NASCAR is turning into NASA CAR, but no one seems to care. In an era when Toyotas have pushrods and Chevys mount their distributors up front, all four manufacturers now field clean-sheet engine platforms that are designed specifically for competition and are completely unrelated to any production motor. This shift in engine philosophy means that the final vestiges of production-car hardware have been entirely eradicated from stock car racing. While the cutting-edge technology used in these motors—such as compacted graphite iron blocks, valvespring oil squirters, and cylinder heads whittled down like Renaissance sculptures to reduce mass—is impressive, they look like something heisted straight out of the Jet Propulsion Laboratory. Consequently, the average enthusiast can hardly relate to them, which makes the concept of racing on Sunday and selling on Monday a history lesson.

What would make things a heck of a lot more interesting for car guys is if LS1s, mod motors, and new-age Hemis duked it out every weekend, but since NASCAR's fan base is too mainstream to make a big stink about it, we're screwed. Interestingly enough, there is land where stock cars actually race with stock-car engines—GM LS3s to be exact—that harkens back to the glory days of 426 Hemis and Ford 427 Cammers. You just have to venture south of the equator to find it.

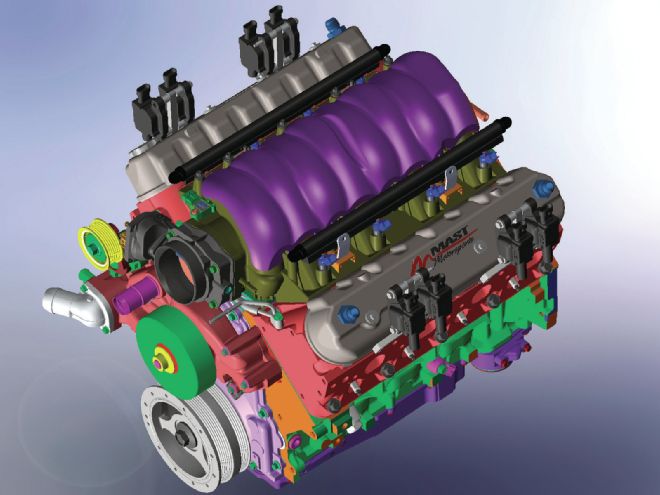

Brazil's Copa Nextel (Nextel Cup), the nation's premiere stock car series, pits rear-drive Chevys and Peugeots against each other at various road-course venues throughout the country. Like NASCAR Sprint Cup, the series has transitioned from production-car chassis to tube frames to improve safety and level the playing field. Unlike Sprint Cup, however, Copa Nextel stock cars are powered by ethanol-burning, 416ci GM LS3s that produce 617 hp and use stock blocks, cylinder heads, and intake manifolds. In other words, every single part on these motors will bolt right up to the LS3 in your Camaro or Corvette. What a concept. In an effort to promote parity and keep costs under control, the sanctioning body supplies identical spec motors to each team, and they are built by a single engine shop—Texas-based Mast Motorsports. Intrigued by what it takes to R&D a Brazilian-American hybrid of a stock-car motor, we followed along as Mast Motorsports put one together. To make things more interesting, we dyno'd the motor on both ethanol and 93-octane pump gas. While the 416 made 26 more horsepower on ethanol than on gasoline, it's not for the reasons you might expect, so keep reading before you contemplate an E85 conversion for your street machine.

Design Goals

Copa Nextel organizers aren't coy about the fact that Brazil isn't a wealthy country, and limiting costs is paramount in order to attract enough teams to fill the grid of 34 cars. The series launched an all-new chassis in 2009, but the engines for that season were carbureted, gasoline-burning, Chrysler-based 480hp small-blocks carried over from the previous-generation chassis. Looking to make the racing action more exciting and the technology more contemporary, the series wanted to add a big-time boost in power while also switching to EFI. Furthermore, since Brazil is home of the world's largest fleet of flex-fuel vehicles, it only made sense for its most popular form of racing to adapt ethanol as well. In stark contrast to the $75,000 it costs to develop and build a NASCAR Sprint Cup motor, the Copa Nextel series set a strict maximum budget of $15,000 per engine. Thanks to its low mass, outstanding power potential, compact size, and cheap and readily available parts, the LS-series small-block was the perfect solution. "The horsepower target was set at 600, since that's what the chassis and transmissions in these cars were designed to handle. The sanctioning body's top priorities were reliability and keeping costs down, but they didn't have any kind of displacement limit," explains Horace Mast of Mast Motorsports. "This helped tremendously in meeting their objectives, since it allowed us to build a 416ci motor that only needs to turn 6,400 rpm to meet their power goal. The extra cubic inches take a lot of stress off of the valvetrain, which is extremely important in a road-race application."

Replacing engines after every round of competition is far too costly, so the Copa Nextel series needed a package that would last the entire season. This is no small feat, as the cars log a total of 2,800 total miles throughout the course of a 12-race season. The 17 teams are issued a primary motor and backup motor for each of their two cars. At the halfway point in the season, all teams send their engines to the sanctioning body, where they are inspected, dyno'd tested to check their health, and refreshed as necessary. Furthermore, the top five finishers of each event are subject to an additional inspection following every race to ensure their motors haven't been modified in any way. While the bearings are checked for wear, Mast says that the rotating assemblies, rings, and valvesprings should last the entire season.

Short-Block

The grueling durability requirements of the Copa Nextel series would suggest that an ultra-exotic bottom end is a must, but surprisingly, most of the short-block components can be ordered straight out of the Summit catalog. In the quest for cheap and lightweight cubic inches, a 4.065-inch bore GM LS3 block was the natural choice, which Mast finish-hones to 4.070 inches. Combined with a 4.000-inch Callies/Compstar 4340 crank, it nets a 416ci displacement figure that hits a sweet spot on the cubes-per-dollar spectrum. While dropping the same crank in a 4.125-inch-bore LS7 block would yield 427 ci, an LS3 block is half the price at $1,400, making it a much more appealing proposition for the cash-strapped race series. Conversely, a factory 4.000-inch-bore LS2 block would sacrifice 14 ci and only costs $300 less. With the bore and stoke dimensions settled, Mast finished off the rotating assembly with Callies/Compstar 6.125-inch steel rods and 11.3:1 Mahle forged pistons. While the compression ratio may seem conservative, Mast didn't feel the need to raise it any further, as the target horsepower mark had already been reached.

Due to the strenuous conditions under which the cars are designed to operate, Mast Motorsports relied heavily on Finite Element Analysis (FEA) testing during the early design stages of the Brazilian 416. FEA software simulates the effects of stress and strain on the motor to accurately predict how critical components such as the block and heads will distort under load.

Due to the strenuous conditions under which the cars are designed to operate, Mast Motorsports relied heavily on Finite Element Analysis (FEA) testing during the early design stages of the Brazilian 416. FEA software simulates the effects of stress and strain on the motor to accurately predict how critical components such as the block and heads will distort under load.

Mast wouldn’t disclose an exact figure, but they were able to stay below the $15,000-per-engine budget set by Copa Nextel organizers. An ATI damper quells harmonics, and the dyno figures were achieved using 2.000-inch headers. To avert cheating, after arriving in Brazil, the motors are affixed with 18 tamper-proof seals in strategic locations before they’re released to the teams.

Mast wouldn’t disclose an exact figure, but they were able to stay below the $15,000-per-engine budget set by Copa Nextel organizers. An ATI damper quells harmonics, and the dyno figures were achieved using 2.000-inch headers. To avert cheating, after arriving in Brazil, the motors are affixed with 18 tamper-proof seals in strategic locations before they’re released to the teams.

Nothing more than ordinary, off-the-shelf components, the reciprocating hardware consists of Callies/Compstar 6.125-inch steel H-beam rods with ARP bolts and Mahle 11.3:1 forged pistons. The slugs use Mahle’s Grafal coating on the skirt surfaces, which cuts friction and allows running tighter piston-to-wall clearance for improved ring seal.

Nothing more than ordinary, off-the-shelf components, the reciprocating hardware consists of Callies/Compstar 6.125-inch steel H-beam rods with ARP bolts and Mahle 11.3:1 forged pistons. The slugs use Mahle’s Grafal coating on the skirt surfaces, which cuts friction and allows running tighter piston-to-wall clearance for improved ring seal.

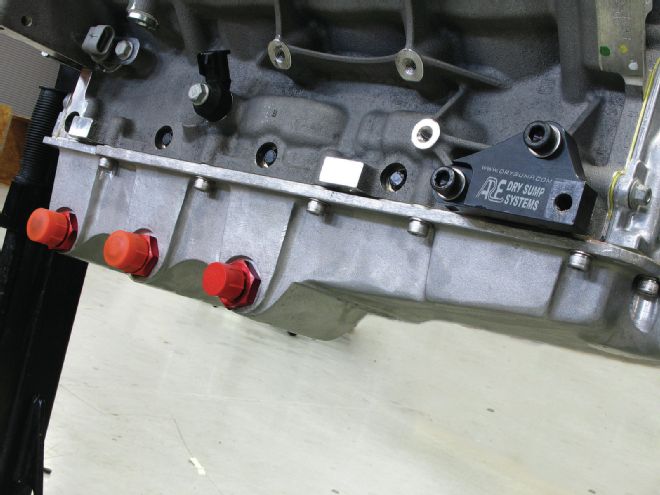

The sustained high-rpm operation and constant lateral loads of road racing present technical challenges straight-line racers rarely have to worry about. To improve oil control during hard cornering, acceleration, and braking, the Brazilian LS3s employ an ARE dry-sump system. Furthermore, the Indy Car–style six-speed Xtrac gearboxes used in the cars put additional stress on the valvetrain. "The Brazilian stock cars use sequential transmissions, and the drivers downshift to slow the cars down using engine braking to help keep the rotors cool," says Mast. "This puts a ton of stress on the timing chain and gears, so we developed our own gear-drive setup for improved strength. The oil pumps on LS motors are driven off of the crank snout, so running a dry-sump system freed up the space necessary to design a gear drive that bolts right up."

Nothing more than ordinary, off-the-shelf components, the reciprocating hardware consists of Callies/Compstar 6.125-inch steel H-beam rods with ARP bolts and Mahle 11.3:1 forged pistons. The slugs use Mahle’s Grafal coating on the skirt surfaces, which cuts friction and allows running tighter piston-to-wall clearance for improved ring seal.

Nothing more than ordinary, off-the-shelf components, the reciprocating hardware consists of Callies/Compstar 6.125-inch steel H-beam rods with ARP bolts and Mahle 11.3:1 forged pistons. The slugs use Mahle’s Grafal coating on the skirt surfaces, which cuts friction and allows running tighter piston-to-wall clearance for improved ring seal.

Heads and Valvetrain

Bolting un-ported production cylinder heads to a race motor might sound rather odd, but the L92/LS3 castings aren't your ordinary heads. As the L92/LS3 heads are the direct descendents of the GM LS7 heads—which were derived from the American Le Mans Series C5R Corvette racing program—calling them "race-bred" is more reality and less a hackneyed cliché. Improving upon the original cathedral-port LS1 castings, the LS3 heads feature raised 260cc rectangular intake ports for a more gradual transition at the short-turn radius. This dramatically improves airflow above 0.600-inch lift, where the cathedral-port design goes turbulent. With 2.165/1.590-inch valves and 70cc combustion chambers, the LS3 heads flow 330 cfm right out of the box. For not much more money than the hallowed, cast-iron Gen I GM Vortec heads, the LS3 castings blow them away by more than 90 cfm.

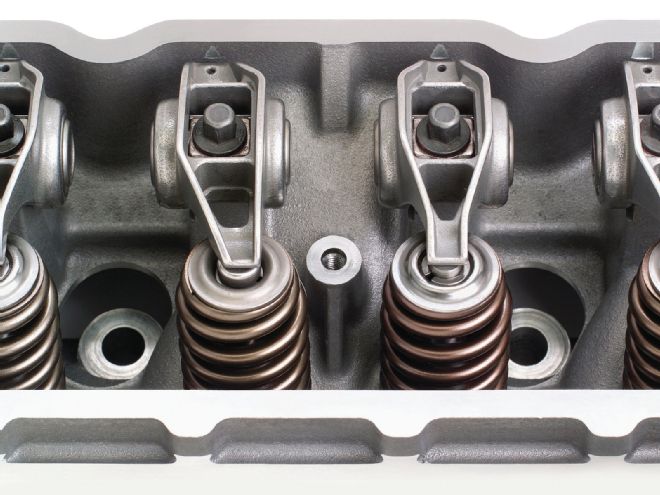

To enhance valvetrain stability, Mast fits the heads with hollow-stem, stainless-steel intake valves matched with nitrided Pac beehive valvesprings and titanium retainers. Thanks to the tremendous flow of the LS3 heads, hitting 600 hp didn't require the added cost and maintenance of a mechanical roller cam. A broad powerband is essential for brisk corner exits in road-racing applications, so Mast spec'd out a 240/256-at-0.050 hydraulic roller cam with 0.610/0.634-inch lift ground on a wide 114-degree lobe-separation angle. The combo works as intended, with the 416 laying out 380 lb-ft of torque at just 2,000 rpm. "Valvetrain stability is the most important factor at sustained high-rpm operation," Mast opines. "With a solid roller motor that turns over 7,000 rpm, you're usually better off with dual springs. Hydraulic lifters are more sensitive to valvetrain weight, and since these motors only turn 6,800 rpm, a lighter beehive spring matched with titanium retainers improves valve control over a heavier dual spring."

Since cylinder seal, durability, and oil control takes precedence over max horsepower, Mast uses a 1.5mm Mahle (chrome?) moly top ring gapped at 0.020 inch and a 1.5mm Napier second ring gapped at 0.024. A standard-tension, stainless-steel 3mm oil ring keeps the lube in the crankcase.

Since cylinder seal, durability, and oil control takes precedence over max horsepower, Mast uses a 1.5mm Mahle (chrome?) moly top ring gapped at 0.020 inch and a 1.5mm Napier second ring gapped at 0.024. A standard-tension, stainless-steel 3mm oil ring keeps the lube in the crankcase.

Induction and Engine Management

As with the cylinder heads and block, a stock LS3 intake manifold and drive-by-wire throttle-body are up to the task of feeding the 600hp Brazilian mill. Far more interesting is how airflow is regulated into the intake. Since frequent passing makes for exciting racing, the Brazilian stock cars use a push-to-pass feature that's controlled by a Bosch engine management computer. "The system works by electronically limiting the opening of the throttle-body at 75 percent under normal conditions," Mast explains. "This cuts engine output by 80 hp, and when the drivers hit a button, the throttle-body opens back up to 100 percent. The exact figures vary by track, but on average the drivers are given 10 seconds of push-to-pass operation 10 times in each race."

Further extending component longevity are safeguards built into the engine management software. If coolant temperatures exceed a set threshold or oil pressure drops, the engine automatically shuts down. "Whenever the cars contact each other, you run the risk of busting a radiator or knocking coolant lines or oil lines loose. When that happens, instead of throwing a rod out the side of the block or burning up a piston, the computer prevents the motor from blowing up, which helps keep costs down," says Mast.

The internally-balanced-shelf, 4.000-inch Callies/Compstar 4340 crank rides on ACL tri-metal bearings and is anchored in placed by stock main caps and ARP studs. Only minor grinding is necessary for the rod bolts to clear the crankcase. Although a 4.125-inch-stroke crank can be crammed inside a stock-deck-height LS block, Mast says that it pulls the pistons too far down the bore. This can cause the pistons to rock back and forth at BDC and force the rings to lose contact with the cylinder walls, which compromises oil control.

The internally-balanced-shelf, 4.000-inch Callies/Compstar 4340 crank rides on ACL tri-metal bearings and is anchored in placed by stock main caps and ARP studs. Only minor grinding is necessary for the rod bolts to clear the crankcase. Although a 4.125-inch-stroke crank can be crammed inside a stock-deck-height LS block, Mast says that it pulls the pistons too far down the bore. This can cause the pistons to rock back and forth at BDC and force the rings to lose contact with the cylinder walls, which compromises oil control.

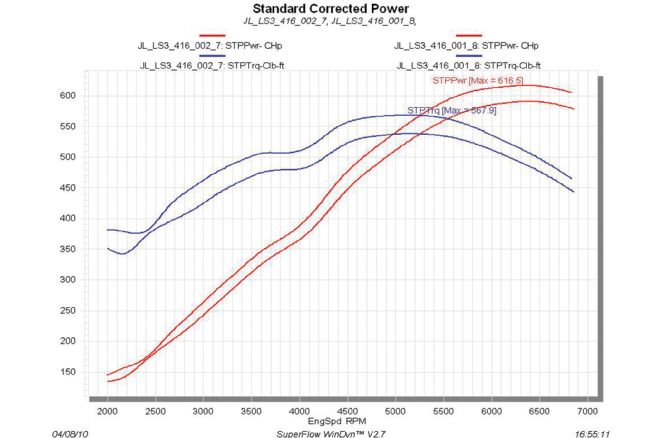

Ethanol vs. Gasoline Shootout

Dyno'ing the 416 provided an excellent opportunity to test the merits of ethanol and gasoline back-to-back and put some ugly myths to rest. From a horsepower standpoint, ethanol was the clear victor, as it produced peak outputs of 617 hp and 568 lb-ft compared with 591 hp and 538 lb-ft on 93-octane pump gas. Likewise, on ethanol the motor dished out an additional 30 lb-ft of torque at 2,000 rpm and carried that advantage throughout the powerband. It's important to clarify that the Brazilian 416 runs on 100 percent ethanol as opposed to the 85 percent ethanol/gasoline mix (E85) sold in some areas of the U.S. Nonetheless, considering that ethanol releases 35 percent less energy when burned than does gasoline (76,000 BTU per gallon versus 115,000), this is a bit surprising. Many hot rodders attribute results like this to ethanol's superior octane rating of approximately 105, but that conclusion is a half-truth at best, since the compression ratio in this test wasn't changed, and ignition timing was only advanced 2 degrees on ethanol. Moreover, a substantially greater quantity of ethanol must be burned to make up for its BTU handicap compared to gasoline.

Machined from 8620 steel, the Mast gear-drive assembly uses a single-idler gear that rotates on Torrington bearings. Its support bracket bolts to the stock oil-pump holes, and installing the gear drive doesn’t require any machining to the block or timing cover. The primary benefits are enhanced strength and precise cam timing.

Machined from 8620 steel, the Mast gear-drive assembly uses a single-idler gear that rotates on Torrington bearings. Its support bracket bolts to the stock oil-pump holes, and installing the gear drive doesn’t require any machining to the block or timing cover. The primary benefits are enhanced strength and precise cam timing.

The lifters of choice are GMPP pieces that were originally designed for the Cadillac CTS-VR factory race car. They incorporate a ceramic check ball that allows them to operate at engine speeds up to 8,500 rpm

The lifters of choice are GMPP pieces that were originally designed for the Cadillac CTS-VR factory race car. They incorporate a ceramic check ball that allows them to operate at engine speeds up to 8,500 rpm

Since the oil pans used in LS motors are a structural member of the block, Mast prefers using cast aluminum pans—such as this ARE dry-sump unit—instead of stamped pans. It’s scavenged by a four-stage pump with adjustable pressure settings. A side benefit of the low-profile, dry-sump pan is that it enables the motor to be positioned lower in the chassis for improved handling.

Since the oil pans used in LS motors are a structural member of the block, Mast prefers using cast aluminum pans—such as this ARE dry-sump unit—instead of stamped pans. It’s scavenged by a four-stage pump with adjustable pressure settings. A side benefit of the low-profile, dry-sump pan is that it enables the motor to be positioned lower in the chassis for improved handling.

According to Mast, the difference in power is a product of ethanol's greater (latent) heat of vaporization. "As ethanol changes states from a liquid to a gas, it pulls more heat out of the intake charge than does gasoline. This increases the air density and volumetric efficiency of the motor and increases horsepower and torque," Mast says. "Although we were able to advance the ignition timing as much as 5 degrees before the motor started detonating, we only ended up running 2 more degrees of advance on ethanol. Bumping up the timing any more than that didn't improve torque output, so we settled on a conservative tune that gives us a safety margin in case one cylinder runs lean. Total advance on ethanol was 28 degrees compared with 26 degrees on gasoline, so most of the power difference is due to ethanol's cooler intake-charge temperature. A downside of ethanol is that its stoichiometric air/fuel ratio is 9.0:1 compared with 14.7:1 on gasoline, so you have to burn one and a half times more fuel to make similar power. The brake-specific fuel-consumption figure on the 416 was about 0.450 lb/hr on gasoline versus 0.680-lb/hr on ethanol."

Fuel expert Tim Wusz of Rockett Brand Racing Fuels agrees with Mast's assessment. "Ethanol has many undesirable characteristics, but its cooling effect is similar to methanol and is a big performance benefit. In humid environments, you can actually frost up the intake and freeze the throttle blades on a methanol sprint-car engine at night," Wusz explains. "Ethanol's better resistance to detonation has more to do with its cooling of the intake tract, not its octane. If ethanol and gasoline had the same octane number along with optimized air/fuel ratios, the ethanol would still be more resistant to detonation. As long as an engine isn't detonating, it doesn't even care what the octane number of the fuel is. In fact, there's really no way to accurately measure ethanol's octane using the motor-octane-number (MON) test procedure. The test was originally designed for gasoline and is conducted in a lab on a single-cylinder, variable compression engine at 900 rpm using variable spark timing and a mixture temperature of 300 degrees Fahrenheit. Gasoline comprises many different compounds and begins boiling at a temperature range of 80 to 400F degrees. Since ethanol is a simple chemical, it has one boiling point instead of a boiling range and is vaporized by 170F degrees. That's why it's impossible to accurately compare the octane numbers of ethanol and gasoline."

Granted, ethanol's power advantage over gasoline is legit, but Wusz has some words of wisdom for anyone contemplating jumping on the E85 bandwagon. "First off, any potential horsepower gains won't be nearly as great with E85 as it would be with pure ethanol, and the gains will be even less noticeable in an engine combo that already operates at high volumetric efficiency. Second, since ethanol requires more heat to vaporize, it can make cold starts very difficult," he says. "Federal regulations allow gasoline content of greater than 15 percent in E85, so during cold months, what you think is E85 can actually be E65. Also, there are no stipulations for what the quality of that 15 percent of gasoline must be. That's not a big deal for EFI flex-fuel vehicles that can adjust their air/fuel mixtures on the fly, but it's a very big problem for carbureted motors and non-flex-fuel EFI vehicles. Additionally, ethanol's oxygen content is good for emissions and power, but its low BTU content hurts fuel economy considerably."

The stock GM LS3 heads have been fitting with stock-diameter 2.165/1.590-inch Ferrea stainless-steel valves. Mast uses 0.040-inch Cometic multilayer steel head gaskets and decks the mating surfaces of the heads a hair to ensure positive cylinder seal, but they retain the stock 70cc combustion chamber volume. The heads are otherwise untouched and cinched down with ARP studs.

The stock GM LS3 heads have been fitting with stock-diameter 2.165/1.590-inch Ferrea stainless-steel valves. Mast uses 0.040-inch Cometic multilayer steel head gaskets and decks the mating surfaces of the heads a hair to ensure positive cylinder seal, but they retain the stock 70cc combustion chamber volume. The heads are otherwise untouched and cinched down with ARP studs.

Stock-Car Racing, Brazilian Style

Based on the way Brazilians do their partying and jujitsu, it's not surprising that they take a unique approach to stock-car racing. The Copa Nextel series was founded in 1979 and has many of the elements that made NASCAR's top series so exciting to watch back in the '60s and '70s. You already know all about their engines, but the cars they're bolted inside weigh just 2,800 pounds and feature Xtrac six-speed sequential transmissions, big AP brakes, and independent rear suspension. As a spec-car series, all the tube chassis and body panels are built by JL Motorsports (JLInd.com.br) in Brazil, who also provide every component needed to assemble the entire car. While the Chevy and Peugeot bodies look slightly different, they are said to be aerodynamically identical. Interestingly, the teams rent space inside JL's facility and assemble the entire car onsite. Although they still try, this makes it awfully tough for one team to gain a technical advantage over another, but it does promote parity and close racing while significantly reducing operating expenses. The 12-race calendar is spread out over various road courses throughout Brazil, and to keep the intensity level high, the events are run in a sprint format in which race durations are limited to one hour. The three rounds of qualifying are setup in a knockout-style format, and the talent level is quite high as well, with five former Formula One drivers currently racing in the series. For more info, check out StockCar.Globo.com.

Mast LS3 HP and Torque on Gasoline

To optimize valve control and lifter longevity, the 416 relies on nitrided Pac 1.280-inch beehive valvesprings. They exert 130 pounds of seat pressure and 325 pounds over the nose. They’re actuated by stock LS3 rockers, which are offset on the intake side from the factory for uncompromised port geometry.

To optimize valve control and lifter longevity, the 416 relies on nitrided Pac 1.280-inch beehive valvesprings. They exert 130 pounds of seat pressure and 325 pounds over the nose. They’re actuated by stock LS3 rockers, which are offset on the intake side from the factory for uncompromised port geometry.

Mast LS3 HP and Torque on ETHANOL

Potential rocker-stud flex was a major concern when sorting out the valvetrain, so Mast contemplated using the company’s shaft-mount rocker arms to enhance stability. However, side-by-side testing of the stock rockers and shaft mounts using FEA software revealed that the factory units would hold up just fine.

Potential rocker-stud flex was a major concern when sorting out the valvetrain, so Mast contemplated using the company’s shaft-mount rocker arms to enhance stability. However, side-by-side testing of the stock rockers and shaft mounts using FEA software revealed that the factory units would hold up just fine.

Engine Specs: Engine type: Mast Ethanol LS3

Displacement:416 ci Bore x stroke:4.070 x 4.000 Compression ratio:11.3:1 Deck height (actual):9.23 Rod length:6.125 Main bearing clearance:0.0023-0.0026 Rod bearing clearance:0.0024-0.0028 Rod side clearance:0.018 Crankshaft endplay:0.005 Camshaft endplay:0.006 Piston-to-wall clearance:0.0035 Piston top ring end-gap:0.02 Piston second ring end-gap:0.024 Piston compression height:1.105 Piston dome volume:-4cc Piston-deck clearance:0 Head gasket compressed thickness:0.04 Combustion chamber volume:70 cc Intake valve diameter:2.165 Exhaust valve diameter1.59 Valvespring diameter:1.28 Valvespring seat pressure:130 lbs Valvespring open pressure:325 lbs Camshaft specs:240/256-at-0.050; 0.610/0.634; 114 Ignition timing:28 degrees Injector size:65 lb/hr Fuel type:Ethanol Main cap bolt:60 lb-ft Rod bolt:75 lb-ft Head bolt:70 lb-ft While 39-lb/hr fuel injectors are plenty to feed a 600hp motor on gasoline, the 416’s ethanol diet requires stepping up to massive 65-lb/hr high-impedance units. They’re fed by a Mast aluminum fuel rail that are said to improve flow. Ethanol is far more corrosive than gasoline, so flex-fuel-compatible O-rings are mandatory.

While 39-lb/hr fuel injectors are plenty to feed a 600hp motor on gasoline, the 416’s ethanol diet requires stepping up to massive 65-lb/hr high-impedance units. They’re fed by a Mast aluminum fuel rail that are said to improve flow. Ethanol is far more corrosive than gasoline, so flex-fuel-compatible O-rings are mandatory.

Mast’s cast aluminum valve covers feature an internal baffling system that routes crankcase pressure to an external barb fitting. This eliminates the need for an ugly breather and creates an OE-style, closed-loop system that directs fumes back into the motor. By doing so, this arrangement reduces the potential of oil spitting out the breathers and igniting on the headers during high-g cornering. The Mast coil brackets isolate the coils from heat and vibration.

Mast’s cast aluminum valve covers feature an internal baffling system that routes crankcase pressure to an external barb fitting. This eliminates the need for an ugly breather and creates an OE-style, closed-loop system that directs fumes back into the motor. By doing so, this arrangement reduces the potential of oil spitting out the breathers and igniting on the headers during high-g cornering. The Mast coil brackets isolate the coils from heat and vibration.

For an engine of its size, the 416’s torque output of 400 lb-ft at 2,500 rpm is exceptional. On ethanol, the motor produces an additional 15 to 30 hp and 25 to 35 lb-ft of torque throughout the entire operating range.

For an engine of its size, the 416’s torque output of 400 lb-ft at 2,500 rpm is exceptional. On ethanol, the motor produces an additional 15 to 30 hp and 25 to 35 lb-ft of torque throughout the entire operating range.