<p>

<p>

This month, we're taking a little different approach to our '76 Camaro project car: rather than spend a lot more money on parts, we're taking a scientific approach and hitting the laboratory. Our lab, in this case, is the chassis dyno at Westech Performance in Mira Loma, California. Simply put, we need more power, and we need it soon. We've gone through most of our $20,000 budget, and our project car needs to stay smog-legal, so our options are limited.

With only $470.48 left in our budget, we decided that some expert tuning was the best route. The Superflow chassis dyno at Westech has wide-band tuning capability, which we deemed necessary for squeezing every last ounce of power out of our smog-legal 383. We had been to another dyno before without wide-band capability, and this produced only modest results: 238 hp at the rear wheels. Some seat-of-the-pants tuning further improved that count to 251 hp (our baseline test here). But for us to get anywhere close to the 12s, we needed a lot more oats in the feedbag.

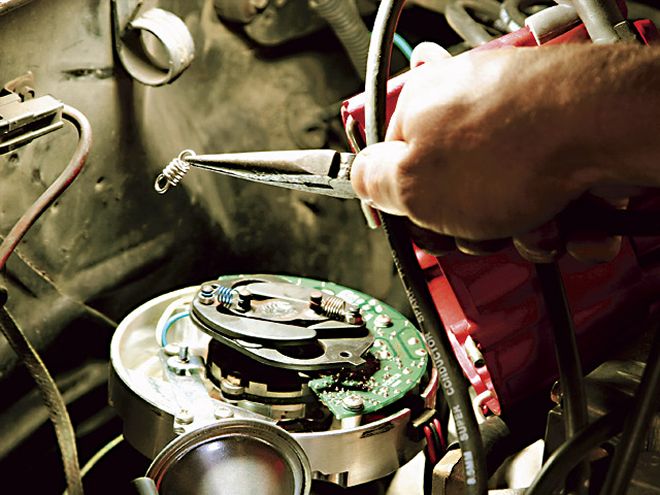

An advance kit came with our MSD Pro Billet HEI distributor, but you can buy the kit (PN 121-8464) from Jeg's for $12.99. It comes with a selection of bushings and springs. This didn't add peak power, but did make g/28 feel a lot scrappier on the street.

An advance kit came with our MSD Pro Billet HEI distributor, but you can buy the kit (PN 121-8464) from Jeg's for $12.99. It comes with a selection of bushings and springs. This didn't add peak power, but did make g/28 feel a lot scrappier on the street.

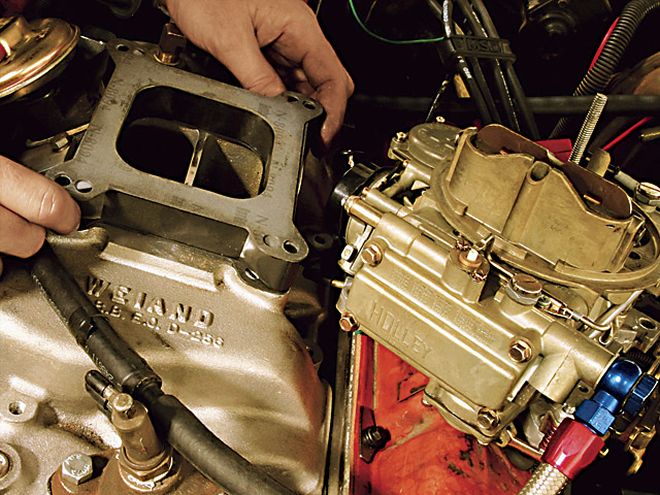

Before we get to that, first some review. Our power recipe consists of an internally balanced Lunati Sledgehammer 383 stroker kit with 10.6:1 compression and Holley 20-degree aluminum SysteMAX heads fed by a Weiand Action +Plus 8000 intake topped by a Holley 600-cfm vacuum-secondary four-barrel 4160 carb. The valves are actuated by a Lunati cam with 272/284 degrees duration (216/228 degrees at .050-inch), and 0.454/0.480-inch lift on a 112-degree lobe separation angle. The heads, cam, and carb combo all falls under the Holley SysteMAX smog Exemption Order number D-115-8. The engine was assembled by Speed-O-Motive in West Covina, CA and dyno tested 403 hp at 5,400 rpm, but has yet to reach its full potential installed in the car. You may further recall that the best ET g/28 has managed was a 13.85 at 101.62 which we reported in our November 2005 issue.

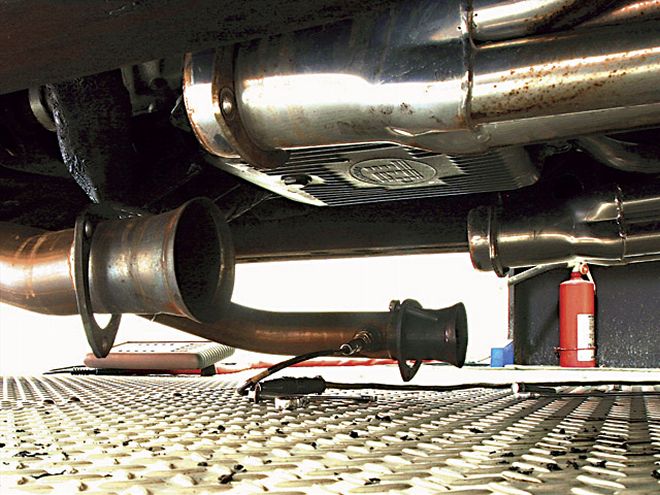

The general consensus around the office was that we were being robbed--but by who, or what? The snotty small-block we knew on the engine dyno was weak on the street. The hard parts were there, we just needed the right tools to find the answers. That's where Tom Habrzyk at Westech comes in. After he wired up g/28 with a wide-band sensor, we quickly found out what a wiz Habrzyk was with the dyno. The tuning tips and diagnostic techniques we learned were well worth the money. We came in with 251 hp showing at the rear wheels and left with 290--an increase of 39 hp. It cost us the dyno time ($320), a spring kit for the vacuum secondaries ($9.99) and a 1-inch carb spacer ($19.99) for a total of $349.98. Read on and see how Habrzyk did it, then check out the track results.

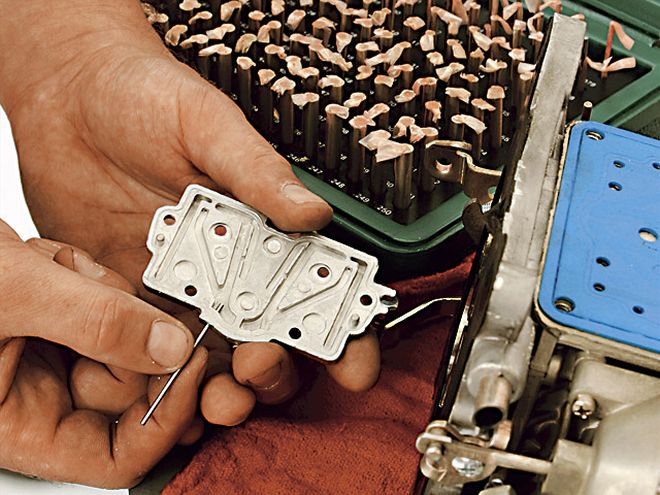

Westech's Tom Habrzyk used gauge rods to find the size of the original holes in the secondary circuit metering plate, which was .072-inch. That's equivalent to roughly a 68 or 69 jet size, according to the chart in the Holley catalog. We needed something smaller than that to lean it out.

Westech's Tom Habrzyk used gauge rods to find the size of the original holes in the secondary circuit metering plate, which was .072-inch. That's equivalent to roughly a 68 or 69 jet size, according to the chart in the Holley catalog. We needed something smaller than that to lean it out.

Dyno Run 1:

After welding a bung to the exhaust system and attaching the wide-band oxygen sensor, Tom Habrzyk put g/28 on the chassis dyno for a baseline test. We also added a can of NOS octane boost to a tank of 91-octane pump gas to maximize our power potential. Prior to testing, total timing was checked and found to be 40 degrees. Rear-wheel horsepower measured 251.5 peak hp, but the tach signal wasn't working correctly, so an MSD optical trigger was added to the crankshaft to get a signal for run two. This was the exact tune used for our last track outing when we ran 13.85/101.62.

Dyno Run 2:

With the optical trigger attached and no changes made to the engine, peak horsepower was observed at 251.0 hp at 4,777 rpm. The infrared heat gun showed cylinder No. 5 running a little cool, so that plug was removed and tested on an MSD distributor machine. It checked out fine. The timing curve in our MSD Pro Billet HEI distributor was checked and found to be coming in too late. The advance springs (a light-silver and a heavy-silver spring) were swapped for a light silver and a blue spring. This will bring the timing in much sooner. This isn't expected to change the peak power, but it will feel better on the street. Total timing was then set at 36 degrees prior to the third run.

Habrzyk drilled and tapped the metering plate to accept the two emulsion bleeds. The emulsion bleeds were drilled out to .059 inch, roughly equivalent to No. 60 jets. This started us out lean, but we would eventually drill these out as large as .076-inch, or approximately the size of 72 jets.

Habrzyk drilled and tapped the metering plate to accept the two emulsion bleeds. The emulsion bleeds were drilled out to .059 inch, roughly equivalent to No. 60 jets. This started us out lean, but we would eventually drill these out as large as .076-inch, or approximately the size of 72 jets.

Dyno Run 3:

No change in power was observed. The air/fuel ratio is too rich at full throttle, costing us power. Our Holley 4160 carb does not have adjustable jets in the secondary barrels and Habrzyk doesn't want to lean it out by reducing the jet size in the primaries, so he'll have to figure out a way to lean out the secondary main circuit. He decides to modify the secondary metering plate to accept two emulsion bleeds to serve as replaceable jets. These are normally used in high-end race carbs to adjust the mixture quality, but we will highjack them for low-buck jets. There isn't a lot of meat in the metering plate, so it must be drilled and tapped with much care so the plate doesn't split. Emulsion bleeds come undrilled and can be drilled to any size as long as the hole is relatively small. The end result was that we went down the equivalent of eight or nine jet sizes in the secondary.

Dyno Run 4:

Power peaks at 252.0 hp. With no change in power after a change in jetting, we suspect the secondaries aren't opening up all the way, so Habrzyk uses a temporary mylar zip-tie to hold the secondaries open at wide-open throttle.

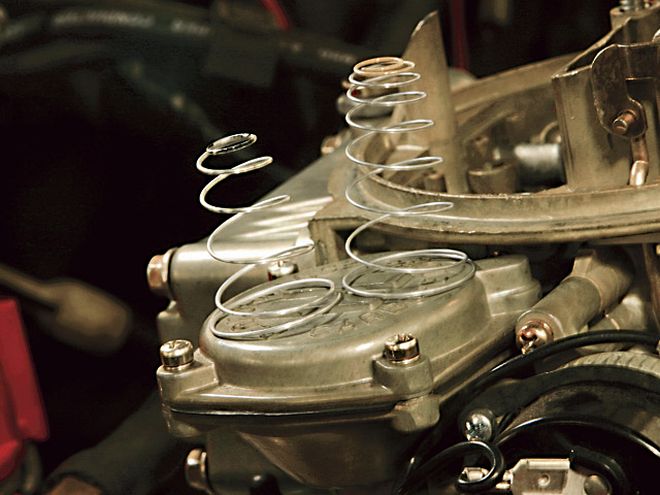

We replaced the vacuum secondary spring, pulling out the stiffer black one (left) and substituting the thinner, softer yellow one (right). Jeg's sells this Holley vacuum secondary spring kit under part number 510-20-13 for $9.99; it has a selection of seven different springs.

We replaced the vacuum secondary spring, pulling out the stiffer black one (left) and substituting the thinner, softer yellow one (right). Jeg's sells this Holley vacuum secondary spring kit under part number 510-20-13 for $9.99; it has a selection of seven different springs.

Dyno Run 5:

Now we're moving in the right direction with 261.1 hp at 4,759 rpm. The horsepower increase of almost 10 hp indicates that the secondaries aren't opening soon enough or fast enough. For the sixth run, Habrzyk swaps the spring in the vacuum secondary so that the barrels open sooner and quicker. Hint: with a 4160, this can't be done with the carb on the engine because one of the four access screws is hidden.

Dyno Run 6:

With the lighter spring opening the vacuum secondaries, power jumps to 266.7 hp at 4,996 rpm. We notice an improvement in the sound of the engine, too. The barrels open sooner and there's more growl to the exhaust note under throttle. At this point, an argument broke out between Tom Habrzyk and contributing editor, Steve Dulcich, over what to do next. Should we move on to more jet changes or pull off the exhaust system? Dulcich argued that even though we weren't planning on running g/28 with an open exhaust, it might be helpful to know at this stage how much the catalytic converter and single three-inch exhaust was costing us. For the purposes of telling us where to go next in our tuning loop, it certainly sounded like the right thing to do. I agreed, so we pulled off the pipes, leaving only the long-tube Hedman headers.

Dyno Run 7:

With the pipes yanked, power rose to 282.2 hp at 4,976 rpm. We gained just over 15 hp by dumping the exhaust, but it wasn't as much as everybody expected. That's of course why you dyno test: to take away the guessing and find out exactly what's happening in the engine. The open pipes sounded great, but left us with no wide-band sensor to observe the air-fuel ratio. Without this, no meaningful jetting could be done, but we could pull off the mechanical fan to see how much it was costing us.

Running on the street with the exhaust off isn't an option, but it did allow us to check how much power it was costing. With the exhaust off, WOT manifold vacuum went up to 1.5 inches Hg and power went up 15 hp. The manifold vacuum told us we were right on the edge with our carb size. Any more vacuum and a larger carb would be indicated.

Running on the street with the exhaust off isn't an option, but it did allow us to check how much power it was costing. With the exhaust off, WOT manifold vacuum went up to 1.5 inches Hg and power went up 15 hp. The manifold vacuum told us we were right on the edge with our carb size. Any more vacuum and a larger carb would be indicated.

Dyno Run 8:

With the fan unbolted, power swelled to 292.5 at 5,143 rpm. By now, a crowd had gathered and everybody thought this would be worth about 20 hp, but they were wrong. The stock non-clutch flex fan (which we recycled from our old 305) hogs only 10 hp. At this point we were looking for that 300hp number, so the next move was a COMP Cams 1-inch open carb spacer. This would give us more top-end power by allowing the cylinders to have access to all four barrels of the carb. The extra plenum volume would also have a positive effect on power, but how much?

Dyno Run 9:

The spacer adds a disappointing 5 hp, bumping the total pony count up to 297.8 hp at 5,019 rpm. Heads get together and calculate that the mixture is too lean, so fuel is added. The primary jets are bumped from 66 to 70, and the emulsion bleeds in the secondary metering plate (acting as jets) are bored out from .059-inch to .062-inch--the equivalent of going from 60 jets to 63 jets.

Dyno Run 10:

Wow! Power jumps to 311.4 hp at 5,168 rpm. That's a lift of over 13 hp. All agree it's the right time to reconnect the exhaust (and flex fan) to see where the air/fuel ratio is.

More top end was found by bolting on a COMP Cams VH311 polymer 1-inch open spacer, which costs $19.99 from Summit. The spacer took some tuning to maximize, but was ultimately worth 10 to 15 hp.

More top end was found by bolting on a COMP Cams VH311 polymer 1-inch open spacer, which costs $19.99 from Summit. The spacer took some tuning to maximize, but was ultimately worth 10 to 15 hp.

Dyno Run 11:

With the exhaust and fan hooked back up, peak power takes a nose dive to 279.0 hp at 5,134 rpm, a loss of 32 hp. That's a greater loss than the fan or exhaust added when taken off, so we're on to something. The air/fuel ratio is hooked up and measures 10.8:1, way too rich, so the primaries are leaned out to 66 jets (from 70s) and the secondary metering plate gets a new set of orifices drilled out to .059-inch (the same as in run number 9).

Dyno Run 12:

Power takes another dive to 269.7 hp at 5,137 rpm. Apparently, lean is not what our motor wants to see, so Habrzyk moves the other direction and fattens the secondaries up to .070-inch orifices (approximately 68 jets). The primary jets are left at 66.

At the track, we laid down a best ET of 13.35/105.85 with the new tune. That's a full half-second quicker and 4 mph faster through the traps. This matches our hp gain perfectly when compared to our previous best of 13.85/101.62. While we do think some seat-of-the-pants tuning would've helped, we doubt we would've been able to get this much power without the Westech chassis dyno and a wide-band O2 sensor. We've spent $19,879.50--that's close enough to $20,000 to satisfy us. What should we do with g/28 now? Let us know!

At the track, we laid down a best ET of 13.35/105.85 with the new tune. That's a full half-second quicker and 4 mph faster through the traps. This matches our hp gain perfectly when compared to our previous best of 13.85/101.62. While we do think some seat-of-the-pants tuning would've helped, we doubt we would've been able to get this much power without the Westech chassis dyno and a wide-band O2 sensor. We've spent $19,879.50--that's close enough to $20,000 to satisfy us. What should we do with g/28 now? Let us know!

Dyno Run 13:

Bingo! The smog 383 responds with 292.1 hp at 5,155 rpm (up 22 hp)--and that's now happening with the exhaust hooked up and the mechanical fan running. Another heated discussion breaks out: Shouldn't we use a bigger carb than a 600 cfm? A bigger carb wouldn't be legal, but might be worth some information. We decide against it, as manifold vacuum at WOT was .8-inch Hg. More carb won't help with the exhaust hooked up and vacuum so low. Apparently, fat is where it's at, so instead, the secondaries are drilled out again, this time to .076-inch (approximately 72 jets).

Dyno Run 14:

Peak power drops a little to 290.1 hp at 5,072 rpm, but midrange power is up as much as 5 hp everywhere else. Habrzyk and Dulcich figure the fatter secondaries are probably covering a dead spot in the midrange. This will help us get down track quicker, so we decide to keep the 66 jets up front and the .076-inch orifices in the rear. All we need to do now is bolt on the K&N filter and drop base to see if it costs us any power.

Dyno Run 15:

With the filter on, power peaks at 290.0 hp at 5,212 rpm. We carefully close the hood to check clearance, and the carb spacer, carb, and air cleaner just barely rub the bottom of the hood. We decide it's no big deal since a short cowl hood is in our future. We're done, and now it's time for the track. We're up 39 hp, which should be good for four tenths, nominally. Will it work out that way? Check the photo!

The End Is Nigh

It's been a great ride with Project g/28, but it's time to bring the mods to a close with this installment. We set out to make our '76 Camaro an all-around performer, with the emphasis on handling, budget, and making it street-legal. We set four primary performance goals with a budget of $20,000: run the 420-foot slalom course at 46 mph or better, stop from 60 mph in less than 120 feet, circle the skidpad greater than .90g, and run the quarter-mile in less than 13 seconds. We accomplished the first three, and came darned close with the last, all while staying within our budget.

If you missed any of the nine installments prior to this one (we started back in the April 2005 issue), you can log on to www.popularhotrodding.com to read anything you missed. (catch up) Every test session, every bolt-on and every source can be found on our Web site, so if you're hazy about some of the details, don't be afraid to check it out.

So where are we going now? We have a few things we want to try on g/28 that aren't part of our original set of plans. Although the series is technically at an end, you can look for more stories down the line. Drop us a note if you have an idea!