Our "Giant Slayer" 340 found itself at home in its lair between the fenders of cousin Marko's '68 Barracuda. As we prepped it for its maiden voyage to the track, we knew there was power to be gained on the tune. What better place for a dyno tune than Westech?

Our "Giant Slayer" 340 found itself at home in its lair between the fenders of cousin Marko's '68 Barracuda. As we prepped it for its maiden voyage to the track, we knew there was power to be gained on the tune. What better place for a dyno tune than Westech?

Carb tuning has always been nothing short of black art, truly mastered by few. Calibrating the carb to provide an optimal air/fuel ratio over the engine's operating range enhances the power output. Keep in mind, it's the quest for power that has us bolting on a trick induction system in the first place. Using the skills we learned in chemistry class, we know the stoichiometric air/fuel ratio (the correct balance of air and fuel to complete a burn cycle) is 14.7:1. Like a lot of theoretical numbers or mathematically-derived "ideal" values, the actual air/fuel ratio an engine requires for max power is something altogether different.

Typically, we see the most power with air/fuel ratios in the 12.5:1 range near peak torque rpm, and moving to the high 12:1s to low 13:1s as the rpm rises toward the peak horsepower rpm. Tuning for wide-open throttle (WOT) output means the fuel curve must follow the optimal requirements as the engine climbs up its powerband.

Carburetors do an exceptional job of matching engine requirements at WOT. With nearly a century of development, the fundamental principles of a carb have been refined to a high level. A properly designed carb self-compensates the delivered mixture of air based upon engine-airflow demand. These mechanically based criteria of flow, velocity, and pressure differential determine the engine's mixture requirements, derived from what the engine is actually doing. As long as the calibration components of the carb are set to properly read these inputs, the carb will respond with a favorable air/fuel ratio. The challenge for the tuner is to juggle the combination of calibration components to allow the carb to do its job as effectively as possible.

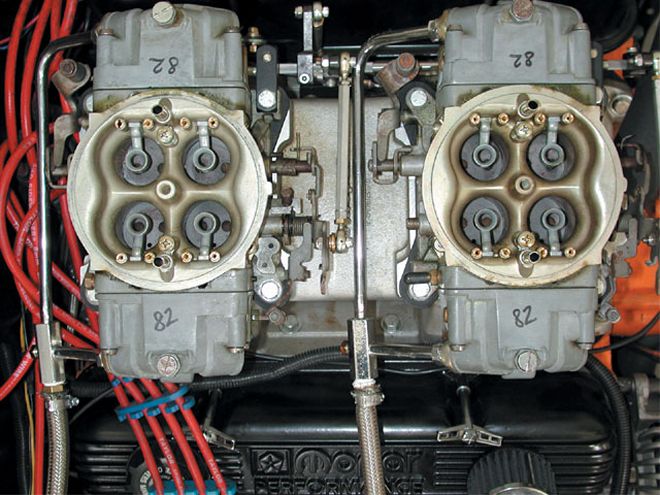

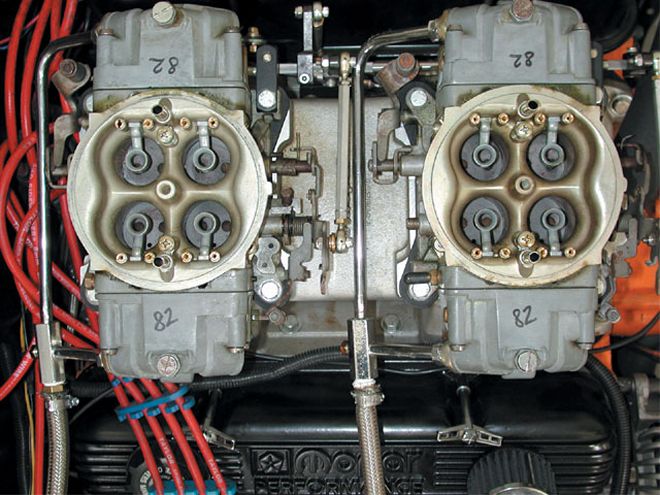

We wanted to iron the bugs out of the tunnel-ram system and explore the possibilities of air-bleed tuning. The 340 sports W-2 heads ported by yours truly, ditto on the wild MP tunnel-ram intake. Arias domed pistons fill the holes, while a stout custom Comp Cams flat tappet works the valves. A pair of 750 cfm ProForm carb bodies mated to swap meet Holley cores supply the mix on a poor man's budget.

We wanted to iron the bugs out of the tunnel-ram system and explore the possibilities of air-bleed tuning. The 340 sports W-2 heads ported by yours truly, ditto on the wild MP tunnel-ram intake. Arias domed pistons fill the holes, while a stout custom Comp Cams flat tappet works the valves. A pair of 750 cfm ProForm carb bodies mated to swap meet Holley cores supply the mix on a poor man's budget.

Traditionally, the intricacies of internal carb calibration have been left to the carb manufacturer, while the end user tweaked the final mixture strength through jet changes. For most applications, changing jets is all that's required to dial in an appropriate mixture. In recent years, we have seen more and more carbs outfitted with replaceable air bleeds as a secondary means of modifying the air/fuel ratio delivery of the carb. Replaceable air bleeds used to be the domain solely of race-only Dominator series carbs, but today, 4150-style carbs with replaceable air bleeds are common and are used in applications from race cars to street cruisers. We'd better begin by explaining what the air bleeds do.

Typically, there are two sets of air bleeds adjacent to the accelerator-pump squirters-the inner pair being the high-speed air bleeds, and the outer pair being the idle air bleeds. Both circuits feed a stream of fuel to their respective passages. The idle circuit channels fuel to the idle discharge port and transfer slots near the throttle blades. The main circuit sends fuel to the fuel-supply nozzle in the booster venturi. The discharge points for either of these circuits draw fuel on demand based upon pressure differential, most easily thought of as a suction originating at the discharge point. Air bleeds introduce a calibrated leak in the circuits, which accomplishes two things: It dampens the suction or "signal" drawing fuel through the circuit, and it introduces air to emulsify the fuel stream.

Looking down the barrels of the ProForm-bodied dual-quads, the replaceable air bleeds can be easily seen. The pair nearest the center are the high-speed bleeds, while the outer set are the idle bleeds. Air-bleed tuning can help optimize a carb, particularly in a wicked combination such as this, but it can also ruin a carb in a hurry if the calibration is goofed-up.

Looking down the barrels of the ProForm-bodied dual-quads, the replaceable air bleeds can be easily seen. The pair nearest the center are the high-speed bleeds, while the outer set are the idle bleeds. Air-bleed tuning can help optimize a carb, particularly in a wicked combination such as this, but it can also ruin a carb in a hurry if the calibration is goofed-up.

The size of the air bleed directly affects the amount of suction signal or operating pressure differential introduced into the fuel stream. It also affects how much air is drawn in to mix with the fuel, creating an emulsion of fuel and air. The idle circuit depends heavily on the air-bleed size to determine the mixture strength or the ratio of the emulsion. A relatively large proportion of the air delivery at idle is through the fuel emulsion, while, in contrast, the high-speed air-bleed effect on ratio is primarily a function of signal strength. While the ratio effect of the emulsion characteristics is secondary, the proportion of air admitted is smaller. In either case, larger air bleeds will lower the signal to the fuel stream and lean the mixture. Additionally, the reduced signal can cause a delay (or "softening") in the initial delivery of the emulsion column.

Tuning The Slayer

Last year, we detailed the buildup of a high-powered, W-2 equipped "Giant Slayer" 340, an engine we conjured up for our buddy Marko's street/strip '68 Barracuda ragtop. We finished the tale with a dyno test in the June '02 issue, seeing 592 hp at the crank from the tunnel-ram equipped, high-compression small-block. Though the output was fierce enough for cousin Marko to have something to talk about at his new digs at the Car Craft office, reviewing the dyno numbers, specifically in relation to the high-rpm fuel curve, left me less than happy. As stated in the story, we had an extremely rich condition at high rpm, something we didn't have time to tune out of our tunnel-ram system at the time of the original dyno test. A year later, with the engine in the car, we were preparing to assault the track. The carbs were hewn from parts off a set of 650 Holley cores and built on a new set of ProForm carb bodies. That rich hook at the top of the fuel curve cost us some peak power. With the engine in the car, we had the opportunity to take a second crack at dialing in the carbs on the chassis dyno.

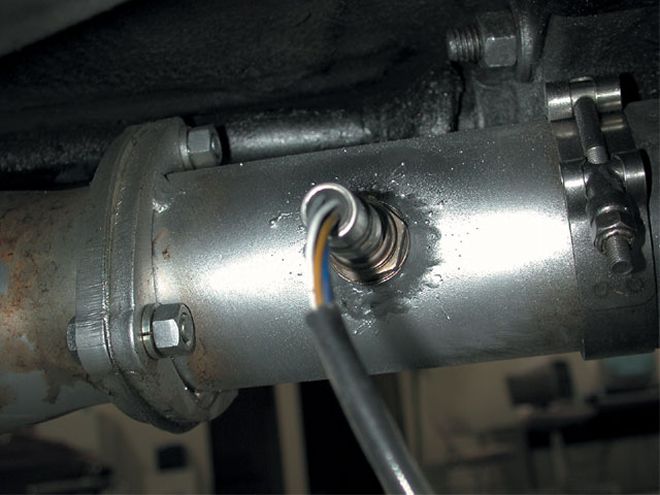

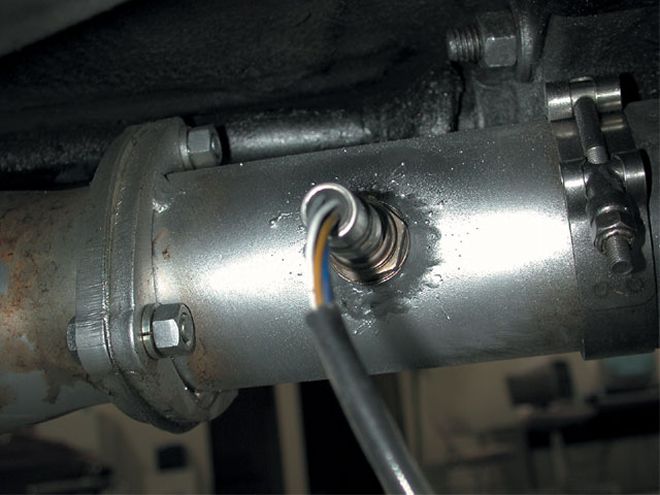

So we could track calibration changes as accurately as possible, a bung was added to the exhaust pipe to accept a sophisticated wide-band Lambda sensor, which measures air/fuel ratio.

So we could track calibration changes as accurately as possible, a bung was added to the exhaust pipe to accept a sophisticated wide-band Lambda sensor, which measures air/fuel ratio.

Tuning a tunnel-ram in a high-rpm application is no easy task, so we came to Westech's chassis dyno prepared. The ProForm carb bodies are equipped with removable air bleeds for both the idle and main circuits. We found that when driving the car, the idle and transition response was clean, so our primary aim was to iron out the high-rpm end of the mixture curve. We were packing a bag of semi-finished air-bleed blanks from Barry Grant and an index of drill bits to size them as required. To get a handle on the relative effect on mixture, the Barracuda was fitted with a bung on the exhaust collector to accept a wide-band Lambda sensor. This sensitive device will transfer real-time air/fuel ratio information to the dyno computer, allowing us to record and analyze the effects of tuning changes.

We set the tires to the rollers and strapped down the 'Cuda for what promised to be a wild ride. After running a preliminary warm-up, we set the controls to begin reading at 4,000 rpm and let it rip. We decided to twist the 340 up to 7,500 rpm-what a sound! We noticed some problems at high rpm as it spooled up under load, and we backed out at around 7,000 rpm. We had recorded a peak of 487 hp at 6,550 rpm and 400.7 lb-ft of torque at 5,850 rpm. The mixture was reading rich at high rpm, with the air/fuel ratio going from mid-12s at around peak torque, to mid-11s at the upper end of the test. The carbs were pulling fuel big time as the revs reached a critical point and drowned high-rpm power.

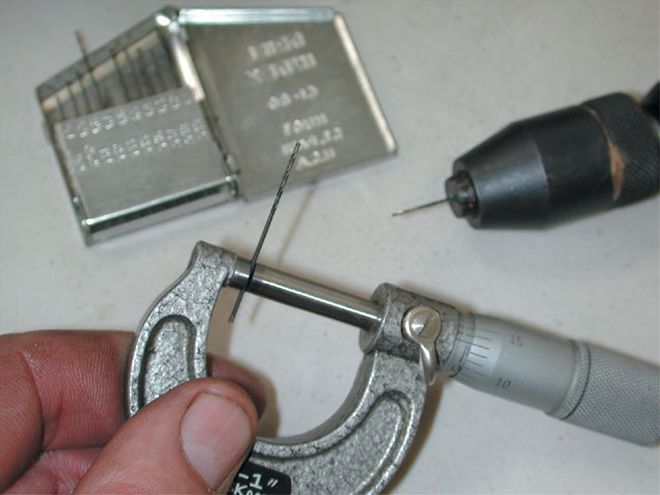

We brought a bag of Barry Grant air-bleed blanks, which are drilled only with a small pilot hole. The blanks were screwed into this holding fixture to make them easier to handle while drilling.

We brought a bag of Barry Grant air-bleed blanks, which are drilled only with a small pilot hole. The blanks were screwed into this holding fixture to make them easier to handle while drilling.

We prepared for the next test with Westech's Tom Habrzyk (pronounced just like it's spelled) positioned to eyeball the carbs during the power-pull. What he witnessed was fuel pulling through the secondary accelerator-pump discharge nozzles in a steady stream at high rpm. This kind of problem can be tough to identify, and we were fortunate to have pegged the source of the abnormal enrichment right off the bat. There are a couple of things that can cause this excess fuel flow, beginning with classic fuel pullover from the vacuum effect of air rushing past the nozzles. Holley makes special anti-pullover pump nozzles just for this problem, but unfortunately, we didn't have a set. Tom's keen eye caught some fluttering of the secondary linkage as high-speed operation rattled the carbs. This kind of fluttering of the throttle plates can cause the accelerator pump to pump fuel into the carb barrels. We checked the linkage and found the primaries were not quite opening to their stop, allowing the secondary to flutter considerably against the link. Could this have been the culprit that plagued our initial engine dyno test? The symptoms were the same, and we had a bear of a time adjusting the engine dyno linkage to pull the carbs wide open.

A precision-drill index is required to size the air bleeds. We used a micrometer to confirm the drill dimension. The pin vice (right) is used to hold the bit for drilling.

A precision-drill index is required to size the air bleeds. We used a micrometer to confirm the drill dimension. The pin vice (right) is used to hold the bit for drilling.

With the linkage problem solved, we were up and running for the next pull. This time, the 340 exhibited stronger numbers, showing 494.7 hp at 6,700 rpm and 404 lb-ft of torque at 5,800 rpm with no visible fuel flow through the pump nozzles. Though the numbers were good, all was not well with the 340. We detected the sound of ignition breakup in the range of 6,500-7,500 rpm. The point was driven home by the fact that peak horsepower still occurred at only 6,700 rpm. There was a definite problem, but at least we confirmed the fuel pullover problem was solved. Looking for info, we pulled the plugs to give them a read, and we didn't need Smokey Yunick to give us a lesson on what we saw. The plugs were fuel-fouled. We were running NGK R 50672A-9 plugs, which were too cold. Autolite AR 3911 plugs were substituted, which are one heat-range hotter. With the plug change, the 340 came to life big time, posting a mind-numbing 524.8 hp at 7,050 rpm and 419 ft-lb at 5,850 rpm. The engine pulled crisply to 7,500 rpm without complaint. Remember folks, these are rear-wheel numbers, and we were turning the rollers with power-robbing wrinkle-wall slicks. Using a conservative factor, we were pushing around 620 hp at the crank, although the dyno software estimated much more than that.

Bleeding The Beast

Satisfied that the problems were solved, we turned our attention to tuning. Our main goal was to try and tailor the fuel curve to maximize the high-rpm power and explore the effect of air bleeds. It has been said altering the air bleeds is the best way to ruin a perfectly good carburetor, and there is some truth to that. Air-bleed tuning isn't for the novice carb doctor to play around with. Carb companies employ tremendous resources to arrive at the air-bleed calibration best suited to the carb design to cover most applications. We were running dual-quads on a tunnel-ram with a small-cube, high-rpm small-block. This was an application far removed from the typical use of the style of carb the engine was equipped with. Armed with the information from the chassis dyno, a Lambda meter for air/fuel ratio, and lots of experience with carb tuning, we were well prepared to tune air bleeds. Think twice before leaping into this area of carb tuning unless you have a way to log data and quantify the results. Along with the jet, the air bleed adds a second variable in the air/fuel ratio calibration, and this one additional tuning point makes the job four times harder to get right.

Drilling the bleeds is done by hand, simply twirling the pin vice until through. The small pilot hole already in the air bleed guides the bit.

Drilling the bleeds is done by hand, simply twirling the pin vice until through. The small pilot hole already in the air bleed guides the bit.

On Marko's Barracuda, we were only interested in tuning for dragstrip action. Since the car will be equipped with an automatic sporting a loose 5,000-stall 8-inch converter and a 4.88:1 gear, our focus was narrowed to output at high rpm. The tunnel-ram and carbs were exhibiting excellent low-speed tractability and a nice idle (for this level of performance) at 1,200 rpm. The plan was to run an air-bleed tuning loop, dropping from the factory-installed .038 bleeds to .033, and work our way up to gauge the effect. Smaller bleeds will richen the mixture, particularly higher in the curve, and this is the safer direction to start. The test pulls would be between 4,000 and 7,500 rpm, so we set the average markers to calculate the average effect on air/fuel mixture below peak torque (4,000-5,800) and above (5,800-7,400). We pulled the .038 air bleeds and swapped in a set of .033s, a direction we were fairly sure would be wrong. We would use this rich setting as a baseline and open up the bleed diameter from there to target the most powerful combination.

Replacing the air bleeds is a piece of cake-just unscrew the old, and screw in the replacements. Getting the calibration dead-nuts on, however, isn't easy.

Replacing the air bleeds is a piece of cake-just unscrew the old, and screw in the replacements. Getting the calibration dead-nuts on, however, isn't easy.

With the .033 bleeds in all eight barrels, we found power was down. We recorded 512.5 rwhp at 7,150 rpm and 410.5 lb-ft of torque at 5,850 rpm. The mixture averages read 11.2:1 below peak torque and 12.7:1 averaged over the test range above peak torque. With this baseline in, we pulled the bleeds and, using a pin drill, enlarged the orifice in the air bleeds from 0.003 inch to 0.036 inch. We swapped in the new bleeds and ran against the rollers again to see what difference the change would bring. This time, output was up substantially to 519.1 rwhp at 7,050 rpm and 416 lb-ft at 5,750 rpm. Checking the averages, we found 11.42:1 below peak torque and 12.88:1 above, noting that the larger bleed indeed leaned the ratio, and the engine liked it.

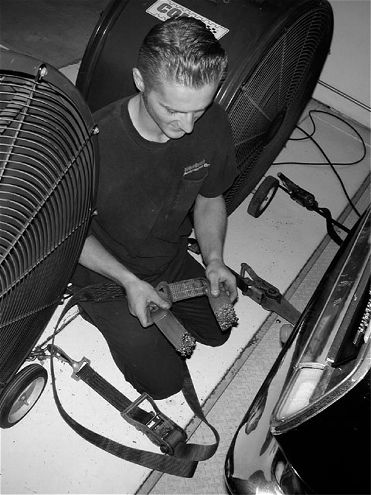

Are Mopar small-blocks powerful? Damn skippy, things got hairy when one of the restraining straps let go, a function of mega force and outrageous exhaust heat exiting the straight-through mufflers at the axle. Fortunately, Westech uses redundant restraints, so all we felt was a disconcerting sideways jerk when it let go.

Are Mopar small-blocks powerful? Damn skippy, things got hairy when one of the restraining straps let go, a function of mega force and outrageous exhaust heat exiting the straight-through mufflers at the axle. Fortunately, Westech uses redundant restraints, so all we felt was a disconcerting sideways jerk when it let go.

Next, we increased the bleed size another 0.003 inch to 0.039 inch, just 0.001 inch larger than the bleeds we'd determined to work the best on the engine dyno. The .039 bleeds were on the mark, cooking the books past our previous best, with 531.5 hp at the rear wheels and 427.3 lb-ft of torque coming in at 5,850 rpm. At this rear-wheel output, the 340 was in the 630hp range, outstanding considering the true displacement of only 346 cubic inches. This little 340 was living up to its "Giant Slayer" name, blowing past numbers we were accustomed to seeing from stout big-blocks. The air/fuel ratio averages were at 11.5:1 and 13.20:1, taken over the range below and above peak torque rpm, respectively. It's not uncommon to see high-output, high-compression engines with good distribution make best power with the air/fuel ratio toward the lean side at over 13:1.

Our test session concluded with the air bleeds again pulled for an increase to .041. We were fairly confident after scrutinizing the numbers that the .039s were on the money but figured we'd take it past the optimal point to confirm our suspicions. Power indeed was down, dropping to 525.7 at 7,050 rpm and 420 lb-ft of torque at 5,750 rpm. Even this small change in bleed was enough to tip the ratio a little too deep to the lean side, and power was measurably off. Our carbs were outfitted with No. 82 jets all around, and the air bleed/jet combo, with our unique carbs, proved best with the .039 bleeds.

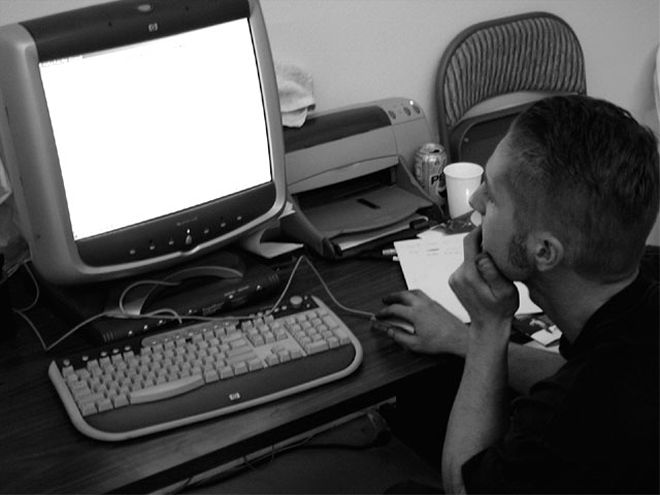

The SuperFlow chassis dyno logs information on multiple channels via a remote computer. We closely monitored engine coolant and oil temperature (factors that can skew the results if not controlled) between runs. Here, Tom was puzzling over how this 346ci Mopar lays down 532 hp at the tire. Editor's note: It's voodoo, baby. There was a 21hp variable at the rear wheels between the output numbers of the best and worst air-bleed combination. With the power we found, we can't wait to get the slicks off the rollers and into the bleach box to lay down some damage at the track.

The SuperFlow chassis dyno logs information on multiple channels via a remote computer. We closely monitored engine coolant and oil temperature (factors that can skew the results if not controlled) between runs. Here, Tom was puzzling over how this 346ci Mopar lays down 532 hp at the tire. Editor's note: It's voodoo, baby. There was a 21hp variable at the rear wheels between the output numbers of the best and worst air-bleed combination. With the power we found, we can't wait to get the slicks off the rollers and into the bleach box to lay down some damage at the track.

An interesting pattern, noted by the crew at Westech, is there seems to be an ideal combination of jet and bleed for a given carb and engine application that will show the best output. They noted that even if a different bleed/jet combo provides nearly identical air/fuel ratio and fuel-flow data, as recorded on the dyno, the engine will favor a specific bleed/jet combo. For instance, tuning a race tunnel-ram on a serious 605-cube Pro Stock-style motor, Westech's Steve Brule found that a .031 air bleed with a No. 96 fuel jet had a fuel curve identical to a .026 and No. 92 combo, but there was a significant difference in how well peak torque held on. Tuning air bleeds can be unpredictable and almost always requires trial and error and educated guesses, but when calibrating a difficult combo, it can make the difference that counts.

Data Chart

346 W-2 MoparAir BleedRWHPTorqueA/F-1A/F-2.033512.4 at 7,090 410.5 at 5,865 11.20:1 12.70:1.036519.1 at 7,029 416.5 at 5,767 11.42:1 12.88:1.039531.5 at 7,110 427.3 at 5,828 11.50:1 13.20:1.041525.7 at 7,033 420.1 at 5,761 11.63:1 13.30:1A/F-1: Average air/fuel ratio from 4,000-5,800 rpm

A/F-2: Average air/fuel ratio from 5,800-7,400 rpm