'We've tested a lot of cam and valvetrain components in the past few years and have decided to give you an education by reviewing some of the more interesting results we've found and condense it into data you can use for your next engine project. The best way to approach this story is to not get caught up in the fact that most of these tests were performed on a small-block Chevy. Instead, see what trends you can pick up from the testing and then apply these same concepts to your next engine. After all, the engine doesn't know what logo is stamped on the valve cover.

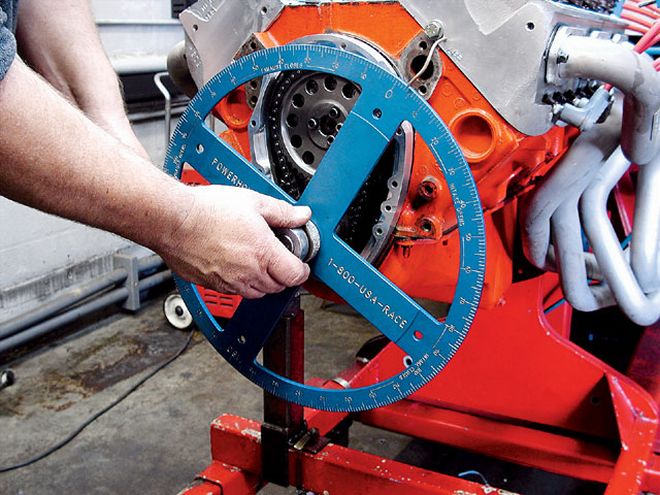

Degreeing a CamIf you've read more than two engine-buildup stories in your lifetime, then you've no doubt been exposed to the concept of degreeing the camshaft. The cam companies emphasize this process so the builder knows that the camshaft is properly phased with the engine. Why this is important is the subject of a Marlan Davis test from the February '98 issue where he performed a series of three tests on the same engine on Flowmaster's Superflow dyno in which the only variable was to advance or retard the camshaft. The test was designed to look at actual power numbers to verify the theory of advancing and retarding cam timing.

The test was performed on a (what else?) small-block Chevy, but the results would be reinforced with almost any engine configuration. They pretty much followed the theory that advancing the camshaft improved bottom-end torque, while retarding the cam from the zero or "straight up" position hurts bottom-end power while slightly improving power at higher engine speeds. One thing to keep in mind is that many cam manufacturers build in a certain amount of advance when grinding the camshaft. This particular Crane cam uses a recommended intake centerline of 108 degrees while the lobe separation angle (LSA) is 110 degrees. This means the cam is actually ground with 2 degrees of advance built in. A cam ground with zero advance will always have an intake centerline equal to the LSA, which in this case is 110 degrees. This cam actually uses an intake centerline of 108 and an exhaust centerline of 112 degrees for an LSA of 110 degrees (108 + 112 = 220/2 = 110 degrees). Advancing the cam further in this case did not improve overall power compared to the zero baseline, although it did pump up the torque down low. The point of all this is that you should be aware of what the cam companies are doing before you decide to make changes. In most street cam examples, that advance has already been done for you.

CAM SPECS DURATION DURATION DESCRIPTION (ADV.) (@ 0.050) LIFT LSA Crane Intake 284° 222° 0.480 in 110° Exhaust 292° 230° 0.496 in POWER CHART AVERAGE HP RPM 4 ADV. 0 4 RET. 2,000 127 124 121 2,500 163 161 155 3,000 229 227 223 3,500 271 270 266 4,000 311 310 306 4,500 340 340 340 5,000 365 366 363 5,500 386 388 386 6,000 381 391 392 Avg thru 4,000 220.4 218.2 213.7 Avg. 4,{{{200}}}-plus 365.9 368.2 368.4 Avg. overall 293.2 293.2 291.1 ADV RET ZERO 4 DEG. 4 DEG. Intake lobe centerline 108 104 112 Exhaust lobe centerline 112 116 108Roller-Rocker TestThere was a time when aluminum roller rockers were a status symbol of only the most elite road race or drag race engine. Today, you have to look for a reason not to run a set, especially when you read this test that originally ran in the January '01 issue. Here, the guys at Westech bolted a mild 350ci small-block Chevy to the dyno equipped with a Comp Cams Xtreme Energy 268 hydraulic flat-tappet cam, stock stamped-steel rockers, a set of TFS 23-degree aluminum heads with 2.02/1.60-inch valves, an Edelbrock Performer RPM intake, a Barry Grant 750-cfm Speed Demon carb, and a set of 151/48-inch headers feeding into a 211/42-inch Flowmaster exhaust.

The test was a simple comparison of stock stamped-steel 1.5:1 ratio rockers to a set of Comp Cams Pro Magnum steel 1.5:1 and 1.6:1 rockers and a 1.65:1 ratio Comp High Energy aluminum rockers. The following chart reveals the power increases that generally track right along with the ratio. Where else can you bolt on something simple like a set of rocker arms in about an hour that will add an average of 15 lb-ft of torque and 13 hp? Granted, not all engines will respond as this one did. Basically, a bone-stock set of heads would probably not have gained as much as this combination. Clearly, the better cylinder heads that flowed 250 cfm at 0.500-inch lift offer proof as to why this test was successful. That's probably the lesson here-that stock heads will not benefit as much from more lift compared to ported or aftermarket heads. This test does point out the power of a well-matched package of cam and valvetrain.

RATIO GAMES STOCK STAMPED 1.5:1 (GAIN) 1.6:1 (GAIN) 1.65:1 (GAIN) Lift intake 0.477 0.477 0.509 0.524 Lift exhaust 0.480 0.480 0.512 0.528 Avg. TQ 386.8 393.4 (+6.6) 401.9 (+15.1) 402.4 (+15.6) Avg. HP 329.9 335.6 (+5.7) 343.2 (+13.3) 343.5 (+13.6) Gains are expressed compared to the stock stamped rocker baseline CAMSHAFT CHART DURATION DURATION DESCRIPTION (ADV.) (@ 0.050) LIFT LSA Xtreme Energy Int. 268 224 0.477 in 110 Exh. 280 230 0.480 inBudget Cam SwapNot all of our testing involves high-end, mega-dollar stuff. We've also tested some very easy-on-the-wallet deals like this flat-tappet cam swap for a mere $245.67, including the cost of the gaskets. We started with a typical 350ci small-block Chevy equipped with a stock-style flat-tappet hydraulic cam. Next, we jumped in with an Erson TQ40H mild flat hydraulic cam and lifter package along with a new set of springs to replace the tired originals.

With the engine on the dyno at Westech, it peaked at 326 hp at a mere 4,700 rpm with impressive torque at 398 lb-ft at 3,700 rpm. The valvesprings were also clearly overworked even with the stock cam, so the swap included a set of new Erson single-wound springs as well. The Erson cam added a solid 23 degrees of duration on the intake side and 26 degrees on the exhaust side, both measured at 0.050-inch tappet lift. The Erson also added a whopping 0.082 and 0.062 inch of valve lift. The combination of the two points, plus some overlap, are clearly the reasons why this inexpensive cam swap was worth an honest 77 peak horsepower. Because the stock cam made such good torque, the bigger cam actually lost torque between 2,000 and 3,000 but compensated with a ton more power between 4,000 and 5,900 rpm. The best indicator of all is the 44hp average power increase over the entire rpm band. That tells you this is a substantial gain. When you can get all that for under $250, that's a win, baby.

CAM SPECS DURATION DURATION DESCRIPTION (ADV.) (@ 0.050) LIFT LSA (1.5:1) Stock GM, Intake 310 195 0.390 in 112 PN 3896929, Exhaust 320 202 0.410 in Erson TQ40H, Intake 284 218 0.472 in 110 PN E113321, Exhaust 296 228 0.472 in POWER CHART STOCK CAM ERSON CAM DIFFERENCE TQ HP TQ HP TQ HP Max Power 399 326 419 403 20 77 Avg. Power 349 254 384 298 35 44 2,000-5,{{{900}}} rpm PARTS & PRICES DESCRIPTION PN SOURCE PRICE Erson TQ40H cam E113321 {{{Summit}}} Racing $89.95 Erson hyd. lifters E914501 Summit Racing 69.95 Erson valvesprings E915005 Summit Racing 45.95 Fel-Pro intake gasket 1205 Summit Racing 13.88 Fel-Pro timing cover gasket 45121 Summit Racing 13.99 Fel-Pro valve cover gasket 1603 Summit Racing 11.95 Total $245.67Lobe Separation Angle TestIn another dyno flog, we tested three cams in the same small-block Chevy with the only change being the lobe separation angle (LSA). This is defined as the spread in camshaft degrees between the intake and exhaust lobe centerlines and can be determined by adding the intake and exhaust lobe centerline figures together and dividing by 2. For example: 110 + 114 = 224/2 = 112 degrees LSA. This lobe spread is designed and ground into the camshaft and can only be changed by grinding another camshaft, unless you're working with a dual overhead cam (DOHC) motor, in which case you can move the intake cam or the exhaust cam or both to change the lobe spread all you want. Regardless of engine design, this spread determines overlap, which affects idle quality, midrange torque, as well as top-end power. What the testing showed us is that a tighter lobe separation angle (like 106 degrees) was worth more average power and more peak power than a wider lobe separation angle (like 114 degrees).

It's also important to remember that LSA is a mere angle. As you add duration to the intake and exhaust lobes while retaining the same LSA, the number of degrees of overlap will increase even with the same LSA. Of course, the opposite is also true when widening the LSA. This is why you will often see bigger cams with a wider LSA, which is an attempt to limit the amount of overlap.

Keep in mind that this particular test moved both the intake and exhaust lobes when increasing the lobe separation angle from 106 to 114 degrees. This also changed the opening and closing points for both the intake and exhaust. Since the intake closing is the most important, note that the 114-degree LSA also creates the latest intake closing point. This tends to improve top-end power. If we add the exhaust closing and intake opening point numbers at 0.050-inch tappet lift, this will deliver actual overlap at that checking height as shown in the chart. An interesting test would have been to retard and then advance the 110-degree LSA cam by four degrees. Retarding the cam would maintain the overlap yet put the intake closing point at the 45-degree ABDC that would duplicate the 114-degree test. Advancing the cam would have placed the intake closing at the 106-degree cam position. Those results would have allowed us to see the difference between overlap and the effect of intake closing. Basically, the wider (114-degree) lobe separation angle lost torque in the midrange compared to the tighter 106-degree LSA but made up ground with top-end power. Our contention is that the 114-degree LSA's better top-end power came as a result of the later-closing intake valve and not because of the reduced overlap. This tends to support the idea that a tighter LSA with a later-closing intake would be the best of both worlds. The price you pay for this would be greatly reduced bottom-end torque and a more erratic idle.

As you can see, there are a number of variables present in each and every camshaft that can be used to dial in the ultimate power in a street or race engine. Each engine will respond a little differently to these changes, but this test illustrates how overlap does have a positive affect on power.

CAM SPECS DURATION DURATION LIFT GRIND (ADV.) (0.050) Lunati H230-235 Intake 280 230 0.489 in Exhaust 285 235 0.507 in VALVE EVENTS @ 0.050-INCH TAPPET LIFT EXH. OPEN EXH. CLOSE INT. OPEN INT. CLOSE OVERLAP 106 LSA 47.5 BBDC 7.5 ATDC 13 BTDC 37 ABDC 20.5 110 LSA 51.5 BBDC 3.5 ATDC 9 BTDC 41 ABDC 12.5 114 LSA 55.5 BBDC 5 BTDC 5 BTDC 45 ABDC 10.0 ATDC-After Top Dead Center BTDC-Before Top Dead Center ABDC-After Bottom Dead Center BBDC-Before Bottom Dead Center TEST 1 TEST 2 TEST 3 106 LSA 110 LSA 114 LSA Peak HP 434 @ 5,{{{900}}} 434 @ 5,500 428 @ 5,500 Peak TQ 455 @ 4,500 449 @ 4,400 440 @ 4,400 Avg. TQ 416.8 lb-ft 414.4 lb-ft {{{405}}}.6 lb-ft Avg. HP 347.0 345.7 339.5 Idle Vac. 8.5 in-Hg 9.6 in-Hg 11.4 in-Hg Crank Comp. 167 psi 160 psi 156 psi DYNO DATA HYDRAULIC ROLLER DIFFERENCE RPM TQ HP TQ HP TQ HP 3,400 472 306 469 304 -3 -2 3,{{{600}}} 484 332 485 333 1 1 3,800 496 359 498 361 2 2 4,000 500 381 507 386 7 5 4,{{{200}}} 501 401 512 410 11 9 4,400 503 422 516 432 13 10 4,600 502 440 520 455 18 15 4,800 499 456 521 476 22 20 5,000 492 469 521 496 29 27 5,200 483 478 513 508 30 30 5,400 469 482 {{{505}}} 519 36 37 5,600 453 483 492 525 39 42 5,800 434 480 479 528 45 48 6,000 416 476 463 529 47 53 6,200 393 464 445 526 52 {{{62}}} 6,400 - - 426 519 - - Avg 443.5 401.8 465.4 424.2 21.8 22.4 Peak 503 483 521 529 TALE OF THE TAPE DURATION DURATION Description (ADV.) (@ 0.050) LIFT LSA Isky MegaCam, Int. 280 232 0.485 in 108 Exh. 280 232 0.485 in Comp Xtreme, Int. 280 242 0.556 in* 110 Exh. 286 248 0.559 in* * These are net lift numbers-lobe lift rocker ratio minus hot-lash clearance.Hydraulic Flat-Tappet vs. Mechanical RollerThis test originally appeared in our November '00 issue with the plan to pit a typical flat-tappet hydraulic cam against a more aggressive mechanical roller. While most car crafters will recognize that this is anything but a fair fight, the concept was not to see who wins, but rather how much of a difference the mechanical roller cam is worth. The follow-up question then becomes, is the gain worth the additional price of the roller? The guinea pig for this test was a Steve Dulcich-built 440ci Mopar using a set of ported mid-'70s 742 iron castings, a Mopar Performance M-1 intake, an 850-cfm Barry Grant Speed Demon carb, and a set of 171/48-inch Hooker headers flowing through a pair of Flowmaster mufflers.

The difficulty with doing this story is coming up with a fair comparison, which in reality is not easy because the mechanical cam has lash figures of 0.016 and 0.018 inch, which do not allow comparing advertised duration at, say, 0.006-inch of tappet lift. The duration-at-0.050 numbers indicate that the mechanical roller is much "bigger" but most of that is inherent in the roller design, the exact concept this test was intended to evaluate. The included cam-specs chart indicates how much more aggressive the mechanical roller cam is merely by evaluating the differences in valve lift. The mechanical roller comes in with almost 0.070 inch more max valve lift that certainly contributes to the significant power increase inherent with a mechanical roller cam.

Is this truly a fair test? We'll let you decide. A concrete result of this apple-to-oranges comparison is that the roller cranked out over 20 lb-ft and 20 hp more average power with a peak horsepower difference well over 60 hp. Those are numbers that are hard to ignore as long as your wallet can accommodate the price of admission.

'Latest E-Mail Joke: A pirate walks into a bar with an enormous steering wheel sticking out from the front of his trousers. The bartender can't help but ask, "What's with the steering wheel?" "Arr," answers the pirate, "It's drivin' me nuts!"

'Read faster. Other people would like to use the bathroom, you know.

'Button C on the steering wheel of Speed Racer's Mach 5 activates rotary saws that cut down all obstacles in the car's path.

'Currently listening to: "Top Fuel Armageddon" by The Spectres.