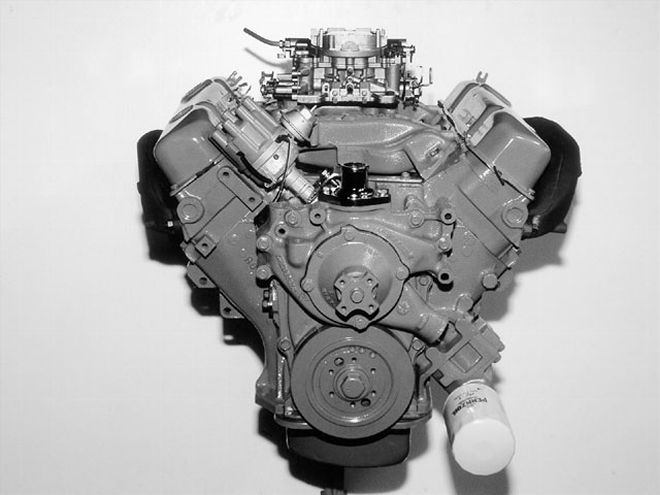

It's back to the summer of '69, with a fresh, factory spec 440 Magnum.

It's back to the summer of '69, with a fresh, factory spec 440 Magnum.

Over the last few months, regular readers of Mopar Muscle were treated to a buildup of a 340, built to stock specs, then wound against the dyno in original trim. With some carefully selected bolt-ons, the simple and straightforward 340 produced nearly 400 hp, gaining more than 110 hp over its tested stock 280 hp. That done, the next logical question was whether it would work with a 440. There was only one way to find out, so we dug into the engine-core pile and plucked out a 440 Magnum powerplant for a stock buildup as well.

Like the 340, the objective was to build the engine as close to stock specs as possible for baseline testing. This makes the parts selection nearly predetermined; OE replacement-type parts would be used throughout, but with the necessary machine work done to ensure as-new performance from the factory package.

Parts Package

Though it was going to be constructed to stock specs, there were some decisions to be made in the final parts selection. Generally these decisions are not centered around power production questions, but fall more into the category of durability. Do we use the cheapest "rebuilder's special" cast-iron piston rings or higher-quality low-wearing moly rings? Economical replacement cast pistons, or the forged version? Standard or high-volume oil pump? Really, in terms of power, the cheaper stuff or the higher quality stuff will not make a difference.

The block was bored .030 inch and decked .020 inch at M&R Machine in Glendale, California. That was it for machine work to the block. The heavy cut on the deck compensated for the thicker-than-stock replacement head gasket.

The block was bored .030 inch and decked .020 inch at M&R Machine in Glendale, California. That was it for machine work to the block. The heavy cut on the deck compensated for the thicker-than-stock replacement head gasket.

The real choice centers around the level of durability. The cast pistons may be fine, but while spinning high rpm on the dyno, the forged units provide better peace of mind. Cast pistons can grenade unpredictably, while such failures are much more rare with forged units. Plain iron rings work great, but wear the bores faster over the long haul. Think about the intended use of the engine when selecting parts, especially the internals that can't be readily inspected or changed later.

For this build, all of the components were ordered from PAW, one of the least expensive retail outlets of engine rebuilding parts in the country, and they sell everything required to renew the 440 in a parts package. The basic rebuild kit can be upgraded with higher-quality components at an added cost. For this engine, we only upgraded the parts that served as the backbone for a durable high-performance street engine. PAW's system of offering a basic kit which can be customized by making substitutions or upgrades allows fantastic flexibility for putting together a parts package that meets requirements for a budget or performance specs.

We chose forged TRW #2266 pistons. The TRW #2355 "Six Pack" piston with its taller compression height and valve-clearance notches would have been better for a high-performance rebuild, but the #2266 got the nod because it's the stock replacement piston for the 440 Magnum being duplicated in this build. These pistons have a deck clearance of a whopping .089-inch in a standard block, same as the stockers, which makes us wonder how the factory arrived at its advertised compression ratio specs. Federal Mogul non-file-fit moly rings were selected to go around the pistons, since we wouldn't use anything other than moly in any engine build. We used non-file-fit because no production engine had hand-fitted ring end-gaps.

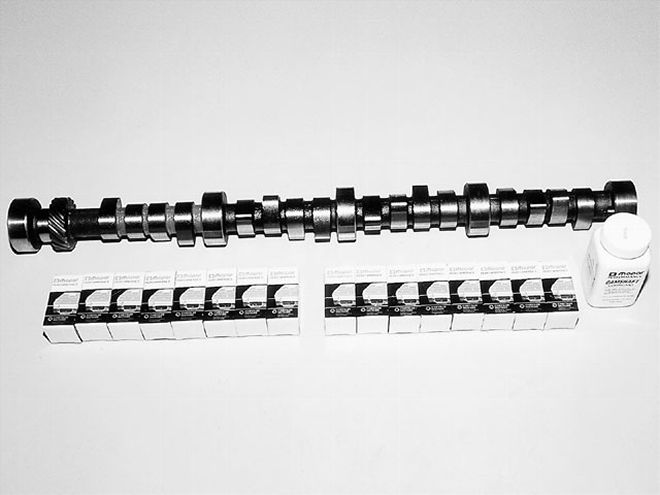

A high-volume oil pump was chosen in place of the standard piece because the cost of the upgrade was minimal. Since the premise of the build was to begin with a 440 built to stock specs, the cam would have to be the original 440 Magnum piece, still being sold by Mopar Performance. The Mopar Performance cam and lifter package was a substitution for the cam and lifter package included in the PAW kit. Finally, we chose Clevite Tri-Metal replacement bearings, a new steel roller timing chain, and an upgrade to a Felpro gasket set. A set of high-strength Milodon rod bolts were ordered, since this is the most highly-stressed fastener in the engine. The rest of the old stock bolts would be cleaned and reused.

Stock as stock is; the cam is the real deal-a factory 440 Magnum cam, still available through Mopar Performance under part number P4452783. Specs are .450/.458 lift; 268/286 degrees advertised duration with 115 degrees lobe separation. Mopar Performance does not furnish a duration number at .050 inch.

Stock as stock is; the cam is the real deal-a factory 440 Magnum cam, still available through Mopar Performance under part number P4452783. Specs are .450/.458 lift; 268/286 degrees advertised duration with 115 degrees lobe separation. Mopar Performance does not furnish a duration number at .050 inch.

Clearance Clearinghouse

The block and heads were taken to M&R Machine in Glendale, California, for machine work. The block was bored .030-inch over and finish-honed for moly rings. Our gasket kit, like any aftermarket replacement set, comes with a composition gasket; they have a compressed thickness of .040 inch, while stock 440s came with a steel-shim gasket of about .020 inch. This costs compression, so the block was decked .020 inch to compensate, bringing the final deck clearance back to stock specs with the composition gasket installed. Had this engine been built without trying to duplicate actual production specs, the block would have been decked considerably more with these pistons.

Our stock '69 LY rods (the heavy "Six Pack" rod didn't debut in the 440 until 1970) were fitted with Milodon rod bolts and resized on the big ends. The factory forged crank was ground .010-inch under on the rods and mains, completing the bottom-end machining.

Taking care of the top-end, a set of factory correct -906 castings were prepped by M&R Machine. The heads received a basic valve job, retaining the original factory valves. To survive under hard street use with unleaded, a set of hardened exhaust inserts were installed. The valve guides checked OK.

All in all, a resto-type 440 such as this was simple and inexpensive to build. The actual engine assembly is straightforward, requiring none of the custom massaging usually needed in a high-output mill. Beginners should have a factory service manual on hand, which can be purchased new from Year One. The photo captions detail how this one was put together in one day, once all of the required parts were cleaned and painted.

The 440 Magnum

The 440 was undoubtedly one of the most respected engines of the musclecar era, not for screaming horsepower, but for big-time torque at lower speeds. Looking inside, what's really good? The best bore/stroke ratio of any domestic big-block V8 with its 4.32-inch bore and 3.75-inch stroke. Unlike many other big-blocks, the 440's long rods and short stroke make for an optimal rod ratio as well, with high output and street durability. The basic B/RB bottom end, particularly the earlier forged crank type, is extremely durable; in our experience, generally safe to 6500 rpm+ in factory form. In fact, practically any of the production systems, from the lubrication to the valvetrain, were capable of working well in a high-performance application, without the major modifications required with some other engine types. The piston/rod bobweight is quite high, but this is irrelevant in a street performance situation.

Looking at the factory valvetrain, the stamped steel rockers seem unsophisticated; but the system is durable while being lightweight. Less weight in the valvetrain really counts at higher rpm, especially with hydraulic cams running moderate "street" spring loads. The time to give the factory valvetrain the ax is when an adjustable valvetrain is required, or when high lift necessitates a roller-tipped rocker to reduce side loading the valves, which can lead to valveguide durability problems (conservatively .500-inch+ valve lift). For hydraulic cams under .500-inch lift, don't expect big power gains by going to a more exotic valvetrain; the factory stuff works.

The most benefit is in the breathing area, particularly in the heads. It takes a great deal of air to fully feed 440 cubic inches of engine. Unlock the head flow, and the output can go from good to phenomenal. In our 340 test, the production heads were retained throughout the modification sequence. However, the 340 has outstanding cylinder-head airflow per cubic inch displacement for a production wedge head. On the 440, the temptation is to make an aftermarket or modified production head part of the modification plan. Headers and induction changes will be tried on the dyno to see what their influence would be on an otherwise stock engine.

What will this stock spec 440 put out? The factory rating of 375 hp is claimed to be optimistic by many sources, including Chrysler, with the consensus more like 350 hp. For now we're not making any predictions-the dyno will tell the story next month, and we'll all see.-Steve Dulcich