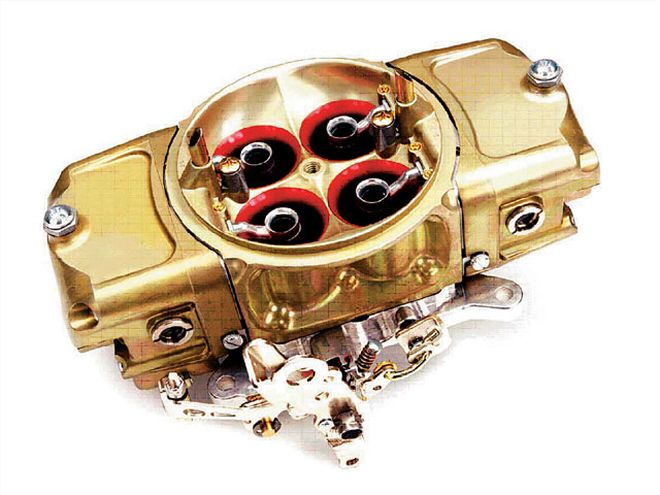

Although carburetor specialist Doug Schriefer works exclusively with Barry Grant's Demon carburetors, his tips for advanced tuning will work with just about any brand.

Although carburetor specialist Doug Schriefer works exclusively with Barry Grant's Demon carburetors, his tips for advanced tuning will work with just about any brand.

Doug Schriefer, Barry Grant's tech specialist for racing carburetors, would like you to know that-much as many stock car racers may think-carburetor tuning is not voodoo. It is true that many racers aren't afraid to make suspension changes during practice on race night, but if the carb needs more than a jet change, it's going back to the engine builder.

It doesn't have to be that way. It's no secret that race engines perform their best with a well-tuned carburetor, but there is more you can do than simply bolt it up and cross your fingers. Whether you are the driver, the owner, or just the guy who puts air in the tires, here are Schriefer's guidelines for making yourself a top-flight carburetor tuner.

Before we can get into the secrets of making power, Schriefer says it is important to make sure we are all on the same page when it comes to exactly what we want. As stock car racers, we expect three things from the carburetor. First, it has to properly mix the fuel in the form of tiny droplets into the airstream entering the engine. This is called emulsification. Second, it has to control the engine rpm, and finally, it has to properly control the air/fuel ratio.

All three aspects affect each other. For oval track racers, part-throttle operation is of critical importance. You demand a crisp throttle response on turn exit with a nice, smooth feel and no stumbling. And then, of course, you also want maximum power from the engine when you hold the throttle to the floor. Tuning for one is relatively easy-tuning for both situations is more challenging. Finally, add in the fact that at some point during a race you may spin and stall your car, or you may have to kill the engine during a red-flag period. In either case, you must be able to re-fire a hot engine. If your carburetor doesn't hold idle at a consistent rpm to allow you to re-fire and return to the action, your night is over.

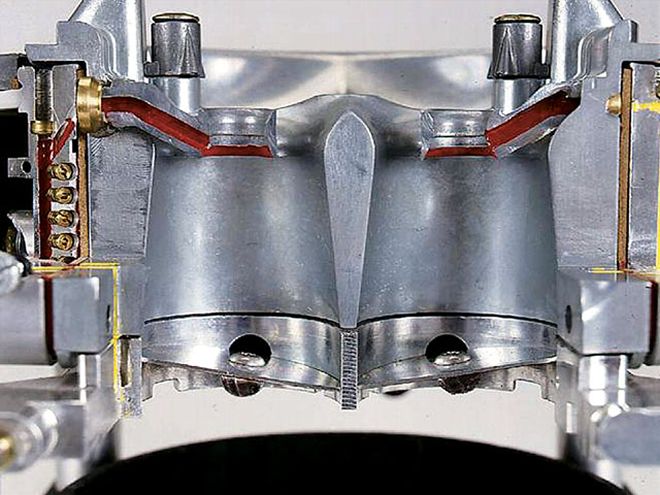

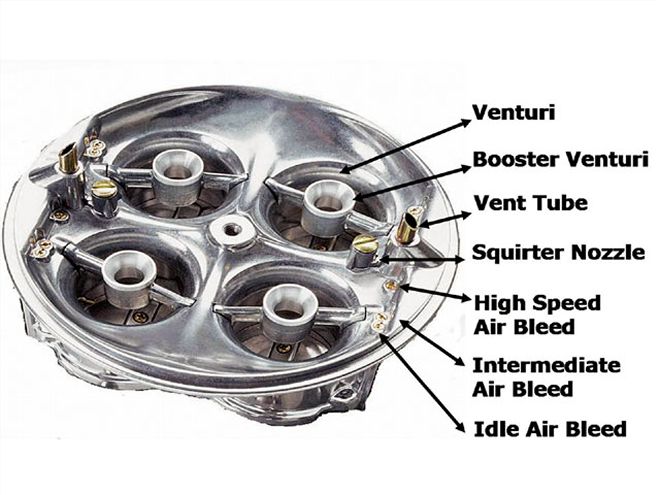

The faster air flows through the carburetor, the better the carb can emulsify the fuel into the air. The shape of the venturis increases the airflow by forcing it to flow through a smaller area, and the boosters positioned inside the neck of each venturi speeds the air up even more.

The faster air flows through the carburetor, the better the carb can emulsify the fuel into the air. The shape of the venturis increases the airflow by forcing it to flow through a smaller area, and the boosters positioned inside the neck of each venturi speeds the air up even more.

OK, the title of this article is "Advanced Carburetor Tuning," but it is worth taking a minute to discuss exactly how a carb works. Simply put, Schriefer says any carburetor works on pressure differential. For our example, we are obviously only talking about naturally aspirated engines. The pistons moving downward in the cylinder bore create low pressure in the manifold plenum and inside the carburetor. The higher atmospheric pressure (14.7 lb/in at sea level) causes air to pass through the carburetor to fill the low pressure inside the plenum. The low pressure also causes fuel to pass through the carburetor and mix with the air flowing through the venturis.

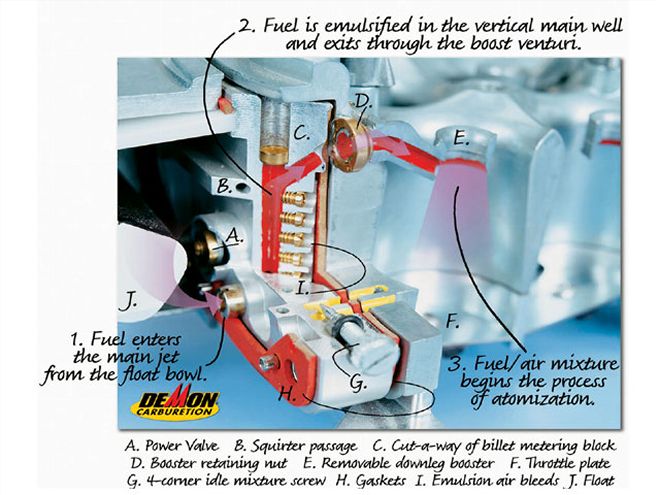

"As the air travels through the carburetor's venturi, the velocity increases and the pressure decreases," Schriefer adds. "The decrease in pressure allows the fuel to be drawn easier from the fuel bowl through the carburetor's circuits. The increase in air velocity aids in the atomization of the fuel being drawn into the engine. The size and shape of the venturi will affect how much the air velocity increases and the pressure decreases.

"Most carburetors have some type of booster venturi installed within the main venturi to increase the vacuum signal and help draw the fuel from the bowl more efficiently," says Schriefer. The venturi adds velocity to the airflow through the air filter, and the booster increases that velocity even further. Essentially, the booster is a venturi inside the venturi. Since the final speed increase takes place inside the booster, this is the area where the fuel from the main circuit is added. Keep in mind that these are not idle circuits or boosters that activate for a short time when the carburetor reaches wide-open throttle (WOT).

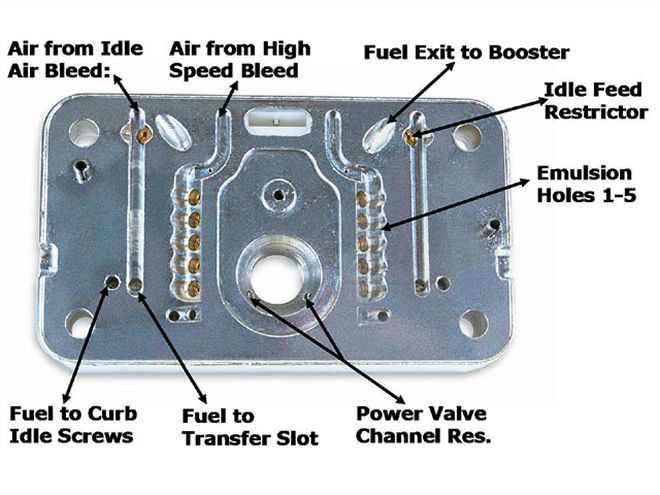

You aren't limited to just jet changes. There are several points along the fuel's path (from the float bowls to the point that it mixes with the air in the booster) that you can use to influence the air/fuel mixture, from idle all the way to WOT.

You aren't limited to just jet changes. There are several points along the fuel's path (from the float bowls to the point that it mixes with the air in the booster) that you can use to influence the air/fuel mixture, from idle all the way to WOT.

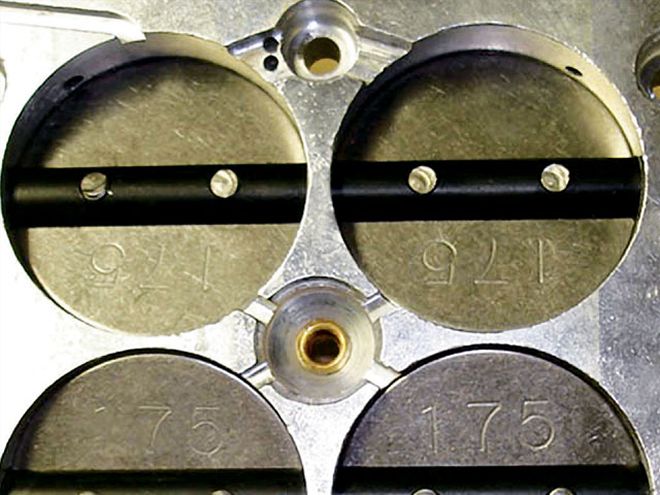

Different booster designs have varying amounts of effectiveness. Consequently, changing the type of booster affects how much fuel can be drawn through it, and also how much air can be drawn through the carburetor. The most common booster style for street, or stock, carburetors is the "straight-leg" style, which uses a bar across the center of the booster to introduce fuel to the air. This works, but the bar greatly disrupts airflow.

A "downleg" booster is easily recognizable because the leg of the booster is on an angle. It eliminates the bar and introduces fuel to the air by a bleed hole on one side of the booster. While the elimination of the bar enhances the airflow, this type of booster uses a less efficient single bleed hole to get the fuel to the air.

Finally, the "annular" booster is the most effective style. Like a downleg booster, it eliminates the bar across the center of the booster's venturi, thus enhancing the airflow. However, it introduces fuel to the air at several points around the booster rather than a single bleed hole. In addition, it uses a channel inside the booster's venturi. The net result is a much better and more consistent air/fuel flow that helps to achieve the goal of creating as much air velocity, not necessarily volume, through the carburetor as possible.

The higher air speed atomizes the fuel better, and since small droplets of fuel burn faster than large droplets of fuel, engine performance is improved. This is why you don't always want to slap the largest carburetor you can buy on your engine when you have an open carburetor rule. A very large carburetor can help move more air into the engine and potentially produce better peak power numbers, but it will not boost the air's velocity as well as an intelligently sized carburetor, and overall performance-especially part-throttle response-will suffer.

Savvy engine builders have for years been using clues such as burn patterns on the spark plugs and even the color at the exhaust pipe exits to tell them how the carburetor should be tuned. But if you don't have 20 years of engine-building experience, you can rely on testing and diagnostic tools.

To get good results, you don't have to invest hundreds of thousands of dollars in wet-flow benches and other exotic pieces of equipment, such as those Schriefer has available at Barry Grant's headquarters in Georgia and its R&D facility in North Carolina. One invaluable tool you should consider is a portable air/fuel meter, several of which have recently shown up on the market at very affordable prices. Both F.A.S.T. and Innovate offer small, portable units that are perfect for racers, as they are easily installed for testing and removed again for race day. A good air/fuel meter hooks up with sensors in the exhaust headers and will tell you your air/fuel ratio at every point along your engine's rpm range. Most record readings and play them back later. Some hook up to a laptop and allow you to store your findings. For more information on tuning with a F.A.S.T. air/fuel meter, check out "Better Measure" (Apr. '07 Circle Track).

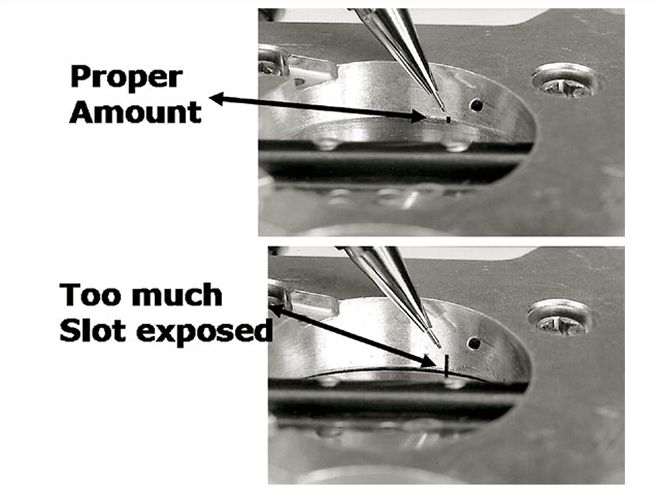

Schriefer says the best place to start when tuning a carburetor is with the idle settings. "The first key to getting an engine to idle and drive properly is butterfly positioning. If the butterflies are open too far, they will expose too much of the transfer slot," he says. "This will cause the engine to draw fuel from the slot, giving poor throttle response, acceleration, fuel economy, and performance.

"I always find it amazing to watch a race and see flames shoot out of the exhaust when the driver is off the throttle. Ninety-nine percent of the time, with a carbureted car, it is because the transfer slots are open too far."

Every motor is different, so there is no single setting for the butterflies and transfer slots to achieve optimum idle. Generally, you only want approximately 0.020 inch of the transfer slots exposed. This means that the area of the slots you can see basically forms a square. That being said, different cam profiles mean engines will require different amounts of air to idle properly. Proper idle speed, while usually between 800 and 1,200 rpm, is really the point at which your engine will idle reliably and crank consistently. But getting your engine to optimum idle isn't just a matter of adjusting the butterflies to allow enough air through the carburetor when the driver has his foot off of the throttle. For example, if you are using a distributor with a mechanical advance mechanism, you will need to adjust the timing at idle to achieve a good, steady idle. When doing this, you don't want your timing at full advance to change. Consequently, you will have to work with your advance mechanism to get both the idle timing and full-advance timing constant.

The most common method for carb tuners to tune idle speed is to drill small holes in the butterflies to allow air to pass while still keeping the correct amount of the transfer slots exposed. The problem with this is once the hole is drilled, it is there forever. Putting this carburetor on a new engine can prove to be a problem. The only tuning options you have are to drill the hole bigger or pony up for a new set of butterflies if you wish to go smaller.

Schriefer prefers instead to install a jet in the center of the baseplate. It achieves the same goal as drilling, but changing the amount of airflow when the butterflies are closed is now as simple as unscrewing the existing jet and installing one with either a larger or smaller hole. Not only is this simpler, it is also a very easy change to make at the racetrack, unlike drilling the butterflies. Barry Grant's Race Demon carburetors are manufactured with this as a standard feature. However, it is possible to add a jet in the center of the baseplate for most other four-barrel carburetors. But it is slightly more involved than simply drilling and tapping a hole in the center of the baseplate. You must also cut grooves in the baseplate from each of the venturis to the hole because this area of the baseplate is normally sealed off from the airflow in the venturis. Although it certainly can be done, this is probably the type of project best reserved for a carb specialist.

Once the butterflies are properly set, you can move on to the idle mixture. Schriefer has four tips for working with the idle mixture screws:

Different engine packages require different amounts of air to idle properly. On race engines that require more air, you can affect idle speed by setting the butterflies so that they do not fully close, but that exposes too much of the transfer slots, which will hurt performance on the racetrack.

Different engine packages require different amounts of air to idle properly. On race engines that require more air, you can affect idle speed by setting the butterflies so that they do not fully close, but that exposes too much of the transfer slots, which will hurt performance on the racetrack.

1. Take your time; the engine must draw the fuel through the carburetor.

2. Adjust the mixture at the temperature you're going to run the engine. In other words, make sure the engine is up to typical race-operating temp before you start changing anything. Adjusting the mixture at 160 degrees when your typical race temp is 190 will result in tuning right into a rich condition. That's a waste of fuel and a loss of power.

3. Don't be afraid to go through the mixture screws multiple times. Record each adjustment and note the results. This is the old "measure twice, cut once" principle.

4. Remember your goal: get the engine to idle as high as possible with the butterflies as closed as possible.

If you own an air/fuel meter, setting the idle screws is simple: just adjust until you get between a 13.5:1 and a 14:1 reading, which is slightly rich but still safe. If you don't have the luxury of a meter, you should adjust the screws until you have a steady idle and the engine doesn't stumble when the driver picks up the throttle.

And finally, here's one tip to help keep your engine safe and healthy. Schriefer says that if you question any adjustment you've made, always ensure the air/fuel mixture is too rich rather than too lean. A lean condition can quickly burn pistons, but a rich condition will only hurt power. Obviously, this tip is applicable just as you begin the tuning phase. If you start rich and work to optimum, you won't risk damaging your motor.

Instead of adjusting idle speed by changing the position of the butterflies, you can either drill small holes in the butterflies to allow more air through the carburetor when the butterflies are closed, or you can install a jet in the baseplate, as Schriefer has here. The jet has the advantage over holes in the butterflies because it allows easy and quick adjustments at the racetrack.

Instead of adjusting idle speed by changing the position of the butterflies, you can either drill small holes in the butterflies to allow more air through the carburetor when the butterflies are closed, or you can install a jet in the baseplate, as Schriefer has here. The jet has the advantage over holes in the butterflies because it allows easy and quick adjustments at the racetrack.

The main jet is used to control the amount of air flowing through the carburetor's main circuit, while the air bleeds control the shape of the fuel curve. To get a better idea of how these components function, Schriefer says to imagine a funnel. The small end of the funnel represents fuel flow at idle, and the large end of the funnel represents fuel flow at WOT. Changing the main jet will change the size of the funnel, or the size of the holes at both ends, while changing the bleed will change the shape of the funnel, or the shape of the transition from the big end to the small end. Schriefer cautions, however, that you should only work with the air bleeds and emulsion circuitry when you have the tools, such as a real-time air/fuel meter (not the portable one mentioned earlier), to measure the results of the changes you are making. A small change here can cause serious engine damage if you aren't careful.

"We all know how to set the floats in a carburetor, but there are subtle changes you can make in the float level that can affect the way an engine drives," Schriefer says. "The higher the float level, the quicker the engine will start to draw fuel from the boosters. This can help tremendously with driveability." Quick trick: Raise the float levels until fuel drips from your boosters, then drop it back down until it stops.

One tuning change that helps driveability at part-throttle is working with the size of the power valve channel restrictors (PVCR). A larger PVCR allows more fuel to pass, which means you can run less main jet. This gives you a leaner part-throttle while maintaining proper WOT air/fuel ratio. When experimenting with this, you won't need to change much. Just increase the restrictor by one number or two to begin. Remember, anytime you make changes (not just carb changes), make the change and then test it. Don't make two or three changes and then test-you'll never be able to properly analyze the results.

Keep the air bleeds clean at all times. They are extremely small, so a slight restriction can have a major effect on the performance of the engine.

Keep the air bleeds clean at all times. They are extremely small, so a slight restriction can have a major effect on the performance of the engine.

Schriefer says you shouldn't only look at spacers as a way to boost peak power. They can also be used to move the engine's powerband up or down in the rpm range to make it more useable with your gearing at a particular racetrack. There are no hard-and-fast rules that work for every engine package when it comes to spacers, but there are a few general guidelines you can use to help determine your needs. The greatest role of the spacer is to increase the distance between the bottom of the carburetor and the roof of the plenum in the intake manifold. This allows a straighter path of flow for the air/fuel charge-which helps keep the fuel droplets suspended in the moving air-and also increases the plenum volume. Generally, adding plenum volume will increase top-end power at the expense of some bottom-end power. Reducing the plenum volume (by using a shorter spacer or switching from an open to a four-hole spacer) will help bottom-end torque while taking away some of the engine's ability to make power in the upper rpm range. Decreasing the plenum volume also increases the engine's signal to the carburetor and may, in some cases, help throttle response. Ask questions about the track on which you run. Is top-end power what you need, or is bottom-end torque, where you can really hustle off the corners, more important? The analysis of what you need on the track will direct you to the changes you need to make in the carb.

Even the carburetor's float bowls can be used to tune driveability. The higher you set the float levels in the float bowls, the quicker the carburetor will draw fuel through the boosters.

Even the carburetor's float bowls can be used to tune driveability. The higher you set the float levels in the float bowls, the quicker the carburetor will draw fuel through the boosters.

The spacer's design can also influence the relationship between the carburetor and engine. A four-hole spacer increases the distance between the carburetor and the plenum roof without adding more plenum volume than necessary. The holes are sized the same as or just slightly larger than the venturis and are helpful when it comes to straightening out the air/fuel flow at part-throttle, when the butterflies are at an angle to the air path. This makes a four-hole spacer a popular choice on tight or slippery tracks, when the driver spends a good portion of the lap at part throttle.

A tapered spacer begins as a four-hole spacer and transitions into an open spacer at the bottom. It isn't legal in many racing classes, but the tapered four-hole is by far the most popular choice for classes in which it is legal. The transition gives the spacer the ability to boost both low- and high-end power because the transition creates a venturi effect that actually serves to increase air speed through the carburetor-and as we've already discussed, greater air speed or velocity through the carburetor almost always equals better fuel atomization.

"Hopefully, I've given you some areas to look at that will help your program," Schriefer says. "Remember, there isn't going to be an end-all answer in each situation. The bottom line with carburetion is if you're having a problem, try to isolate when it's happening, determine which circuit(s) in the carburetor [is/are] being used, and add fuel. This will at least let you know if you're too rich or too lean, and where you can go from there. Please make sure to keep good notes when you're tuning so you can go back if the problem is not any better."