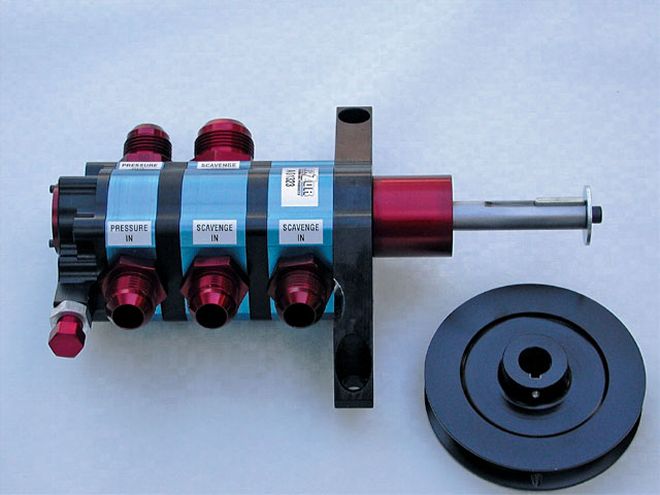

The dry-sump pump is a verycompact unit. Notice the pump drive has a simple V-belt design.

The dry-sump pump is a verycompact unit. Notice the pump drive has a simple V-belt design.

The quest for horsepower, as it seems, is never-ending. We will try many unproven, unseen, unusual and unscientific products or processes in the search for that holiest of grails-horsepower. Sometimes the answer is right there in front of you, and all you have to do is reach out and grab it. If you are racing in a class that allows dry-sump oil systems, and you are still running a wet-sump oil system, you are giving away horsepower. But, you say, "If I have to buy some other stuff, it's not free." You are right, it is not free; but that is only the short-term view, and it just shows how many of us are trapped by conventional thinking. In the longer term, we may be saving money and gaining power. One of the many advantages to using a dry-sump oil system is not just the power to be gained, but also the ability to develop a level of control over various engine subsystems in addition to your oil system. These subsystems will be significant toward filling the grail with previously untapped power gains. There are gains from using a dry-sump system that transcend other measurable gains. They go well beyond being able to control the level of oil in the engine. Once you remove all of the traditional problems associated with a wet-sump application in racing engines, you have the ability to rethink many of the other systems on the engine in order to release even more horsepower. We need to start thinking about the big picture.

The engine in your race car goes through some dynamic conditions over the course of a race: acceleration and cornering loads, which force the oil back and to either side, and deceleration loads driving the oil to the forward portions of the engine. These conditions can cause oil starvation at a time when the engine needs the protection of the oil system the most. This starvation is caused by the pump pickup becoming uncovered for brief periods of time as the car goes through these transitions. For example, as you reach the end of the straightaway (when the engine is at max rpm and max load), this is the time you really need your oil system to work at its peak. Unfortunately, just the opposite is a real possibility.

Let's step back for a second and look at the advantages that are not horsepower related, from both a qualitative and quantitative perspective. First and foremost, the dry-sump system allows you to run the engine lower in the car due to the fact that the oil pan is 4 to 5 inches shorter than a stock OE pan or even a well-designed racing wet-sump pan. The ability to move the engine lower in the chassis gives you more freedom in the placement of the engine. If you could lower your engine and subsequently lower the center of gravity in the car, would you do it? Of course you would. Even if lowering the engine is not an option, it gives you added track-to-pan clearance and/or clearance for other suspension components. Placing the engine lower in the chassis also allows for a lower hood line, which may allow a lower coefficient of drag. If the drag is lowered, then more of the horsepower you develop can be used to accelerate the car, as opposed to being consumed by overcoming aerodynamic drag. Would you like a car that is a bit more slippery from an aerodynamic perspective? From a purely physical perspective, it is clear that the advantages are additive.

If you feel that you need to adjust the amount of oil in the oiling system, you are very limited in a wet-sump application. The addition of more oil capacity in a wet-sump system can cause some other serious issues. Elevated oil levels will cause some serious windage issues. Oil that comes into contact with the crankshaft and rods at speed can cause the oil to become overly agitated and introduce high levels of air into the oil. This foaming of the oil can cause problems, such as loss of oil flow and pressure. Oil that has a high air content or becomes foamed will not cool as well. In fact, it will tend to get even hotter, which causes a variety of other issues (e.g., cooking of the oil, reduced ability of the oil to lubricate, bearing failure). Ultimately, the engine blows up in your wallet. That makes the extra costs associated with using a dry-sump almost free. Are you seeing a pattern yet?

The back of the pump shows the externally adjustable pressure relief valve. This is just one more feature that allows the user to tune the system to the exact parameters desired.

The back of the pump shows the externally adjustable pressure relief valve. This is just one more feature that allows the user to tune the system to the exact parameters desired.

By utilizing a dry-sump oil system, you have an infinite level of control over the whole oil system that you couldn't have with a wet-sump system, where you are stuck with the pump running at half the engine speed. In the dry-sump system, you can adjust the pump's speed. If you want to run the pump slower or faster, you have that option (which you do not with a wet-sump system)-all it takes is a simple drive pulley change. This may not sound like a big deal, but if your racing rpm does not vary much, or you run for a very short duration at elevated rpm levels, it may make sense to slow the pump and use the extra power that would be required to drive the pump to drive the car. Variations in mounting options may place the pump on the cam cover with no external drives to fail. You have a choice here, unlike the situation with a wet-sump system.

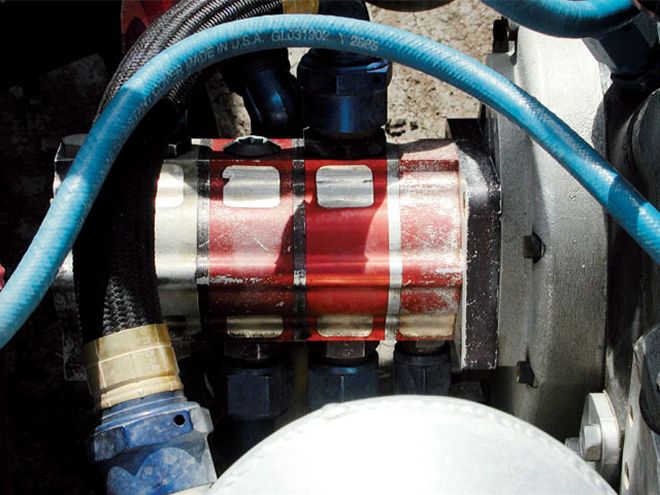

With the pump torn down, it is clear that dry-sump pumps are not as mystical as you have been led to believe. All sealing surfaces utilize O-rings for a leak-free unit. Ball bearings are used on all of the drive gears. If you can assemble a racing engine, you should have no problem with a dry-sump pump. Every manufacturer we talked with was more than willing to make sure your experience would be a positive one.

With the pump torn down, it is clear that dry-sump pumps are not as mystical as you have been led to believe. All sealing surfaces utilize O-rings for a leak-free unit. Ball bearings are used on all of the drive gears. If you can assemble a racing engine, you should have no problem with a dry-sump pump. Every manufacturer we talked with was more than willing to make sure your experience would be a positive one.

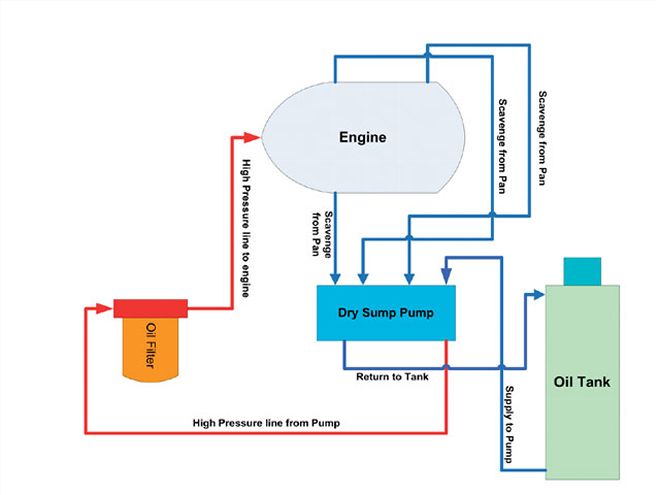

Historically, oil systems used in race cars worked with a greater volume of oil, so special (and expensive) oil pans were needed. The additional oil volume was needed to make up for the fact that more oil would be slow to return to the pan because it was trapped in and on the rotating assemblies or was pooling in the heads or the lifter valley. This was done to preclude running the pump dry and starving the engine of oil. With a dry-sump system, you still need to be concerned with windage issues, and you will still be using scrapers to reduce the total amount of oil that clings to the rotating assembly. But you can be assured of a steady supply of oil to the pump because you are feeding the pump from a tank. The tank is replenished by scavenging and pumping the oil back into it from multiple places on the engine. In this way, you can run enough oil in the system to make sure that you always have a steady supply.

There is a good bit of science involved in a quality dry-sump tank. The tank is part of the system and isn't just designed to fit in an obscure area of the car. It is more than just a vessel to hold oil. It becomes a tool that assists in making sure the oil is free from air in suspension by filtering the oil through various strainers and foam. The tank can also be used to prepare the oil prior to a race. It is not uncommon to see heaters in the oil tank that ensure the oil is up to temperature before the start of a race. In a well-designed system, the dry-sump tank is a part that adds value to the whole as it helps develop horsepower.

Let's spend a bit of time talking about the pump itself. Dry-sump pumps are constructed in stages. From the simplest perspective, a dry-sump pump is just several oil pumps run on a common driveshaft that is driven off of the engine. Just think of multiple oil pumps stacked end to end. There is the pressure pump, which draws oil from a remote tank. Then there are a number of other pumps, usually at least three, that pull the oil out of the engine and return the oil to the tank. The term used for this process is scavenging. This scavenging action is the heart and soul of making more power. The scavenge pumps are not always moving only oil. They also evacuate air from the crankcase.

This is where the story really gets interesting. As the crank spins and the rods are moving the pistons up and down, there is a whirlwind of activity in the crankcase. The scavenge pumps move a good bit of air out of the crankcase-enough to pull a vacuum inside the crankcase. The vacuum can be as much as 22 inches of Mercury. This vacuum allows the piston rings to seal better. Rings? Aren't we talking about oil pumps? Contrary to popular opinion, rings seal in a multitude of ways. The popular idea is that rings seal just on the face, OD (outside diameter) of the ring against the cylinder.

This pump is mounted on the front of a 360 Sprint Car. It is mounted to the cam drive cover and driven off the front of the cam. This pump is obviously not new, but it is still working well enough to supply the oiling needs of a 700hp engine.

This pump is mounted on the front of a 360 Sprint Car. It is mounted to the cam drive cover and driven off the front of the cam. This pump is obviously not new, but it is still working well enough to supply the oiling needs of a 700hp engine.

While true, that is only one of the three ways rings seal. The other two are the sides (top and bottom) of the ring against the ring land in the piston. This aligns with the three potential leak paths that compression gasses can follow: past the face of the ring, by the ring end gap, and around the ring past the ring lands. One of the oracles of piston ring technology, Keith Jones of Total Seal, had this to say: "The rings are responsible for the greatest level of parasitic drag in the engine. When you are using a dry-sump oil system and you are pulling a good vacuum, you have the ability to adjust the ring package to take full advantage of the lower pressure in the crankcase."

For a ring to seal against the outer face and the cylinder wall, it has to exert a load against the cylinder wall. This is accomplished by the ring tension against the cylinder wall. The greater the force against the cylinder wall, the greater the seal-up to a point. The problem is that the force to move the piston up and down within the cylinder goes up. Add three rings to each piston and then multiply that force by the number of cylinders in the engine. "The oil control ring is the biggest offender," states Jones. "The drag number can be quite high." Remember that we are only producing power on every other stroke. The piston is going on a free ride for three of those four strokes. While the ride is free for the piston, the ride will cost your engine power.

If we were to place a set of rings that were optimized for a dry-sump system into an engine with a wet-sump oiling system, we would create an oil burning machine. The rings would not hold compression and/or power stoke pressures. Also, the oil ring would allow an excessive amount of oil into the combustion chamber. None of these things are good.

The tank on a Sprint Car is mounted directly to the engine. The tank is part of the engine and is easily removed from the car as a unit. On stock cars, the oil tank is usually mounted in the passenger compartment on the left side.

The tank on a Sprint Car is mounted directly to the engine. The tank is part of the engine and is easily removed from the car as a unit. On stock cars, the oil tank is usually mounted in the passenger compartment on the left side.

The increase in differential pressure created between the top of the piston and by the lowering of the pressure in the crankcase is contributing to making the rings seal better without additional tension. Remember the three areas of sealing. This differential pressure forces the rings to seat harder to the top or the bottom of the ring land, depending on the direction the piston is traveling. This mP (Delta Pressure) created by the pan scavenging is one of the keys to develop better ring seal with lower parasitic losses due to ring drag. We are able to reduce the ring tension and lower the parasitic drag on the piston(s). Power levels increase. It is a win-win scenario. Just how big of a win is it? Jones says that the number is 19 to 22 hp on the engine in their house Sprint Car (a 360ci injected small-block), and that seems to be the norm. So, depending on the engine and the state of tune, it seems that a 3 to 5 percent gain in horsepower is completely possible. Those numbers were gathered using 15 inches of vacuum. So, using typical racer logic, if a little is a good thing, more should be even better. Why not add several more stages to the pump and pull a greater vacuum, or mount a separate vacuum pump to generate even higher levels of vacuum? While a possibility, the power required to run an additional pump may negate any gains, especially at high engine speeds. The consensus among the engine builders we spoke with was that a level of vacuum greater than 15 inches causes more problems than power. Many were concerned with wristpin bushing failures, due to the oil mist being evacuated from the crankcase. It's just like your mom always said: everything in moderation. The reason they were concerned is that many have tried to run the vacuum levels above the 15-inch level and have experienced failures. They were not postulating on this point-they had an empirical data set from which to draw. The lesson here is to learn from the knowledge of others. These engine builders paid to learn these lessons so that you wouldn't have to.

What will you need to install a dry-sump system in your race car? In addition to a pump, its mounting brackets, and associated drive, you will need a tank, some hoses, an adapter plate on the engine where the oil filter normally mounts, and an oil pan designed for dry-sump applications. All of these components are available from a variety of sources that supply the racing marketplace. The process is really quite easy. All of the hard work has been accomplished by those who have gone before you.

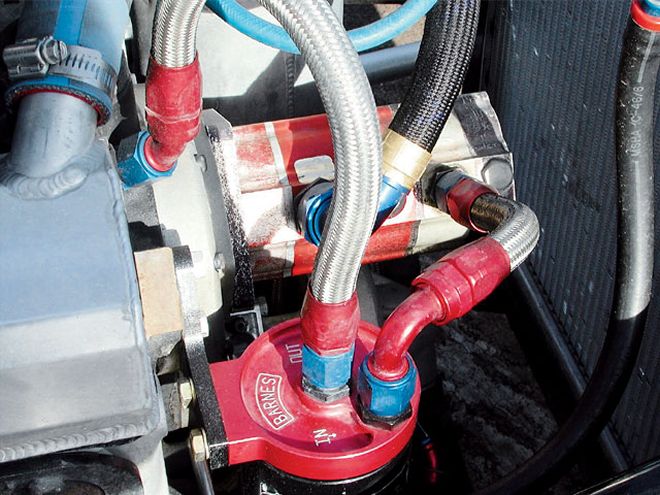

The oil filter was mounted on a remote filter mount. This is not standard, as some cars still utilize the stock filter location. With a dry-sump system, you have options.

The oil filter was mounted on a remote filter mount. This is not standard, as some cars still utilize the stock filter location. With a dry-sump system, you have options.

Obviously, we have oversimplified the installation process, but the process is not that complex. There are some other positives. Plumbing the oil outside of the motor allows you a much more accessible view of what is happening inside the engine. This is accomplished with inline filters. These are low-restriction filters that are not indented to replace cartridge filters, but allow a quick look at any possible debris that may be contaminating the oil system. They are placed upstream of the cartridge filters and are easily disassembled to allow you to view the filter element and look for contaminants. Another benefit of all the extra oil volume in the tank and hoses is increased cooling of the oil.

The reality is that speed costs. A dry-sump system is going to cost more than a high-volume wet-sump pump and pan. You can negate the cost of the pan because you will have a specialty pan for your wet-sump system anyway. You may already have the adapter plate on the engine if you are running an external cooler and/or a remote oil filter. From a parts perspective, you're almost there.

Something we have neglected to mention is that dry-sump pumps can be rebuilt. Should you have a major engine failure and the pump becomes damaged, every manufacturer we contacted offers overhaul of pumps as a service or sells the parts you need to do it yourself. Leo Rayas at Barnes Systems says, "It is not uncommon to see pumps come in for repair or overhaul that are as much as 18 years old." While that may be exceptional, it is clear that these products are very durable. This comment was also echoed by Terry Palmer of Razor Pumps: "If there is some sort of issue within the engine that damages the pump, it is very common for the end user to return the pump to us, and we can repair the pump to like-new condition." The reality is that the scavenge pumps see the debris first, so they are prone to the most damage.

A few manufacturers utilize some very high-tech alloys of steel to preclude pump failure in the event any small engine bits make their way to the pump. This way, the pump will not stop. Larry McDonald of Johnson's High Tech Performance says, "We use 12L14, [which is] an alloy of steel and lead that is durable enough to use on the gears, but will not fail if a particle as large as one eighth of an inch enters the pump." This means that the pump will still be moving oil in the event of a failure, so a lack of oil will not make a bad situation worse. "We also use dowel pins to align the pump housings to make sure there is no misalignment and the pumps do not move around under the extremes of a racing environment," says McDonald.

Some tanks are a bit more robust than others. Maybe this guy knows something we don't.

Some tanks are a bit more robust than others. Maybe this guy knows something we don't.

There are even some manufacturers experimenting with plastics on the scavenge pump gears. Terry Palmer of Razor Pumps spoke about some very successful tests using plastic in the scavenge pump. This was done to look for some better pumping actions and improved pump efficiency. Even with the standard gears, the pumps can approach 90 percent efficiency.

Some manufacturers are using technologies borrowed from F1 and the aerospace industry, and are exploring making the pump housings and the scavenge gears out of high-carbon polymers. This would result in a reduction of over 50 percent in weight. While this may not be as attractive to the stock car world from a cost versus weight savings perspective, some Sprint Car guys would kill to save that much weight. The fact that some of the manufacturers are even looking is reason enough to believe there is a market for such a pump.

The bottom line is the data is speaking. From a power-to-cost perspective, dry-sump oiling systems are the winners, hands down. As we look all over the country and see the emergence and growth of crate engine and claimer classes, we have to wonder why a system with all of the benefits that dry sumps offer is not a mandatory addition to the crate engine. Many of the classes allow aftermarket oil pans and a heavy-duty pump, all in the name of durability. Many of the manufacturers we spoke with offer systems that use fewer scavenge pumps and are indented for crate or claimer classes. Consequently, they cost less. The use of the dry sump, when viewed from a long-term cost, durability, rebuild ability, and chassis perspective, ignoring the power and systemic advantages, is really the only logical choice.