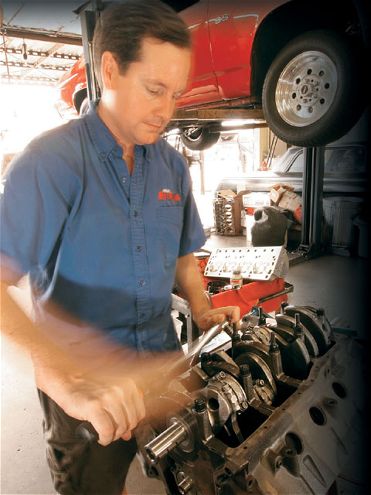

The rod bolts of our 408ci Windsor stroker are torqued to 40 lb-ft using the ARP assembly lube supplied with our stroker kit by Eagle.

The rod bolts of our 408ci Windsor stroker are torqued to 40 lb-ft using the ARP assembly lube supplied with our stroker kit by Eagle.

The reality is, it doesn't cost much more coin to build a stroker than it does to stay with the factory displacement. Last month (see "The Twister: Part 1") we detailed the combination of our build, and explained why we chose those power parts. The key player of this combo is the stroker kit from Eagle Specialty Products. For $1,279.95, we got a cast-steel crank, dished 19cc forged pistons, forged I-beam rods, and all the rings and bearings. That's a pretty smoking deal for most of the parts in the short-block. The extra 57 cubes did not cost much more than building a 351-inch plant of the same quality, and the performance potential is much higher.

The design of this engine has been a balance between street manners and track performance. We didn't want a peaky engine that made all its power up top and idled like a crackhead having a seizure. We wanted good power across the band in a package that was as fun to cruise as it was to race. Simply put, it's not about making a moonshot "peak" number to impress our friends.

The first machining step is boring and honing the cylinders. We rough-honed the bores .025, and finished them to .030-inch over.

The first machining step is boring and honing the cylinders. We rough-honed the bores .025, and finished them to .030-inch over.

With this in mind, we ignored the desire to build a solid-roller engine, and went with a more user-friendly hydraulic roller setup. Our DynoSim computer simulation put us at just over 500 hp with an equal amount of torque, but the real numbers will come from the engine dyno, and from the track later on.

This month, we're going to tackle our 408 short-block. Most of the work involves prepping the block to receive the new parts, and luckily we have Andy Mitchell of Outlaw Racing to help us with the mystical art of machine work. Aside from the Eagle rotating assembly, we're using high-quality fasteners from Milodon and ARP, along with a more robust oiling system. We could have done it cheaper, but we plan on putting a ton of hard miles on project Fastlane 500, and spending a few extra bucks will help us sleep better at night.

It's been said that horsepower sells cars, but torque wins races. It's true, sort of. The real saying should be, "peak horsepower sells cars, but low- and mid-range torque makes a car fast and fun." Torque is king, and we know if we want to get our 3,460-lb '70 Fairlane project in motion, we're going to need lots of twist. We also plan on hitting the drag strip to see if we can get this 17-second slug into the 11s. For this, we need a mill that can generate a good amount of horsepower with a nice, flat torque curve. We need a stroker.

WHERE THE MONEY WENT 408 WINDSOR SHORT-BLOCK Item: Source: Part No.: Cost: 351W block, early AA Midwest n/a $250 Eagle 408 stroker kit Eagle 16123030 $1,279.95 Cam bearings {{{Summit}}}/Clevite CLE-SH510S $17.95 Hydraulic roller camshaft COMP 35-426-8 $255.95 Double-roller timing set COMP 2135 $48.99 Standard-volume oil pump Summit/Melling MEL-M83 $24.95 Oil pump pick-up Milodon 18365 $39.95 Windage tray Milodon 32215 $49.95 Expansion plug set Milodon 34035 $12.99 Cam bolt ARP 254-1001 $4.88 Oil pump bolts ARP 150-6901 $7.99 Oil pump driveshaft ARP 154-7901 $17.88 Main studs Milodon 81166 $70.00 Aluminum timing cover Edelbrock 4250 $134.99 Parts total: $2,216.42 Machine work: Balancing of rotating assembly from Eagle $333 Bore and hone block w/torque plate $235 Deck surfacing $140 Align hone block $175 Machine shop labor total: $883 Parts & labor total: $3,099.42