One of the things that makes the Gen III family of engines so attractive is that they are very simple to work on. This month, we wanted to try just the addition of the GM Performance Parts Hot cam package in conjunction with stock heads and intake to see what kind of power we could make.

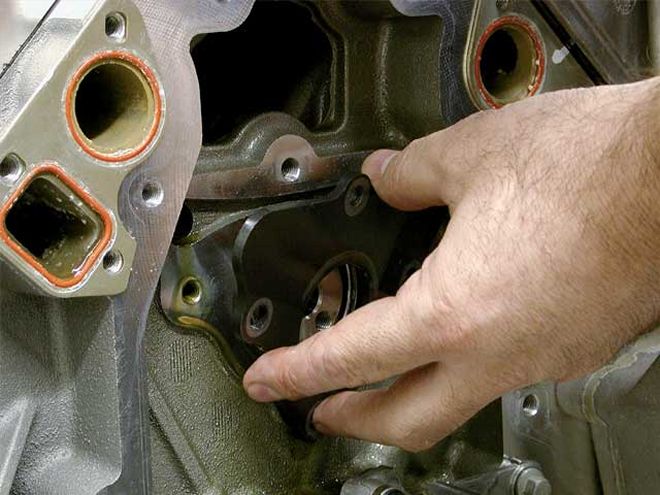

While cam swaps on the dyno have always been relatively easy, the LS1 makes it even simpler. With all other small- and big-block engines, you have to yank the intake manifold and then remove the lifters before the cam will come out. The Gen III engines employ a plastic roller-lifter retainer that captures the lifters so you don't have to remove the intake. Just pull the rockers off to unload the lifters, spin the engine around two revolutions, and you're ready to go.

We loaded up our GM Performance Parts LS1, which came from our friends at Scoggin-Dickey Performance Center in Lubbock, Texas, and we began beating on it right away.

Dyno DayOnce we had baselined the LS1 with the stock heads, intake, cam, and 131/44-inch headers, dyno guy Ed Taylor cooled the engine and swapped cams. In addition to the new GM Performance Parts cam (the specs are in the "Lobe Prospecting" sidebar), the Hot cam also comes with a set of LS6 valvesprings to ensure proper valve control at the cam's higher engine speed.

You'll note that the Hot cam's lift is not all that much bigger than the stock LS1 cam. In fact, the lift increase is only slightly more than 0.025 inch. The big difference is in the duration. The Hot cam adds a solid 20 degrees of duration while narrowing the lobe separation angle from 119 to 112 degrees. This combination is significant since it adds a bunch more overlap, which helps mid- to high-rpm breathing. Another reason for the conservative lift increase is to ensure that this is a bolt-in cam. GMPP offers a bigger ASA cam, but it requires deeper valve reliefs be machined in the pistons. The price is a little higher than a typical hydraulic-roller cam for a Gen I small-block, but the cam and spring kit is still affordable at $415 from Scoggin-Dickey.

With the LS1 buttoned back up, Duttweiler's Digilog dyno cranked out some interesting numbers. The longer-duration cam was still able to improve the low- and mid-range torque with a power increase of 20 lb-ft. Oddly, this was followed by a slight torque dip between 4,200 and 4,800 rpm compared to the baseline. Looking at our dyno reports, the fuel flow dropped off slightly in this range since the air/fuel ratio leaned out to around 13.4:1, which isn't terrible but not conducive to best power. This could certainly be adjusted to eliminate that power dip.

Above 4,800 however, the Hot cam package really improved. From 5,200 to 6,200, the torque jumped dramatically, kicking the peak horsepower up to 419, a solid 28 hp gain over the previous peak of 391. At 6,200, the Hot cam also delivered an increase of 49 hp. Even with the slight midrange dip, the average torque gain was 11 lb-ft, while average horsepower also jumped a solid 9. Those are significant gains for a simple cam swap with no other changes to the engine, which still idles very smoothly. While the Hot cam may not pass smog, it is certainly worthy of consideration if you're looking for a mild power increase with very little affect on durability.

Knowledge Is Power

We continue to find out more about the complex factory computer that runs our LS1 engine. In talking further with Steve Cole and also with TPIS' Myron Cottrell, we learned a funny thing happens on the way to wide-open throttle (WOT). The factory computer is designed with what are called short-term fuel trim and long-term fuel trim. Let's say our LS1 engine is running at part-throttle with a short-term fuel trim condition that requires fuel to be added to the base fuel map, and let's say that number represents 5 percent additional fuel.

Lube the new cam with a viscous lube like Engine Assembly lube from Federal-Mogul, but don't use that black moly lube. Also remember to install the cam thrust plate to prevent the cam from moving. We didn't degree the cam, since we figured that most in-car swaps will not include this.

Lube the new cam with a viscous lube like Engine Assembly lube from Federal-Mogul, but don't use that black moly lube. Also remember to install the cam thrust plate to prevent the cam from moving. We didn't degree the cam, since we figured that most in-car swaps will not include this.

If the engine goes to WOT at the same instant it adds 5 percent part-throttle fuel, the computer is programmed to add this same 5 percent of additional fuel to the WOT fuel trim. This is done to compensate for a possible weak fuel-delivery situation, a slightly clogged fuel filter, or any other condition that could possibly reduce fuel flow both at part- and full-throttle.

Given this situation, let's say that in an attempt to tune our engine, we reduce the fuel pressure, which is a common approach. Since the lower fuel pressure reduces the amount of fuel delivered, the oxygen sensors at part-throttle will see a leaner air/fuel ratio as well. The computer will compensate and add fuel with the short-term fuel-trim setting, which appears as a negative number if you use a diagnostic-link scanner like the EFI Live system we use. Increasing numbers like -5 or -8 will dictate this same amount of correction when the engine experiences WOT. This is the main reason why our baseline tends to shift over time. In an attempt to have as consistent a baseline as possible, we have resorted to warming up the engine, then shutting it down and disconnecting the battery to clear the computer memory of any "learned" fuel trims. However, if the computer is adding fuel at part-throttle when we hit WOT, then the WOT tuning will go richer by that amount.

One trick you can try is to increase fuel pressure to ensure a positive part-throttle trim number. When the computer generates a positive short-term trim number, it does not reduce the base fuel map for WOT operation. This way, the computer never delivers a leaner base fuel trim than what the engineers programmed in, and there is less of a chance the engine will run lean at WOT and burn a piston.

This explains why our engine will baseline with different power levels: When it rolls into WOT, the short-term fuel trim could be in many different trim modes adding varying amounts of fuel. The more we learn, the better our engine will run, because we can make this engine work for us rather than against us.

TEST NUMBERS Test 1: New baseline of LS1 with stock cam, stock intake, and 13¼4-inch headers Test 2: Added GM Performance Parts cam, retained stock 1.7:1 rockers TEST 1 TEST 2 DIFFERENCE RPM TQ HP TQ HP TQ HP 2,000 {{{323}}} 123 338 128 +13 +5 2,{{{200}}} 330 138 332 139 +2 +1 2,400 336 154 335 153 -1 -1 2,{{{600}}} 341 168 343 170 +2 +2 2,800 344 183 354 189 +10 +6 3,000 349 199 364 208 +15 +9 3,200 354 215 373 228 +19 +13 3,400 360 233 380 246 +20 +13 3,600 367 252 384 263 +17 +11 3,800 375 271 386 279 +11 +8 4,000 382 291 387 295 +5 +4 4,200 389 311 387 310 -2 -1 4,400 394 329 388 325 -6 -4 4,600 396 347 389 341 -7 -6 4,800 396 362 391 357 -5 -5 5,000 393 374 393 374 0 0 5,200 387 384 393 389 +6 +5 5,400 379 389 391 402 +12 +13 5,600 366 391 386 412 +20 +21 5,800 351 387 378 418 +27 +32 6,000 331 379 367 419 +36 +40 6,200 310 367 352 416 +42 +49 AVG 362 285 373 294 Peak 396 391 393 419 Lobe Prospecting Dur. @ Lobe Camshaft 0.050 Lift (in) Sep. Stock LS1, Int. 199 0.497 119 Stock LS1, Exh. 208 0.498 Stock LS6, Int. 204 0.550 117.5 12565308, Exh. 218 0.550 Stock LS6, Int. 207 0.525 116 12560950, Exh. 217 0.525 GMPP Hot, Int. 219 0.525 12480033, Exh. 228 0.525

With the cam in and the front dress all buttoned back up, the Hot cam and spring change was worth as much as 49 hp at 6,200 rpm, but average power and torque improved as well. This is a good swap.