Sometimes for one reason or another, projects can take a turn midstream, and in the case of our 446 build, timing and circumstance have led to just that. With our robust short-block built, fitting the top-end package marked the home stretch for our build-up. Our cylinder head criteria was to use aftermarket aluminum heads with relatively large Max Wedge ports, and we sought very high flow. We had planned on a set of extensively modified MP 383/440 replacement heads. in seeking to make these basic castings fit our requirements, the heads were radically ported, including filling in the pushrod pinch and cutting the as-cast intake ports to the maximum cross-sectional area. When we saw the new Indy 440-EZ heads at the recent trade shows, we began to rethink the practicality of our original approach.

Enter The Indy EZ

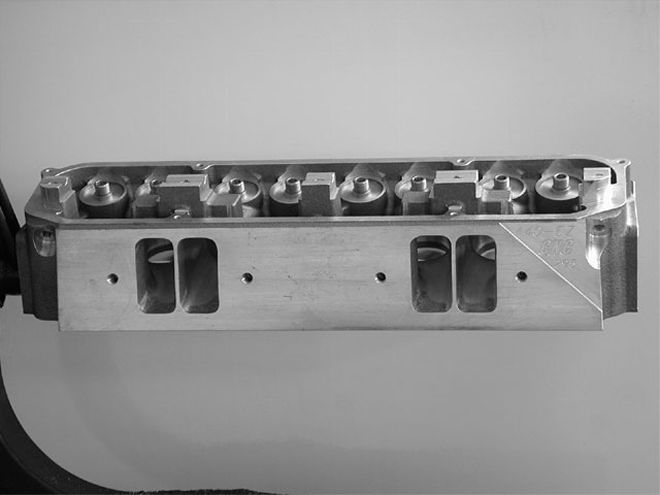

The 440-EZ series is based upon the popular Indy SR series of heads, but with casting revisions to the intake, and a relocated exhaust port, putting the exhaust back to the stock location from the raised SR position. The stock exhaust location eliminates potential complications in fitting existing header designs in most applications, but what really got our attention was the EZ performance potential. We had scores of hours of porting time in our low-port MP heads, and achieved respectable flow, but the new Indy heads offered something our highly modified castings couldn't match-power and performance right out of the box. Weighing which approach would better serve those looking to duplicate our effort, the cold reality is our insanely modified castings represented more work and one-off esoteric mods than even we'd ever want to attempt again, much less pay for. The architecture of the Indy head was designed from the onset with large high-flowing ports in mind. With the raised intake runners working down the port to Indy's trademark long valves, the layout has distinct performance advantages, including a taller, deeper, port in the bowl and short turn, and a more appropriately sized port volume for a big-block engine. The Indy heads free up the area under the spring seat, which is critically short in production-style short-valve heads. The clincher was a look at the flow numbers.

Indy offers the 440-EZ head in four versions, covering applications over a wide performance level. The most basic version is the standard 440-EZ, which retains the factory port window size at the manifold flange to mate with any standard factory or aftermarket intake manifold. The EZ heads preserve the factory layout for the pushrod location and rocker arms, and oil the rockers through the heads, just like the originals. Basically, all that is required are longer pushrods and the Indy valley plate to make the swap a bolt-on. Helped by the streamlined shape afforded by Indy's long-valve, and an ample 2.19-inch valve diameter, the as-cast 270cc 440-EZ intake ports flow 305 cfm, while the exhaust handles 215 cfm. With a flow gain approaching 40 percent as compared to stock castings, there's tremendous power potential in these heads. That's very good, but Indy offers three even hotter versions of the EZ head in the Max Wedge port window configuration.

If more flow is called for, Indy opens the EZ head to larger proportions with the 440 EZ-1, with CNC porting to the bowls and intake runner opening, taking the head to a Max-Wedge-size port window, with a port volume of 275 cc. The larger intake port opening and CNC work raise the intake flow to the 3TK level, and allow the use of higher-capacity factory or Indy Max-wedge intake manifolds. The EZ-1 is otherwise the same as the standard EZ head, in regard to stock rocker oiling and the standard location exhaust.

Things really get interesting with the EZ casting treated to Indy's full Windjammer CNC porting of the intake, exhaust, and chamber. Measuring in at 295 cc, the Indy 440 EZ-295 CNC, affectionately called the Little Easy, scales intake port flow up to a lofty 355 cfm, while still utilizing standard factory-spec rockers. The fully CNC-ed Little Easy, at 355 cfm, was just too tempting for us to pass up in our project, offering awesome power potential, simple installation, and plenty of port volume to make our 446 really come to life. For bigger inch stroker or higher-powered applications, Indy has an even larger version of the EZ available, the 440 EZ-325 CNC, called the Big Easy. With a 325cc intake port, the Big Easy utilizes the offset intake rocker arrangement of the original Indy-1 heads. Like the Little Easy, the Big Easy receives the full Windjammer CNC treatment, and flow is through the roof at 370 cfm. For the popular stroker combos being built these days, this cylinder head offers the flow potential, volume, and cross-section to make serious use of the available displacement. Both the Big and Little Easy full CNC ported heads are designed to oil the rockers via Indy's convenient external oiling system.

Making the swap to any of the Indy heads requires the factory style intake "bathtub" gasket be replaced by the Indy valley plate. The separate valley plate offers improved sealing of both the block's valley, and the intake manifold. The use of individual composition gaskets (supplied by Indy) to seal the intake manifold facilitates fit and alignment when milling has been done to the block, heads, or both. Two configurations of the valley plate are offered: Indy's one-piece PN 440-6 R/B, or the PN 440-6R R/B that includes an access plate. Since the valley plate becomes captive when the heads are installed, we prefer the latter, which allow access to the lifter valley in the event of a cam change or other maintenance. As mentioned, the full CNC-ported versions of the EZ requires the Indy external oiling system, which is simple to set up and plumb.

Though the Indy heads are offered fully assembled and ready to run, we elected to go with our choice of Comp's new beehive valvesprings (PN 26120). We've seen the beehives in action on other applications, typically hydraulic rollers, with impressive results. We have witnessed these springs dramatically increase rpm potential, while running at a reduced spring load, and were eager to give them a try in a Mopar flat-tappet hydraulic application. The beehive springs reduce spring mass, and the winding design makes the springs much less susceptible to harmonic spring surge, a primary factor in loss of valve control. Installed at 1.900 inches, the springs will provide 148 pounds of seat load, and 369 pounds of load over-the-nose with our cam combo. The Comp springs were installed with the required special retainers, and a set of Comp SuperLocks for the Indy 111/432-inch stem valves. Our cam combo would put them to the test, with the extraordinarily fast Comp XEHL hydraulic flat-tappet cam, and our selection of custom 1.7:1-ratio Harland Sharp rockers. With only 231-degrees of duration at .050-inch lift, our combo will open the valves to a maximum of just a hair under .600-inch, representing a very demanding combination. The aggressive number 5964 lobe our custom cam is based on may seem short on duration when the .050-inch number is quoted, but the duration at .200 inch is a healthy 149 degrees. We were after a short duration/high lift combo to maximize idle quality and vacuum in a tame street application.

The balance of our assembly included the excellent Indy 440-2D dual-plane intake manifold, ported and prepped in a previous issue to flow 360-plus-cfm. We will top the intake with a large Demon carburetor. Needless to say, we are going out on a limb with this unusual combination of large, high-flowing heads, combined with a very short duration, high-lift cam, and a large two-plane intake capped with a big four-barrel. The goal is an exceptionally good idle and strong torque, with impressive power into the lower 6,000-rpm range. We expect to put the theory to the test in a full dyno session in an upcoming issue. We'll sample several capacities of Demon carbs from Westech's inventory of dyno carburetors, and hope to experiment with an Indy single-plane intake, to see how the power at higher engine speeds responds. Will it work? We sure hope so, but you can bet we'll be packing a big solid roller stick as a back up, just in case we turn out to be all wet with our experiment. Hey, but it just may work. Stay tuned.

INDY EZ HEAD SPECS 440 EZ 440 EZ-1 EZ-295 CNC EZ 325 CNC Intake volume 270cc 275cc 295cc 325cc Exhaust volume 79cc 79cc Chamber volume 75 or 80cc 75 or 80cc 78 or 82cc 78 or 82cc Intake window stock B/RB Max Wedge Max Wedge Max Wedge Porting as-cast partial CNC full CNC full CNC Rocker oiling standard standard external external Rocker offset standard standard standard offset Intake valve dia. 2.19" 2.19" 2.19" 2.19" Exhaust valve dia. 1.81" 1.81" 1.81" 1.81" INDY PORT FLOW - Intake Tested by Indy 28-inch H2O Depression 440 440 EZ-295 EZ 325 LIFT EZ EZ-1 CNC CNC .{{{200}}} 156 162 .{{{300}}} 216 216 .400 264 274 .500 290 324 .{{{600}}} 300 351 .700 305 355 INDY PORT FLOW - Exhaust Tested by Indy 28-inch H2O Depression 440 440 EZ-295 EZ 325 LIFT EZ EZ-1 CNC CNC .200 98 98 110 110 .300 129 129 149 149 .400 158 158 176 176 .500 178 178 196 196 .600 199 199 211 211 .700 215 215 225 225