For our tests to see how windage affected engine power, we used threeoil pans in multiple variations and with varying oil levels to makenearly 70 dyno pulls.

For our tests to see how windage affected engine power, we used threeoil pans in multiple variations and with varying oil levels to makenearly 70 dyno pulls.

Sometimes, it can seem like a lot of the stuff parts manufacturers arepushing on racers as the "next big thing" is really nothing more thansmoke and mirrors. It's marketing hype masquerading as something that'sactually useful.

As competitors, racers usually don't mind spending a few of theirhard-earned bucks on products that will help their efforts on theracetrack. The problem is, there is so much out there it can be easy toget suckered by big promises and a shiny package--especially if youdon't have the R&D budget to actually test new ideas and designs.

Wet-sump oil pans designed specifically for oval-track racing aren'texactly new, but there is a lot going on under the crankshaft that aracer needs to understand in order to make an educated decision. Windagetrays, scrapers, gates, kickouts, you name it--do all these optionsreally do anything?

To find out exactly what a good oil pan is worth in terms of power,Circle Track partnered with the NASCAR Technical Institute (NTI) inMooresville, North Carolina, to do a little dyno testing of our own.Actually, we ended up doing a lot of dyno testing, with nearly 70 pulls.We spent over two days swapping oil pans, installing and removingwindage trays, changing oil levels, and doing just about anything elsewe could think of with the oiling system to see if we could find just alittle more power. Instead of simply spouting off a lot of design theorymumbo jumbo, we wanted our findings to be backed up by good, hard dynonumbers. In some cases, our findings were quite interesting.

Even without its windage tray installed, Champ's dual kickout panfeatures a small scraper on the right side of the pan and a baffle toseparate oil in the sump from the spinning crank.

Even without its windage tray installed, Champ's dual kickout panfeatures a small scraper on the right side of the pan and a baffle toseparate oil in the sump from the spinning crank.

NTI is a technical training school that combines a general automotiveeducation with courses designed specifically for students hoping to joinrace teams. In addition to fabrication, pit crew training, and otherracing-specific courses, NTI also offers an involved engine buildingprogram for its students. When we approached administrator Danny Breuerabout working on some dyno tests, he was eager to provide theopportunity to the students.

Circle Track would provide the hardware, while NTI would provide thedyno and operator. Breuer asked only that the school's students get asmuch hands-on time with the project as possible. We gladly agreed tothat since we weren't exactly looking forward to spending two daysswapping out oil pans filled with 190-degree oil. (For some reason,though, the students seemed to enjoy it. Maybe we're just getting old.)

Since the testing was done to determine how different characteristics ofoil pans help control windage, we chose not to use a high-end race motorfor our testing. Instead, we wanted stability and repeatability. Forthat, we went with a Chevy crate long-block. The stock-based, 350 V-8that Chevy sent us is about as dependable as they come. With 8.5:1compression and standard, 23-degree cast-iron heads, it's rated at 290hp at 5,100 rpm and 326 lb-ft of torque at 3,750 rpm. Not exactly ascreamer, but it should be able to pull those same results all day long.We finished the long-block with a dual-plane intake from Weiand, a650-cfm four-barrel from Holley, a self-contained high-voltage HEI fromMallory, and a water pump and pulley system from CV Products.

For help testing our theories on oil control, we turned to Champ Pans,which makes some of the best wet-sump oil pans on the market when itcomes to oval track racing. Champ's Jerry Redetzke recommended two pansfor our test: a double kickout pan (CP100LT) he says is Champ's mostpopular wet-sump oil pan for everything from Street Stocks to Modifiedsand Late Models on both asphalt and dirt, and a single kickout pan(CP1001KO) he says is "designed to be as good as can be, short of goingto a dry-sump system." Redetzke also recommended a quality, high-volumeoil pump for the pans, which we decided to use. To keep everything asequal as possible, we used the same pump for every test and just changedthe pickup depending on which pan we were running (the Champ pans usedthe same pickup while the stock pan required a different design). Pickupclearance on all three pans was 3/8 inch.

Understanding Windage

The windage tray is a piece of sheetmetal with louvered holes stamped init. The direction of the louvers is important. Oil slung off the crankcan easily pass through the louvers into the sump, but there is noline-of-sight path between the oil in the sump and the crank. This makesit much more difficult for oil in the pan to splash back on the crank.

The windage tray is a piece of sheetmetal with louvered holes stamped init. The direction of the louvers is important. Oil slung off the crankcan easily pass through the louvers into the sump, but there is noline-of-sight path between the oil in the sump and the crank. This makesit much more difficult for oil in the pan to splash back on the crank.

For our tests, we are only concerned with how oil control in the engineaffects horsepower. Although it can be manipulated to create power, inthis instance we aren't experimenting with oil viscosity or quality. Forconsistency, after engine break-in, all tests were performed with QuakerState's synthetic Q Racing oil. At 15W-50, we like it because it's ahigh-quality oil that will provide good protection against the abuse itwill experience during dyno testing, and the synthetic blend remainsquite stable as heat changes. This will help make our dyno runs morereliable, even if the oil temps aren't quite the same on every pull.

The strict definition of windage is the power loss caused by thefriction of the oil in the engine coming into non-lubrication contactwith the moving parts inside the engine. For the most part, this is oilsplashing against the counterweights of the crank as it spins. If thereis poor oil control inside a race engine, windage can cause some prettysignificant power loss. First, as rpm increases, the amount of powerloss for a given amount of windage increases dramatically. As a liquid,it's the same concept as water in a swimming pool providing littleresistance if you slowly dip your hand into it. The feeling ofresistance becomes much different if you do a belly flop off the highdive into that same pool. Second, life inside a circle-track race engineis much different than any road-going engine cruising down theinterstate. In racing, high-g turns, rough racetracks, and good, oldengine vibrations put much more kinetic energy into the oil collected inthe bottom of the pan, which makes oil control much more difficult.

Oil Pan Designs

Kickouts are valuable because they can greatly increase an oil pan'svolume without increasing depth. This allows the engine to remain low inthe chassis to keep the car's center of gravity down. Kickouts alsoallow the oil a place to collect without being directly underneath thespinning crankshaft. The right-side wall (left in this photo) of thisChamp pan is pulled out. The bottom of the crank spins toward this wall.If this wall is pulled away from the crank, then oil that slings off thecrank is less likely to bounce off the wall of the pan back onto thecrank. This design, however, does make the pan harder to install. Thereare three plugs in the bottom of the pan, and you actually have to boltthe right side of the pan to the engine block through the inside of thepan.

Kickouts are valuable because they can greatly increase an oil pan'svolume without increasing depth. This allows the engine to remain low inthe chassis to keep the car's center of gravity down. Kickouts alsoallow the oil a place to collect without being directly underneath thespinning crankshaft. The right-side wall (left in this photo) of thisChamp pan is pulled out. The bottom of the crank spins toward this wall.If this wall is pulled away from the crank, then oil that slings off thecrank is less likely to bounce off the wall of the pan back onto thecrank. This design, however, does make the pan harder to install. Thereare three plugs in the bottom of the pan, and you actually have to boltthe right side of the pan to the engine block through the inside of thepan.

In terms of pan designs and their quality when it comes to racing, thestandard stock pan is at the bottom of the evolutionary ladder. Narrowand rarely deep enough for adequate oil volume, a stock pan is typicallylittle more than a bucket that holds oil at the bottom of the block. Inthe interest of keeping costs down, manufacturers rarely make an effortto control oil. That may be fine for over-the-road cars, but it'sterrible for racing. That's why replacement pans are normally allowed,even in strictly Stock classes.

The most noticeable characteristic for most racing pans is a kickout onthe right side. A kickout is an excellent way to provide greater volumeinside the pan while minimizing the overall depth. A deep pan is aliability because it either hangs too low in the chassis (which createsthe possibility of damaging the pan against the track surface), or itrequires the engine to sit too high (which raises the car's center ofgravity). Many race pans feature kickouts on both sides, but in designsthat use only a single kickout, it is always on the right side. Thisallows the oil to remain in the kickout as the car rolls through theturns, which helps keep it away from the crank.

Inside the pan, it is critical that there is a means to maintain oilaround the oil pump pickup. In a stock pan, this is normally achieved byhaving a deep, narrow sump, but a racing pan--because of thekickouts--normally has a wide bottom. As the car rolls through theturns, accelerates, and decelerates, it can be easy for the oil in thepan to slosh away from the pickup. If there is even an instant that theoil pump gets air instead of a steady supply of oil, it can bedevastating to a race engine. The solution is to use a system of one-waygates that allows oil to flow toward the pickup and not away. Thissounds simple, but there are specific locations and sizes for the gatesthat are incorporated in every good pan design that ensures the oil isalways available at the pickup without piling up underneath the crank.

New racers often confuse scrapers and windage trays, but they performquite different functions. At high rpm, oil tends to "rope" or windaround a crankshaft, causing big power losses. A scraper is a preciselyshaped piece of sheetmetal that normally attaches at the pan rail anduses narrow slots that allow the crank's counterweights to spin pastwithout contacting the scraper. The scraper catches oil off the crankand allows it to drain into the bottom of the pan. A windage traynormally separates the crank from the pan sump almost completely. Itallows what drains into the pan to access the sump (either throughshaped louvers or a screen), but makes it difficult for that oil, onceit is in the sump, to splash back onto the crank.

The Test

Good dyno testing requires making as many pulls as possible while theatmospheric conditions are the same. NTI's engine building classes wereinstrumental in helping make the many pan changes quickly throughout ourtests.

Good dyno testing requires making as many pulls as possible while theatmospheric conditions are the same. NTI's engine building classes wereinstrumental in helping make the many pan changes quickly throughout ourtests.

NTI instructors Luke Woroniecki and Rick Touchette led our dynosessions. After a 30-minute break-in session to allow the hydraulicflat-tappet lifters to mate to the cam, we made a few runs to establishour baseline setup. Timing was set at 38 degrees, the Holley carb wasoutfitted with No. 70 jets, and a 1-inch open spacer was used betweenthe carb and intake. Once we settled on these parameters, they were notchanged for the duration of the test. We also determined that holdingthe water temperature around 180 degrees F and the oil temperaturearound 195 degrees F would keep the pulls as consistent as possible.This provided us with 267.8 peak horsepower at 4,300 rpm and 349.7 lb-ftof torque at 3,600 rpm with the stock pan and 5 quarts of oil. Valvecontrol faded well before 5,000 rpm, so all pulls were run between 2,500and 4,500 rpm. The dyno cell used Nextel Cup-legal race gas. It wasn'tthe best choice for our heads, which don't feature a super-efficientcombustion chamber (like full-race heads) and only allow 8.5:1compression, but we saw little reason to change it. There is certainlymore power to be found in this Chevy engine by tweaking the tuning, butthis is the combination we felt would provide us the most repeatability.

Notice the kickout on the right side of this Champ pan (left in thisphoto) that extends all the way up to the block. To install this pan,the bolts have to be inserted through plugs in the bottom of the pan andinstalled blind. It makes for a difficult install, but the windagesavings can be worth it.

Notice the kickout on the right side of this Champ pan (left in thisphoto) that extends all the way up to the block. To install this pan,the bolts have to be inserted through plugs in the bottom of the pan andinstalled blind. It makes for a difficult install, but the windagesavings can be worth it.

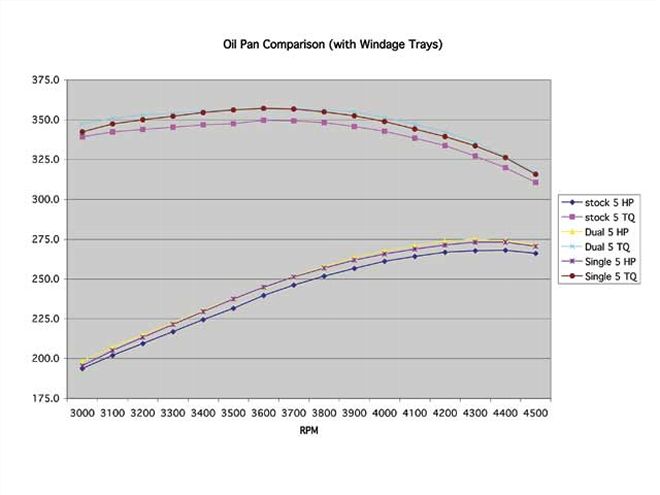

One of the difficulties with this test is that the stock heads andlightweight springs we used significantly limited the rpm. Windagebecomes a much more pronounced problem the faster you spin the engine,and we were looking at horsepower changes that were quite small (as youcan see from the accompanying charts). Still, in racing, an extrahorsepower or two can make all the difference in the world, andimprovements of single horsepower that you see in the charts at 3,000rpm likely will translate to three or four at 7,000 in a full-blown racemotor. This is by no means an exhaustive test that answers everyquestion when it comes to oil control, but it does reveal a lot aboutwhat is going on inside an engine.

The Dyno Mule

Our baseline comparison of all three pans. The Champ pans had theirwindage trays installed. As you can see, this just isn't a fair fightfor the stock pan even at just 5 quarts.

Our baseline comparison of all three pans. The Champ pans had theirwindage trays installed. As you can see, this just isn't a fair fightfor the stock pan even at just 5 quarts.

Our Chevrolet test engine was assembled with repeatability in mind. Wewere looking for changes in the range of 1-2 hp, and the dyno mule hadto be able to make pull after pull consistently. For that reason, wewere careful with the components we chose that would represent thepieces a racer may use but that would also work well through the stressof repeated dyno pulls.

Engine

Chevrolet supplied a stock long-block 350 with cast-iron 23-degree heads(non-Vortec), 8.5:1 compression, flat-tappet hydraulic lifters, andfour-bolt main caps for stability. The valves were 1.94 intake and 1.50exhaust. Properly tuned for power, the engine is rated at 290 hp with326 lb-ft of torque.

Intake

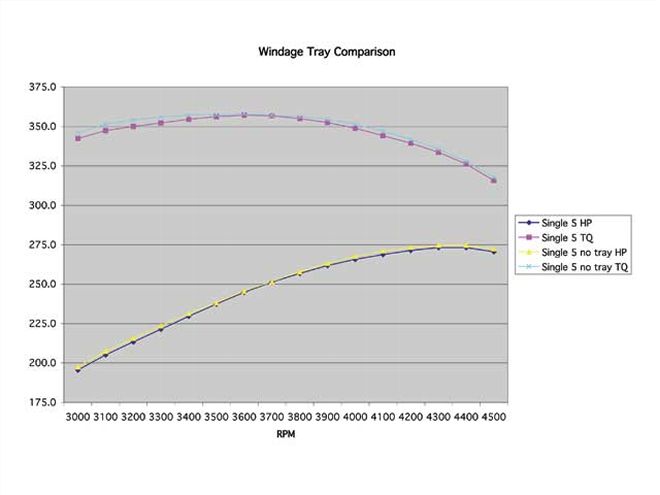

This chart was our big surprise over the two days we spent testing. Weran Champ's high-end single kick-out pan with and without the windagetray and were surprised to see the results were better without the tray.This, however, turned out to be a flawed test. With just 5 quarts of oilin the system, the pan could adequately protect the crankshaft from theoil with or without the pan. But use 7 quarts in the system, as weshould have done, and put the engine in a car that's on a racetrackwhere the oil will slosh around, and the results will be much different.

This chart was our big surprise over the two days we spent testing. Weran Champ's high-end single kick-out pan with and without the windagetray and were surprised to see the results were better without the tray.This, however, turned out to be a flawed test. With just 5 quarts of oilin the system, the pan could adequately protect the crankshaft from theoil with or without the pan. But use 7 quarts in the system, as weshould have done, and put the engine in a car that's on a racetrackwhere the oil will slosh around, and the results will be much different.

Since we were using a low-rpm engine package, a good dual-plane intakemanifold was a must to properly match the powerband. Weiand's new ActionPlus intake fit the bill perfectly.

Carburetor

The vast majority of all stock car racers out there use Holley-basedproducts, so that's what we wanted. We went with a 650-cfm four-barreland only had to make one jet adjustment to the jets.

Belt/Pulleys/Water Pump

A dyno mule needs to be as simple as possible. They aren't going to beused, so there is no need for brackets for an alternator orpower-steering pump. CV Products produces a pulley set for racers thatuses a square-tooth belt that is very adaptable. We ran just the crankand water pump pulley, and the toothed belt meant we didn't need anadjuster. This is perfect for racers who don't want to run an alternatorduring short events.

Ignition

A Mallory HEI is the ultimate in simplicity and ease of use. The HEIdesign is upgraded with a hot coil that provides plenty of power wellbeyond 8,000 rpm.

Accessories

NTI had never run anything on its dyno except Nextel Cup engines, sohooking up our wet-sump motor provided a few challenges. Another problemwe encountered at the last minute was that the stock valve coverswouldn't allow installation of a racing-style breather or relievecrankcase pressure. Bradley Auto Parts is a speed shop specializing inassisting stock car racers that we turned to for everything from aproper set of valve covers, to a multitude of brackets, plugs, andadapters, to a reusable oil-pan gasket to facilitate our multiple panchanges. Because the company specializes in racing, everything was instock when we arrived to look for a new set of plug wires at the lastminute.