Most rods purpose-built for racing utilize a fully machined con-struction with cap-screw style fasteners such as this A-beam rod from Carrillo Industries. This is a super-light rod at just 486 grams, designed for limited-horsepower applications. Carrillo'snew A-beam style creates a very narrow beam profile, whichshould also help cut downon windage losses.

Most rods purpose-built for racing utilize a fully machined con-struction with cap-screw style fasteners such as this A-beam rod from Carrillo Industries. This is a super-light rod at just 486 grams, designed for limited-horsepower applications. Carrillo'snew A-beam style creates a very narrow beam profile, whichshould also help cut downon windage losses.

Engine failures that many racers blame on the connecting rods are often actually installation mistakes. When their characteristics are correctly understood, connecting rods can be one of the strongest parts of a modern racing engine.

Let's do a quick mental exercise: How many times-either at the track or while watching television-have you heard a driver or crewchief explain away a blown engine with the phrase, "we broke a rod"?

Plenty of times, probably. But what does that mean? Connecting rods built for racing are manufactured with as much or more precision (and expense) as any other piece that goes in the engine. Rods are often the most stressed pieces in an engine, yet many Winston Cup engine builders will tell you they have rarely seen a rod failure that is truly the fault of the rod.

The fault can come from any number of places, but the failure often occurs at the rod because of the stresses involved. Often, the fault from an early rod failure comes from sheer human error. Simple things such as improper rod bolt installation, rough handling, or over-cycling the rods can lead to expensive rebuilds. Fortunately, these mistakes are easy to prevent if you have a solid understanding of what types of forces you expect your connecting rods to live through (horsepower, reciprocating weight, expected life cycle, etc.) and how to install them properly.

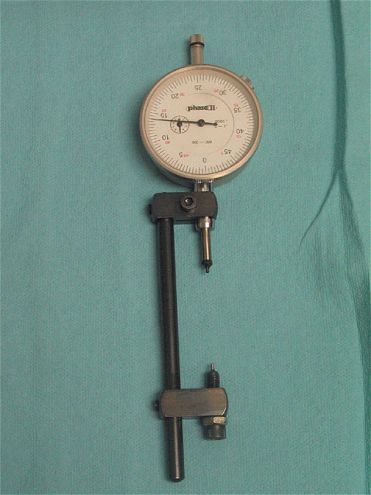

Although it can be done with different styles of calipers, a dedicated bolt stretch gauge is designed to do its job while the rod is installed in the engine. It will make your life easier.

Although it can be done with different styles of calipers, a dedicated bolt stretch gauge is designed to do its job while the rod is installed in the engine. It will make your life easier.

Since almost all forms of stock car racing limit rods to stainless steel in the interest of cost containment, this article will concentrate only on processes involving that material. For stainless rods, there are several options for construction, namely forged, powder forged, billet, and fully machined.

Powder-forged rods are used almost exclusively in OEM applications. Powder forging allows for a cheap, fairly rugged rod, but it isn't the quality of a standard forging. You will be hard-pressed to find a purpose-built racing rod that has been powder forged. However, if you are racing a strictly stock class that doesn't allow aftermarket rods, this might be what you are stuck with. As long as they are balanced, you aren't likely to exceed a powder-forged rod's horsepower limitations in a stock engine.

Next up the durability scale are forged rods. "The advantage of forging is that steel, just like wood, has a grain direction," explains Jack Sparks of Carrillo Industries. "When put in the proper position, it enhances the fatigue properties of the part. Forging a rod allows you to manipulate the grain direction in the steel. The optimum is to have longitudinal grain flow (up and down) in the blade area and cylindrical grain flow around the big end."

The problem with a forged rod also comes from the act of forging. The forging process leaves an inconsistent, rough surface on the rod. This roughness creates a multitude of stress points on the rod. "If you disregard the fasteners, most failures in a connecting rod are generated from some sort of inclusion or stress riser on the surface," Sparks explains. "It's like putting a notch in a coat hanger. When you bend it, it is going to break at the notch."

Ken Troutman of KT Engine Development demonstrated the process of checking rod bolt stretch for us. Step number one is to put the bolt in the gauge and zero out the dial.

Ken Troutman of KT Engine Development demonstrated the process of checking rod bolt stretch for us. Step number one is to put the bolt in the gauge and zero out the dial.

A billet rod is created by literally machining the rod out of a solid chunk of metal. The machining process creates a smooth surface that is (unless there is a problem in the manufacturing process or simply a bad design) free of surface inclusions. By avoiding the forging process altogether you have avoided a weakness, but you haven't been able to take advantage of strength by influencing the grain flow.

Enter what is commonly known as the "fully machined" rod. This process produces the strongest rod (gauging material strength only) by taking the best traits of the forging and billet processes and combining them. A fully machined rod starts out as a large forging (over six pounds in the case of most of Carrillo's rods) and then is machined into its final form much like a billet rod. This produces a rod that has the optimum grain structure of a forging along with the smooth exterior that you find in billet pieces. It's the best of both worlds.

Fasteners, no matter what type, are the greatest weakness in a connecting rod. However, if installed correctly, most fasteners from quality manufacturers are capable of handling the stresses they are designed for. Before we talk about correct installation, we first need to have an understanding of what's out there.

Next, he secures the rod in a rod vise, makes sure the bolt is properly coated in lubricant, and torques it to a number just under his target figure.

Next, he secures the rod in a rod vise, makes sure the bolt is properly coated in lubricant, and torques it to a number just under his target figure.

The fasteners used to hold the two pieces of the big end of the rod together come in two designs. Thru-bolt designs have a complete bolt and nut to clamp the rod together. A cap-screw design eliminates the nut, instead utilizing threads in the rod for the bolt to thread into. A thru-bolt design requires flat faces to be cut into the big end of the rod for each bolt (one for the head of the bolt and one for the nut). Eliminating the flat for the nut makes the cap screw that much stronger. Additionally, threading the bolt directly into the body of the rod also helps rigidity.

Now, it's time for the good stuff. Sparks says the most common reason for rod bolt failures is failing to install the rod bolts so that they achieve the proper clamping load. That's the complicated way to say "aren't torqued right," but that can be misleading because it's the use of a torque wrench that causes most of the problems.

The only way to make sure a bolt is exerting the proper clamping load is to measure stretch, not torque. On this point, Sparks can get downright militant. "Carrillo and every other quality rod manufacturer strongly suggest that the bolt is installed by stretch," he says. "Using a torque wrench only measures friction, and there are a lot of variables that can cause you to get the torque reading you are looking for without achieving the stretch that you need.

Now with the bolt in the rod, he checks the stretch with the gauge. Once it reads the recommend number, usually between 0.005 and 0.007, he knows he has the right amount of stretch. By starting below his target torque number, he can work his way up to the correct amount of stretch.

Now with the bolt in the rod, he checks the stretch with the gauge. Once it reads the recommend number, usually between 0.005 and 0.007, he knows he has the right amount of stretch. By starting below his target torque number, he can work his way up to the correct amount of stretch.

"I get calls all the time from people trying to get by with just torquing the rod bolts and asking what lube to use or what torque number they should look for with a particular lube. I tell them they need to be checking stretch, and then it won't matter if they are using peanut butter as a lubricant."

Of course, Sparks admits that peanut butter makes a much better sandwich than it does a lubricant, but he makes his point. Take, for example, moly-based lubes, which are most commonly used for rod bolts. Moly lubes have a metallic base. It's good because it doesn't come off easily, but that also means that every time you pre-fit the rod bolts you are polishing those threads, and every time you add another coat of moly lube, you are also making those threads progressively slicker. If you use the same torque number throughout an engine build, the amount of stretch on the rod bolts will be less every time the rods are assembled.

"Rod bolts are designed very carefully, so we have a pretty good idea after a multitude of tests that around 0.006 stretch equals approximately 9,600 pounds of clamping load. You have a lot of variables when assembling your connecting rods. They include the actual torque wrench, the lubricant, quality of mating surfaces between the bolt and the rod, and even the operator. If you try to go only by torque, you have to take all of these factors into account, but if you measure bolt stretch, all of these variables are suddenly not a part of the equation."

The lubricant's main job is to keep the bolts from galling in the rods so the engine can be easily disassembled when it is time for a rebuild. Make sure you use a lubricant that doesn't wipe off easily or boil away under heat, and use it to coat both the threads and the underside of the head of the bolt.

Many engine builders try to get away with assembling the connecting rods with only a torque wrench for one simple reason: It can be a pain to measure rod bolt stretch.

The most critical time to measure stretch is on final assembly, but that is when the rods are located in the cylinder bores and being bolted to the crank. It is easy to measure stretch when the rods are sitting on the work bench; it's not quite so easy when they are in the block.

Sparks understands this and offers a practical solution for the engine builder. As you build an engine, you will have the rods together and back apart several times. As you do this, you will be polishing the threads on both the bolt and rod, making all more consistent. Keep track of your stretch and torque numbers to make sure that all the bolts torque to the same number. Now, when you are ready for final assembly, you know that all your bolts stretch at the same torque number. Check the stretch on one set of rod bolts and mark your torque reading. You can safely torque the rest of the bolts to that number and be assured you have the correct amount of stretch.