Those of you who have been following our engine challenge know that horsepower and torque were only two aspects of each engine that were rated in our challenge. The cost of the parts in each engine was also factored to achieve a composite score for each engine. Our competition was very close with only decimals separating the competitors, a clear indication of the time each builder spent picking the proper parts to make cost effective horsepower. this month's two feature engines placed third and fourth in our challenge, and we must say we were impressed with the raw power of these two entries. Jeff Dickey of J.D. Engine and Machine made top power with his dual Dominator-fed Hemi, posting a very respectable and contest-leading 728.2 hp. August Cedarstrand of Speed-O-Motive wasn't far behind, leading the single carburetor entries with 722.6 hp. This month, we'll go inside both motors and look at what makes these combinations perform.

J.D. Engine And Machine; Columbia, MO

Jeff Dickey of J.D. Engine and Machine was very clear about his goal in our engine challenge. His engine would make so much horsepower and torque that no one could compete with his entry no matter how economically they built their engine. Had it not been for a couple of weak valvesprings causing valve float above 6,700 rpm, we're pretty sure he would have achieved that goal. Jeff is no stranger to powerful engines, having built everything from street friendly small-blocks to Pro Stock mountain motors. Jeff and his crew are avid racers and campaign a 10.5-inch-tire "street" car that has been upwards of 200 mph in the quarter-mile. His latest endeavor involves applying what he's learned racing the 10.5-inch car to a true NHRA legal Pro-Modified ride, which should be complete and ready to race this season. Jeff's shop in Columbia, Missouri, is a full-service machine shop and can build as much power as your budget, or your car, can handle. His keys to being competitive in the engine challenge were power, power, and more power. Knowing that cost would be factored, however, Jeff did use economical parts where he could, saving a substantial portion of his budget for his tunnel-ram and dual Dominator induction. Jeff's theory was you can't make big power unless you move air and fuel through the engine. Even with valve float greatly reducing power above 6,700 rpm, this engine posted the highest horsepower in the competition.

When it came to the short-block, Jeff knew that since his engine would need to survive six pulls at a painfully slow acceleration rate, durability would be the key to surviving this contest. After checking his Mopar Performance Siamese block, he discovered the lifter bores were not located precisely enough for his exacting standards. Realizing this would effect valve timing, he chose to bore and bush the lifter bores to their proper locations. Additionally, the block was decked so the piston was at the top of the bore, and the main journals were line honed for accuracy. He also modified the block to help the oil return to the pan, picking up extra ponies through reduced crankcase windage. Inside his block, Jeff used an Eagle 4.150-inch stroke crankshaft along with Eagle 6.76 length steel H-beam rods spinning on Clevite bearings. The crankshaft's indexing was checked and was micro-polished prior to installation. Diamond custom pistons round out the rotating assembly, which is kept oiled by a Melling pump and Milodon oil pan and windage tray. An ATI Super Dampener was utilized to keep harmonics to a minimum, as well as to make this engine legal with racing sanctioning bodies.

The J.D. Engine and Machine entry certainly wasn't going to starve for fuel with twin Bob Brook Racing-prepped Holley 750 Dominators perched atop an Indy 426-5 tunnel-ram intake. Careful camshaft selection optimized this setup, but a couple of weak valvesprings kept us from seeing this engine's true potential.

The J.D. Engine and Machine entry certainly wasn't going to starve for fuel with twin Bob Brook Racing-prepped Holley 750 Dominators perched atop an Indy 426-5 tunnel-ram intake. Careful camshaft selection optimized this setup, but a couple of weak valvesprings kept us from seeing this engine's true potential.

Knowing that his tunnel-ram induction would require a precisely matched top end, Jeff utilized Stage V aluminum cylinder heads, which were fully ported by Total Flow Products. Manley stainless-steel valves were matched with Manley valvesprings and kept in place with titanium retainers and ten-degree locks. We can certainly attest to the strength of this valvetrain setup, as this engine floated the valves from 6,700 to 7,000 rpm each pull without dropping a valve or doing any noticeable damage. It seems that during testing prior to our contest, several valvesprings were weakened to the point of causing this float. Cast stands and roller rockers pushed the valves off their seats and a Competition Cams mechanical flat-tappet stick actuated the valvetrain. This camshaft was carefully selected to match the flow of the cylinder heads and induction system, taking advantage of the Hemi's ability to make killer top-end horsepower. Intake lift was .635 inch; exhaust was .627; and duration at .050-inch lift was 263 and 267 degrees, respectfully. Matched with 1.6-ratio intake and 1.55-ratio exhaust rocker arms, this combination definitely let enough air and fuel into the combustion chamber to rattle the wax out of your ears in the open-header configuration. Topped off with an in-house ported Indy 426-5 tunnel-ram intake and dual Holley 750-cfm Dominators, this engine definitely had the intimidating looks to back up its power.

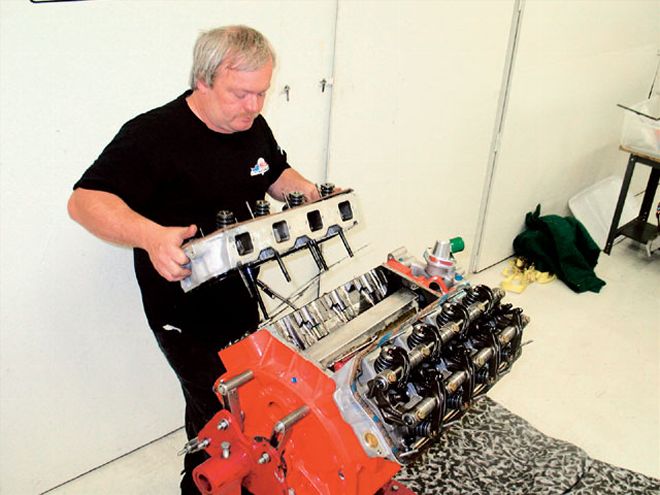

Jeff Dickey assists with the post dyno inspection of his motor by pulling the Stage V cylinder head so that bore and stroke could be measured. This engine was just shy of our 500ci limit and would be a fun ride in any street or race Mopar.

Jeff Dickey assists with the post dyno inspection of his motor by pulling the Stage V cylinder head so that bore and stroke could be measured. This engine was just shy of our 500ci limit and would be a fun ride in any street or race Mopar.

While the costly induction system and valve float issue did cost J.D. Engine and Machine top honors, we congratulate them on their third place ranking and were impressed by the power this engine made. Some may say that a tunnel-ram doesn't belong on the street, but we say pull up next to us without one, and we'll show you our taillights!

Speed-O-Motive; West Covina, California

It is generally known that the hot-rodding craze began shortly after World War II in southern California and quickly spread throughout the country. One company that was there from the inception was Speed-O-Motive. Opening their doors to support the automotive aftermarket in 1946, Speed-O-Motive quickly gained a reputation for providing gearheads with go-fast goodies. Their reputation as a quality, full-service machine shop specializing in stroker combinations continues to this day. Speed-O-Motive has years of motorsports experience and is known for providing lots of power-for-the-dollar, no matter what you're building. Their engines are a healthy combination of power and real-world streetability on pump gas. For their entry in our Hemi challenge, they drew from years of trial-and-error experience in combination with modern parts selection and metal coating technology to build the most powerful single-carburetor entry in our challenge.

The Speed-O-Motive entry utilized the same Mopar Performance block as the rest of our competitors, which was fully CNC machined on their Rottler equipment and honed with torque plates. Inside their block, August and the guys from Speed-O-Motive began with the solid foundation of a forged Eagle 4.150-inch stroke crankshaft and Eagle H-beam connecting rods measuring 6.86 inches. Eagle crankshafts and connecting rods were the choice of most of our competitors due to their excellent strength and affordable cost. Ross custom-forged pistons were utilized to fill the holes after being coated with a thermal barrier coating and Federal Mogul main, and Clevite rod bearings kept things spinning freely on a film of Royal Purple synthetic engine oil. Total Seal gapless piston rings and a low-tension oil ring kept the combustion chambers sealed. The rotating assembly was balanced and held together with ARP fasteners. A Melling high-volume oil pump was matched with a Milodon low-profile oil pan and windage tray to keep everything lubed. A Chrysler SFI-approved vibration dampener was then bolted on to keep harmonics to a minimum.

The Hemi engine is synonymous with top-end power, so Speed-O-Motive took advantage of Stage V aluminum cylinder heads for their build. Porting and polishing were performed in-house to maximize flow before installing stainless-steel Ferrea intake and Manley exhaust valves. Manley springs and titanium retainers were also utilized to keep the valvetrain stable. Stage V roller rocker arms were matched with T & D rocker shafts to actuate the valves. Combustion chambers were coated with a thermal barrier coating designed to reduce detonation, allowing for slightly higher compression while using our Rockett Brand 93 octane fuel. When it came to camshaft selection, Speed-O-Motive chose Competition Cams to custom grind their flat-tappet bumpstick. Not wanting to give away any secrets, they would only say that lift was in the ".550 to .650-inch lift range." Based on the idle qualities and performance of this engine, it's our guess that lift was closer to .650 inch than .550 inch. Comp solid lifters were matched to the camshaft, which was spun by a billet timing set with a Torrington-style thrust bearing. Topping off this potent combination is a Stage V single-plane aluminum intake with a 4500 series carburetor flange. A Barry Grant Race Demon carburetor handled the air/fuel mixing duties and an MSD Pro-Billet distributor fired the mixture.

How did it perform? How about 722.6 hp and 618.8 lb-ft of torque! This engine definitely has power to spare for a street application and should carry a mildly prepped race car into the nines with ease. While the use of specialized coatings did increase the cost to build this engine, the added protection should ensure long engine life.

We congratulate August Cedarstrand and Speed-O-Motive for their fourth place finish and for making more power than any other single-carbureted entry in our challenge.

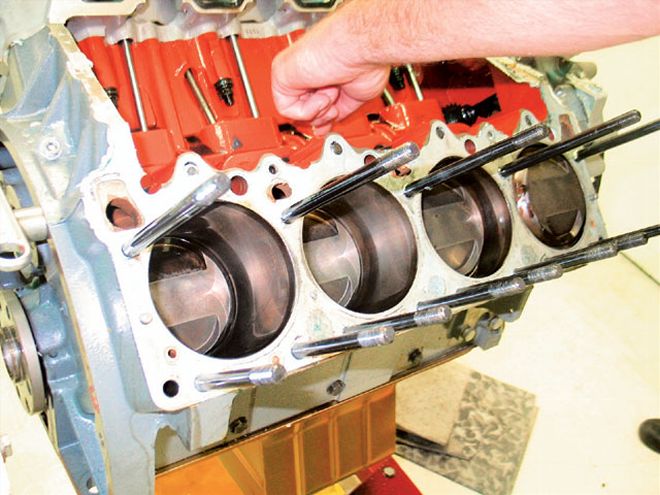

Post dyno inspection of the Speed-O-Motive entry revealed nothing but quality parts, machining, and assembly techniques. Bore and stroke measured to confirm the engine's 496ci displacement, four inches shy of our 500ci limit.

Post dyno inspection of the Speed-O-Motive entry revealed nothing but quality parts, machining, and assembly techniques. Bore and stroke measured to confirm the engine's 496ci displacement, four inches shy of our 500ci limit.