For the last several years, many engine builders and individual hotrodders have experienced a raft of seemingly unexplained flat-tappetcamshaft lobe failures. As one engine builder puts it, "I've failed morecams in the last three years than I have in the last 30." There areseveral theories as to the primary causes of these failures, and withall the usual finger pointing and blame game such unfortunate episodesinevitably generate, the result has been a muddying of the waters that'sleft average hot rodders confused and uncertain as to the best course ofaction. What's the real source of the failures, and more importantly,rather than whining over spilled oil, what can be done to minimize theoccurrence of these failures? Various parties have blamed camshaftmanufacturing quality control, inferior flat-tappet lifters, theaggressiveness of today's modern cam profiles, and engine oilformulation as the primary factors behind the failures. What we know forsure is that the most serious complaints have cropped up within the lastthree years or so, around the time that major changes occurred in boththe flat-tappet manufacturing industry and in the formulation ofpassenger car and light-duty truck motor oils.

The Great Lifter Shortage

New automobile manufacturers basically call the tune when it comes tosupplier capacity and even motor oil composition due to the OEMs' hugeproduction volumes in comparison to aftermarket requirements. Flattappets are not used in today's new cars. All current pushrod enginesuse roller tappets, while overhead-cam motors use either rolling orsliding tappets. From the standpoint of the traditional lifter-supplycompanies, five years ago it looked like there was no future in theflat-tappet lifter business -- the projected volume was insufficient tojustify investing in new tooling and equipment.

As Survival Motorsports'Barry Rabotnick puts it, "Go back five years ago and there were a bunchof U.S. companies making flat-tappet lifters -- Eaton, Delphi [GM],Stanadyne, and Hylift [Johnson]. Within about a three-month window, twoout of the four went out of business. Eaton decided it no longer wantedto be in the flat-tappet business --there was no volume -- and it soldout to Stanadyne, which initially added no capacity and in fact shutEaton's line down. Hylift -- the premiere supplier of Johnson lifters tomajor cam companies as well as aftermarket suppliers such asFederal-Mogul -- went through one of those corporate scandals we'vesadly become all too familiar with before going bankrupt."

GM's lifter foot and body are made from dissimilar materials joined byproprietary processes. Identify them by a distinct parting line ordiscoloration near the bottom of the lifter body. Traditionally priceyChevy hydraulic lifters were sold individually (GM PN 5232720 or ACDelcoPN HL66), but a set of 16 (PN 12371044) is now available from GMperformance dealers like Burt Chevrolet at a much more friendly price.

GM's lifter foot and body are made from dissimilar materials joined byproprietary processes. Identify them by a distinct parting line ordiscoloration near the bottom of the lifter body. Traditionally priceyChevy hydraulic lifters were sold individually (GM PN 5232720 or ACDelcoPN HL66), but a set of 16 (PN 12371044) is now available from GMperformance dealers like Burt Chevrolet at a much more friendly price.

This led tothe flat-tappet lifter shortage the industry experienced several yearsago. GM was still in business, but it made lifters primarily for GMproducts, and they were pricey. As a major OEM supplier, Stanadyne hadother fish to fry and initially did not increase its flat-tappetproduction capacity. Cheap, poorly made offshore lifters flooded in totake up the slack. Most of these inferior lifters had questionablemetallurgy, a poor surface finish, and an improper crown radius. Butthey were affordable and available.

Major cam companies, including Compand Crane, maintain that they never sacrificed lifter quality or soldinferior lifters. "We figured we were better off selling nothing thanselling junk," says Crane's Chase Knight. Yet some engine buildersinsist there was a definite durability difference in lifters producedprior to '01 compared to some later production runs. At present, GMcontinues in business with a good lifter, Stanadyne has finally gearedup again (it currently has about 70 percent of the lifter market), andJohnson is back in business. But the off shore stuff still permeates themarket, and many budget hot rodders are tempted to use them even onname-brand cams because the price is so low compared to the qualityU.S.-made parts. Unfortunately, without lifter disassembly, it's nearlyimpossible for the average hot rodder to identify its manufacturer --and, hence, its quality. One exception is genuine GM/ACDelco/Delphitappets.

Reformulated Motor Oil

For severe-duty use with mechanical cams, Comp Cams offers an optionalsolid lifter with a small oil hole in the foot that provides positivelubrication at the cam lobe/lifter contact point. They are available forboth 0.842-inch-od GM (PN 800-16, shown) and 0.875-inch-od Ford (PN817-16) applications.

For severe-duty use with mechanical cams, Comp Cams offers an optionalsolid lifter with a small oil hole in the foot that provides positivelubrication at the cam lobe/lifter contact point. They are available forboth 0.842-inch-od GM (PN 800-16, shown) and 0.875-inch-od Ford (PN817-16) applications.

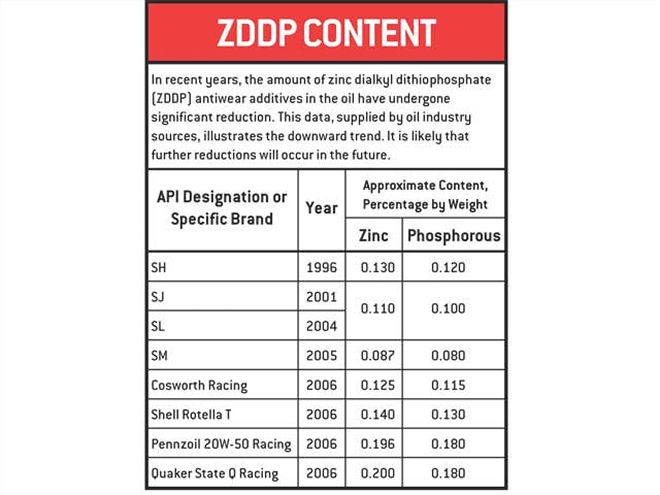

Around the time of the flat-tappet lifter shortage, motor oil wasexperiencing its own changes. Engines with flat-tappet cams haveextremely high pressure loading at the contact point between the liftercrown and the cam lobe. According to Mark Ferner, team leader for QuakerState Motor Oil Research and Development, "Even stock passenger cars cansee pressure in excess of 200,000 psi at the point of flat-tappet/camlobe contact." To prevent excess wear, traditional motor oil included agenerous dose of antiwear additives, primarily zinc dialkyldithiophosphate (ZDDP). "The chemistry is such that the additive is acombination of zinc and phosphorous," says Rockett Racing Fuel's TimWusz. "Typically the phosphate amounts are about 75 percent of the zincamounts. For example, if there was 0.100 percent zinc by weight in themotor oil, then the phosphate is about 0.075."

Ferner adds, "The zincreacts with the cam lobe's iron surface. That creates a sacrificialchemical coating strong enough to keep parts separated to reduce thewear." Although great for keeping a flat tappet alive, as an engine agesand develops blow-by, some of the additives flow out the exhaust wherethey can degrade oxygen sensor and catalytic converter performance.Faced with ever more stringent emissions standards and the governmentalmandate for extended emissions-control- system warranties, the OEMs gottogether with the motor oil makers and decided to reduce the amount ofZDDP in street-legal, gasoline-engine motor oils. After all, theyweren't needed with modern roller lifters and overhead-cam followers.The reduction first started in the mid-'80s, and it has been a gradualprocess, but the latest API SM and GF-4 specs have reduced ZDDP contentto such an extent that the new oils may not provide adequate protectionfor older, flat-tappet-equipped vehicles running nonstock, performancecams and valvetrains. And it will only get worse; projected future oilspec revisions will likely reduce ZDDP content even more.

Cam Quality Control

Motor oil industry sources maintain that even with their significantlyreduced antiwear additive content, the new oils still pass standardindustry tests that measure valvetrain wear (including with flattappets). But cam grinders counter that the type of heat-treat used onthe reference test cams was atypical of standard industry practice.Who's right on this one is hard to determine.

The overwhelming majorityof industry flat-tappet cam blanks are made by two big independentfactories in Michigan. In other words, just about everyone's flat-tappetcam blanks are, says Rabotnick, "cast in the same place, and thehardening for them is all done in the same place. A cam blank doesn'tknow whether it'll be any specific blank; the various cam grindersmerely put the finished lobes on the already hardened blank. In fact,for high-volume cams, some cam companies may outsource the entireproduction of the cam to one of these two big factories." Since thesefactories have been making cams to OEM quality standards for years, andthey supply the cores for just about everyone, it's hard to accept thatthey would be putting the wrong heat-treat on them, or that the standardtest would use a weird heat-treat not supported by mainstream coremanufacturers.

Cam company insiders do allow that in recent years themajor cam companies have tightened up their tolerance standards, revisedtheir heat-treat specs to conform to the latest industry practice, andeven changed the lobe taper to ease critical cam break-in. The newtapers help the lifters rotate easier at the possible expense ofslightly shortened life over 100,000 miles. Comp Cams says it has done"a tremendous amount of work" improving the Parkerized finish of the camand lifters. According to Billy Godbold, Comp has improved control overthe acids used in the process and reduced the grain size of thephosphate crystal structure. "This better spreads the load and improvesthe resulting finish while still leaving extra phosphates for thesurface."

The argument has also been made that today's cutting-edge camprofiles are more aggressive than those of 20 or even 10 years ago. Justas profiles got more aggressive, lifters went south and motor oil wasreformulated. Something had to give. This argument is disputed by Comp'sGodbold, who points out, "Cams fail top-down, not bottom-up," meaningthat the more aggressive profiles actually allow a larger nose radius,reducing overall loading. "We have less cam failure on the Xtreme Energyline than on the old Magnums," Godbold maintains. On the other hand,because the profiles are more aggressive, many builders are using higherspring loads than the previous norm, then failing to break in the cam onthe outer springs only.

My opinion is that cams from reputablemanufacturers never sacrificed quality; however, today's production frommajor manufacturers is by necessity improved from that of five years agoin an attempt to crutch the cams' inevitable use with reformulated motoroils and offshore lifters.

Other Factors

Rabotnick mentions yet another possible contributing factor: "Manydaily-use or street/strip hot rod engines are built up from35-to-40-year-old engine blocks. The average builder never checks thelifter-body-to-lifter-bore clearance. It may have doubled. Pro guys bushthe lifter bores, but most homebuilders just dust the bore with abrake-hone to make the bore smoother and remove varnish. If there's morethan 0.001-0.0015-inch clearance, you could be in trouble." But Comp'sGodbold counters, "We see the same type [of] problems whether it's abrand-new CNC-machined Dart block or a junkyard block."

What mayactually be contributing to this perceived block problem is the wayengines are currently built. As Comp's Scooter Brothers points out,"Most performance engines today use windage trays, limit oiling to thetop of the engine, modify rod side-clearance for less splash oil, anduse special oil pans. This has greatly reduced the oil film at thecamshaft/lifter interface."

What to Do About It

Obviously the ultimate solution to flat-tappet failure problems is tonot use a flat tappet -- just move up to a roller camshaft. But due tofinancial and/or specific racing body rules limitations, that is notalways possible. On the extreme high end, NASCAR Nextel Cup enginebuilders use their own exotic custom tool-steel cam billets and $1,200tappets, but that stuff is way beyond the average enthusiast. What's theaverage hot rodder to do?

You'll see this starburst symbol on the latest API ILSAC GF-4street-legal, energy-saving oils. It means they meet all the latestindustry oil specs, fully satisfy emissions requirements, and fulfillall the new car manufacturer warranty requirements. But it alsoindicates seriously reduced ZDDP content, which can cause problems withhigh-performance flat tappets.

You'll see this starburst symbol on the latest API ILSAC GF-4street-legal, energy-saving oils. It means they meet all the latestindustry oil specs, fully satisfy emissions requirements, and fulfillall the new car manufacturer warranty requirements. But it alsoindicates seriously reduced ZDDP content, which can cause problems withhigh-performance flat tappets.

If you are building up the engine from scratchand intend to run flat tappets, adjust your build specs and techniqueaccordingly. Don't excessively restrict oil to the lifter galleys, checkand maintain proper tappet-bore clearance, and consider grooving thelifter bores for increased lubrication (Comp has a special tool forthis). Where offered, use beehive springs in place of traditionalheavy-duty dual springs. "With the beehives, you get better control withless load," says Godbold. Above all, avoid no-name, brown-bag, offshorelifters like the plague. True, they're much less expensive, but you getwhat you pay for. We can say with reasonable confidence that all major cam companies arecurrently supplying quality lifters with their cams. For you GM guys,there's also the real GM or ACDelco solution.

When it comes time to fireup an engine with a new cam, do not skimp on proper break-in procedure.Put moly lube on the lobes during installation and pour a can ofbreak-in prelube into the oil pan in all cases. Any engine with morethan 300 pounds of open spring pressure or 170 pounds of seat pressure(as multiplied by the rocker ratio) should be run in on the outersprings only.

For in-service engines, consider running cam and lifterprelube in the oil all the time, not just during break-in. Anotheralternative is to use heavy-truck diesel-oil, which is formulated for18-wheelers and at present still has a full complement of traditionalantiwear additives that have been significantly reduced in today'sstreet-legal passenger car oils. (Though even diesel oils will startreducing zinc content in 2007 as big rigs gear up to receive catalyticconverters.) Comp Cams swears by Shell Rotella T diesel oil for use inhigh-performance street cars. It's available in both mineral-based andfull-synthetic formulations with both types containing basically thesame superior additive package. Rotella viscosities are generally higherthan today's modern formulations, but that's not a detriment for classicmusclecars. Diesel oils also add a superior detergent package that cankeep the piston rings cleaner for better oil consumption control. Thedrawback, if any, would be on a high-mileage engine where blow-by cancause detergent to accumulate in the combustion chamber, possiblycontributing to detonation.

Modern heavy-duty truck diesel oils with lots of ZDDP additives will bemarked "CI-4" or "CI-4 Plus." They also easily pass the API Service SLgasoline engine performance test (but due to the high ZDDP content, notthe SL chemical composition specs). Such truck oils are an economicaland effective solution for flat-tappet longevity, according to manysources.

Modern heavy-duty truck diesel oils with lots of ZDDP additives will bemarked "CI-4" or "CI-4 Plus." They also easily pass the API Service SLgasoline engine performance test (but due to the high ZDDP content, notthe SL chemical composition specs). Such truck oils are an economicaland effective solution for flat-tappet longevity, according to manysources.

Even better than diesel oil are speciallyformulated racing motor oils. Although the most expensive solution,these oils usually contain even more antiwear additives than dieseltruck oil, as well as other performance-enhancing ingredientsspecifically designed for hardcore, high-performance gasoline engineusage. According to Cosworth's Thomas Hayden, some diesel oils may nothave friction modifiers that he claims are helpful in preventing pistonscuff on high-performance gasoline engines, especially if running modernlow multiviscosity oils. But Dan Arcy, technical marketing manager forShell Lubricants, takes issue with the importance of friction modifiers,which he says "are only present in the very low viscosity GF-4 oils forfuel economy reasons."

At any rate, because they have a full load of antiwear additives,today's real racing motor oils are sometimes marked "for off-highway useonly" on the bottle. They definitely aren't embossed with theconsumer-friendly starburst insignia. Such racing oils won't meetmanufacturer's warranty requirements for new vehicles, may degradecatalytic converter performance in long-term use, and in some cases havenot been formally submitted to the oil industry's current benchmarkperformance test and validation procedure. But for older cars runningflat tappets, they are the best oils available.

If you make provisionsto adequately lubricate the lifter/lobe interface, use only qualitylifters, fill the sump with diesel or racing motor oils, and followproper break-in procedure, any flat-tappet cam failures should beminimized. It's a lot more effort than we've become accustomed to, butif you still want to run a high- performance flat-tappet cam, it'ssomething you'll just have to get used to doing.