Car crafters love competition, and there's nothing like a good shootout to dump fuel on the Chevy versus Ford versus Mopar fire. So it is with the Battle of the Titans comparison of three street-ready small-blocks. The plan was to see which engine could generate the best overall power curve. By now you should be familiar with the rules, but if not, the Cliff's Notes are that the engines couldn't be bigger than 365 ci, they had to run on pump gas, and they had to stick to a budget of $2,500. This was difficult for the Ford and Mopar guys, mainly because these engines cost more to build than a small-block Chevy. But that's the reality of the performance world.

The first man up to the plate was CC's Mopar man Marko Radielovic, who laid down the gauntlet by choosing a "damn the idle vacuum-full speed ahead" Crane cam measuring 242/252 degrees at 0.050-inch tappet lift with a 108 degree lobe separation angle. That friends, falls relatively far from the daily-driver category, but since there were no rules concerning idle vacuum, Marko went for the jugular.

Henry De Los Santos, our resident Ford guy, built a very similar 351W-based small-block using GT-40P iron heads. He splurged on a set of 1.7:1 Crane roller rockers, but when it came time for the cam, Henry chose a more conservative route with a Crane Power Max hydraulic flat-tappet stick with 234/238 degrees at 0.050-inch tappet lift with a similar lobe separation angle of 108 degrees. While the 8-degree-shorter duration at 0.050 on the intake doesn't sound like much, it proved to be the smallest of the three cams and may have hurt the Ford's chances for a stronger finish.

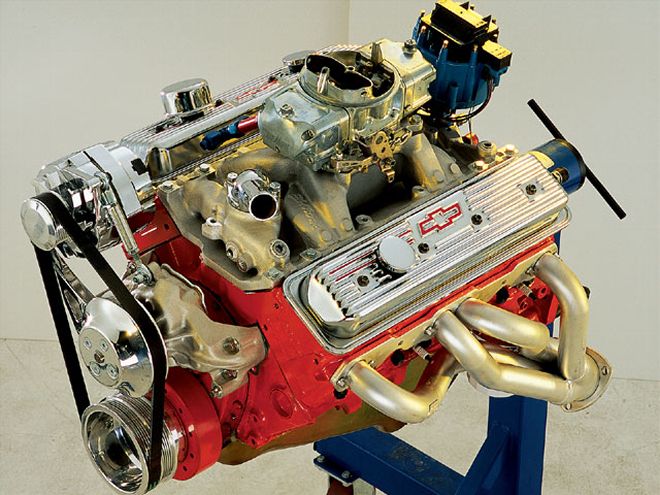

Terry McGean got the nod to construct the Bow Tie engine, and he followed the now-familiar path for the short-block with production-based components and a set of Vortec heads modified by Scoggin-Dickey to accommodate the additional lift of a big Crane PowerMax hydraulic flat-tappet cam. McGean also pumped up the cam with a similar grind to the Mopar with a 244/252 degrees at 0.050-inch tappet lift selection and an even tighter 106-degree lobe separation angle.

All three engines used Edelbrock Performer RPM dual-plane intakes, a Barry Grant Demon 750-cfm carburetor, and similar Hooker chassis headers. All three engines were machined, assembled, and tested at JMS Racing Engines so we didn't have to worry about variations between different dynos.

The classic line is that the combination is what determines the power curve, so we decided to look a little closer at the camshaft numbers relative to the cylinder-head flow data. We couldn't find flow data on the Mopar head, but some info on the GT-40P head indicates that the exhaust side is a little weak (typical of many production Ford small-block heads) and probably could have used a greater exhaust duration to help evacuate the cylinders, especially at higher rpm levels.

Conversely, the Chevy Vortec heads, offer a slightly better exhaust port but really benefit from excellent intake flow numbers in the 0.300- and 0.400-inch valve-lift areas. While max cam lift for the Chevy was more than 0.525 inch, it is the cylinder head's flow potential at the mid-valve lifts that generally contribute to a strong power curve throughout the entire rpm band. This is the case with the Vortec heads. In fact, comparisons of the Vortec heads to the top-10 aftermarket aluminum small-block heads consistently places the Vortec head in the top five category in these mid-lift flow areas. This cannot be emphasized enough, and no doubt it was the cylinder heads that contributed more to the Chevy's success than any other single component.

Numbers Don't LieThe goal of this test was really twofold. The first was overall power, and the second was peak power. Often you'll find an engine that makes great peak power but is a little weak when it comes to the midrange torque curve. However, in this case the Chevy not only won the peak power contest but also made more overall power than the other engines. The Mopar did make a little more torque between 3,500 and 4,000, but that was the only place where the Bow Tie engine was challenged. As you can see from the charts, the small-block Mopar put up a great effort with peak numbers very similar to the Chevy's, but closer inspection of average torque reveals the Chevy made more than 14 lb-ft more torque than the Mopar and 30 lb-ft more average torque than the Ford engine. Unfortunately, the Ford was down compared to the other two engines, coming in over 50hp shy of the Chevy and the Mopar and around 30-lb-ft short on the torque side.

Take a DipIf you look at the graph of all three engines, you can see an interesting dip in the torque curve for both the Mopar and the Chevy. The Mopar hits the dip first between 3,000 and 3,300, while the Chevy sags between 3,500 and 4,000. These troughs in the power curve are common in engines with large amounts of camshaft overlap. As mentioned earlier, both the Mopar and Chevy engines used larger-duration cams with tight lobe separation angles that increase the amount of overlap (when both the intake and exhaust valves are open). This can cause higher pressures in the intake manifold that can reduce the signal to the carburetor and cut fuel flow. Increasing the fuel flow in this rpm area only often returns that lost power. This fuel-flow increase can be worth from 10 to 15 lb-ft of torque. This is of importance if you happen to be using a torque converter with a stall speed of 3,000 rpm, for example, as in the Mopar's case. With torque multiplication ratios in a converter of over 2:1, a loss of 25 lb-ft here is the equivalent of losing 50 lb-ft to the input shaft of the transmission.

ConclusionsWe can be assured of at least two things that will result from our first shot at Battle of the Titans. The first is that no self-respecting Ford guy is going to jump ship and build a Chevy just because the Ford engine didn't do well in our test. Does that mean all small-block Ford 351W engines are lame? Hardly. The second obvious result is that this Titans shootout will only feed the controversy over which engines are better. We don't claim to have any better handle on the crystal-ball routine than those phony Coney Island madams, and it looks like the Battle of the Titans has created as many questions as it answered. And if there are enough of you out there who'd like to see a pocket-porting rematch, we could be coerced into another round. Tell us what you think. Just keep the verbal abuse to a minimum.

RPM FORD MOPAR CHEVY TQ Power TQ Power TQ Power lb-ft hp lb-ft hp lb-ft hp 2,800 386 205 407 217 2,{{{900}}} 387 214 390 215 413 228 3,000 391 223 386 220 417 238 3,{{{100}}} 395 233 384 226 419 247 3,{{{200}}} 396 241 383 233 417 254 3,{{{300}}} 397 249 387 243 414 260 3,400 399 258 397 257 413 267 3,500 403 268 407 271 413 275 3,{{{600}}} 406 278 416 285 415 285 3,700 410 289 423 298 420 296 3,800 413 299 429 310 427 309 3,900 415 308 435 {{{323}}} 434 322 4,000 415 316 442 337 439 334 4,100 414 323 442 345 443 346 4,200 414 331 440 352 446 357 4,300 413 338 439 359 447 366 4,400 411 344 436 365 447 375 4,500 409 351 435 373 445 382 4,600 408 357 434 380 442 388 4,700 {{{405}}} 362 431 385 440 393 4,800 399 365 427 391 436 398 4,900 393 368 423 394 431 402 5,000 387 369 419 399 427 407 5,100 380 369 415 403 423 411 5,200 376 372 411 407 420 416 5,300 370 373 407 411 417 421 5,400 363 373 401 412 412 424 5,500 356 372 393 412 407 426 5,600 348 371 385 410 400 427 5,700 336 365 379 411 393 426 5,800 373 412 387 427 5,900 370 415 6,000 Avg. TQ 366 418 Avg. TQ Avg. TQ 393.8 409.3 423.8 Avg. HP Avg. HP Avg. HP 320.4 342.3 346.3Wheel to WheelSince the only people who race dynos are magazine writers, we decided to plug all three power curves into the Racing Systems Analysis (RSA) Quarter Pro dragstrip simulation program. We have over a dozen years of experience using this program to evaluate quarter-mile potential with various power combinations.

The beauty of a computer simulation is that we can "bolt" all three engines into the same theoretical car. We chose a car that shifted at 6,500 rpm and spec'd out at 3,400 pounds using a 2,500-stall converter with 5 percent slippage, a three-speed automatic trans turning a 3.73 rear gear, and 26-inch-tall sticky rear tires. To no one's surprise, the simulations followed the power curves, but the interesting thing was the subtle performance difference between the Chevy and the Mopar. Despite the Chevy's obvious power advantage, the simulation showed a quarter-mile e.t. difference of only 0.03 second and 0.60 mph (11.74/117 for the Chevy and 11.78/116.4 for the Mopar). The e.t. difference could easily be the differential in reaction time, making it a true heads-up contest. The Ford cranked out a respectable 12.19/111.9 mph pass. All runs were simulated at sea level on a 72 degree F day with a barometer of 29.92.

Engine e.t. Speed 60-ft. Chevy 11.74 117.00 1.70 Mopar 11.78 116.40 1.71 Ford 12.19 111.{{{90}}} 1.72With a Little Help From Our FriendsA project like this is not only very time-consuming but also downright expensive. First of all, we'd like to acknowledge JMS Racing Engines for the time, consideration, and effort that went into a battle of this scope.

Of equal importance are the several layers of help that came directly from Crane Cams and the crew from Daytona Beach, Florida. Several other companies also contributed to this exercise and we also want to note their involvement.

ChevroletAt first blush, most onlookers would immediately assume that the clear advantage in our competition would be had by the Chevy. It seemed obvious given the two primary constraints of the shootout-use a factory iron head and don't spend more than $2,500-since the best parts at the best prices are available for the Chevy. But the times, they are a changin', and cheap, effective hardware is no longer the sole property of the small-block Chev. As a result, Team Chevrolet (in this case, me) soon found that victory would not be had without a fight.

The SpecsDisplacement: 355 ciCompression: 10.4:1Cam type/specs: Crane PowerMax hydraulic flat-tappet, 244/252-degrees duration @ 0.050-inch valve lift, 0.516/0.525-inch liftCylinder heads: Scoggin-Dickey-prepared cast-iron GM Vortec, 64cc chambers, 1.94/1.50-inch valves, Z28-style valvesprings, LT4 retainersInduction: Edelbrock Performer RPM Air-Gap, dual-plane intake, 750-cfm Speed Demon carbHeaders: Hooker Super Competition, 151/48 inchesCost: $2,188.84

Dyno DayAfter we filled the crankcase with 10W30 oil, JMS dyno guy Robert Hendrix fired the engine and ran it around 1,500-2,000 rpm to break in the cam for the better part of a half-hour. Later, the break-in lube was drained and replaced with Mobil 1 synthetic 5W30. The first pulls were partial runs to make sure everything was copacetic, though as we took the engine higher and higher in its rpm range, things were looking increasingly promising. Our stated goal had been 430 hp, and while some had scoffed, we knew we had to come at least close to that figure to best the Mopar, which we now knew had generated 418 hp.

When the printout showed that we were making 404 hp at 5,000 rpm, we started feeling pretty good, figuring we'd hit peak power right around 6,000. The next pull showed 421 hp at 5,500 and climbing. We now had the Mopar covered, but we were still looking for that 430hp goal. However, the first full pull showed that the peak was actually occurring at 5,800, and that 421 hp was about it. To this point, all pulls had been made at 36 degrees total timing. We dialed in 33 degrees and the engine responded with 427hp, still at 5,800 rpm. Optimism remained high at that point, but the 427 number turned out to be the best. The carb's jetting proved to be just about right, so we left it alone, and dialing back the timing more than 33 degrees actually shaved off a few ponies. Even the tried-and-true dyno trick of adding a 2-inch carb spacer wouldn't nudge us any further. Still, our engine had come very close to our horsepower predictions while also making nearly 450 lb-ft, besting all comers on all fronts.

ConclusionsWhile we were certainly pleased with the performance of the little Chevy, our combination was the source of some controversy around the office. Naturally, the Mopar contingent pointed out that we had more compression (barely a half point) and more cam timing (really just a narrower lobe separation at 106 vs. 108 for the Mope), though they didn't bring up their extra 10 cubes of displacement, or their biggest-of-the-test valves (2.02/1.60). The real debate was over streetability, which as you may recall, was a stated objective of the shootout. Naturally, in the interest of competition, some of us took that to mean anything that wouldn't rattle on 91 octane, but the true streetability of this engine is questionable. It idled at 850 rpm comfortably but with a notable chop and not much vacuum (less than 5 inches). A hard-core guy would motor this combo to work, particularly if he had a manual trans (and manual brakes), but he'd have to be the sort that wore his car's ill temperament like a badge of courage. Some guys dig that. However, for true sit-in-city-traffic-during-90-degree-heat reliability, this combo might prove to be a bit much for the average street guy.

We don't really consider this a failure, though. The engine isn't absolutely unstreetable, and it did make strong torque over a broad range of rpm. Still, a simple cam swap would change its personality in an afternoon. Trade off some top-end power for a broader curve with a lower peak and you could drive it cross-country. Even if the compression was deemed too high, a set of typical 0.043-inch composite head gaskets in place of our 0.015-inch steel shims would quickly shave the ratio back to around 10:1.

We'll know more about the behavior and potential of this combination as it's slated to be slid into a street/strip machine for further evaluation. Watch for it to emerge in these pages soon.

Mopar Dyno FlogFor those tuning in to this series for the first time, a recap of the small-block Mopar is in order before moving on to the dyno battlefield. The Battle of the Titans rules stipulated a budget of $2,500 and a maximum of 365 inches and a 0.030-inch overbore netted us the limit in cubic inches. We squeezed Federal-Mogul flattop hypereutectic pistons into the bores, resized the stock rods, and fitted them with with Pioneer rod bolts. Next, our pals at Johnson Machine Service (JMS) ground the cast crank 0.010-under on both sets of journals and we added a lumpy Crane hydraulic flat tappet. We then bolted on a set of Aerohead Racing reconditioned "587" 360 smog castings with 2.02- and 1.60-inch valves. For the intake we added an excellent Edelbrock Performer RPM Air Gap intake manifold along with a 750-cfm Speed Demon carburetor. Hooker 151/48-inch headers shuttled the exhaust. We even reused the stock stamped-steel rocker arms and stock pushrods to stick with our budget, though we still went around 22 bucks over. No big deal, we just had no lunch money for a couple of days.

The SpecsDisplacement: 365 ciCompression: 10:1Cam type/specs: Crane hydraulic flat-tappet 242/252-degrees duration @ 0.050-inch valve lift, 0.528/0.552-inch liftCylinder heads: Aerohead reconditioned "587" iron castings, 2.02/1.60 valvesInduction: Edelbrock Performer RPM Air Gap intake, 750-cfm Speed Demon carbHeaders: Hooker Competition 151/48-inchCost: $2,522.11

ConclusionsStreet manners are largely a matter of what a person is willing to tolerate, which is largely subjective. Even though the relatively long duration of the cam in the Titan 360 does not pull enough vacuum for power brakes or daily driving, we have found that its characteristics are far from objectionable in this particular application. Obviously this engine will also need a deeper rear gear and a 3,000-stall converter to make the most of this combination, which adds up to an engine that may not be everyone's first choice. When the results were tallied up, we came in a little short of McGean's Chevy, and significantly ahead of Henry's Ford in peak horsepower and torque output. Considering the liberal use of factory stock parts, we are immensely pleased with the results of the Mopar Clash of the Titans buildup.

The DynoOn the morning of our dyno test, we still had no headers that would fit the tight confines of Johnson Machine's DTS dyno. We located another set of Hooker headers that featured shorter head pipes that would clear the dyno. In addition, we discovered the intake needed a great deal of milling to properly fit our 360. This was because we milled the block a full 0.040-inch to achieve a zero deck and our targeted 10.0:1 compression.

So, dyno day arrives and we're still jacking with the exhaust and induction. By noon we were ready to light it off and break in the cam. The engine started without a fuss, showed good oil pressure (75 psi), and didn't leak-much. After breaking in the cam for 20 minutes, we made a partial pull to check the air/fuel ratio. By the third pull, we took the little motor up to 6,000 rpm. On this pull, it broke the magic 400hp mark with 403 hp at 5,800 and 413 lb-ft of torque at 4,000. The engine idled with more than a little lump, pulling a mere 3.5 inches of vacuum at 850 rpm, so we won't be using power brakes with this combination! By the eighth pull, we added a 1-inch open spacer to the combo, which made the idle choppier. The first pull with the spacer netted an unremarkable 403 hp, but it added torque up to 427 lb-ft at a slightly higher 4,300. Test number 15 was the "martini run." We swapped the Road Demon Jr. for a more appropriate 750-cfm Speed Demon mechanical-secondary carb. This was worth 418 hp and 443 lb-ft of torque! Were we happy? You bet.

More TestingSince the little Mopar was the first to be completed, it consequently was the first engine to find its way into an engine compartment. With a set of borrowed and used-up slicks and running 4.88 gears, the best the Barracuda could muster to the 60-foot mark was a 1.66. The good news is that our times were all in the 7.58-second range at 90.5 mph, which equates to roughly 11.90s on a quarter-mile track. A subsequent trip to the track with more appropriate 4.10 gears netted a best of 7.49 (in the 11.70s) at 90 mph with a best short-time of 1.61. That's cookin'!

Ford 351 WindsorThe MissionOur goal was to build an entry-level engine that would produce good power with basic parts on a penny-pinching budget without sacrificing reliability or quality with a $2,500 spending cap. And to be perfectly honest, we did exceed our budget by $44.83, which is close but still over. Regardless, this 351W buildup is very real world, and we think this is a good engine for such a small amount of green.

Prepping the CoreIf you recall from the buildup story in the September issue ("Battle of the Titans" pg. 40), we procured a typical stock used block that had been languishing in the corner of our friend's shop. This was the foundation for our 351W engine with JMS doing all the machine work.

Piecing the 351For the heads, we used Central Coast Mustangs' (CCM) modified GT-40P heads. These are factory OEM heads that were used on several production vehicles, including the Explorer, and will outflow the standard production E7TE heads that were used on 5.0L Mustangs. For $639 a set, you can replace the entire valvetrain with higher-quality components, including back-cut stainless valves, beefier springs, keepers, and hardened retainers. Definitely a great bang for the buck.

Our camshaft was a little more expensive than anticipated, but we realized that the right camshaft can make all the difference. We opted for a Crane Cams hydraulic flat-tappet with matching lifters and pushrods. Since we didn't have access to stock stamped-steel rocker arms, we stepped up to a set of 1.7:1 Crane roller rockers originally used on '93 Cobra engines for a reasonable cost of $190, keeping us originally well under the budget.

When it came to an engine kit, we found it cheaper and easier to purchase a Summit Racing engine rebuild kit. The kit is very complete and came with forged pistons, bearings, chrome-moly rings, freeze plugs, a high-volume oil pump, a complete gasket set, and a packet of engine-assembly lube for only $420. We added a Summit Racing timing chain for $24 to round it out.

For the remainder of the buildup, we used an Edelbrock Performer RPM dual-plane manifold, a Milodon replacement oil pan and water pump, and a set of six-point ARP head bolts to firmly clamp the heads into place. Total price: $2,545.

Results Once mounted to the in-house JMS dyno, Dyno Operator Robert Hendrix started by gingerly breaking in the 351W for the initial 20 minutes before the flogging. Even though our cam was a little on the lumpy side with 234/238 degrees duration at 0.050-inch lift, the engine idled comfortably at around 800 rpm and had a tone that any gearhead would love.

With total timing set at 32 degrees and the fuel pressure at roughly 8 psi, we performed a test pull up to 4,000 rpm that seemed promising. The chart revealed 316 hp and 415 lb-ft of torque. Everything looked good leading up to the first full pull that netted 360 hp and 399 lb-ft of torque. After several pulls with similar results, we increased the timing progressively to 35 degrees total, only to lose power, and ultimately found our peak power by gradually pulling the timing down as low as 29 degrees total. With a 2-inch open spacer, our final numbers came in at 374 hp at 5,300 rpm and 415 lb-ft of torque at 4,000 rpm.

ConclusionGiven the short cam specs and the excellent torque this engine made, we think our 351 Windsor buildup makes an excellent powerplant. As we've said before, the idea was to create a solid entry-level engine that could be placed within the confines of a true street vehicle. We certainly did that. You can easily drop this 351W into a wide array of Ford bodies, mate it with a 10-inch, 2,500- to 3,000-stall converter with mild 3.55:1 gears, and rip the tires to shreds by simply stabbing the throttle. Horsepower is nice, but it's the torque down low that makes for great fun on the street. And considering our torque curve is pushing over 400 lb-ft as low as 3,500 rpm, you can bet it'll put a silly grin on anyone's face.

Granted, our horsepower and torque levels didn't put us on top compared to our Chevy and Mopar cronies. Sure, we could have changed the cam for one with a much more aggressive profile for peak power figures, but for a street machine application we decided that a lumpy idle that still delivers a decent amount of vacuum to support power accessories is still a good idea.

If you should ever decide to upgrade this combo for more power and don't mind sacrificing street manners, there are a myriad of configurations that this 351W could evolve into. You could swap in a set of thinner gaskets or mill the heads to pump the compression. Swapping to a more aggressive camshaft, and even going with a single-plane manifold would make the motor more strip-friendly, though this would certainly kill midrange torque. Nevertheless, we're more than content with the results. However, if you feel this engine deserves a second look, send us your cam and induction ideas and perhaps we'll run 'em up the Windsor flagpole. There's certainly a little more power left in this blue oval performer.