Today most of us are driving a fuel-injected car or truck, but many of us grew up driving older carburetor-equipped vehicles. We all remember pumping the accelerator pedal on those cold winter mornings, hoping the engine would start, or having to give a little more pedal at a stop light to prevent a stall. Certainly, those of us that drove during that period can fully appreciate all the benefits a modern electronic fuel-injection system has to offer.

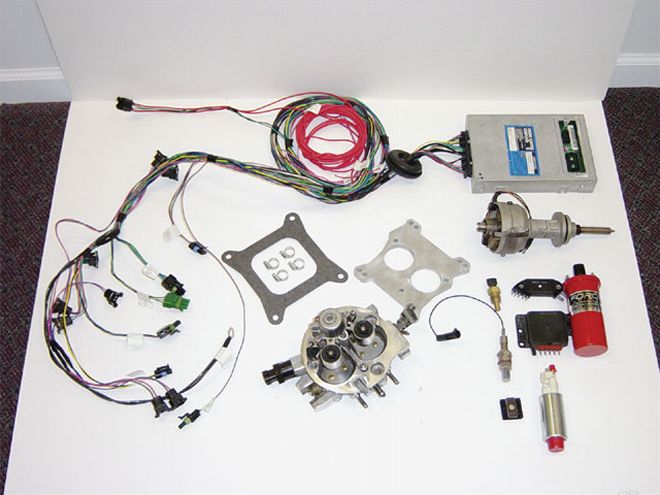

All the parts required for the retro fit from Performance Injection Equipment are included in the kit. While these kits are not designed for high-horsepower applications, they are just the ticket for stock-style drivers.

All the parts required for the retro fit from Performance Injection Equipment are included in the kit. While these kits are not designed for high-horsepower applications, they are just the ticket for stock-style drivers.

For years, GM and Ford enthusiasts have been retrofitting various types of fuel-injection systems onto older model cars. Those enthusiasts have had access to systems designed for cars like the tuned port-injected Camaros and Firebirds, and the EFI-equipped Ford Mustangs of the mid-'80s and '90s to make their conversions possible. But Chrysler enthusiasts have been at a distinct disadvantage. For us, the ability to retrofit a practical, reliable, inexpensive, electronic fuel-injection system onto a stock V-8 engine in an older vehicle simply wasn't possible. Yes, there are the fuel-injected, small, front-wheel-drive models of the '80s and '90s, but those four-banger EFI systems can't be installed onto larger engines. For the Chrysler stock small-block/big-block engine driver, the only alternatives to a carburetor were a small selection of over-the-counter universal systems, and the so-called laptop-tunable, custom, electronic fuel-injection systems produced by several manufacturers.

Various universal EFI systems have gained a great deal of notoriety over the years. sadly, some have given fuel injection a bad reputation. Most often, these systems comprise a stand-alone, fuel-only controller tuned by adjusting knobs on the face of the unit. Because of their generic nature, these controllers are not vehicle specific and do require tuning for the application. But with only the ability to turn knobs, how accurate can their tuning be? this method of tuning is somewhat unscientific, at best. These controllers do not permit access to the engine performance maps, and they only allow for adjustments to the fuel curve. Generally, these devices lack the sophisticated electronics necessary to alter engine timing; timing is still controlled by a vacuum-advance distributor. by not facilitating an oxygen-sensor input, they cannot allow for a closed-loop operation to enhance fuel economy. It is true these controllers can offer a semblance of fuel injection, but they ignore half of the process. The principal advantage of the EFI systems is price. While they may not be entirely satisfactory in their performance, they can be inexpensive to purchase.

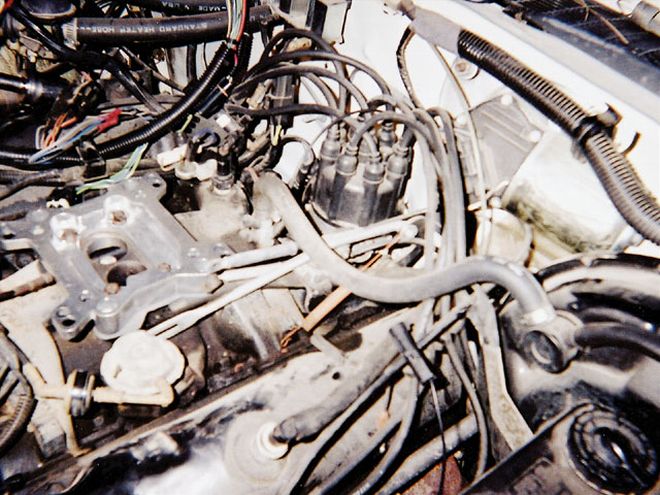

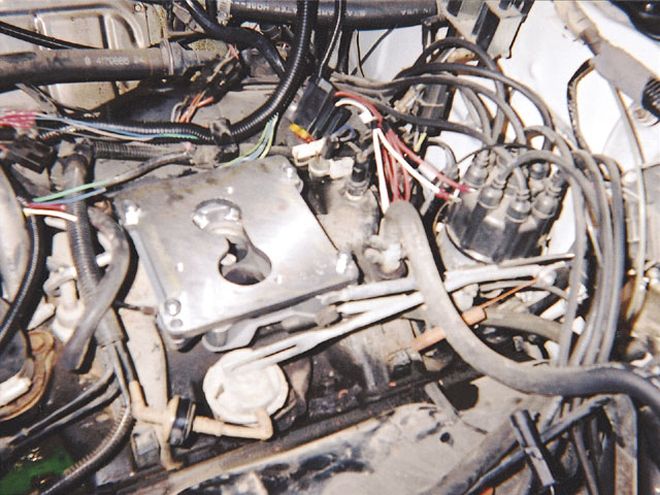

In order to get the larger throttle body to fit our intake, we needed to use an adapter setup. The adapter pieces are included in the kit.

In order to get the larger throttle body to fit our intake, we needed to use an adapter setup. The adapter pieces are included in the kit.

Laptop and hand-held calibrator tunable systems can be calibrated to work in nearly any vehicle, and they can perform extremely well. Their tuning is accomplished by altering the engine's individual fuel and timing maps at various engine speeds throughout the power range. For the most part, the implementation of these systems requires the skills necessary to interpret engine performance curves and to tune an engine through a computer.

Certainly, these are a collection of skills we don't all possess. Lacking these skills, the buyer must obtain expensive dyno-time to achieve the desired result. these systems can also come with a hefty price tag, often thousands of dollars. while these systems are state-of-the-art and champion the cause of retrofit EFI, we believe they are best suited to high-performance applications, where their higher purchase costs can be justified. But what about drivers who want to enjoy all the benefits modern electronic fuel-injection systems have to offer and not spend thousands to do so? Until now, there hasn't been a complete bolt-and-go, retrofit, electronic fuel-injection system for Chrysler enthusiasts driving stock or mildly modified V-8s.

Performance Injection Equipment (PIE) has released the first in its line of retrofit products designed from the ground-up for Chrysler stock small- and big-block engines. These EFI systems are practical, reliable, and inexpensive. these stock-engine retrofit systems literally are bolt-on kits. There are no special engineering or computer skills required to install or use them, and no poke-and-hope fiddling with dials and knobs to adjust these systems. These easy-to-install Chrysler retrofit EFI systems come with all the necessary components to install them. The stock small-block kits include: a throttle-body, a throttle-body-to-intake-manifold adapter, fuel injectors, a fuel pump, an electronic distributor, an electronic control unit, all necessary sensors, and a replacement wire harness. The soon-to-be-available, stock, big-block kits will include: a completely machined intake manifold, an air door, fuel rails and piping, fuel injectors, a fuel pump, an electronic distributor, an electronic control unit, all necessary sensors, and a replacement wire harness. each kit comes pretuned and preprogrammed with extensively tested software for specific Chrysler stock engine types. Because no additional tuning or dyno time is required, these kits are ideal for the enthusiast on a budget.

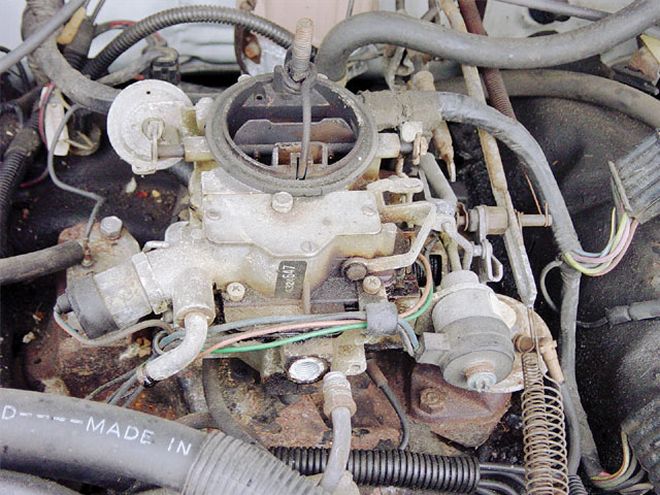

We decided to give it a try. our test vehicle is a well-worn, completely stock '88 Dodge Diplomat. The car is equipped with a non-modified production 318 engine with a factory installed two-barrel intake manifold, factory cast-iron exhaust manifolds, and three catalytic converters. this car is not equipped with a police package and has more than 92,000 miles on its original engine and drivetrain. The Dyno-Jet chassis dynamometer was used for performance testing. As the dyno sheet reveals, after the installation of the PIE bolt-and-go, retrofit, electronic fuel-injection kit, this little 318 developed 164.7 peak horsepower at 3,500 rpm, and 283.4 lb-ft of peak torque at 2,500 rpm.

Fuel injectors are small electronically operated fuel valves that emit-under pressure-a measured quantity of fuel for combustion. Fuel injection is the method in which a measured quantity of pressure-atomized fuel is introduced into the combustion zone of an engine cylinder for a specific instant in time. Pressure-atomization is the process in which liquid fuel is reduced to a fine spray by centrifugal movement and the heat of compression inside the injector-body. Pressure-atomization is far superior to the method of air-atomization employed by carburetors because the tiny droplets of fuel (formed from each drop of liquid fuel as a result of the process) offer a greater total surface area for mixing and ignition than does a single drop of liquid fuel. The greater surface area presented by these many tiny droplets results in remarkably cleaner and more complete combustion. that completeness of combustion yields greater power by volume of fuel and enhances the efficiency of fuel utilization.

Electronic fuel-injection systems fall into two categories: throttle-body injection or multi-point injection. A throttle-body housing has as many as four electronically controlled fuel injectors, depending upon manufacture and engine power requirements. These injectors aspirate outside air into the fuel spray from the computer operated injectors in order to promote thorough mixing of the atomized fuel and combustion air in the intake manifold. A throttle-body is similar in appearance and function to a carburetor only in that it is mounted atop the intake manifold, and serves to introduce a mixture of fuel and air into the manifold for distribution via the intake runners to the intake valves. Simple in design, throttle-body-based fuel-injection systems are much more economical to operate than carburetors and have enjoyed many years of success. However, because they employ the principal we refer to as air/fuel pre-mix-defined as the process of achieving fuel and air mix away from the combustion zone in order to achieve satisfactory performance and efficiency-successful throttle-body injection systems must rely completely upon proper intake manifold design. When fueling through the intake manifold, the internal design of the manifold dictates how well and how evenly atomized fuel and combustion air are mixed, and then introduced into each cylinder for combustion. a poorly designed intake manifold will allow atomized fuel to adhere to and collect along rough internal surfaces, as well as permit the formation of air eddy-currents around sharp turns inside the manifold, both of which can interfere with the combustion process.

Unlike throttle-body systems, multi-point-more commonly called multi-port-electronic fuel-injection systems comprise a single air door and an electronic fuel injector for each cylinder. In a multi-port system, a fuel injector is mounted at the end of each intake runner or port to introduce pressure-atomized fuel directly into the combustion chamber in each cylinder. Air for combustion is introduced through an air-door (similar in appearance and function to the air-handling components of the throttle-body) and is aspirated through the intake manifold into the combustion chamber. In this system, the primary mixing of pressure-atomized fuel and combustion air takes place in the cylinder, rather than in the intake manifold, in a process referred to as air/fuel post-mix. While multi-port injection systems still depend upon a proper intake-manifold design for optimum performance, the elements of intake design peculiar to fuel handling can largely be ignored. The particular advantage of multi-port systems compared to throttle-body systems, is that pressure-atomized fuel is introduced nearer the point of combustion, thereby permitting cleaner, more efficient firing than with a throttle-body system with a minimum of unburned fuel carried into the exhaust. More sophisticated, sequentially fired, multi-port injection systems allow for the precise coincidence of fuel injector opening and intake valve opening, yielding maximum power and minimum waste from each cylinder. While multi-port injection systems are superior in operation and performance to throttle-body systems, they can be substantially more expensive to purchase and install. Thus, they are not necessarily a cost-effective alternative in every electronic fuel-injection application. Performance Injection Equipment employs throttle-body injection systems in small-block applications and uses the more robust multi-port injection systems for big-blocks.

Dyno Run 1

318 With Fuel Injection Bolted OnRPMTorquePower2,500283.4134.92,600279.2138.22,700275.6141.72,800272.5145.32,900269.3148.73,000267.5152.83,100265.7156.83,200263.6160.63,500247.2164.73,600239.7164.33,700232.6163.93,800224.9162.73,900219.5163.04,000213.2162.44,100206.2160.94,200200.9160.74,300192.1157.34,400182.6153.04,500173.0148.24,600168.0147.2Column Max:283.4164.7Column Min:168.0134.9Column Avg:233.8154.4

There you have it. Does it seem too simple? That's the idea. Build a kit that anyone with basic hand-tools can install on their car. From what we've seen, Performance Injection Equipment has done just that.