greater volume requirement of the large rear pistons demanded more master-cylinder piston movement. This led to the rear brakes locking up first because the pressure was still too high.

We spoke with the tech folks at Baer Brakes, and they were very familiar with this situation. Their safety margin is to recommend that the front calipers be a minimum of 25 percent and preferably 40 to 50 percent larger than the rear calipers. So let's say that your front Chevelle calipers use a single floating piston that measures 2.8 inches in diameter. Using Baer's recommended 50 percent figure to be safe, that means that the total rear-caliper piston should be no larger than around 2 inches in diameter. Keep in mind that this is really about piston area, using the formula Pi times radius squared, and the radius of a circle is half its diameter. So if the area for a 2.8-inch front piston is 6.15 square inches (1.4 x 1.4 x 3.1417 = 6.15), the rear caliper must not exceed a piston area of around 3 square inches. This calculates out to roughly a single rear-piston diameter of 2 inches, or multiple pistons whose areas add up to 2 square inches. Front or rear calipers that use pistons on both sides of the rotor generate what is called opposing forces, so you only calculate the total piston area based on one side.

Also, the master cylinder must be able to supply sufficient volume to both the front and the rear brakes. Basically, a smaller master-cylinder piston generates more hydraulic pressure with the same pedal effort but does so at the cost of reduced fluid movement. This means we need both pressure and fluid volume, and sizing the master cylinder must also be part of the equation. In our experience with Chevelles and Camaros, a master-cylinder piston diameter of 71/48 inch to 151/416 inch is a good compromise between pressure and volume. This can also be used with manual brakes (no vacuum booster) with reasonable pedal effort.

The reason that our Camaro friend couldn't dial out the rear brake lockup with his adjustable proportioning valve is because all adjustable prop valves are designed to allow a minimum amount of pressure to the rear brakes, even with the adjustment backed completely out. Once this minimum pressure is achieved, then you can use the valve to adjust the pressure curve needed for your application. In the Camaro's case, the rear piston was so large that the minimum pressure allowed by the prop valve was more than enough to lock up the rear brakes under hard braking. Our friend only discovered this when he started doing aggressive braking tests, because the higher braking effort by the front brakes created a greater weight transfer to the front, reducing the load on the rear tires. The larger rear calipers needed only a minimum amount of pressure to create leverage over the tires and lock them up. The fix for this Camaro was a Baer rear-brake package with a dramatically smaller rear-piston area. It balanced the system and improved the Camaro's 60-to-0 braking distance from a heavily modulated 117 feet to a much more stable 106 feet-that's almost a full car length and could make the difference between hitting something and missing it by inches. These are excellent numbers, by the way. Most street cars require at least 130 to 140 feet, depending upon the quality of the brakes and especially the tread width and traction quality of the tires.

Holley Idle Fix

Fran Blacker, Cheshire, CT: Jeff Smith's June '07 Holley Makeover answer helped me discover a serious idle problem. I have a cross-ram Hemi with black spark plugs. These are the only two Holleys I've owned. The story mentioned reducing the hole size of the idle feed restrictor in the main metering block. The holes in my Holleys were drilled to over 0.090 inch! These carbs were on a race car, and I have since found other problems. To fix these carbs, I plugged the holes with small solder balls and drilled 0.026-inch holes through the solder using a drill I bought in a hobby shop. Thanks, CC, from another Mopar whiner.

Jeff Smith: Thanks for writing, Fran. It's always nice to get feedback from our readers that information that we present in this column can help fix a problem without their resorting to buying new parts when the old parts can be repaired. We've seen this situation before, where hackers have modified their carburetors without really thinking about what they were doing. In your case, a 0.026-inch-diameter hole represents a flow area that's roughly 12 percent the size of that 0.090-inch-diameter hole. We're talking about flow area here, which affects part-throttle operation as well. For a street-driven car, establishing an accurate idle feed restrictor and idle airbleed sizes that will push the air/fuel ratio realistically between 13:1 and 14:1 will not only keep the spark plugs clean but also make the engine run much crisper and more throttle-responsive. Plus it will waste less fuel. This means you can have more fun and spend less money on gas. And that means you have more money left over to buy more speed parts and perhaps the occasional steak dinner. We like steak.

You've got problems? We've got solutions!

CarCraft@primedia.com

CarCraft.com

Car Craft Mag6420 Wilshire Blvd.Los Angeles, CA 90048