<BR>

<BR>

Although not sold in a Pontiac since 1981, the traditional Pontiac V-8 engine continues to benefit technologically from a seemingly endless array of new parts that are being developed to increase power and improve reliability and efficiency.

Despite the fact that Rochester mechanical fuel injection was introduced in 1957 on the Bonneville, electronic fuel injection didn't become a factory-installed Pontiac option until the early '80s as a throttle-body system. Hence a traditional Pontiac V-8 engine was not factory-fitted with any type of fuel-injection system after 1958.

Automakers went to fuel injection to address several issues, chiefly the mandated Federal emissions standards and consumers who wanted a more refined engine package that would start, idle, and perform consistently under all conditions.

Basic Basics

Based on the opening of the throttle blades and the amount of air entering the unit, the carburetor determines the amount of fuel required to atomize with the air. The resulting mixture enters the intake-manifold plenum via the carb's throttle blades. It then flows through the intake-manifold runners and into the intake ports of the cylinder heads. When the intake valve opens, the mixture enters the combustion chamber.

The basics of electronic fuel injection are similar to the throttle-body style-other than the electronic part, that is! An electronic control unit (ECU) commands the fuel-injection system, be it throttle-body or port-type, via various sensors.

Port fuel-injection systems introduce the fuel via injectors placed in the intake manifold as opposed to through the throttle body, therefore the intake manifold only flows air and is considered a dry-flow system. By dispersing fuel in a fine mist right before it enters the port of the cylinder head, better mixture control can be maintained in a port-injection system than with a carburetor or throttle-body system. Due to the nature of their design, these wet-flow systems are more subject to fuel dropout and distribution issues.

According to David Butler of Butler Performance, "From a power perspective, there is very little difference between a carburetor that is properly sized and dialed-in versus an EFI system. The primary benefits of an EFI system are that rather than replacing jets or secondary rods to compensate for increased temperatures or atmospheric conditions, a street engine or full-race application can allow the ECU to adjust various parameters, ensuring consistent performance."

Converting a classic-Pontiac engine to electronic fuel injection is not the daunting task that it once was. Complete systems and high-quality parts are now available that allow the hobbyist to tailor an EFI system to their particular requirements.

Follow along as a selection of fuel-injection systems are highlighted. We will also explore a selection of other components available to transform your classic Pontiac into an electronically fuel-injected vehicle.

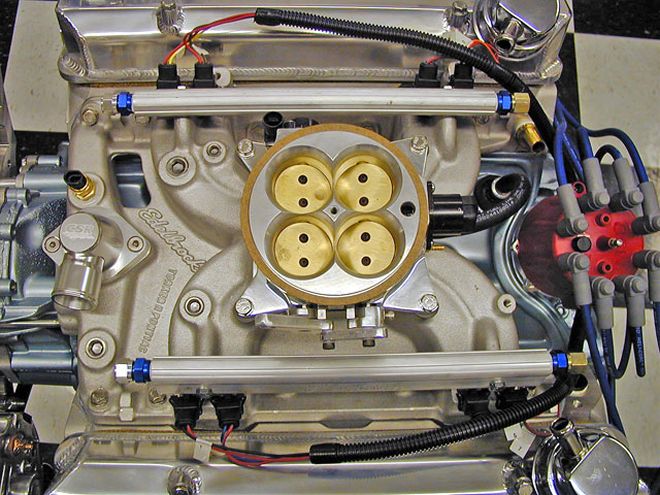

A Butler Performance crate engine outfitted with an EFI kit awaits delivery to a customer. This 600-horse street engine is using the baseline EFI kit and is optioned with a MSD Pro-Billet distributor and Cap-A-Dapt phasable rotor.

A Butler Performance crate engine outfitted with an EFI kit awaits delivery to a customer. This 600-horse street engine is using the baseline EFI kit and is optioned with a MSD Pro-Billet distributor and Cap-A-Dapt phasable rotor.

Butler Performance

For about a year, Butler Performance has been marketing and selling complete classic-Pontiac EFI kits that start at $3,499. The baseline kit supports up to 650 hp, and options are available to handle upwards of 1,000 hp. In kit format, the system is setup to utilize speed-density tuning via the F.A.S.T. XFI-computer Windows-based software. Fuel delivery is handled in an efficient bank-to-bank mode, firing half the engine's injectors every 360 degrees of crankshaft rotation for great fuel control and excellent drivability.

ECU: F.A.S.T. XFI ECU with O2 sensor provisions. Includes wiring, fuel-injection and ignition harnesses, a wideband O2 sensor, water and air temperature sensors, and a 1-bar MAP sensor. The base kit contains provisions to hook up the ignition harness to a standard GM HEI or a magnetic pickup distributor such as MSD's Pro-Billet (recommended).

Fuel Rails/Throttle Body: Edel-brock aluminum fuel rails with 91/416-inch-id fuel passage and accessories to support eight Pico-style injectors (1.5-inch O-ring spacing); includes Edelbrock 35 lb/hr injectors. The throttle body is an Accufab or F.A.S.T four-barrel unit rated at 1,375 cfm, and it includes a GM-based throttle position sensor (TPS) and idle air control valve (IAC).

The base Butler Performance EFI system supports up to 650 hp and operates using the F.A.S.T. XFI ECU. The ECU uses two different strategies to calculate fuel and spark: speed-density and Alpha-N. Individual cylinder control is a feature that can be used with either of these strategies. A laptop is employed to alter the calibration through specific user-friendly software.

The base Butler Performance EFI system supports up to 650 hp and operates using the F.A.S.T. XFI ECU. The ECU uses two different strategies to calculate fuel and spark: speed-density and Alpha-N. Individual cylinder control is a feature that can be used with either of these strategies. A laptop is employed to alter the calibration through specific user-friendly software.

Manifold: The intake is an Edelbrock Victor EFI (based on the Torker II) or Super Victor EFI. Super Victor EFIs are available to fit standard-bore and Dominator flanges. Any manifold, including custom sheetmetal units, can be converted to a fuel-injection-ready manifold.

Fuel System: Barry Grant (BG) model 171006 fuel-injection electric fuel pump, BG model 171023 bypass fuel regulator, and BG fuel filter.

Operating Modes: The F.A.S.T. XFI ECU is a microprocessor-controlled unit that utilizes F.A.S.T.'s C-COM XFI software. Its Windows-based software is tuneable while the engine is running and is done via laptop. The ECU is capable of sequential fuel injection or bank-to-bank operating modes. Additional capabilities include multiple ignition strategies such as HEI or IPU (inductive pickup unit), 1-3-bar MAP capabilities, and the ability to data log a host of other critical engine elements. The computer can control auxiliary components such as fuel pumps and fan controls and allows up to four custom ECU tunes to be stored with switching capability.

Not Included: Fuel lines, distributor.

Options: Butler Performance will design a system to meet the customer's needs. All systems can be optioned to support nitrous and power-adder (turbo or supercharged) choices. Options include larger fuel injectors (up to 160 lb/hr), a 2,000-cfm throttle body, and 2- and 3-bar MAP sensors. Complete fuel systems are available as well as custom fuel-tank modifications. An MSD Pro-Billet distributor with a fully phasable rotor is also available. For customers without experience in tuning aftermarket fuel systems, Butler will supply custom tunes ($200) that have been developed for street engines in the 500-600hp range.

System Availability: Systems are custom designed and available 1-2 weeks after order. All supply parts are available through Butler or the original manufacturer.

MASS-FLO EFI

Mass-Flo EFI has just released its classic-Pontiac EFI kits, which retail at $3,750. The baseline kit supports up to 600 hp, and options are available to bump that limit to upwards of 1,000 hp. In kit format, the system is set up to deliver sequential fuel-injection tuning via a MAF system based on the Ford EEC-IV ECU. A custom tune is created for each customer, and once the system is installed, no additional tuning is required.

ECU: Ford's EEC-IV ECU is the basis for the system. The computer is completely refurbished, and a custom Mass-Flo cover is fitted to facilitate mounting. It includes a stand-alone computer harness along with two O2 sensors, a water and air temperature sensor, a barometric sensor, and a mass airflow (MAF) sensor. The base kit contains provisions to hook up the ignition harness to a supplied custom distributor using Hall-effect electronics. This Mallory-based distributor utilizes a custom-machined base for the Pontiac engine and production electronics available at any auto parts store. Mallory's epoxy-core coil is provided.

Fuel Rails/Throttle Body: Mass-Flo aluminum extruded fuel rails with 91/416-inch-id fuel passage and accessories to support eight injectors (2.650-inch O-ring spacing). Includes Delphi high-impedance injectors ranging from 19-70 lb/hr depending on engine output. The four-barrel throttle body is custom-manufactured in-house at Mass-Flo and is rated at 1,000 cfm. It includes a progressive linkage system utilizing sealed roller bearings and has the airflow to support up to 750 hp. The throttle body includes a Ford-based throttle position sensor (TPS) and idle air control valve (IAC). The MAF is based on a GM LS6 85mm unit that is custom-machined to fit on top of the throttle body and inside the air cleaner (only 211/48-inches tall). Once the MAF is machined at Mass-Flo, the meter is flow-bench tested and the electronics are recalibrated for each application.

Manifold: The intake is an Edelbrock Torker II or Victor. Each manifold is modified in-house to accept the Mass-Flo injectors and fuel rails.

Fuel System: Fuel system not included, but available.

Operating Modes: The Mass-Flo Ford EEC-IV ECU is a modern OEM system that uses a MAF in order to meter incoming air and calculate load to determine fuel requirements. Mass-Flo burns a custom chip for each customer based on the customer's engine flywheel horsepower and displacement. The MAF-based system normally supports changes of up to 100 crankshaft horsepower without additional tuning. In cases outside of what the ECU can adjust for, Mass-Flo will recalibrate the MAF and complete a retune of the ECU for a nominal charge. The ECU can control auxiliary components such as fuel pumps and fans and allows up to two custom ECU tunes to be stored with switching capability.

Not Included: Fuel system.

Options: Mass-Flo will design a system to meet the customer's horsepower requirements. A bonnet and ATI tube with integrated MAF supports blow-through turbo and supercharger options. Other options include additional computer functionality such as rev limiters, adjustable timing retard for boosted applications, and CD and multi-strike ignition systems. Complete fuel systems that utilize either a Mallory S110FI electric external pump or a Walbro-based 250-lph in-tank pump are available from $625-$695. A socketless hose from Mr. Gasket is included in the base kit with stainless braided hose as an option.

System Availability: Systems are custom-designed and available 1-2 weeks after order. All supply parts are available through Mass-Flo or at a local auto parts store (distributor cap, throttle body electronics, and so on).

Wilson's throttle bodies, including this square-bore, 4150-flange, 1,136-cfm unit, are all custom-made in-house using 6061-T6 billet aluminum. Fully machined throttle shafts are one of the many high-quality features inherent in the advanced design.

Wilson's throttle bodies, including this square-bore, 4150-flange, 1,136-cfm unit, are all custom-made in-house using 6061-T6 billet aluminum. Fully machined throttle shafts are one of the many high-quality features inherent in the advanced design.

Wilson Manifolds

Wilson Manifolds is most noted for its stellar reputation, providing intake manifolds to some of the top teams in NASCAR, NHRA, and a host of other professional racing series. With this racing heritage and the custom services it provides for intake manifolds, the company has expanded its focus and now offers custom-made EFI conversion kits for classic Pontiacs starting at $2,300. Pricing includes custom-machined high-flow fuel rails, stanchions, injector bosses, billet throttle body, and conversion labor. The ports are polished underneath the injector bosses for maximum flow. In kit format, the system is setup to utilize speed-density tuning via the F.A.S.T. XFI computers Windows-based software.

ECU: F.A.S.T. XFI ECU with O2 sensor provisions. Includes fuel-injection and ignition harnesses, a wide-band O2 sensor, water and air temperature sensors, and a 1-bar MAP sensor. The base kit contains provisions to hook up the ignition harness to a standard GM HEI distributor or a magnetic pickup distributor such as MSD's Pro-Billet.

Wilson's high-flow fuel rails are extruded aluminum with massive 111/416-inch-id fuel passages. The anodized purple fuel rails support high-horsepower applications. Various sizes of fuel injectors are sold separately, and Wilson's design team will work with you to properly size the injectors.

Wilson's high-flow fuel rails are extruded aluminum with massive 111/416-inch-id fuel passages. The anodized purple fuel rails support high-horsepower applications. Various sizes of fuel injectors are sold separately, and Wilson's design team will work with you to properly size the injectors.

Fuel Rails/Throttle Body: Custom-made Wilson Manifolds extruded aluminum fuel rails with 111/416-inch-id fuel passage and accessories to support the customer's choice of fuel injectors. The supplied billet-aluminum throttle body is a Wilson Manifolds four-barrel unit designed for a standard 4150-flange that is rated at 1,136 cfm. It includes a GM-based throttle position sensor (TPS) and idle air control valve (IAC).

Operating Modes: F.A.S.T.'s XFI microprocessor-controlled ECU unit employs the company's C-COM XFI software, which is Windows-based and field-flashable with tuning done via laptop. The ECU is sequential fuel-injection or bank-to-bank mode capable. Multiple ignition strategies such as HEI or IPU (inductive pickup) are available; 1-3-bar MAP capabilities are built in; and data logging of fuel pressure, EGT, and a host of other critical engine elements can be performed. Auxiliary components can be controlled, and up to four custom ECU tunes can be stored with switching capability.

Not Included: Manifold, fuel injectors, fuel pump, fuel lines, distributor.

Options: Fuel injectors run between $300 to $400 depending on horsepower application. For higher horsepower, throttle bodies that flow up to 2,008 cfm are available in Dominator flanges. A full race setup with a 90-degree elbow and a 90mm billet single-port throttle body are popular options for supercharged and turbocharged applications. Additional labor to perform manifold conversions that include custom nitrous port injection (one, two, or three stage) is also available at an added cost, along with intake porting for $600. Wilson sells MagnaFuel brand fuel systems, and a popular choice is the Pro-Star 600 EFI pump that flows 325 lph and supports up to 2,000 hp (retails for $440.99). MagnaFuel regulators and fuel filters are also available.

System Availability: Systems are custom-designed and available 2-3 weeks after Wilson receives the customer's manifold. Additional custom work takes longer and is quoted to the customer at the time of the order. All supply parts are available through Wilson Manifolds or the original manufacturer.

Edelbrock Corporation

Edelbrock has been developing a line of EFI conversion kits for classic-Pontiac engines for the last couple of years. Release of the Pro-Tuner small- and big-block Chevrolet EFI package is scheduled for late Fall 2006, with classic Pontiacs available in early 2007. Anticipated retail is under $3,000 for the Victor series Pontiac kit, with pricing to be determined on the Super Victor kit. The basis of the package is a Motorola ECM that operates with Edelbrock's own Pro-Tuner Windows-based software.

ECM: Motorola ECMs are used, which can be configured to run in Alpha-N, speed-density, or modeled airflow speed density. The Pro-Tuner EFI kit includes a complete engine, ignition, and fuel-pump wiring harness.

Sensors: All necessary sensors are included in the kit; water and air temperature sensor, a 1-bar MAP sensor, and a narrow-band oxygen sensor (a wide-band sensor is optional). The base kit also contains an MSD Pro-Billet distributor and ignition module.

Injectors: Edelbrock's 60 lb/hr injectors can support from 300 hp at 30 psi to over 1,000 hp at 100 psi. Edelbrock Pico injectors are also compatible with the Pro-Tuner for those with limited room for fuel rails.

Operating Modes: Edelbrock's Pro-Tuner series EFI systems can be software-configured to run in any one of three tuning methods:

Not included: Manifold, fuel rails, throttle body, fuel pressure regulator, or plumbing.

Options: Edlebrock offers upgrades to the Pro-Tuner kits, including a Pro-version software key that opens advanced tuning features (standard with the Super Victor series), 0-100-psi sensors for fuel and oil pressures, 2-bar MAP sensors for boosted applications, and a second narrow-band oxygen sensor for monitoring each bank of the engine.

Available separately are Edelbrock square-bore throttle bodies flowing 1,000 cfm and Dominator flange units flowing 1,600 or 2,000 cfm. The Pro-Tuner can support any throttle body with a PWM-type (pulse width modulated, such as a Ford two-wire) idle motor.

Intakes can be ordered separately, and a user can choose from the Edelbrock Victor EFI (based on the Torker II intake) or Super Victor EFI. Super Victor EFIs are available to fit standard 4150 and Dominator flanges. Also available separately are the Edelbrock aluminum fuel rails with 91/416-inch-id fuel passage and accessories to support eight standard or Pico-style injectors (1.50-inch O-ring spacing).

Edelbrock fuel pumps and regulators can be ordered and are sized appropriate to the horsepower requirements.

System Availability: Systems are scheduled to be available in early 2007.

Universal Systems And Auxiliary Components

Some companies listed below provide universal EFI kits with myriad choices for components, therefore, what is listed here is not all-inclusive of the products they offer.

ACCEL DFI

ACCEL offers its latest revision of the ACCEL/DFI ECU and engine-control software; the Generation 7.0+ programmable ECU and CalMap engine-control software. The Gen-7.0+ generation of ECU operates in speed-density mode and is capable of batch and sequential fuel-injection strategies. Carried under part number ACC-77046P at Scoggin Dickey (SDPC), it retails for $1,298.99 and includes the CalMap software and interface cable.

According to ACCEL, the Gen 7.0+ system not only provides precise control of all aspects of fuel delivery and ignition timing, but also offers features and benefits that have never been available from a programmable engine-management control system before. This system provides enhanced idle air control, including preset control values for most engine combinations and improved fueling control for street and race applications. The Gen 7.0+ system offers crisper or heightened throttle response for single and multiple throttle-body induction systems, improved cold-weather startup, and enhanced communications for faster program file uploads and downloads.

Also, its water-resistant enclosure and main harness connections allow the Gen 7.0+ electronic control unit to be mounted in the passenger compartment or under the hood. Other features include enhanced knock control, enhanced acceleration enrichment management, and improved O2 control for wide-band and standard feedback systems.

Though the primary focus of this guide is port fuel injection, we should mention that Holley has four-bbl and two-bbl TBI Commander 950 Systems (PNs 950-19S through 950-24S). According to Holley, "These are complete EFI systems that will replace the carburetor with a four-bbl TBI and will work with the Wide-band Upgrade kit. They are the quickest and most economical way to add EFI to an older engine." They are made for a square-bore bolt-pattern intake.

Though the primary focus of this guide is port fuel injection, we should mention that Holley has four-bbl and two-bbl TBI Commander 950 Systems (PNs 950-19S through 950-24S). According to Holley, "These are complete EFI systems that will replace the carburetor with a four-bbl TBI and will work with the Wide-band Upgrade kit. They are the quickest and most economical way to add EFI to an older engine." They are made for a square-bore bolt-pattern intake.

This is the Holley Commander 950 ECU.

This is the Holley Commander 950 ECU.

Holley Commander 950

Holley offers the Commander 950 ECU as well as the Commander 950 Multi-Point universal fuel-injection kits. The ECU operates in speed density or Alpha-N modes (throttle position sensor and rpm-based computer logic). It (PN 534-120) allows the use of 1-, 2-, or 3-bar MAP sensors and can control eight high-impedance or four low-impedance fuel injectors, or eight low-impedance injectors with an auxiliary injector driver (PN 534-122). Commander 950 Pro software is Windows-based, and the fuel and ignition timing maps can be viewed graphically. The ECU has built-in internal data-logging capability and will interface with multiple timing strategies including GM HEI. This system operates in open- or closed-loop and is capable of controlling a standard O2 sensor or a wide-band O2 sensor when the Wide-band Upgrade kit (PN 534-188) is used.

Universal fuel-injection kits are also available for a 1,000-cfm (PN 534-183; retail $1,496.99, SDPC) or 2,000-cfm (PN 534-184; retail $1,763.99, SDPC) throttle body. The kit contains the Commander 950 ECU, software, wiring harness, fuel rails, MAP, air temperature sensor, oxygen sensor, and billet fuel-pressure regulator. Aluminum fuel rails are included, as are eight injector bungs so you can retrofit the system into the manifold of your choice.

This LS6 MAF and 3-inch Pro-Tube retail for $358.56.

This LS6 MAF and 3-inch Pro-Tube retail for $358.56.

A polished version of the Pro-Tube is available for $380.97.

A polished version of the Pro-Tube is available for $380.97.

Professional Mass Air Systems

Professional Mass Air Systems markets high-flow mass airflow (MAF) meters, and in addition to supplying Mass-Flo with custom-calibrated GM LS6 MAFs that will fit in the air-cleaner assembly, the company offers its Pro-Tube that places a high-flow MAF within a polished 3- or 3.5-inch aluminum tube. For high-horsepower supercharged and turbocharged applications, the Pro-Tube can be combined with a forced-induction throttle-body (carburetor) bonnet such as ATIs and supports over 1,000 hp.

Professional Mass Air Systems also provides custom MAF tuning to support various GM computer configurations that prevent the MAF from being saturated by the late-model GM computer's nominal 533 grams-a-second measurement capability. Rescaling the MAF on LS1/LS2/LS6 applications allows the stock GM computer to be retained without resorting to an aftermarket ECU.

The Aeromotive 11101 in-tank pump supports extreme horsepower and flows approximately 335 lph. Included in the Stealth series tank is a 100-micron stainless steel fuel filter. Options exist to run dual pumps in the Stealth series with one pump, triggered by a Hobbs switch, providing auxiliary fueling for boosted applications.

The Aeromotive 11101 in-tank pump supports extreme horsepower and flows approximately 335 lph. Included in the Stealth series tank is a 100-micron stainless steel fuel filter. Options exist to run dual pumps in the Stealth series with one pump, triggered by a Hobbs switch, providing auxiliary fueling for boosted applications.

The pictured Stealth tank is destined for a '69 Firebird. All Stealth tanks feature removable access panels for the pump and filter.

The pictured Stealth tank is destined for a '69 Firebird. All Stealth tanks feature removable access panels for the pump and filter.

Rick's Hot Rod Shop

Rick's Hot Rod Shop specializes in musclecar fuel tanks designed to support EFI fuel-system requirements. Custom-made tanks are produced in-house on state of the art CNC machinery and are constructed of 16-gauge 304 stainless steel. The tanks are slightly deeper in the front and have separate front and rear reservoirs as well as integral side-to-side baffling.

Offered in the FI series, the tanks utilize a Walbro GSS 340 in-tank pump rated at 255 lph and retail from $1,195-$1,295 for all popular GTOs and Firebirds. For applications exceeding approximately 600 hp, an enthusiast can purchase a Stealth series tank. For $1,995, this tank features larger -10 inlet and -8 AN return fittings and uses an Aeromotive 11101 in-tank pump to support extreme horsepower.

In addition to new tanks, Rick's will retrofit any new conventional fuel tank with the F1 series Walbro pump for a delivered price including shipping of $495. Non-stocked tanks can be custom made as Rick's has thousands of available tank patterns. Since each EFI tank utilizes a return-style fuel line, Rick's can meet all of your fuel line and regulator needs to allow your EFI conversion to take off.

Speed-Density Versus Mass-Airflow-Metered Systems

In order to explain electronic fuel injection, one must first determine what type of system is being marketed and the advantages and disadvantages of each.

A speed-density-based system uses a throttle position sensor (TPS) located on the throttle body along with a manifold absolute pressure (MAP) sensor to determine load on the engine.

Since the ECU is programmed for a single engine and its inherent volumetric efficiency, when the engine is modified, changes to the tuning have to occur to compensate. Changes are accomplished via a laptop computer with manufacturer-supplied software. Dyno time and/or real-time data collection is necessary in order to adjust the fuel and timing curves to properly tune the engine. Once dialed-in, the speed-density system is very accurate and dependable.

Usually the favorites of power-adder racers and street vehicles alike, speed-density-based systems used to be criticized for poor engine-idle quality. With the advent of faster processors, the idle issue has been addressed and idle characteristics are much improved.

Mass airflow systems use a mass airflow meter to feed data to the ECU. This MAF fuel-injection system uses the intake-air temperature sensor (IAT), a throttle position sensor (TPS), and the amount of air flowing through the MAF as references for the software to determine how much timing and fuel to provide.

The main advantage of a MAF-based system is the ability of the ECU to adjust based on a greater number of data points than a speed-density-based system can provide. Since manifold vacuum is not a contributor to load calculations of a MAF-based system, typically MAF-based systems have better idle and low-speed operating characteristics.

On the downside, packaging a MAF within a classic-Pontiac air-cleaner assembly is difficult, but even that has now been accomplished.

From a power-adder perspective such as turbocharging or supercharging, the ability of the MAF to read the amount of air passing through it has been a limiting factor. A typical GM MAF supports approximately 800 naturally aspirated horsepower.

Sensors

MAP-Manifold Absolute Pressure Sensor: This sensor is plumbed to a manifold vacuum port and measures the difference between the atmospheric air pressure and the pressure (or vacuum) inside the intake manifold. A 1-bar MAP sensor is designed for normally aspirated engines, while forced-induction motors require either a 2-bar (up to 15-psi max boost) or 3-bar (15- to 30-psi max boost) sensor.

MAF-Mass Airflow Sensor: Plumbed into the intake tract, the MAF tells the computer how much air is entering the engine so it can determine the load.

O2 Sensor-Oxygen Sensor: The O2 sensor compares the amount of oxygen in the exhaust stream with the air outside the engine. It outputs a voltage to the ECU, a feedback signal, that the computer uses to modify the amount of fuel delivered to the engine. A narrow-band oxygen sensor outputs any voltage from 0-1 volt: a high voltage if the air/fuel ratio is richer than 14.7:1 and a low voltage if it's leaner. A wide-band O2 sensor (WBO2) can sense a range of air/fuel ratios, from a rich 10:1 to a lean 20:1, with reasonable accuracy. Wide-band O2 sensors are prominent in boosted applications but are useful to all enthusiasts in order to tune the EFI system to its utmost capabilities.

TPS-Throttle Position Sensor: The TPS is usually bolted to the throttle body where it is mechanically synched up with the throttle shaft. As the throttle shaft moves, the TPS signal is provided to the ECU for interpretation. The TPS signal is critical to proper idle function and acceleration enrichment.

ATS-Air Temperature Sensor: The ATS is calibrated to measure the temperature of the air entering the engine. It's usually plumbed as close to the throttle body as possible (i.e., at the base of the air cleaner) to give the most accurate temperature reading.

CTS-Coolant Temperature Sensor: The ECU needs to know the coolant temperature to determine the proper amount of fuel to provide for both cold-start and normal operating temperatures. A CTS not only gives the computer signals to ensure all-around driveability, but when operating temperatures exceed a certain temperature, the ECU can adjust timing and fuel. The coolant temperature sensor is normally tapped into a coolant passage on top of the intake manifold.

Conclusion

Electronic control units and the software to allow the user to quickly tune the engine have made tremendous strides in the past few years. Debate will continue to rage over speed-density versus MAF-based processing units with valid arguments on both sides of the equation. Suffice it to say that due to faster processor speeds, the days of poor engine-idle control due to low-vacuum readings on a MAP sensor are almost behind us.

For the enthusiast looking to convert a classic-Pontiac engine to an EFI system, there are some very good choices in the marketplace. According to Melvin Benzaquen, president of Classic Restorations and a HPP contributor, "research the market and choose a system based on how the engine is modified: drag-race car versus street car."

Planning is the most important factor in completing a successful EFI conversion. Will you use an in-tank pump or a frame-mounted external pump? Hard steel or stainless braided fuel lines? Where is the ECU going to be placed? In the engine compartment? Or does it have to be protected by installing it inside? Routing of the ECU harness, the fuel-pump harness, and the injector harness is also crucial to planning for a neat and orderly installation, as well as making sure everything is routed away from any heat sources and anything that could potentially be chafed or pinched. Hood clearance, especially on a Trans Am, is very critical. Once all these parameters have been explored and worked out, it should make for a smooth installation with minimal problems.