TO refresh your memory from last issue, the SD-455 that you see before you belongs to HPP contributor Melvin Benzaquen. We were using it as a mule for a fuel-injection swap into his '74 T/A when it expired on the chassis dyno during baseline testing. Cracking open the famed powerplant revealed a poor rebuild was the root cause of the engine failure.

Presented with the opportunity to rebuild the engine as well, the owner decided to upgrade the powerplant for reliability and employ some modern technology, so he sent the engine to RaceKrafters. That quest began in Part I with basic machining using state of the art equipment. Cylinder-wall finish and the valve-job procedure were notable technological improvements, fully explained in the first installment to go along with the basic machining and cylinder head porting.

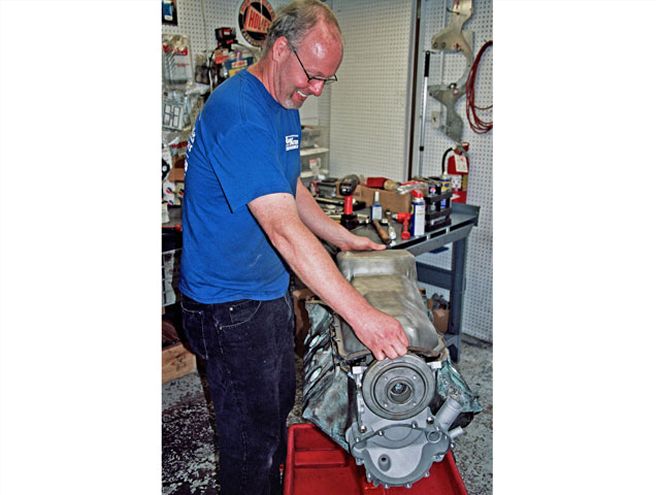

In this issue, the engine will be assembled, and a Comp Cams hydraulic roller cam will be employed to exploit its advantages, such as lower friction and more aggressive ramps to open and close the valves more quickly by realizing more lift per degree of rotation. Craig Wise of RaceKrafters did all of the assembly work. He showed our Pontiac the same care and execution to detail that would be provided to a 1,000hp drag engine.

In the next installment, HPP will work with RaceKrafters to dyno test the engine with a carburetor and then with the high-tech EFI system from Mass-Flo EFI, but first we need to get some wrenches swinging!

SD-455 HEAD FLOWBob Wise's expertise with cylinder heads is quite apparent after examining the flow numbers. It must be recognized that these values were obtained with RaceKrafter's Super Mod porting, which works the bowl area, short turn, and valve angles. Then a gasket match is performed. All of the care that was represented in Part I of this series can easily be seen in the flow results.CFM flow at 28 inches of waterLift in InchesIntake FlowExhaust Flow0.10082.467.80.{{{200}}}156.3130.40.{{{300}}}228.8171.20.400263.2193.00.500278.8208.30.{{{600}}}292.2220.6HIGH PERFORMANCE PONTIAC ENGINE-BUILDUP WORKSHEET & SPECS

Engine Displacement: 463

Bottom End

Block: '74 SD-455

Preparation: Decked 0.020-in, bored, honed, align-honed

Cam Bearings: Dura Bond

Deck Height: 10.210 inches

Crankshaft: Eagle cast-steel 4.21-stroke, PN 104554210

Preparation: Mic'd, balanced

Balancer: Stock

Rods: Eagle H-beam, forged-steel, stock-length, PN CR56625P3D

Preparation: Clean, measure, balance

Bearings: Main, Clevite PN MS-667P; rod, Clevite PN CB-758-H

Preparation: Dress

Pistons: SRP forged flat-top with valve reliefs, PN 149721

Compression Height: 1.480 inches

Preparation: Clean, measure, balance

Piston-to-Deck Height: Zero

Piston Pins: SRP, tool-steel

Method Used to Retain Piston Pins in Pistons: Spiral locks

Rings: Perfect Circle, moly-faced ductile iron (11/416, -11/416, -31/416), PN 315-0032-065

Preparation: File-fit, deburr, clean

Rod Bolts: ARP

Oiling System

Oil Pan: Stock

Oil Pump: Melling high-volume, PN M-54-F

Preparation: Check, clean, weld pickup

Heads

Casting Number: 16 Round-Port SD

Head Mods: Bowl port and polish, milled 0.050 Combustion-Chamber Volume: 98cc

Compression Ratio: 9.49:1

Intake-Port Volume: 206cc

Exhaust-Port Volume: 186cc

Valves, Intake: Ferrea SS 2.11-in, PN F5073

Valves, Exhaust: Manley SS 1.77-in, PN 11355-8

Angles Used in Valve Job

Intake: 30-45-60-75-82-deg

Exhaust: 30-45-55-82-deg

Head Bolts: ARP, PN 190-3603

Retainers: Comp Cams, steel 10-deg, PN 740-16

Keepers: Comp Cams, Super Locks 111/432 10-deg, PN 611-16

Valveguides: Bronze

Valve Seals: PEP, 111/432x0.500

Spring Cups: Comp Cams, 4770-16

Rocker Studs: ARP 71/416-in, PN 235-7204 Rocker Arms: Comp Cams roller 1061-16

Rocker Arm Ratio: 1.65:1

Pushrods: Comp Cams, High Tech, PN 7775-16

Diameter: 51/416-in

Length: 8.650-in

Guide Plates: Comp Cams, PN 4851-8

Cam

Brand: Comp Cams hydraulic-roller, PN K-51-423-9

Duration at 0.050: 224/230-deg

Lift: 0.552/0.561

Lobe Separation Angle: 110-deg

Installed Position: 105.5-deg

Lifters: Comp Cams roller

Valvesprings: Comp Cams, dual, PN 987-16 Seat Pressure: 121 lbs

Open Pressure: 328 lbs

Timing Chain: Cloyes double roller

Induction

Carb: See next issue.

Intake Manifold: See next issue.

Ignition

Distributor: Stock points-type

Coil: Stock replacement

Wires: Stock replacement

Exhaust

Manifolds: Reproduction iron SD

Outlet Size: 2.5-inch

Gaskets

Brand: Fel-Pro

Ancillary Components

Flexplate: RPW, 1845500

Flexplate Bolts: ARP, 200-2904

Plug Kit: Pioneer, PE-115-R

Rear Seal: Fel-Pro, BS-40012