We all have Pontiac dreams. Why? Because we are Pontiac people. Simple enough. Some of us desire to build a Best of Show car, others covet the Quickest-Pontiac-on-the-Track title and still more hope to turn the love for the hobby into a vocation.

What separates us is how we actively pursue our dream to the point of making it a reality. Enter Gary Cygan and his son Gary Jr. of Renfrew, Pennsylvania. The elder Cygan has had a good, solid job for many years but has also desired something more from his hobby of racing Pontiacs (he has a '70 GTO that you have probably seen at major Pontiac races for years) and building engines.

Gary Cygan mans the controls of the Stuska dyno. The unit is all computerized; even the gauges and various readouts are on-screen. (Note: A finicky thermocoupler caused an incorrect water temperature readout on-screen, so the temperature was read from the mechanical gauge on the dyno's water tank.)

Gary Cygan mans the controls of the Stuska dyno. The unit is all computerized; even the gauges and various readouts are on-screen. (Note: A finicky thermocoupler caused an incorrect water temperature readout on-screen, so the temperature was read from the mechanical gauge on the dyno's water tank.)

He wanted to take the next step and delve into the business end of Pontiacs but, like anyone else who has a steady income and a family to support, the thought of the initial monetary investment for an unproven venture is enough to promote night sweats. With the uncertainty of an upcoming contract at his day job, the rationale regarding entering the arena of the self-employed became a now-or-possibly-never proposition. So Gary bought a Stuska dyno and its accompanying software, and constructed a dyno cell and a building on his property to house it. He studied up on operating the dyno and practiced on his own engines. In a short time, he acquired some customers for his dyno service, hence Cygan Speed Engineering was born.

Gary first approached me at the 2006 GTOAA Nationals. He told me about the 600+hp 468 Pontiac engine that he and his son had spec'd out and were building for Gary Jr.'s '81 street/strip Trans Am. While it sounded intriguing, I speak to many people-at events and on the phone all the time-that have very big plans, but few actually follow through to the point of warranting a story. This time it was different. I was contacted by Gary again in February 2007, and he told me the engine was built and was on the dyno. I headed out to Renfrew in March, and the results of that day are presented here.

Consider this a "reader build-up" if you so choose, given the relatively short tenure of this business venture. However, Cygan Speed Engineering is open for dyno business. Gary plans to begin building Pontiac engines for customers as well. Follow along as we flog this 400 turned 468 on the dyno and then rip it apart to show you what's inside.

On The Dyno

Cygan Speed Engineering's Stuska model XS-211 TrackMaster LC dyno can handle up to 1,600 hp and employs Stuska's own PowerPro software. The dyno features an automatic load control using a variable frequency drive on the pump, is equipped with a weather station and will read up to 12 thermocouples.

With the Pontiac engine, the inertia factor for the dyno was set to 0.33, as recommended by Stuska. For comparison, 0.24-0.27 would be set for a Small-Block Chevy. A higher than recommended inertia setting makes for inflated power numbers.

We made a bunch of pulls from 3,000 to 6,500 rpm on the dyno that day, stabilizing oil temperature to 175 degrees each time, and the best one produced 644 hp at 6,300 rpm and 622 lb-ft of torque at 4,900 rpm on 93-octane fuel. The engine has seen 650+ hp but not on this day. Other pulls ranged from the high 630s to the low 640s. Average horsepower through the 644-horse pull was 512 and average torque was 564 lb/ft. (All of these numbers have been corrected using a factor of 1.03.) The delta elapsed time, which gives an idea of the rate of rev for the engine, was 5.10 seconds for the pull, and rpm/second for the pull was 686.3.

The engine did go a bit lean at around 4,900 rpm, which is normal at peak torque, but Gary plans to tune with the air bleeds in the carb to see if he can squeeze more power out of it.

Cylinder Head Flow In CFMLiftIntakeExhaust0.{{{100}}}75.6{{{62}}}.50.{{{200}}}148.3118.70.{{{300}}}210.1174.00.400263.3213.90.500304.3234.40.{{{600}}}{{{323}}}.2243.30.700332.8246.4 Speed Pro file to fit 1/16-inch rings and a 3/16 oil ring were used on the Ross pistons. The compression height of the piston is 1.290 inches, thanks to the longer-than-stock 6.800-inch rods (stock is 6.625 inches). Some engine builders like long rods because of increased dwell time at top dead center, less angularity of the rod (which results in less side loading), quicker building cylinder pressure and the piston can be made shorter, therefore lighter. When using the Eagle crank, it also becomes a matter of economics. With only the 2.200-inch rod journal available, the 6.800-inch rod is simply a big block Chevy piece, which is affordable. In order to get a 6.625-inch rod with 2.200 big end, you have to go custom and that gets expensive.

Speed Pro file to fit 1/16-inch rings and a 3/16 oil ring were used on the Ross pistons. The compression height of the piston is 1.290 inches, thanks to the longer-than-stock 6.800-inch rods (stock is 6.625 inches). Some engine builders like long rods because of increased dwell time at top dead center, less angularity of the rod (which results in less side loading), quicker building cylinder pressure and the piston can be made shorter, therefore lighter. When using the Eagle crank, it also becomes a matter of economics. With only the 2.200-inch rod journal available, the 6.800-inch rod is simply a big block Chevy piece, which is affordable. In order to get a 6.625-inch rod with 2.200 big end, you have to go custom and that gets expensive.

HPP Engine Buildup Worksheet

Bottom End

Cam

This Bullet solid roller cam features duration at 0.050 of 263/271-degrees and 0.700/0.700 lift.

This Bullet solid roller cam features duration at 0.050 of 263/271-degrees and 0.700/0.700 lift.

Induction

Oiling System

For those of you who just have to see clean parts, here is the block freshly machined prior to assembly. The front of the block on the passenger side had to be slightly clearanced for the crank counterweight. (Photo by Gary Cygan Jr.)

For those of you who just have to see clean parts, here is the block freshly machined prior to assembly. The front of the block on the passenger side had to be slightly clearanced for the crank counterweight. (Photo by Gary Cygan Jr.)

Heads

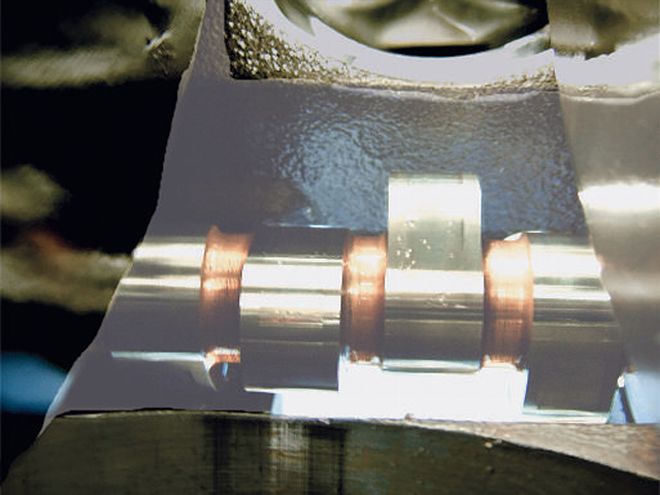

Here's the 3.00-inch main 4.250-inch stroke Eagle crank, prior to installation. (Photo by Gary Cygan Jr.)

Here's the 3.00-inch main 4.250-inch stroke Eagle crank, prior to installation. (Photo by Gary Cygan Jr.)

Ignition

Exhaust

Gaskets

Ancillary Components