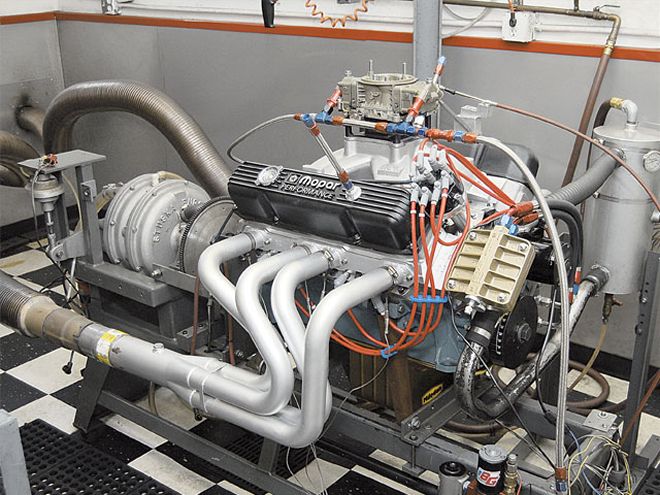

We strapped our little 383 stroker back to the dyno after treating it to some big Indy EZ heads and a healthy Comp cam. We saw 625 horses, and then we saw smoke.

We strapped our little 383 stroker back to the dyno after treating it to some big Indy EZ heads and a healthy Comp cam. We saw 625 horses, and then we saw smoke.

The Situation

In our May 2006 issue, we built a 383 stroker motor using a 413 crankshaft and rods from 440Source, and pistons from Diamond Racing. This little 432-inch stroker-motor cranked out 500 hp using cast-iron 906 heads, and then stepped up to 545 hp when topped with some Edelbrock aluminum heads. While that was a nice amount of power for a fairly simple combination, we got a little greedy and decided to see how much power our simple 3.75-stroke short-block would make when we topped it off with a pair of Indy EZ heads. Not only did we step up to these brand-new Indy heads, we treated the heads to a CNC porting job at Modern Cylinder Head, and we called Competition Cams for a bigger bumpstick.

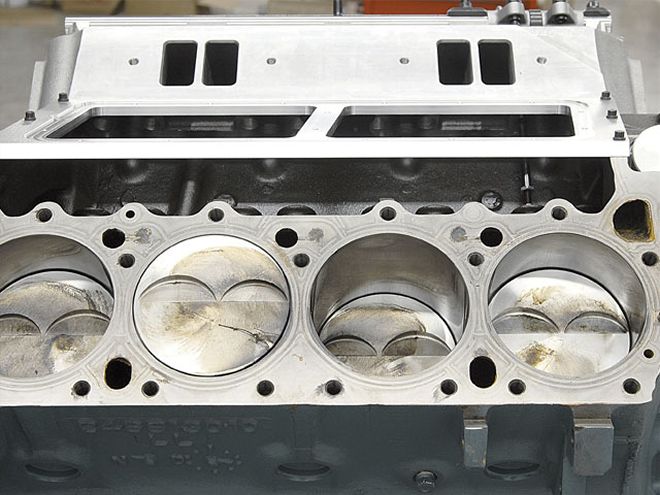

Here is what our 383 stroker short-block looked like after dyno testing with the 906 and Edelbrock heads. This short-block was built with Diamond Racing pistons, 440Source rods, and a reworked RB crankshaft. Final displacement is 432 inches.

Here is what our 383 stroker short-block looked like after dyno testing with the 906 and Edelbrock heads. This short-block was built with Diamond Racing pistons, 440Source rods, and a reworked RB crankshaft. Final displacement is 432 inches.

The Short-block Combination

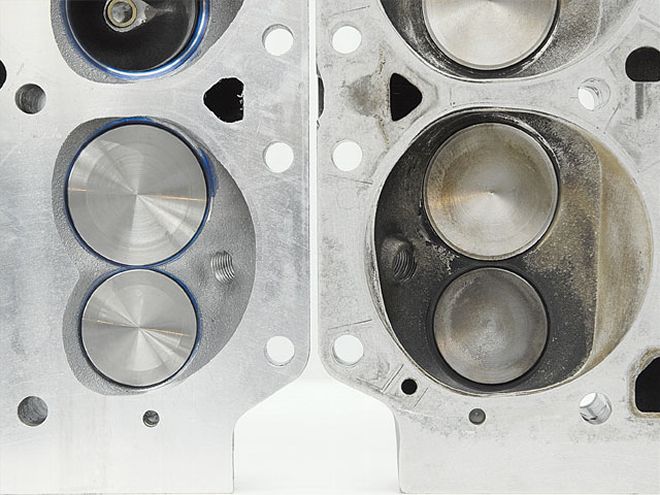

Those of you who read part one in our May issue will recall we were using the new flat-top pistons from Diamond Racing hung on 6.760-inch-long I-beam rods from 440Source. This combination gave us a compression ratio of 10:1 with the 84cc Edelbrock heads, but with the smaller 75cc chambers in the Indy heads the compression ratio increased to 11:1.

We did not make any changes to the short-block for this next round of testing other than changing the oil and sliding in the bigger camshaft. The camshaft we ordered from Comp Cams was a custom grind using what Comp calls their SQ lobes. The SQ family of lobes are an aggressive design when used with an .0875-inch diameter solid lifter (Ford diameter), but work well with the slightly larger .904-inch diameter lifters. This particular camshaft used number 7265 lobe on both intake and exhaust. The 7265 lobe has 270 degrees of duration at .050-inch lift and has a lobe lift of .400. The lobe center angle was 106 degrees, and the cam was installed straight up on a 106-degree centerline. We were able to reuse our existing lifters since we are using Schubecks with the super hard face material. The Schubeck lifters can be cleaned up and dropped back in on the new cam without any break-in period required.

The combustion chamber of the Indy head is on the right; the Edelbrock chamber is on the left. As you can see, the Indy chamber is slightly smaller. On this 432 motor, the smaller Indy combustion chamber increased the compression ratio from 10:1 to 11:1.

The combustion chamber of the Indy head is on the right; the Edelbrock chamber is on the left. As you can see, the Indy chamber is slightly smaller. On this 432 motor, the smaller Indy combustion chamber increased the compression ratio from 10:1 to 11:1.

Indy EZ heads

These new heads from Indy Cylinder Head are the answer for engine builders who need to keep the exhaust ports in the factory location. While other Indy heads have the exhaust ports raised for better flow, the guys at Indy figured out how to get a decent exhaust port into a fairly stock location on these heads. These EZ heads can be ordered in four different configurations, including an unported version and three different versions of CNC porting. The CNC porting available from Indy includes their 275cc EZ-1 version, as well as their 295cc and 325cc version. The Indy EZ head with the 295cc port is called the Little Easy; the 325cc version is called the Big Easy. The EZ-1 head uses stock-type rocker arms and provides oil to the valvetrain through the block-like stock heads. The 295cc and 325cc heads from Indy have to use external oiling since the porting makes the wall thickness too thin in that area. In addition to the external oiling, the Indy 325cc head has to use offset rocker arms on the intake valves since the pushrods have been moved to accommodate the larger runner size.

The size of the runner is important to consider when building an engine since there is a direct relationship between the size of the motor, the size of the intake runner, and the rpm where the torque peak occurs. A subject such as this can start to get a little complex, so your best bet is to call the guys at Indy Cylinder Head and have them help you pick the correct version for your application.

We sent the heads to Modern Cylinder Heads in Clinton Township, Michigan, for their CNC porting. They profiled the chamber, as well as fully ported the intake and exhaust runners.

We sent the heads to Modern Cylinder Heads in Clinton Township, Michigan, for their CNC porting. They profiled the chamber, as well as fully ported the intake and exhaust runners.

Porting the Heads and Intake

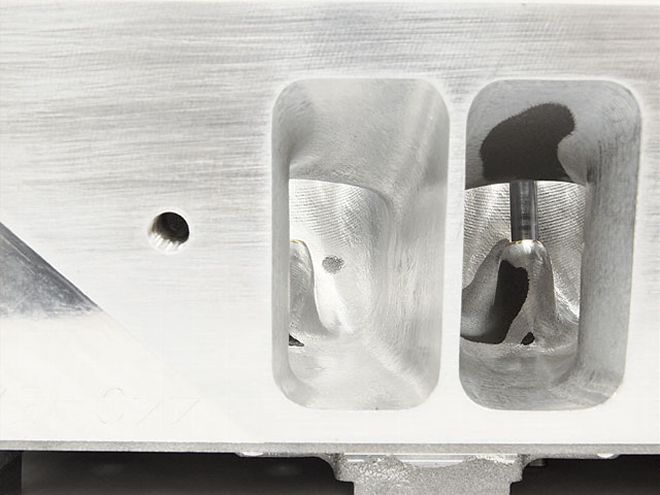

We originally ordered the unported version of the EZ heads with the standard size ports so we could run the motor with a standard port Victor manifold. We had run the Victor intake manifold with the Edelbrock heads in the last dyno test and were quite happy with the results. But some discussions with different engine builders, combined with a few quick dyno pulls, convinced us the standard port heads and intake were not going to be happy with our big cam. The big cam killed the torque at lower speeds, while the smallish heads and intake manifold didn't allow the motor to come alive on the top end. We've since learned our lesson. It was a classic case of mismatched components, so we pulled the heads off and sent them to Jeff Kobyiski at Modern Cylinder Head (MCH). Jeff is well known in SS/AA circles as the guy who makes Hemi heads and intakes really work, but he also has CNC porting programs for Indy and Edelbrock wedge heads.

A view down the intake ports shows the result of the CNC porting. The intake runners have been opened up to Max Wedge size. Opening up the ports to this larger size really picks up the flow on these EZ heads. Porting with a CNC program ensures an even flow characteristic with all the cylinders.

A view down the intake ports shows the result of the CNC porting. The intake runners have been opened up to Max Wedge size. Opening up the ports to this larger size really picks up the flow on these EZ heads. Porting with a CNC program ensures an even flow characteristic with all the cylinders.

The CNC program that Modern Cylinder Head uses for the EZ heads resulted in a finished intake volume of 308 cc on our heads, which made it about halfway in between the Indy choices of 295 cc and 325 cc. But the MCH version does not require external oiling or the use of offset rocker arms so it is a little easier to install. The CNC machining of the combustion chambers makes them slightly larger, but after a quick cut of the deck they are back to 75 cc, so the compression ratio stays the same. Final flow-bench numbers after the heads were finished up showed them flowing 340 cfm at .600-inch valve lift on the intakes, and 224 cfm on the exhaust side at the same .600 lift. This is about 50 cfm more than the Edelbrock heads flowed the last time we tested, so the potential to pick up some power was there.

With the heads opened up to Max Wedge size, we needed an intake manifold to match. There aren't a lot of choices for a low-deck Max Wedge intake since this was never a factory option, but Indy has tooled up a manifold to cover this option. PN 400-2 is one we purchased since we were planning on running a 950 Ultra HP Holley carb. Indy also has a version of this manifold with the big Dominator carb flange for you drag race guys. Since any intake manifold can always use a little help, we sent the brand-new manifold to MCH, along with the heads, for some plenum blending and port matching.

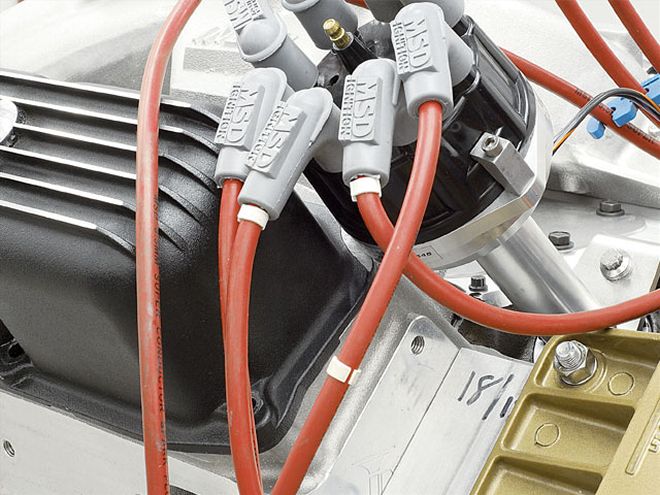

The taller Indy cylinder head caused the valve cover to interfere with the distributor housing. A few minutes with a die grinder and everything fit again.

The taller Indy cylinder head caused the valve cover to interfere with the distributor housing. A few minutes with a die grinder and everything fit again.

Valvetrain

We ordered our EZ heads from Indy without springs since we had a complete top end kit from Competition Cams ready to put to work. Comp provided us with a set of their premium flat-tappet cam valvesprings, as well as titanium retainers, 10-degree Super Locks, and assorted spring cups and shims. The valvesprings were the top-of-the-line springs designed for flat-tappet cams in the .600- to .650-inch lift range. Since we were planning on running our cam with both 1.50- and 1.60-ratio rocker arms, these springs were a perfect match for us. The springs were installed in our heads at 200 pounds of seat load, which is quite high for a flat-tappet cam, but that is exactly what the folks at Schubeck recommended.

While we were on the phone with Comp, we also ordered a set of their Pro Magnum roller rocker arms. These Comp rocker arms have been around for several years and have proven to be tough enough to handle most big flat-tappet cams as well as many roller springs. They are made from 8650 chrome-moly steel, which is significantly stronger and tougher than aluminum. The Comp arms do not have a bushing at the shaft, but this doesn't seem to be a problem if the maximum spring pressure is kept below 500 pounds. If you're going to put the rocker arms under loads higher than that, you may wish to talk to the engineers at Comp to see what they recommend.

With the head's intake ports opened up, we couldn't let the factory port size on the intake, so Modern Cylinder Head worked some magic on the Indy manifold and the heads.

With the head's intake ports opened up, we couldn't let the factory port size on the intake, so Modern Cylinder Head worked some magic on the Indy manifold and the heads.

Day One on the Dyno

It started out great, but ended well before we wanted. We started the testing with a small 750 Holley carb, and the timing was set at a conservative 36 degrees of total advance. On the first run, the dyno needle swung up to 600 hp, but we could see by the EGT readouts that the carb was a bit lean. After adding a jet size and bumping the timing to 38 degrees, we made a quick second pull. On this run, we saw 504 lb-ft of torque at 6,000 rpm and 625 hp at 7,500 rpm.

Feeling encouraged, we swapped on a larger carb and got ready to make some serious power. But the third pull of the day ended quickly when a serious stream of smoke started to come out of the valve covers. A quick teardown revealed a split cylinder wall in the number six hole, so our day was over.

We use the Cometic head gaskets on all the motors that have aluminum heads. They cost a bit more than conventional gaskets, but they sure work well. Also, you can get them custom-made in different diameters and thicknesses, so you can fine-tune your compression and quench height.

We use the Cometic head gaskets on all the motors that have aluminum heads. They cost a bit more than conventional gaskets, but they sure work well. Also, you can get them custom-made in different diameters and thicknesses, so you can fine-tune your compression and quench height.

Even though we only got one decent dyno pull on this combination, it gave us a bit of insight into what the performance could have been. The second run showed 625 hp at 7,400 rpm, and the power curve was still climbing. Obviously, these Indy heads were working with the bigger camshaft to really make power at the higher speeds. The torque peak was about the same level as when the motor had Edelbrock heads, but the peak had shifted up the rpm band from 5,100 rpm to 6,000 rpm. This shift in the torque and power peak is due to the larger cross section in the heads as well as the larger cam profile. We're pretty sure we would have seen a good solid 650 hp from this combo if we had gotten a chance to wring it out with the larger carb. The Indy advertisement says, "take the iron 906 combo off and pick up 100 hp." On this combination we saw an increase of 125 hp over our 906 heads before we even got the combination tuned; it looks like the guys at Indy have hit the nail on the head.

What Went Wrong and Lessons Learned

A full autopsy of the motor showed the whole mess was started when the number six rod bearing spun. Once that bearing got chewed up, the piston kissed the cylinder head, then cocked in the cylinder, and split the block. We're not sure why the rod bearing spun in the first place, but it was probably due to our stock oiling system not being able to keep up at 7,500 rpm. For years, the Mopar racers have been telling people to upgrade the oiling system when spinning a big-block past 7,000 rpm. Our bottom end was dead stock with the factory 31/48-inch pickup, standard oil pump, and stock oil passages in the block. When we first built this motor we weren't planning on spinning it so high or making so much power, so we just didn't invest the time and money into the oiling system, and we paid for that mistake. Guess those Mopar racers knew what they were talking about all along!