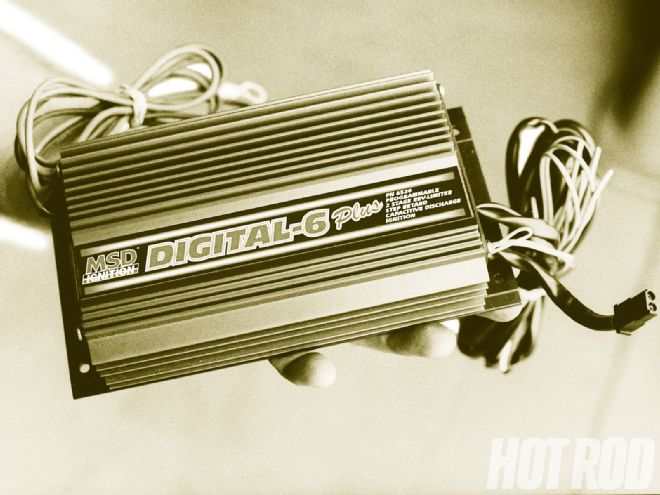

Increased performance and reduced complexity don't often go hand in hand. But in the case of the new Digital 6 Plus ignition control module from MSD (PN 6520), the benefits of an adjustable two-step engine-speed limiter, top-end timing retard, and increased voltage output are all contained in one compact unit at a price that is about 25 percent below the cost of assembling a similar system with stand-alone components. And because all of these functions are self contained, the usual tangle of wires and corrosion-prone connectors are eliminated entirely.

This Nova racer realized a 9 horsepower increase when the MSD ignition control retarded timing 4 degrees. Car owner John Ortega expects to see further improvements with on-track testing.

This Nova racer realized a 9 horsepower increase when the MSD ignition control retarded timing 4 degrees. Car owner John Ortega expects to see further improvements with on-track testing.

We were able to obtain an early production unit so that we could get a feel for the benefits of this new digital (rather than analog) approach to one-stop ignition-system shopping. To put the Digital 6 Plus through its paces, we asked John Ortega, a successful Southern California bracket racer, for the use of his 9-second '64 Nova and then brought it to Superior Automotive's chassis dyno for some truth-or-dare action. Even though Ortega's alky-burning Nova is a strip-only piece, MSD tells us the Digital 6 Plus unit is suited for most any high-performance, street and strip application, as our test results confirm.

Why a Two-Step?

With a conventional one-stage rpm limiter like that built into the MSD 6AL, maximum engine speed is governed by interchangeable plug-in chips. For instance, if you upshift at 6,500 rpm, you might want to use the 7,000-rpm chip. This is a very effective system, which protects the engine from damage if you miss a shift or encounter a driveline failure. But a one-stage system can't protect the engine from the dangers of excessive rpm during a burnout. As the tires spin in the water box, there is very little load on the motor, and the rods are subjected to tremendous "toss" loads during this exercise. That 7,000-rpm-rev limit is way too high for heating the tires. However, the two-step limiter built into the Digital 6 Plus allows you to dial in a lower rpm for the burnout and retain the higher limit to govern shift points during the race.

Adjustments to the two-step rev limiter and timing-retard function are a simple matter of turning rotary switches with a screwdriver, eliminating the "pocket full of pills" required to tune analog equipment.

Adjustments to the two-step rev limiter and timing-retard function are a simple matter of turning rotary switches with a screwdriver, eliminating the "pocket full of pills" required to tune analog equipment.

Instead of a plug-in chip, the operating range of the Digital 6 Plus two-step function is set with built-in rotary switches. Both the low- and high-limit circuits are adjustable in 100-rpm increments from 2,000 to 9,900 rpm. The two-step feature also comes in handy on a trans-brake-equipped car where starting-line rpm must be carefully controlled. The wide range of adjustability allows racers to increase or decrease launch rpm to work with varied traction surfaces, an important tuning aid to touring bracket guys like Ortega.

Top-End Retard

When some of the very first drag racers discovered that engines ran better on the dragstrip during the second half of the quarter-mile if the ignition timing was retarded, many of them connected spring-loaded cables to the distributor housing, so they could "pull out" a few degrees on the fly. The idea worked then, and it still works today. The air/fuel mixtures employed in racing engines take a while to become fully ignited during the combustion process. If the spark is administered at exactly top dead center (TDC), the mechanical requirements placed on the piston and rod would have it traveling back down the cylinder bore before combustion is complete. To remedy this, the spark is advanced, or induced, before the piston reaches the apex of its travel in an attempt to synchronize the moment that maximum combustion pressure is achieved with the moment that the piston begins its downward power stroke. But, while timing advance is critical to maximizing combustion efficiency, it can also be the cause of power losses if the burning air/fuel mixture is allowed to expand too much, which can lead to destructive preignition.

All adjustments are clearly marked for ease of operation. The small LED light at the top left corner of the faceplate monitors the operating conditions of the MSD and remains illuminated when everything is functioning properly. However, if battery-supply voltage falls, the light will blink once per second to alert the user of a charging problem or a poor connection. The LED also flashes for every trigger signal from the distributor, a help when static-timing the ignition.

All adjustments are clearly marked for ease of operation. The small LED light at the top left corner of the faceplate monitors the operating conditions of the MSD and remains illuminated when everything is functioning properly. However, if battery-supply voltage falls, the light will blink once per second to alert the user of a charging problem or a poor connection. The LED also flashes for every trigger signal from the distributor, a help when static-timing the ignition.

Timing requirements change when the motor is under maximum load, as the car nears the finish line. The transmission is in high gear, wind resistance is on the rise, and friction between the moving parts will never be greater than it is at that moment. Combustion temperature is high, and what was the right amount of advance at the starting line can quickly become too much under these severe conditions. During this phase of the race, power can be boosted by delaying, or retarding, ignition timing, even if there are no signs of preignition. By limiting the amount of advance, the conflict between the ascending piston and expanding air/fuel charge before TDC can be reduced. It takes some trial and error to find the efficiency zone, and no two engines will be alike, but the old-timers were definitely onto something.

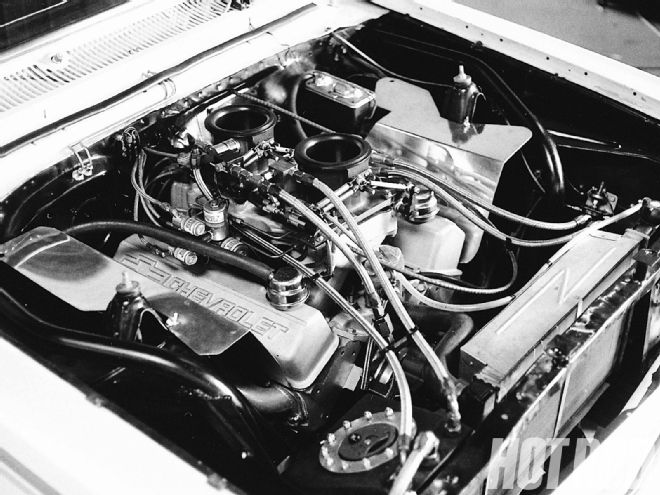

Ortega's Nova is powered by this 377-cube small-block. Dual "Flying Toilet" throttle bodies are part of the mechanical fuel-injection system. The four-plate NOS system is not used during bracket competition; rather, Ortega pushes the button when he just wants to let it all hang out. So far, it has pushed Ortega to a 9.11 at 145.

Ortega's Nova is powered by this 377-cube small-block. Dual "Flying Toilet" throttle bodies are part of the mechanical fuel-injection system. The four-plate NOS system is not used during bracket competition; rather, Ortega pushes the button when he just wants to let it all hang out. So far, it has pushed Ortega to a 9.11 at 145.

The Digital 6 Plus has a built-in timing retard, which can remove 0 to 9.9 degrees of total timing in 1/10-degree increments. The retard function is activated whenever 12 volts are applied to its circuit, and a simple toggle switch or button can be used to pull timing out at will. And because nitrous oxide creates a tremendous boost in cylinder pressure, the ignition-retard feature of the Digital 6 Plus will also be of particular value to squeeze addicts looking to keep their engines out of preignition under load.

Digital Delights While this new multifunction ignition controller is newsworthy unto itself, it is also a hint of things to come. Unlike previous MSD ignition systems, which used analog internal circuitry, the Digital 6 Plus is among the first MSD products to employ digital microprocessor controls. The benefit is that these digital controls are small computers capable of measuring their own inputs and outputs much faster than analog electronics. This allows them to more rapidly compute any changes deemed necessary as rpm and triggering values change. Another digital bonus is that it has the ability to operate with greater output while drawing less current. The veteran MSD 6AL draws 1.0 amp per 1,000 rpm while delivering an energy output of 110 milliJoules with 470 volts available to the coil, but thanks to digital efficiency, the Digital 6 Plus makes 135 milliJoules and 535 volts and requires only 0.8 amps to operate. This reduces the load on the alternator and frees up power.

On our test car, the Digital 6 Plus replaced a race-only MSD 7AL, and frankly, we wondered if it would be able to cope with the alcohol motor's 13.8:1 compression and nearly 9,000-rpm crankshaft speed. Our concerns were unfounded as the Digital 6 Plus took over without a hitch, happily supplying spark until Ortega lifted his foot at 8,500 rpm. Look for digital operation to become available on other MSD products soon.

The Test To test the effects of retarding ignition timing under full throttle, we made a series of with/without comparisons. With its complete MSD ignition (PN 85551 Pro Billet distributor, PN 8202 Blaster 2 coil, PN 3108 8mm Heli-Core ignition wires) intact, we set the little alcoholic at 44 degrees of total timing and made a series of dyno runs. The best of these was 490.9 hp and 402.7 lb-ft of torque. Then we dialed 4 degrees of retard into the Digital 6 Plus, and we instructed Ortega to activate it with a handheld microswitch when the tachometer read 7,000 rpm-to more or less duplicate the high engine loading encountered near the finish line. When Ortega hit the switch, total timing dropped from 44 to 40 degrees BTDC and rear-wheel power readings jumped to 499.9 hp and 418.4 lb-ft of torque. Clearly, the timing retard feature works.