Have you ever wondered how much of a difference various rocker arm designs can have on your engine's performance? We did, too, and decided to find out with a full repertoire of rockers from Comp Cams and a lot of dyno time.

Have you ever wondered how much of a difference various rocker arm designs can have on your engine's performance? We did, too, and decided to find out with a full repertoire of rockers from Comp Cams and a lot of dyno time.

For racers, the most pressing questions we ponder late at night aren't about the meaning of life, the true meaning of beauty, or other such silliness. Yes, those things have their place, but we all know the real head-scratchers are questions like "Where's the balance between outright speed and a good-handling package to get through traffic?" or "How do I make the outside line work for me?" and maybe even "Is spending the extra money on a new (insert your engine or chassis component here) worth it?"

We can't do much with meaning-of-life questions, but we can help with the motorsports-related ones. In the Mar. '06 issue of Circle Track, we debuted our Chevrolet 350 dyno mule by testing several oil pan configurations. Now we are back again, curious to find out how different rocker arm designs affect performance.

The idea behind Circle Track's dyno mule is to scientifically test different ideas to get to the real truth and not just repeat the same old magazine blather you've read year after year. The idea that press-in rocker studs on stock heads should always be replaced with screw-in studs was tested. We also used the dyno mule to find out if full-roller fulcrum rockers versus the less-expensive pivot ball rockers are worth the money.

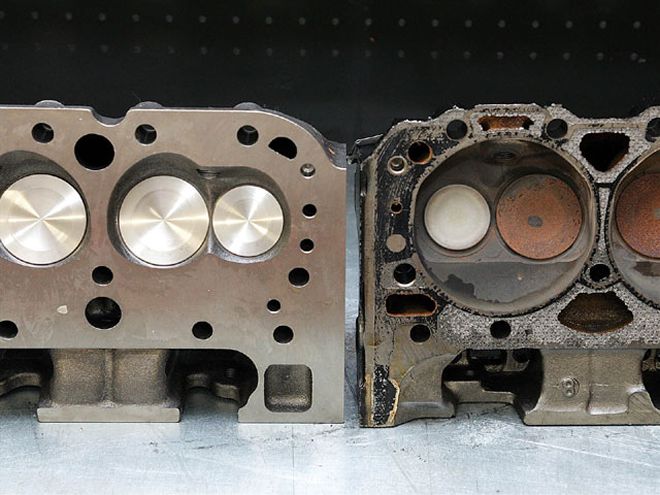

On a previous dyno session, our mule started wheezing at 4,500 rpm, which isn't nearly fast enough to stress the drivetrain as much as we wanted. To cure that ill, we switched out the stock 23-degree cylinder heads (right) with a pair of Pro Action iron heads from Racing Head Service. Bigger valves, better ports, and a more efficient combustion chamber helped move the peak power to 6,100 rpm.

On a previous dyno session, our mule started wheezing at 4,500 rpm, which isn't nearly fast enough to stress the drivetrain as much as we wanted. To cure that ill, we switched out the stock 23-degree cylinder heads (right) with a pair of Pro Action iron heads from Racing Head Service. Bigger valves, better ports, and a more efficient combustion chamber helped move the peak power to 6,100 rpm.

To verify these notions, we devised a plan with our test partner, the NASCAR Technical Institute (NTI) in Mooresville, North Carolina. NTI is a technical training school that combines general automotive education with an advanced regimen specializing in stock car racing. In addition to fabrication, pit crew training, and other racing specific courses, NTI also offers its students an engine-building program stocked with two dyno cells (engine and chassis) and enough Nextel Cup-legal engines to start your own multicar team. We provided the engine and test components, NTI provided the dyno facilities, and the students got to see firsthand how small changes in an engine's components package-this time rocker arms-can affect overall performance. When we tested with NTI before, we were quite impressed with the knowledge of the instructors as well as the quality of the students and were eager to work with them again.

The parameters for the test are simple: Test each set of rockers on the same engine on the same dyno and compare the numbers. For consistency, we chose to work only with rockers from Competition Cams. Comp's products are of consistently high quality, so we knew that any differences would be attributed to differences in design and not quality. We also kept the rockers as close to a 1.50:1 ratio as possible. For the stud-mount rockers, ARP studs were used.

In all, we tested six different sets of rocker arms. We chose Comp's High Energy (PN 1212-16) stamped steel, Magnum Roller (PN 1412-16), Hi-Tech Stainless (PN 1104-16), Pro Magnum (PN 1304-16), aluminum (PN 1004-16), and shaft mount (PN 5412160) rockers. The High Energy and Magnum Roller used a 31/48-inch rocker stud while the Hi-Tech, Pro Magnum, and aluminum rockers used a 71/416-inch rocker stud. For the High Energy, the lash was set at 0.010 for both the intake and exhaust. After experiencing trouble, which will be discussed in detail later, the lash for all other rocker arm sets was opened up to 0.014 for the intake and 0.016 for the exhaust and not changed again.

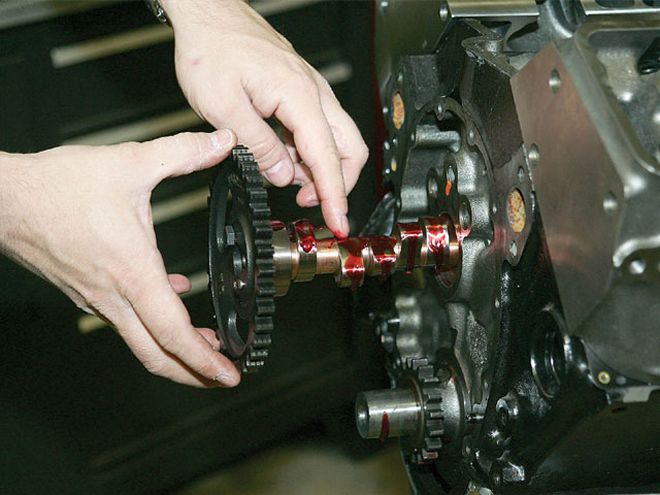

In addition to the new heads, we also added a new camshaft from Comp Cams. We asked Comp for something that would really test the stability of the rockers and studs, and they responded with a solid roller with 0.400 lobe lift and pretty strong opening ramps. With the heads and correct rockers, the combination produced an amazing 50 lb-ft increase in torque and 133 more horsepower.

In addition to the new heads, we also added a new camshaft from Comp Cams. We asked Comp for something that would really test the stability of the rockers and studs, and they responded with a solid roller with 0.400 lobe lift and pretty strong opening ramps. With the heads and correct rockers, the combination produced an amazing 50 lb-ft increase in torque and 133 more horsepower.

For the first round of dyno runs testing oil pans, we used a standard Chevrolet crate motor with a cast crank, cast pistons, 8.50:1 compression, and four-bolt main caps. It was outfitted with a Weiand Action Plus dual-plane intake, a Holley 650-cfm four-barrel carburetor, a 1-inch carb spacer, and a CV Products water pump and pulley set. Peak power averaged 355 pounds of torque at 3,600 rpm and 275 hp at 4,400 rpm.

That was fine for an oil pan test, but for rocker arms the horsepower peak was definitely too low to find any valve instability problems. The main problem was the stock cylinder heads started starving the engine of air way too soon. To properly stress the rocker arms, we needed a test mule capable of much higher rpm levels.

By working with Comp's engineers, we spec'd in what we thought would be a much better test mule. The oil pan from Champ Pans was kept because it showed good performance on the dyno. The stock heads were ditched in favor of a set of cast-iron heads from RHS (PN 12319). These 23-degree cylinder heads feature small 64cc chambers, 2.020 intake, 1.600 exhaust valves, and 200cc intake runners. They were assembled with beehive springs that tested around 180 pounds on the seat. Intake and head gaskets from Fel-Pro sealed everything, and ARP head studs were used to lock down the heads. We also asked Comp for an aggressive camshaft that would really stress the valvetrain, much like a typical race engine. They complied with a solid roller unit with 0.400 lobe lift (when matched with the 1.5 rockers that was 0.600 lift at the valves), and some very aggressive opening ramps. Since we had a new cam, we also had to ditch the stock hydraulic flat-tappet lifters in favor of a set of solid roller lifters from Comp. The cam was installed in the engine with no advance. Finally, to make sure we had plenty of clearance for the many different styles of rocker arms we planned to bolt up, Moroso set us up with a set of high-rise fabricated aluminum valve covers (PN 68326).

The NASCAR Technical Institute in Mooresville, North Carolina, was the location for the tests. The students-led by instructor Doug Wolfe-did all the wrenching.

The NASCAR Technical Institute in Mooresville, North Carolina, was the location for the tests. The students-led by instructor Doug Wolfe-did all the wrenching.

Because we were striving for consistency from one dyno pull to the next, the engine wasn't tuned for maximum power. Timing was set at 38 degrees with the advance locked out. The Holley carburetor was set up with No. 70 jets at all four corners, and 7 quarts of Royal Purple synthetic racing oil was used for lubrication. Those factors did not change throughout the tests. When the pulls were made, lead instructor Doug Wolfe made sure that the water and oil temperatures were as consistent as possible. Our targets for the beginning of each pull were 190 degrees F for the oil and 180 for the water.

Comp's High Energy rockers can be best described as high-quality stock replacement rockers. These stamped steel units are designed to be used with stock or High Energy camshafts. They are very popular among Street Stock racers because they look like stock pieces but are manufactured to tighter tolerances and can be purchased with a higher ratio than the stock rockers for some engines. They are also the least expensive rockers we tried, with a list price of $141 for a set.

In terms of technology, the Magnum rockers are definitely a step up from the High Energy rockers. Magnum rockers are constructed from chrome-moly steel and feature roller tips for reduced friction. With a list price of $212 for 16, they are still quite a bargain. Both the High Energy and Magnum rockers swivel on a pivot ball system.

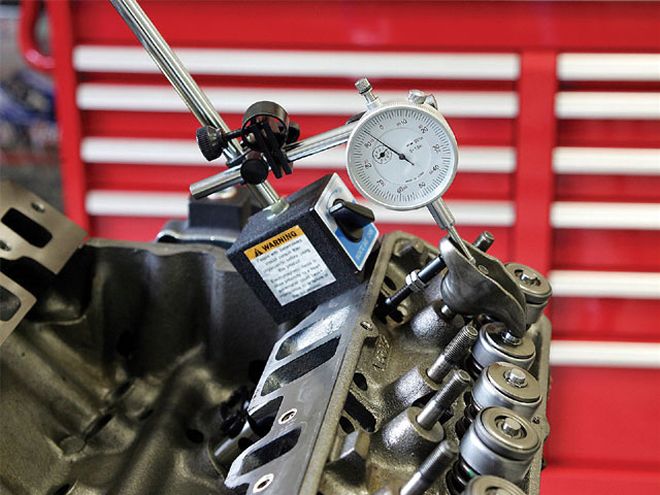

As part of this experiment, we wanted to test how much rocker stud stability played into the equation. Surprisingly, a dial indicator set up on the original stock head with the stock springs showed nearly 0.006 inch of movement at the top of the 3/8-inch pressed-in rocker stud when the engine was rolled over by hand.

As part of this experiment, we wanted to test how much rocker stud stability played into the equation. Surprisingly, a dial indicator set up on the original stock head with the stock springs showed nearly 0.006 inch of movement at the top of the 3/8-inch pressed-in rocker stud when the engine was rolled over by hand.

We knew from the start that both of these rockers wouldn't be the best choices, given the radical camshaft and stiff valvesprings we would be using. Pivot ball rockers have been used for years in OEM and lower division racing classes with great success, but our engine combination was just too much. The problem was that the pivot ball that locates the rocker pivot point was not as efficient at reducing friction as rockers with a bearing trunnion. On the dyno, the high spring pressures combined with the large amount of lobe lift burned up the fulcrum area of the rockers. We had to kill both runs quite quickly, and as a result, we have very little information regarding these rockers. We got one pull to 5,000 rpm for the High Energy rockers and didn't make a pull for the Magnums.

The lesson here? There is a good reason that valvetrain component manufacturers and engine builders try to steer you to the high-end stuff-and it usually isn't because they just want you to spend all your money. Extended operation at high rpm levels is incredibly hard on your valvetrain, and it is critical to get the right parts for the right job. The pivot ball system just isn't designed to be used in the high-rpm, high-lift application to which we subjected these rockers. We want to stress that neither the High Energy nor the Magnum rockers are poor designs. With a milder camshaft, we've seen them operate perfectly and make good power. This was simply a situation of poor component matching. Learn from it.

By comparison, the 7/16 screw-in ARP stud showed only 0.0015 inch of movement with the aluminum rockers installed. The extra rigidity is the result of thicker studs and the threads helping to lock the stud into the head for less flex.

By comparison, the 7/16 screw-in ARP stud showed only 0.0015 inch of movement with the aluminum rockers installed. The extra rigidity is the result of thicker studs and the threads helping to lock the stud into the head for less flex.

The next step up in terms of cost is Comp's aluminum roller rockers. At this point, all of the rockers tested used 71/416 screw-in rocker studs. The aluminum rockers are also marked to transition to needle-bearing trunnions, meaning they are rated for spring loads with up to 350 pounds of open pressure. The list price for the aluminum rockers jumps up quite a bit, but they are still the cheapest bearing trunnion option at $343 for a set.

On the dyno, the aluminum rockers performed flawlessly. Peak torque was 404.2 lb-ft at 4,600 rpm, and horsepower maxed out at 406.1 at 6,000 rpm. For all tests, peak numbers stayed very close to those two points. Only horsepower varied by 100 rpm. We also tracked average torque and horsepower across a range of 4,000 to 6,000 rpm to simulate on-track operating rpm range. Again, the aluminum rockers displayed the best numbers. Average torque was 388.33 while horsepower was 368.31.

The advantage almost certainly comes from the fact that the aluminum reduces the overall weight of the rocker, which cuts down on the inertial forces in the valvetrain. Aluminum's drawback is its tendency to fatigue, unlike steel. But it isn't usually an issue in circle track racing if the engine is regularly rebuilt. Your power level and on-track rpm range will determine the duty cycle of the rockers, and the manufacturer's tech department can normally help you with determining when the rockers should be cycled out. The improvement over the other rockers is slight, as you will see in the next tests, but it was measurable.

Comp's High Energy rockers are a great choice for a Street Stock engine, where stock-style rockers are required, but they weren't designed for the environment in which we put them, and they were simply overmatched.

Comp's High Energy rockers are a great choice for a Street Stock engine, where stock-style rockers are required, but they weren't designed for the environment in which we put them, and they were simply overmatched.

Comp's Pro Magnum roller rockers are designed to be an effective middle ground between inexpensive aluminum rockers and extremely strong and reliable, but more costly, stainless steel rockers. These rockers sport a list price of $351 and are constructed from chrome-moly steel designed to maximize strength with a minimum of mass. They also have a roller tip. The one deviation with the Pro Magnum rockers is the slightly different 1.52:1 ratio. This small change didn't seem to affect results compared to the 1.50:1 rockers.

On the dyno, the Pro Magnums produced slightly lower numbers than the aluminum rockers. Torque peaked at 401.7 lb-ft while horsepower was 404.1. Average power in the selected range was 386.11 and 366.17, respectively. Looking at the average across the 4,000 to 6,000 sweep, the Pro Magnums were losing approximately two units of both torque and horsepower to the aluminum rockers, which may be attributed to the slightly greater mass.

Comp's Hi-Tech rockers are constructed from ultrastrong stainless steel, which provides race engines with both rigidity and durability. Minimizing power-robbing deflection, which can become a problem with stiff valvesprings at high rpm levels, is the goal here. These are high-end, high-performance rockers, and the list price reflects it at $465. Fortunately, these rockers are rebuildable, so the extra upfront cost can be offset with a longer service life.

Both the High Energy and Magnum rockers (shown here) are the pivot-ball type. With this engine's high spring pressures and strong cam, there was simply too much friction, which burned the fulcrum of the rockers. Interestingly, even though not all rockers showed this kind of burn coloring, all the rockers opened up on the lash approximately 0.010 within a few minutes of operation, showing it wasn't a design flaw in the rockers but a bad match between parts and application.

Both the High Energy and Magnum rockers (shown here) are the pivot-ball type. With this engine's high spring pressures and strong cam, there was simply too much friction, which burned the fulcrum of the rockers. Interestingly, even though not all rockers showed this kind of burn coloring, all the rockers opened up on the lash approximately 0.010 within a few minutes of operation, showing it wasn't a design flaw in the rockers but a bad match between parts and application.

On the dyno, the Hi-Tech rockers were more productive than the Pro Magnums and just south of the aluminum rockers. We got 403.7 lb-ft of peak torque with an average of 387.0. Peak horsepower was 405.2 with an average of 367.06. The average was slightly less than the aluminum rockers. This was surprising, but we feel the valvetrain wasn't being stressed enough for the stainless rockers to shine. As the spring pressures and rpm limit reaches 7,500 and beyond, the Hi-Tech rockers should be able to reduce deflection better than most other designs.

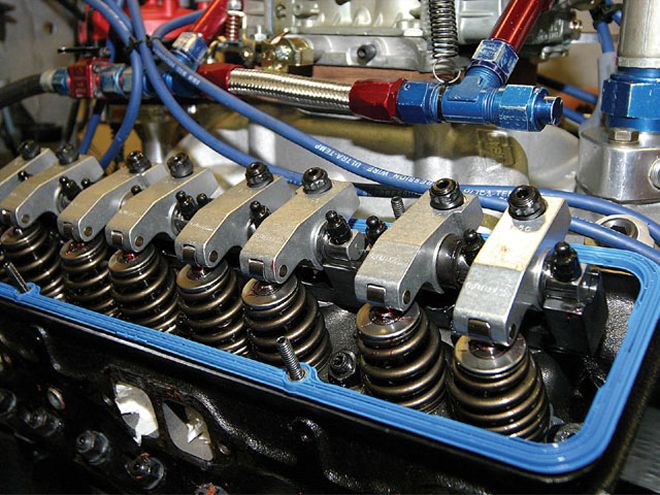

For any true gearhead, these shaft-mounted aluminum rocker arms look like jewelry. Comp says the rocker arms themselves are fully machined and not extruded. There is also an internal oiling system that increases rocker durability by providing pressurized oil from the pushrod cup to the roller-bearing trunnion and to the roller tip. Shaft-mount rockers are gaining popularity in all forms of stock car racing because they provide more stability than stud-mount designs. In addition, the geometry of the stand helps ensure that the rocker tip stays centered over the valve stem at the correct time. Because of the extra machine work required, a shaft-mount rocker system costs significantly more than stud-mount designs-Comp's list price is $1,285-but there isn't a Nextel Cup team today that doesn't use some type of shaft mount system exclusively in its engines, so there must be something to it. The question is, does the benefit extend to the engines typically used by Saturday night racers?

The Pro Magnum rockers were the first set we tried with a needle bearing trunnion, which allows much higher spring pressures and solved our problem with rocker death.

The Pro Magnum rockers were the first set we tried with a needle bearing trunnion, which allows much higher spring pressures and solved our problem with rocker death.

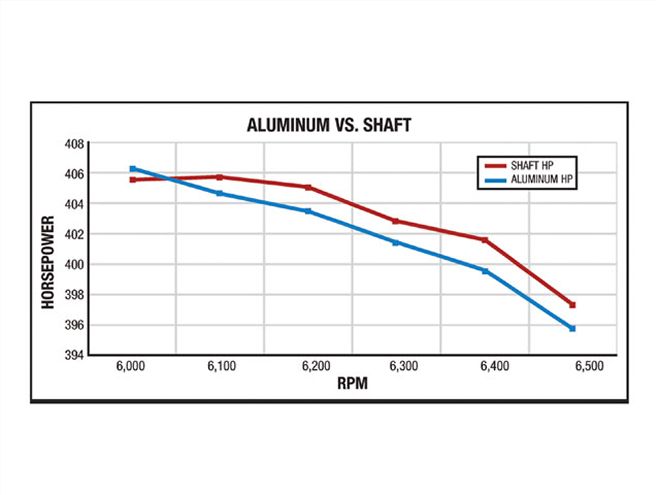

The answer is, "It depends." Initially, the results on the dyno were mildly disappointing. Peak torque/horsepower numbers were 401.6 and 405.8, and the averages were 386.05 and 366.28. Those numbers put the results right in line with the Hi-Tech rockers and behind the aluminum and Pro Magnum rockers. But a further inspection showed that the shaft-mount rocker system was just gaining steam versus the competition right when our dyno mule was giving up. Peak horsepower came at 6,100 rpm, but the numbers after peak are quite telling. By the time we got to the end of the test sweep at 6,500 rpm, the aluminum rockers were producing 395.9 hp while the shaft-mount rockers were holding out at 397.3. That's nearly an extra 1.5 hp on the backside of the curve, just 400 rpm past peak. We believe this hints that the shaft-mounted system, like the Hi-Tech, would shine at higher rpm levels and/or with even stiffer springs and a more radical camshaft.

The best conclusion to draw from this test is that you have to match the correct rocker design to the engine package. For our 400-plus horsepower, 6,000-rpm test mule, the best options turned out to be the aluminum and Pro Magnum rockers. The High Energy and Magnum rockers couldn't survive in the harsh valvetrain environment we created, and the Hi-Tech and shaft-mount rocker systems were overkill. Had we used a milder camshaft and springs, the High Energy and Magnum rockers would have worked quite well. The High Energy rockers are an excellent choice when the rule book requires stock-style rockers, and the Magnum rockers are a good performance choice when the budget is tight. Finally, the way the shaft-mount rockers extended the horsepower curve after peak power tells us that this is probably an excellent choice for an all-out race engine, where the engine speed can exceed 7,500 rpm and valve control is an issue. But if your race engine is a more moderate package-like our test mule-spending the extra cash on the shaft-mount system is a bit of a waste. Instead, go with the more moderately priced aluminum or Pro Magnum rockers and use your savings to benefit your racing program elsewhere.

Comp's aluminum roller rockers provided the best dyno numbers. They were a good match for our dyno mule's peak power and rpm ranges.

During the dyno session, NTI students regularly checked the spring pressures for consistency, and they held true.

The Hi-Tech rockers are designed for high stress environments. They performed flawlessly, but our dyno mule may not have been aggressive enough to really put them to the test. These rockers are probably better suited to a race engine with more power and a higher rpm range.

Comp's shaft-mount rocker system is a premium piece of equipment. The peak torque and horsepower numbers were down from the aluminum rockers, but the shaft-mount system showed an interesting characteristic. After peak power, the horsepower did not drop nearly as quickly with the shaft rockers as it did with the aluminum rocker set. This tells us that the shaft-mount system is better at keeping the valves under control as the rpm increase. The system is expensive, but it is probably your best bet in high-rpm applications where maintaining valve control becomes increasingly difficult.

Here's a problem that's confronting more and more Chevy racers. The stronger beehive valvesprings we used have a wider base than the stock springs. This means the gap between the two exhaust valvesprings in the center of the head is too small to fasten the head bolt. Those springs must be removed before the head is bolted down, and then they must be reinstalled. CV Products sells the perfect valvespring compressor for this job. It works with the head on the engine and can even be used with the engine in the race car if you need to make a spring change at the track.

This chart represents a portion of the dyno pulls of the aluminum rockers and the shaft-mount rockers. It plots horsepower between peak power at 6,000 rpm and 6,500 rpm, when the test ended. Many racers don't pay attention to power on the backside of the curve, but it is important because you want to use your highest power rpm range, and that normally involves rpm on both sides of peak power. Although the aluminum rockers produced better peak numbers, the shaft-mount rocker system exhibited better high-rpm valve control and allowed the engine to maintain better power after peak.

Here are the results from our testing. Note that there are numbers included for the High Energy rockers, but they only go to 5,000 rpm. There are no numbers for the Magnum rockers. The High Energy numbers were from a run executed before we determined peak rpm. The Magnum rockers showed signs of damage before we could get a good dyno pull. Peak numbers on the chart are bold, and the "Average" is the average power numbers from 4,000 to 6,000 rpm. This is designed to simulate the rpm range this engine would see on the racetrack.

RPMHigh EnergyPro MagnumAluminumTorqueHorsepowerTorqueHorsepowerTorqueHorsepower4,000381.7290.7388.1295.6387.8295.44,{{{100}}}386.1301.4393.7307.3394.3307.84,{{{200}}}389.1311.2397317.5398.5318.74,{{{300}}}391.3320.3397.7325.6400.2327.64,400392.8329.1399.8334.9402.7337.44,500395.9339.2401.1343.7403.3345.64,{{{600}}}396.5347.3401.7351.9404.23544,700395.5354401.3359.1402.9360.54,800393.2359.3399.8365.4402367.44,{{{900}}}389.5363.4396.8370.2400.3373.55,000385.6367.1392.9374397.3378.25,100 389.6378.3392.6381.35,200386.8383389.2385.45,300383.3386.8386.4389.95,400380.9391.6383.23945,500377.2395379.3397.25,600373.3398.1375.8400.75,700369.5401.1370.7402.35,800364.2402.2367{{{405}}}.35,900359.1403.4360.9405.56,000353.6404355.4406.16,100347.9404.1348.3404.66,200340.9402.4341.8403.56,300332.6399334.6401.46,400324.4395.3328399.76,500317.1392.4319.9395.9Average386.11404.1388.33368.31 RPMHi-TechShaftTorqueHorsepowerTorqueHorsepower4,000388.3295.7381.7290.74,100393306.8389.6304.14,200397317.5394.7315.64,300398.5326.2398.8326.54,400400.5335.6400.8335.84,500402.6344.9401.6344.14,600403.7353.6401.3351.54,700402.5360.2399.9357.94,800399.9365.5397.7363.44,900396.7370.1395.9369.35,000393.8374.9393.2374.35,100390.4379.1390.8379.55,200387.5383.7387.1383.35,300385.4388.9384387.55,400382.3393.1382.4393.15,500378.4396.3378.5396.45,600375399.8376.4401.35,700370.4402370.4402.15,800365.7403.9365.9404.15,900359.9404.3360.3404.86,000354.7405.2355405.66,100348.6404.8349.4405.86,200341.3402.9343404.96,300333399.5335.7402.76,400325.3396.5329.6401.66,500318.2393.9321397.3Average387367.06386.05366.28