Stock displacement is so '80s. The days of miniscule and primitive displacement gains through offset crank grinding are a more distant memory than Fritz Mondale's presidential campaign. Due to the rise of affordable aftermarket stroker crankshafts in the last decade, cubic inches are cheaper than ever. Concurrently, cylinder head technology has been forced to keep pace with the demands of incessantly swelling displacement, and horsepower has proliferated to obscene proportions. As our hobby collectively frolics in a golden age of horsepower, no single engine component, save for the cylinder head, has advanced the cause as much as the modern crankshaft. So unless your sanctioning body forbids it, if you're building a motor, you're probably in the market for a stroker crank.

Nonetheless, the choices are many, and not all cranks are created equal. Should you settle for a cast-steel piece, or step up to a forging? What's the difference among 5140, 4130, and 4340 steel? Do you really need to step up to forged in all instances? Does billet live up to its hallowed reputation? How do you distinguish between marketing hype and actual product quality? And most importantly, what's the right crankshaft for your application? Fortunately, the misinformation stops here. We've networked with the top crankshaft manufacturers in the country to definitively answer all the aforementioned questions, including insight into metallurgy and various manufacturing techniques. Don't panic if you're into less mainstream makes, because we have Buicks, Olds, and Pontiacs covered as well. While some of the information won't jive with common public perception, the facts aren't always easy to digest. We have the truth, but can you handle it?

Cast vs. Forged vs. Billet

Manufacturing techniques play a substantial role in the ultimate strength of a crankshaft. Casting and forging are the two most common manufacturing methods, and each has benefits and drawbacks. Cast cranks start life as liquid iron or steel, and are poured into a mold. This allows the raw casting to closely resemble its final shape, which reduces the amount of final machining. Combined with the fact that the equipment necessary to produce castings is relatively inexpensive, it's obvious why cast cranks are the predominant choice of the OEs. Aftermarket cast cranks offer significant improvements in strength, and can be had for as little as $200.

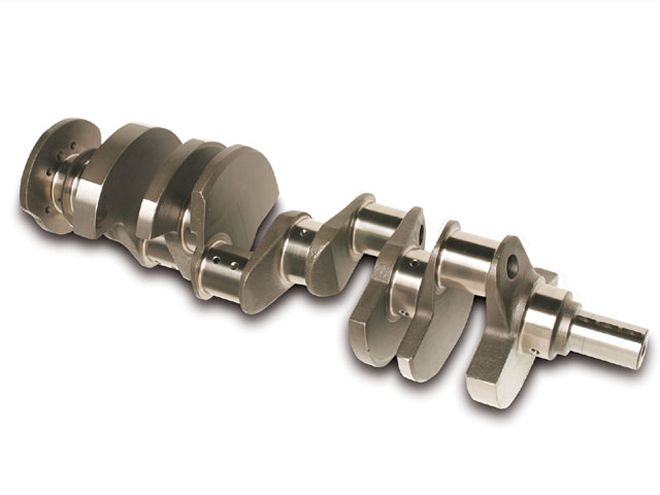

Weighing in at a scant 66 lbs, Eagle's lightweight 4340 forged cranks for big-block Chevys are rated at 1,500 hp. They're available in 4.000- and 4.250-inch strokes, and can be had with smaller 2.100-inch rod journals for those looking to minimize friction.

Weighing in at a scant 66 lbs, Eagle's lightweight 4340 forged cranks for big-block Chevys are rated at 1,500 hp. They're available in 4.000- and 4.250-inch strokes, and can be had with smaller 2.100-inch rod journals for those looking to minimize friction.

In contrast, the forging process requires heavy duty presses and more extensive final machining operations. Forging involves heating up a cylindrical slug of metal to a molten state, then pounding it into shape with presses and dies. It is this compressing action that creates an inherently stronger end product over a casting. "In a casting, the grain structure looks like beach sand," explains Tom Lieb of Scat. "In a forging, the force of the press compresses the grain together so it becomes one uniform grain flow. As the space between the molecules is compressed, each molecule is forced to 'hold hands' with the next molecule." Compared to a cast crank, the drawback of a forging is cost. The heavy duty hydraulic presses used in the forging process are extremely expensive, which leads to a costlier product. Expect prices to start at $500 for more popular engine makes.

Think of billet cranks as an offshoot of forged cranks. Like a forging, a billet crank starts out as a large cylindrical ingot of steel. However, while a forged crank is compressed during the forging process, the steel ingot used in a billet crank is already forged, albeit not quite as compressed as in a forged crank. The key difference between the two is how the ingots are shaped into cranks. "The metal bar used to make a forged 4.000-inch SBC crank measures about 4.75-inches in diameter and the crank's total width ends up being 6.75 inches when the forging process is complete," Lieb says. "The metal bar used in a billet crank of the same stroke is much larger, at roughly 8 inches, weighing 350 lbs compared to 150 lbs in a forged crank. Instead of twisting and pounding the metal in different directions as with a forging, a billet crank is made by whittling away the metal so the grain structure runs parallel throughout the entire length of the crank." Due to the increase in materials and labor over a forged crank, billet cranks are the most expensive of them all. Custom one-offs carry price tags in the neighborhood of $3,000. As for whether a billet crank is stronger than a forging, because there is no consensus in the industry, the various manufacturers will duke it out later in the story and we'll let you make the call.

Strength

Before delving into the specifics of metallurgy, there are strength characteristics universal to all castings and forgings worth nothing. In a lab, metal is tested for strength by pulling a one-inch round bar apart until it breaks. Tensile strength relates to the amount of force required to start stretching the bar. Yield strength describes the force needed to continue to pull the bar apart. The difference between tensile and yield strength between castings and forgings is significant. "With a casting, you only have to reduce the cross section of the bar by six percent before it breaks," Lieb explains. "With a forging, the cross section can be reduced by 20 percent before the bar breaks."

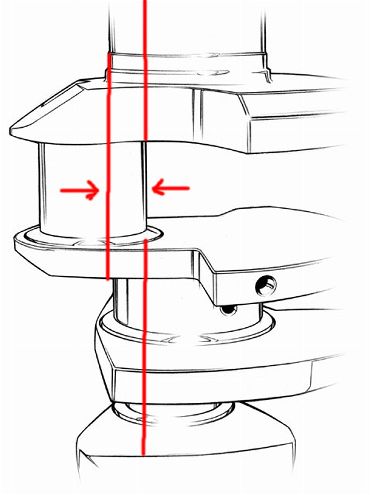

Crank overlap is simply the portions of the rod and main journals that overlap each other. Stroker and off-set ground cranks move the rod journal farther away from the main journals, thereby reducing overlap. Reducing the diameters of either the rod or main journals decreases parasitic friction, but compromises strength.

Crank overlap is simply the portions of the rod and main journals that overlap each other. Stroker and off-set ground cranks move the rod journal farther away from the main journals, thereby reducing overlap. Reducing the diameters of either the rod or main journals decreases parasitic friction, but compromises strength.

Metallurgy

As an alloy consisting primarily of iron, the small quantities of metal added to that iron are what determines the differences in strength among various grades of steel. A set of standards established by the American Society for Metals (ASM) determines the content of metal grades in addition to their nomenclature. "For entry-level cast cranks, increasing the carbon content in proportion to iron improves strength," says Alan Davis of Eagle Specialty Products. The most basic cranks are cast iron, which typically have a tensile strength of about 70,000 to 80,000 psi. Slightly increasing the carbon content of iron produces nodular iron, resulting in a tensile strength of roughly 95,000 psi. Both materials are used extensively by the OEs, but won't quite cut it for more serious aftermarket stroker crank applications. Commonly used in entry-level aftermarket crankshafts, cast steel has greater carbon content than nodular iron, and a tensile strength of about 105,000 psi. "In a typical small-block, a cast-steel crank can easily handle 500 hp. Although we've seen them pushed to much high power levels, we generally recommend a forged crank at anything above that power level."

Moving up the totem pole, factory forged cranks are made from steel alloys such as 1010, 1045, and 1053. While their tensile strengths are similar to that of a cast-steel crank, their elongation rating is more than three times greater. This translates to a far less brittle material. Nonetheless, they're a far cry from the ultimate durability of an aftermarket steel crank. "Factory forged steel cranks have high carbon content, but they lack the chrome and nickel content of the premium alloys used in aftermarket cranks," Scat's Lieb explains. "In these types of alloys, chrome and nickel are what make them stronger. There are other materials involved, but they are used to make sure everything mixes together properly and don't impact strength."

The most basic aftermarket-grade steel is 5140, which boasts a tensile strength of about 115,000 psi. This material used to be-and to some extent still is-an excellent choice for racers on a budget, but is less common than in years past due to the increasing affordability of premium alloy cranks. These include 4130 and 4340 forgings, which have tensile strength ratings of approximately 125,000 psi and 145,000 psi, respectively. Engine builders and crankshaft manufacturers universally accept 4340 as the ideal alloy for strength and durability. Because aftermarket 4340 cranks start between $500 and $600 for common engine platforms, the lesser grades of steel are dwindling in popularity. "We have plenty of customers pushing 1,500 hp through a 4340 forged steel crank," Eagle's Davis says.

The Ford FE maniacs at Survival Motorsports have just unveiled a forged 4340 crank in a 4.250-inch stroke for $1,150. For those on a tighter budget, Scat offers 3.980-, 4.125-, and 4.250-inch cast-steel cranks starting at $700. Survival has put over 750 hp through Scat cast cranks without any hiccups.

The Ford FE maniacs at Survival Motorsports have just unveiled a forged 4340 crank in a 4.250-inch stroke for $1,150. For those on a tighter budget, Scat offers 3.980-, 4.125-, and 4.250-inch cast-steel cranks starting at $700. Survival has put over 750 hp through Scat cast cranks without any hiccups.

Twist vs. Non-Twist Forging

Forged cranks are pressed into place on a die, but there are two different techniques used to accomplish this. The simplest method is to forge one of the crank throws at a time in a flat forging die. The crank is then twisted, and the die forges the next throw. Conversely, in a non-twist forging, all four throws are forged simultaneously, which requires a more complex die. Non-twist forgings are said to reduce internal crankshaft stresses during the manufacturing process, but not everyone's buying it. "If all variables are controlled properly during the forging process, there's little if any difference between twist and non-twist forgings," opines James Humphries of Lunati. "Most aftermarket cranks these days are non-twist forged anyways, so there's no sense in arguing either way. It's more of a marketing thing."

Heat Treating

In addition to materials, and casting or forging techniques, heat treating can greatly impact the strength of a crankshaft. Nitriding is the most prevalent method of heat treating used in aftermarket cranks, where ionized nitrogen is vacuum deposited onto the crank surface in an oven. By penetrating .010 to .012 inch into the metal surface and changing the microstructure of the steel, surface hardness is doubled from 30 to 60 on the Rockwell scale, and fatigue life is increased by 25 percent. The OEs usually favor induction hardening over nitriding, which results in deeper penetration into the metal surface (.050 to .060 inch). This process uses a magnetic field to heat the surface. "There are pros and cons of both methods, but nitriding is most common in the aftermarket," explains Humphries. "Induction hardening is more localized, whereas nitriding treats the entire crank at once. However, induction hardening penetrates more deeply, which enables turning down the journals once or twice during rebuilds before having to heat treat the crank again."

Knife-Edging

Does knife-edging a crank's counterweights really reduce windage and increase power? Not everyone thinks so. "Knife-edging was developed more for ease of balancing than power, and won't do much on a street motor," explains Callies' Dwayne Boes. "Like a snow plow, oil hits a knife edge and gets thrown all over the place when it should ideally land on the nose and flow off to the side. A bull-nose rounded leading edge is the most efficient, like the bow of a ship."

An area of the crank notorious for failure is where the rod journal meets the counterweight. Some contend that the forging process exacerbates this condition because it is the area where the grain flow is stretched and contorted.

An area of the crank notorious for failure is where the rod journal meets the counterweight. Some contend that the forging process exacerbates this condition because it is the area where the grain flow is stretched and contorted.

Overlap

Just as the term implies, journal overlap is simply how much of a crank's main and rod journal diameters overlap each other. As stroke is increased, moving the rod journals farther away from the main journals reduces overlap and compromises strength and durability. Likewise, smaller rod and main journals reduce bearing speed and friction, but also reduce overlap. "The reason why GM increased the size of the mains to 2.65 inches on a 400 SBC compared to 2.45 inches on a 350 was to maintain journal overlap with the longer 3.75-inch stroke," explains Judson Massingill of the School of Automotive Machinists.

Billet Or Forged?

Although we've clearly outlined the hierarchy of the various grades of castings and forgings, we haven't declared whether billet cranks or their forged counterparts offer the ultimate in strength. Quite frankly, we don't know the answer, and we won't even attempt to make an educated guess. There are compelling arguments for each from a host of credible sources, so we'll print their words, and let you decide.

Alan Davis Of Eagle:

"People think billet is stronger than a forging, but that's not true. Billet got that reputation from back when forged aftermarket cranks weren't readily available, and billet was the only way to go for a performance crank. With a forged crank, the forging process creates an interwoven grain structure. With a billet crank, the grain structure just runs parallel with the crank. Billet is a better option if you need a custom one-off crank since it doesn't require expensive tooling equipment. On the other hand, the 200-ton presses required for forgings cost at least six figures, so they're more suited for large production runs."

When looking at a cast (left) and forged (right) crank next to each other, it's obvious why the forging process fetches a higher price tag. The cast crank's rough surface shows very little finishing machine work is required, as the casting process yields a shape that closely resembles the end product. The forged crank's smoother appearance reflects more extensive machining operations required after it leaves the forging die.

When looking at a cast (left) and forged (right) crank next to each other, it's obvious why the forging process fetches a higher price tag. The cast crank's rough surface shows very little finishing machine work is required, as the casting process yields a shape that closely resembles the end product. The forged crank's smoother appearance reflects more extensive machining operations required after it leaves the forging die.

Tom Lieb Of Scat:

"A forging is not as strong as billet because the forging process stretches and shears the grain structure. A forging starts out as round bar of metal and gets twisted and turned to make the rod throws. What used to be centerline of the bar is now offset, and the grains get stretched, traumatized, and weakened, although some sections of it are substantially stronger than in a casting. With billet, there are no stress riser areas because the grain structure runs parallel to the length of the entire crank. Forgings are stronger than billet in bolts and axles because the metal isn't being stretched and sheared. There isn't a single Top Fuel, Funny Car, Nextel Cup, or F1 team that uses forged cranks, so you have to ask yourself why."

Dwayne Boes Of Callies

"If the exact same material is used for both, a forging is stronger than billet because the grain flow is upset and relocated. However, it's much easier to get special alloys in a billet material."

Judson Massingill Of The SAM:

"Up to 600 to 700 hp, forgings are every bit as good as billet cranks, given adequate journal overlap. However, when you start reducing the overlap with long strokes and small rod journals to reduce bearing speed, billet comes out on top. In our motors, billet lets us get away with less journal overlap."

Domestic versus overseas is a hot topic, but the increased competition has definitely resulted in lower pricing for consumers. While best known for its premium cranks, Lunati recently introduced its Sledgehammer line of entry-level 4340 cranks. They're 100-percent U.S. made, and this big-block Chevy unit retails for $860 from Summit.

Domestic versus overseas is a hot topic, but the increased competition has definitely resulted in lower pricing for consumers. While best known for its premium cranks, Lunati recently introduced its Sledgehammer line of entry-level 4340 cranks. They're 100-percent U.S. made, and this big-block Chevy unit retails for $860 from Summit.

Alternative Makes

Traditionally, the aftermarket has neglected the Buick, Olds, and Pontiac camps. When it comes to cranks, this still holds true, but to a lesser degree. The efforts of engine platform-specific diehards have yielded a specialty market of just-released steel cranks in some markets. In others, there are specialists for each engine family that can modify factory cranks to get you the extra displacement you crave. Of course, companies like Winberg, Bryant, and Moldex will make a custom crank out of billet for any engine, but we'll assume most hot rodders are working with a real-world budget.

Pontiac

It's been 30 years in the making, but Pontiac enthusiasts now have both aftermarket cast and forged cranks at their disposal. In the late '90s, Butler Performance teamed up with Eagle to produce the first aftermarket Pontiac crank, a cast-steel 4.250-inch unit for 3-inch main 326/350/389/400 blocks. Just this year, Butler Performance released 4340 forged cranks in 4.000-, 4.250-, and 4.500-inch strokes for 3-inch main blocks. The company also offers 4.000- and 4.250-inch 4340 cranks for 421/428/455 blocks with 3.25-inch mains. "Before we released these cranks, the only option was offset grinding a stock crank, which netted an extra 4 to 5 ci," David Butler says. "Forged cranks are so reasonably priced these days, there's no reason to even bother with a stock piece."

These days, it's no longer accurate to dub Mopars as "alternative makes." Companies such as Eagle and 440 Source have a full line of cast and forged cranks for Chrysler LA, B, and RB motors. Thanks to the big-block Chrysler's massive bore spacing, the modest 4.150-inch stroke of this forged Eagle crank nets 500 inches out of a factory 400 block.

These days, it's no longer accurate to dub Mopars as "alternative makes." Companies such as Eagle and 440 Source have a full line of cast and forged cranks for Chrysler LA, B, and RB motors. Thanks to the big-block Chrysler's massive bore spacing, the modest 4.150-inch stroke of this forged Eagle crank nets 500 inches out of a factory 400 block.

Buick

Unfortunately, the aftermarket hasn't stepped up with a new Buick crank design, but there are still options for increasing displacement by a good margin. According to Buick expert Mike Phillips of Automotive Machine, all 400, 430, and 455 Buicks have the same crankshaft. "Up to '74, the cranks have an 'N' cast into them, which some people think means nodular," he explains. "These things have massive 3.25-inch mains, so you can put 600 hp through them without a problem, and with a 3.900-inch stroke, Buick cranks have more overlap than many big-block Chevys." Thanks to that overlap, they can be offset ground up to 4.15 inches. "With a crank offset ground to 4.150 inches in a 455, you end up with 494 inches, but I think it weakens the crank considerably. It's better to offset grind the crank to 4 inches, in which case you can still externally balance the motor."

Oldsmobile

In the walk of big-block Oldsmobiles, there's the 425 and the 455. Noted Olds engine builder Dick Miller says that all 425 motors came equipped with forged steel cranks from the factory, while the number of 455s with steel cranks are less than 100. The 455 is the most common engine amongst Olds buffs, which features a 4.250-inch stroke. "Some 455 cranks had 'N' cast into them and others had 'CN' cast into them," Miller says. "The 'CN' crank is the stronger of the two." Although Eagle makes a replacement cast-steel crank rated at 700 hp, the factory piece is very stout. "The stock 455 crank can be offset ground to 4.500 inches, which equates to 496 ci. These cranks can handle up to 650 hp."

Taking advantage of the 385-series big-block Ford's towering deck height, Eagle and SCAT offer cast-steel cranks with strokes ranging from 3.850 inches to a jaw-dropping 4.850 inches. This rotating assembly is from SCAT

Taking advantage of the 385-series big-block Ford's towering deck height, Eagle and SCAT offer cast-steel cranks with strokes ranging from 3.850 inches to a jaw-dropping 4.850 inches. This rotating assembly is from SCAT

Ford FE

Never as mainstream as the Windsor or 385-series big-block, the Ford FE has been widely ignored by the aftermarket until now. Scat and Eagle both offer cast-steel cranks with strokes ranging from 3.980 to 4.250 inches. "The 390 is the most popular FE motor, and almost all of them had cast cranks," explains FE engine guru Barry Rabotnick of Survival Motorsports. "People used to get forged FE truck cranks and cut the nose down to fit into a car block or offset grind stock cranks, but there's no need to do that anymore. I've put over 750 hp through a cast Scat crank without any problems." Additionally, Survival Motorsports offers its own forged 4340 crank ina 4.250-inch stroke.

If All Else Fails

If you need something done to a crank that no one else can peform [or if you need a nicely-prepped OE crank for a fun street driver-ed.] give Adney Brown of Performance Crankshaft a call. His specialty is repairing and modifying factory and aftermarket cranks to standards few others can touch. "For applications where aftermarket cranks aren't available, we track down old forgings and put whatever length stroke the customer desires," Adney explains. In addition to simple services, such as fixing up burned journals, Adney can lighten a crank, alter snout diameters, and weld up different flanges. "Don't consider it junk or give up your search until you call us first."

Hierarchy Of Metals

Since the American Society for Metals allows for some leeway within each grade of metal, the tensile strength ratings listed in this chart and elsewhere in the story are approximate, not exact figures. Nevertheless, they do adequately allow comparison among the strengths of different metal grades. While these represent just a small portion of all the steel alloys established by the ASM, they are the ones most common in automotive applications. Here's a quick rundown: