David Bruns and his wife Dianne of Mid America Racing Engines in Washington, Iowa, brought the winning combination to our engine challenge this year, making more than 741 budget-friendly horsepower from their 500ci wedge.

David Bruns and his wife Dianne of Mid America Racing Engines in Washington, Iowa, brought the winning combination to our engine challenge this year, making more than 741 budget-friendly horsepower from their 500ci wedge.

We all expected stout power numbers from the 500ci wedges in this year's engine challenge, and we certainly weren't disappointed. We relaxed the rules a bit for this year's competition by allowing roller camshafts and smaller rod-journal sizes, but aside from that, the rules of our challenge didn't change from last year. The engines were dyno'd between 3,000 and 7,000 rpm, and the peak horsepower and torque were added together for a combined score. This score was then divided into the retail cost of the parts in the engine for a power-per-dollar factor. Manifold vacuum at idle was used as a bonus tie-breaker in case the competition was close. It turns out this year's competition was a close contest, with decimal points separating the top finishers. As it turned out, the winning engine wasn't the most powerful or the most economical of the eight entries. It was actually a combination of the two. David Bruns of Washington, Iowa's Mid America Racing Engines built a very powerful 500ci wedge using a cost-effective combination of parts to win this year's competition.

Most of these big-blocks easily out powered last year's Hemis as more than half the entries produced horsepower numbers in the mid- to high-700s. This was a function of both the relaxed rules of this year's contest and an rpm range for the dyno pulls that favored the wedge cylinder head design. Mopar Engines West holds the honor for the most power in this year's contest as their 500-inch wedge made more than 761 peak horsepower. Knowing the cost of the engine is factored into the combined peak power and torque the engine makes on the dyno, several builders chose not to go for peak power numbers, instead trying to win the contest by building their engines economically. In the end, however, it took a combination of big power and economical parts for engine builder David Bruns to win this year's engine challenge.

When a power outage caused this year's challenge to start a little behind schedule, Rich Smith and the dyno crew at Comp worked late to make up for the lost time. We had four days to dyno eight engines, and thanks to Comp we met our schedule. Overall the contest ran smoothly, and everyone in attendance had a good time. Only two of the eight engines failed to qualify-one couldn't make the required rpm, missing by only 200 rpm, and the other suffered a mechanical failure that was repaired, just not in the allotted time.

In this issue we'll give you an overview of the engine challenge wedges in the order they placed. Look for in-depth articles on each engine in future issues. If you're considering a mean street wedge for one of your projects, this will be a great chance to look at what's inside some of the most potent big-blocks on the planet.

'06 ParticipantsBest Machine Racing EnginesMid America Racing Engines - Washington, Ia

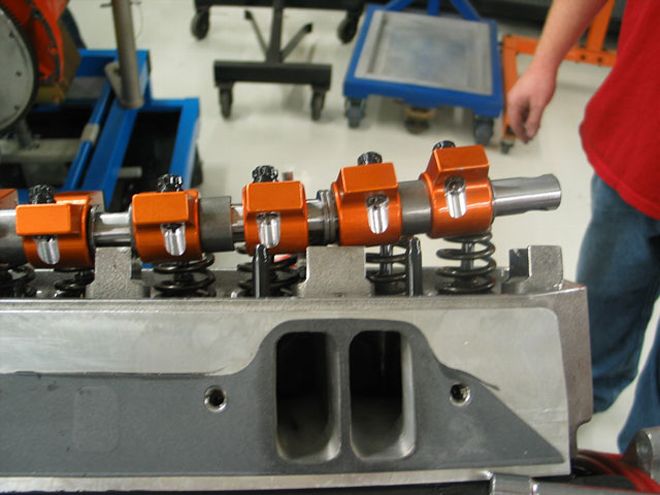

You may remember David Bruns of Mid America Racing Engines from last year's engine challenge, which featured 500ci Hemi motors. While David didn't win last year, he certainly made a good showing and impressing us with a powerful and very street-worthy entry. One thing David did do last year was pay attention. Carefully interpreting the rules, he realized that a stout combination of power and torque, combined with an economical list of parts, would win this year's challenge. The wedge that David brought this year epitomizes the concept of our challenge. It wasn't the most powerful engine, though it did make great power, nor was it the most economical. It was, however, the best combination of the two, and won our challenge with points to spare.

The Mid America Racing Engines' entry was the third engine to run in this year's challenge, and builder David Bruns came ready to compete. The 500-inch big-block fired right up and sounded healthy, needing only minor ignition timing and jetting changes to tune the motor to the conditions of Comp's dyno cell. This entry not only made the most horsepower of any Edelbrock-headed engine, it also made the third highest combined power and torque score. Mopar Muscle congratulates David Bruns, his wife Dianne, and the crew at Mid America Racing Engines for winning the '06 Royal Purple/Mopar Muscle Engine Challenge. Be sure to follow future issues as we go in-depth to tell you what parts and techniques were utilized to build this and the rest of the engines in our challenge.

J.D. Engine and Machine - Columbia, MO

Jeff Dickey of J.D. Engine and Machine is also no newcomer to our engine challenge. In fact, the Hemi Jeff brought to last year's competition set the standard in terms of horsepower and torque, narrowly missing a win in the contest. This year, Jeff kept his spending in check, building a budget-minded engine that made good power as well. Knowing the big-block's propensity for big torque numbers, Jeff tuned his wedge to the highest torque of any of the Edelbrock headed engines, and the second highest torque of the contest. When the final results were tallied, the J.D. Engine and Machine entry was literally decimal points away from first place, netting a second place finish in our contest.

When the J.D. Engine and Machine entry fired up it sounded strong, but at the end of the first qualifying pull Jeff heard a noise. At the beginning of his second pull, Jeff noticed something and aborted the pull early to check his engine. What he found was a broken rocker arm adjuster that had let the number-six cylinder intake rocker back out, rendering that cylinder useless. Since the rules allow a limited time for tuning and maintenance between pulls, Jeff and his crew scrambled to make repairs. Luckily, their experience at the track taught them to work quickly and always have extra parts, so they had their engine repaired with time to spare. Making minor jetting and timing changes, Jeff proceeded to put up some impressive numbers to the tune of 718 hp and a stump-pulling 654 lb-ft of torque. We congratulate Jeff and the crew of J.D. Engine and Machine for a second place finish.

HiTech Motorsport - Ramsey, MN

Engine builder Bart Wells and his crew from HiTech Motorsport were new to the contest this year, and we looked forward to seeing what they could do. With a reputation for building strong engines, they had a lot to live up to. They didn't disappoint us as they were the first engine on the dyno, setting the standard high by making more power and torque than any of last year's Hemis. We knew the wedges in this year's contest would be impressive, but all of these big-blocks exceeded our expectations. By using a budget-conscious parts list, combined with professional building techniques, the crew from HiTech netted a third place finish.

The HiTech Motorsport entry was also ready to run when it was bolted to Comp's dyno, having already been dyno'd in-house before the contest. After their first pull, however, power was down slightly so some tuning was in order. Instead of using jetting to tune their engine, the crew from HiTech made changes to the high-speed air bleeds of their Dominator, netting additional power and torque on each pull. Minor ignition timing changes also helped them get the most from their engine, set at 36-degrees total advance for their final pull. This is a strong, economical engine, and would be a blast in any Mopar, able to propel a well-prepped car to sub-10-second timeslips with ease.

Best Machine - Warren, MI

Fourth place honors in our engine challenge go to Warren, Michigan's Best Machine, another newcomer to this year's challenge. Each having more than 20 years of automotive experience, engine builders Chuck Millen and Pete Costa impressed us by making 746 hp, the second highest power score of the contest. Chuck Millen noted that the Indy 440-1 cylinder heads, combined with proper cam selection, were the keys to making big power from their wedge. Another advantage stated by both Chuck and Pete is that they race what they build. Track time racing wedge-powered cars has given them valuable experience testing the limits of parts and trying new technologies that are adapted to the engines they build.

The Best Machine entry also had already been on a dyno when it came to our contest, so it was no surprise when it fired right up and sounded crisp. At 11.9:1 compression, this engine pushed the limits of the 93-octane fuel, but ran well without a hint of detonation. During the qualifying pulls, Chuck and Pete experimented with jetting and timing, netting additional power with each pull on the dyno. It was after the first scored run, however, that they really improved power by loosening the valve lash from .016-inch to .024-inch, netting nearly 20 additional horsepower. After loosening the lash, Chuck showed his experience with the big-block Chrysler engine by tweaking the timing "about that much" to improve power yet again. A timing light verified total ignition timing was at 41 degrees on the best pull. At 746 hp and 652 lb-ft. of torque, we'd love to try this engine in one of our cars!

Mopar Engines West - Newark, CA

Nobody really knew what to expect from the Mopar Engines West entry in this year's challenge. Though a newcomer to our challenge, we are certainly familiar with the work these guys can perform as we've covered several of their builds, including a 300-plus-horsepower Slant 6. Known for using exotic fuel-injection systems and electronics to tune their engine, we were all wondering how these guys would fare with a simple single carburetor and distributor setup. All questions were answered during their first pull on Comp's dyno when this engine quickly screamed to contest leading power. In fact, with each pull, this engine made more and more power until a best pull of 761.6 hp and 656.4 lb-ft of torque was attained. The combined power and torque score of Mopar Engines West was dominant at nearly 20 points ahead of the second highest power score and earned them a fifth place rating overall.

Engine builders Rich Nedbal and David Timmons were quick to optimize power from the Mopar Engines West entry by making timing and jetting changes. Already solidly in the lead in terms of raw power after their first pull, these guys had nothing to loose. After their first scored pull, they loosened the valve lash to .035 inch and reduced the total timing to a mere 34 degrees. Each change netted additional power until they attained their best numbers on their final pull of the contest. When asked how they made so much power, both Rich and David pointed their fingers at David's daughter, Angie, who was in charge of the cylinder heads for this engine. It turns out that Angie had been to Joe Mondelo's cylinder head porting school and had applied what she learned well, spending some 40 hours massaging the Indy 440-1 heads on their engine. Significant engineering also went into the oil system of the Mopar Engines West entry, freeing up additional power through reduced crankcase windage. This is one killer street wedge! Did we say street? Heck, we'd love to have this engine in our race car.

Engine BuilderHPTorqueCombined ScoreMopar Engines West761.6656.41418.0Best Machine746.7652.21398.9Mid America741.6644.61386.2J.D. Engine and Machine718.8654.01372.8HiTech Motorsport738.5627.61366.1Speed-O-Motive716.7598.71315.4ProMax/CFM*587.6595.61183.2MRL*472.7507.3980.0*These engines failed to qualify for the judged portion of the challenge; results are for {{{comparison}}} only.Speed-O-Motive - West Covina, CA

Since the inception of hot rodding, Speed-O-Motive has been known for providing reliable power to its customers. The Hemi Speed-O-Motive brought to last year's challenge made the second highest combined power score, and the most power of any engine equipped with a single carburetor. This year, August Cedarstrand and the guys at Speed-O-Motive decided to once again show that reliable power can be made with somewhat unconventional parts. By using Brodix B-1 original cylinder heads, they knew they would be sacrificing some torque down low, but felt they could make up for it at the higher rpm range of our test. Their engine was strong and reliable right out of the box, making all its dyno pulls without incident and finishing in sixth place.

Speed-O-Motive certainly lived up to its reputation as a leading provider of reliable power. Their 500-inch wedge fired up immediately and sounded right at home on Comp's dyno, idling smoothly and completing its required dyno pulls without so much as a change in timing. This engine could easily have been dropped into a car and run with no further tuning. In fact, the only tuning technique used by engine Speed-O-Motive's August Cedarstrand was to remove the air filter for the judged portion of the contest, freeing up a few extra ponies. Rather than going for peak numbers, the guys at Speed-O-Motive impressed us again this year with a smooth-running, trouble-free entry that was ready to compete right out of the box. In fact, the dyno pulls went so smoothly it gave us time to have a little fun with this engine in the form of nitrous oxide. For anyone who doubts the durability of a factory 440 block, we'll make the following statement. Speed-O-Motive's 500-inch wedge made some 980 hp and 890 lb-ft of torque by using a 300hp ZEX nitrous-oxide system and held together for multiple pulls, showing no signs of wear upon teardown. Be sure to follow along as we go inside this engine and see the fun we had with nitrous oxide in a future issue.

Ben Gorman from Promax teamed up with the guys from Creative Flow Management to bring the only engine with multiple carburetion. Unfortunately, a rocker-arm shaft problem prevented them from qualifying for the judged portion of the engine challenge.

Ben Gorman from Promax teamed up with the guys from Creative Flow Management to bring the only engine with multiple carburetion. Unfortunately, a rocker-arm shaft problem prevented them from qualifying for the judged portion of the engine challenge.

Rocker-arm problems ended Promax's hopes of winning this year's challenge as too short a retaining bolt stripped the threads from the cylinder head allowing the rocker shaft to bend on the first qualifying pull. This was unfortunate for the Promax team because this engine had what could have been a winning combination of power and economy.

Rocker-arm problems ended Promax's hopes of winning this year's challenge as too short a retaining bolt stripped the threads from the cylinder head allowing the rocker shaft to bend on the first qualifying pull. This was unfortunate for the Promax team because this engine had what could have been a winning combination of power and economy.

Promax - Indianapolis, IN

Tying for seventh place in this year's contest was the Promax entry, which unfortunately failed to qualify for the judged portion of the engine challenge. During its first dyno pull, the Promax engine began making a rattling noise, and builder Ben Gorman chose to abort the pull. Removing the valve covers, the cause of the noise was apparent. The end bolts holding the rocker shafts to the heads were too short, allowing the threads to be pulled from the heads and bending the left rocker shaft in the process. While this did keep Promax from officially finishing the contest, the guys at Comp quickly provided another rocker shaft and longer bolts so repairs could be made. At the end of the competition we allowed Promax to make an additional dyno pull, which netted them a respectable, though unofficial, 587 hp and 595 lb-ft of torque. The mechanical problem was unfortunate since this engine was built on a strict budget, and the Promax entry certainly would have placed better had it made its required runs.

MRL Performance - Jackson, MI

Mike Liston of MRL Performance narrowly missed winning this year's challenge when his engine fell 200-rpm shy of the limits set in the contest rules, netting Mike a tie for seventh place.

Mike Liston of MRL Performance narrowly missed winning this year's challenge when his engine fell 200-rpm shy of the limits set in the contest rules, netting Mike a tie for seventh place.

Mike tuned his engine to some 472 hp, but couldn't achieve the required rpm to qualify for the judged portion of the challenge. Later, Mike discovered a vacuum problem had prevented the carburetor's secondaries from opening, which cost him the contest.

Mike tuned his engine to some 472 hp, but couldn't achieve the required rpm to qualify for the judged portion of the challenge. Later, Mike discovered a vacuum problem had prevented the carburetor's secondaries from opening, which cost him the contest.

Mike Liston of Jackson, Michigan's MRL Performance could have won this year's engine challenge if his engine just would have made it to the 7,000 rpm upper limit of our contest rules. This entry was definitely built using economical parts, and if it would have made the required pulls at the required rpm, it would have been hard to beat. The only engine to use a hydraulic, flat-tappet camshaft, and using Edelbrock's Performer RPM cylinder heads, this engine was designed to win the contest based on cost, not peak power. During the first pull the engine sounded smooth and made decent power, but only turned 6,900 rpm, 100 rpm shy of the contest rules. As additional pulls were made, and as the valvesprings warmed up, rpm peaked at 6,800, preventing Mike from moving to the judged portion of the contest. Even so, power was a respectable 472 hp with torque at 507 lb-ft.

We were all scratching our heads as to why this engine wouldn't turn 7,000 rpm during the contest, but Mike discovered the problem later at home. His wife had videotaped his dyno runs, and when he reviewed the video he noticed the carburetor's secondaries weren't opening. Heading to the shop, he quickly pulled the vacuum actuator apart and found the vacuum port blocked, which had kept the secondaries from opening. If not for this problem, the MRL entry would have certainly placed higher, if not won our engine challenge.

2006 Engine Challenge Final Results First Place: Mid America Racing EnginesSecond Place: J.D. Engine and MachineThird Place: HiTech MotorsportFourth Place: Best MachineFifth Place: Mopar Engines WestSixth Place: Speed-O-MotiveSeventh Place Tie: ProMax/Creative Flow Management and MRL Performance**These engines failed to qualify for the judged portion of the challenge; results are for {{{comparison}}} only.