It's big. When the decision was made to build the 2014 AMSOIL/Street Rodder Road Tour 1959 Chevy Impala, everything had to be upsized. The car is monstrous, the trunk can easily accommodate a small college marching band (minus the tubas), and the wheels and tires are proud of their illusions of grandeur. So it goes without saying that the engine would have to be equally as momentous. That inferred a big-block Chevy or perhaps a W engine.

But this is 2014, not 1965. So something new means LS power with EFI; the call went out to Ron Shaver (the patriarch of Shaver Racing Engines). He said he could build a 427 that would fulfill all the prerequisites of big power, be very streetable, and still be enticing to the eye. We're here to tell you this big dog hunts on all counts. The old standard for a street performance engine used to be 1.1 horsepower per cubic inch (hp/ci). This RHS block–based 427 blows that out of the water with an impressive 1.45 hp/ci with its 622hp peak. Even better, this pump gas performer does it with respectable idle quality, outstanding throttle response, and a power curve that will demand you flatten that skinny little pedal on the right as often as possible. Diplomatic immunity might be a requirement to drive this car.

All this magical power didn't happen accidentally. The first rule was to not cheap out. Shaver could have used a production block, but the commitment to quality demanded the near-legendary RHS aluminum block as its foundation. We combined the RHS block's cornerstone with a durable rotating assembly from SCAT, Mahle pistons, an outstanding set of CNC-ported heads from Livernois, an over-achieving valvetrain from COMP Cams, and an absolutely stunning Inglese 8-Stack Induction System to come up with the ultimate street engine. Please excuse us if we gush a bit, but a mild big-block Chevy 502, for example, can make an impressive 570 lb-ft of torque at 4,200. The Road Tour 427 thumps out over 600 lb-ft at 4,800 rpm and does it while trimming 200 pounds. And we're doing it in style. Let's see how our Road Tour 427 all came together.

Building Blocks

It wasn't long after the LS engine made its debut in 1998 that Corvette escalated the horsepower game with a 4.125-inch bore 427 dubbed the LS7. Since then, the 427 has become the de rigueur displacement for powerful LS street engines. While GM sells a 427 production block, for the Road Tour 1959 we opted for the top-of-the-line RHS aftermarket block. The block comes in several configurations but Shaver spec'd the standard deck height 4.125 finished bore assembly that would also easily accept the 4.00-inch stroke crank necessary to complete the 427 combination. The RHS block includes longer cylinder sleeves to accommodate the longer stroke, which avoids the difficulties stemming from shorter cylinder lengths in the LS2 and LS3 OE blocks.

RHS blocks also feature a 0.388-inch raised cam bore centerline to ensure it can clear even the longest stroke crank. That requires a longer chain that COMP provides. The cross-bolted mains and deep skirt block also increases windage passages to minimize windage difficulties that can occur with longer stroke LS engines.

Combined with a priority main lubrication system with reduced restrictions, this block can easily accommodate much bigger power numbers, which means it promises to make power for a very long time.

The rotating assembly is also up to the challenge with a SCAT forged steel 4.00-inch stroke crank and I-beam forged 6.125-inch connecting rods that Shaver fitted to a set of Mahle flat-top 4.125-inch bore pistons with matching Mahle rings. The cam is a COMP hydraulic roller with mildly aggressive specs but even when combined with the rectangle port heads by Livernois, this engine doesn't sacrifice torque to make horsepower.

1. Many pretty engines are just that–attractive but a little short on real power. The AMSOIL/STREET RODDER Road Tour LS 427 is a rare combination of statuesque good looks combined with eyeball-flattening power. At 620-plus horsepower, Dean Livermore of Hot Rods by Dean is making final adjustments; after dropping it into the Road Tour 1959 Chevy he thinks it will get the job done.

2. We needed a strong foundation for the Road Tour 427 and it doesn't get much better than an RHS standard deck height alloy block. The RHS block comes with priority main oiling, which means the mains and rods get oil first. The block also has a raised cam centerline to clear big stroke cranks.

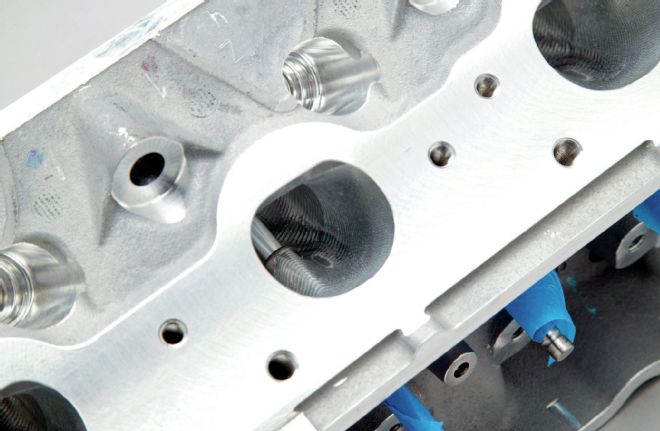

3. A big advantage with the RHS block is spun cast-iron liners that ensure excellent ring seal. We didn't need them, but you can see that the block can accept six-bolt cylinder heads. A standard deck RHS block can accommodate a stroke up to 4.250. With this 4.125-inch bore, that's 454 inches.

4. A forged steel crank is the only choice for an engine like this, so we selected a SCAT forged steel crank and matched it with a set of SCAT I-beam rods.

5. Mahle makes an excellent 4032 alloy flat-top piston for the 427 that includes a nice coating on the skirts. The 4032 alloy does not expand as much as 2618 alloys for a tighter piston-to-wall clearance. This makes for a quiet engine during warm-up.

The heads are worth investigating more closely. Livernois starts with a pair of 821 LS3 rectangle port production castings. These are slightly different than the L92 rectangle port truck heads. The LS3 has a slightly improved intake port floor with a roughly 260cc intake port volume. Livernois applies a CNC porting effort to both the intake and exhaust ports, opening the intake up slightly, which produces a peak lift flow of 360 cfm, which is roughly a 10 percent flow improvement over stock. What is often overlooked with cylinder heads is how well the exhaust port performs. The exhaust cranks out a peak number of 245 cfm (275 if a 1-3/4-inch primary header pipe is used), which generates a very efficient 76 percent intake to exhaust ratio. This enhanced exhaust flow often contributes to excellent high-rpm power numbers. Combined with the Livernois heads is a set of Manley 2.160 intake and 1.590-inch exhaust valves that are basically the stock sizes. COMP then supplied a complete set of LS3 shaft-mount roller rocker package that uses an 8620 hardened steel shaft to create a very rigid mount for the 1.7:1 aluminum rockers. The roller trunion bearings and roller tips are both lube by an internal oiling passage built into the rockers. Combined with a set of dual springs, the valvetrain is more than up to 7,000-rpm escapades.

After engine builder Lee Clap assembled the RHS long-block, it was time for the induction system. Instead of settling for a carburetor or run-of-the-mill EFI, we opted to outfit our Road Tour 427 with a much more intriguing Inglese 8-Stack Induction. The intake centers around eight 58mm EFI throttle bodies that are designed to appear much like '60s-era Weber 48 IDA carburetors. Each throttle body is equipped with a 50 lb/hr FAST injector and connected with a complete fuel rail system that is visually downplayed. Buried underneath the intake is a series of internal passages that combine all eight stacks together to create a mini plenum that's used both to dampen the individual pulsations that can wreak havoc with pure individual runners. This common area also produces a convenient central point for both referencing manifold absolute pressure (MAP) and also for the idle air speed (IAS) motor that the computer uses to control idle speed. That way, when you crank up the Vintage Air A/C compressor, the FAST controller can easily compensate for the compressor load and maintain the desired engine idle speed.

This leads us to the brains behind controlling the Inglese 8-Stack. We could have gone right to the most sophisticated FAST controller, which would have been a logical step, but we decided to try FAST's new self-learning EZ-EFI 2.0. You might already know about the basic EZ-EFI 2.0 system that works with a single throttle body that replaces a typical carburetor. But FAST also makes a relatively affordable multi-point system that is designed to work much like the throttle body system but integrates the eight individual injectors and throttle bodies. The best part of the EZ-EFI 2.0 system is its self-learning capability. You set the parameters with idle, cruise, and WOT air/fuel ratios and the system uses feedback from the oxygen sensor in the exhaust to maintain these inputs at all time. It operates as simply as its description. With the EFI system assembled and the Vintage Air Front Runner accessory drive bolted down, it was time to put the 427 on the dyno and test its mettle.

Dyno Time

With the engine on the dyno, Shaver's dyno operator Ron MacAskill set the WOT air/fuel ratio to 12.8:1 and integrated 30 degrees total timing into the FAST ignition controller and pulled the handle. After several runs up the rpm curve, the Road Tour 427 rewarded us with a solid 534 lb-ft of torque at 3,500 rpm. Had we pulled the engine down to 3,000, it's likely the big-inch LS will make 500 lb-ft of torque. That's enough to get even a big 1959 Impala moving. The power only went up from there with a peak torque of 602 lb-ft at 4,800 rpm and then on to an impressive 622 hp at 6,000 rpm. That's a nice 1,200-rpm power band between peak torque and horsepower and promises to be able to annihilate the tires nearly at will. We can't wait. As we are editing these final words, the 427 is being gently snuggled into its engine compartment at Hot Rods by Dean in Phoenix. The next moves might find our intrepid 1959 moving under power at last.

6. An initial mockup by Shaver engine builder Lee Clapp revealed that the connecting rods required minor clearance on the bottom of the cylinder sleeves. The RHS piston oilers also had to be modified to work with the longer stroke.

7. Pre-assembly includes setting end ring gaps on the 0.043 top and 1.5mm second rings. The oil rings are 3 mm. Conventional wisdom now dictates a slightly wider second ring gap to prevent pressure building underneath the top ring, which can unload it causing leakage.

8. Checking the piston deck height is also crucial to compute the static compression ratio. The Mahle flat-top pistons protrude 0.006 inch out of the top of the block, which is fairly typical for most LS engines when using thick MLS gaskets.

9. Once the block was finish honed to fit the Mahle pistons and subjected to a good cleaning, Clapp dropped the crank in for the first of several test-fits. Bearing clearances, crank endplay, rod side clearances, and a dozen other critical dimensions all have to be checked before final assembly. This time-consuming effort is why it there are no shortcuts to a professional build.

10. After checking wrist pin clearance (0.0015 inch is a good number), Clapp pushed the round C-clips in place. This is best done only after the pre-assembly work is complete in case minor modifications are required.

11. COMP supplied the entire valvetrain, including the XER281HR hydraulic roller cam and the retro-fit short-travel roller lifters. These lifters require precise pushrod length and accurate preloading but perform virtually like a solid roller lifter even at 7,500 rpm.

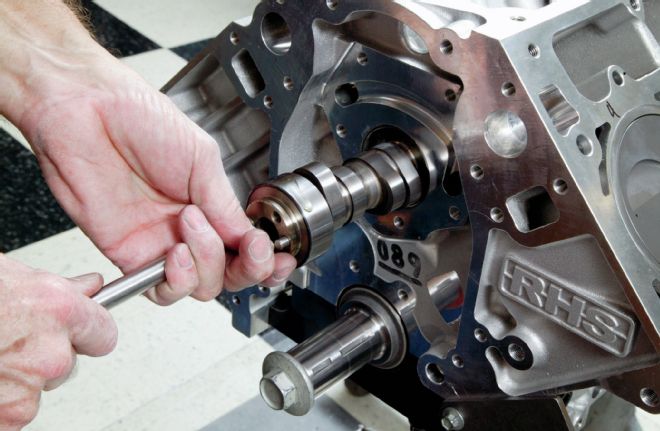

12. Installing the COMP cam with a smidgen of lube is sufficient since the engine will be pressure lubed before firing it for the first time.

13. The RHS block raises the cam centerline, which requires a custom timing chain with two extra links to maintain the proper tension. This was followed by the oil pump attached with ARP fasteners.

14. A balancer plays a critical role in damping natural crankshaft oscillations. The beauty of ATI's three-piece design is that you can match each piece specifically to your engine.

15. Before bolting on the heads, Clapp employed a set of Fel-Pro 0.053-inch MLS head gaskets to reduce the static compression ratio to 10.6:1.

16. Shaver Racing Engines supplied the CNC-ported production LS3 castings for our 427ci. The rectangle port heads are big as-cast, but you'd never know it by how much torque this engine makes.

17. Livernois says these rectangle port heads will flow 360 cfm on the intake side and with a 1-3/4-inch primary header tube the exhaust side will flow 275 cfm, which is an exhaust-to-intake relationship of 76 percent, which is outstanding given the big intake flow numbers.

18. The Stage 3 Livernois heads run 2.160 and 1.590-inch valve sizes to ensure excellent flow. The chamber size is standard at 70 cc.

19. With the large intake valves on the LS3 heads, this moves the valve and requires an offset rocker arm. COMP Cams has a very nice rocker shaft valvetrain for the 427 with the offset intake rocker using the stock 1.7:1 rocker ratio. The shaft offers substantial improvements in valvetrain stability over stud-mounted rockers.

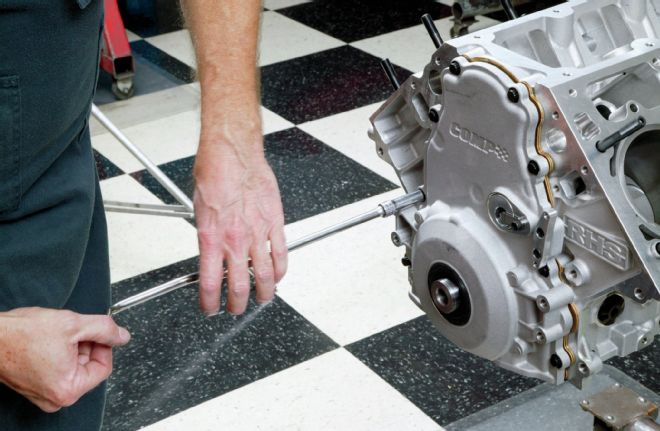

20. A pro build means degreeing the camshaft to ensure that it is installed at its intended intake centerline. The COMP adjustable timing set made it easy to ensure the 109-degree centerline position.

21. COMP also supplied the front cover that includes the cam sensor and Clapp bolted it all together with ARP fasteners.

22. There are lots of reasons to use head studs instead of bolts, including consistent clamp loads. Never torque studs into the block, ideally they should be finger tight with full thread engagement. A portion of the stud thread should show above the deck. This ensures that the top thread in the block is not overly stressed.

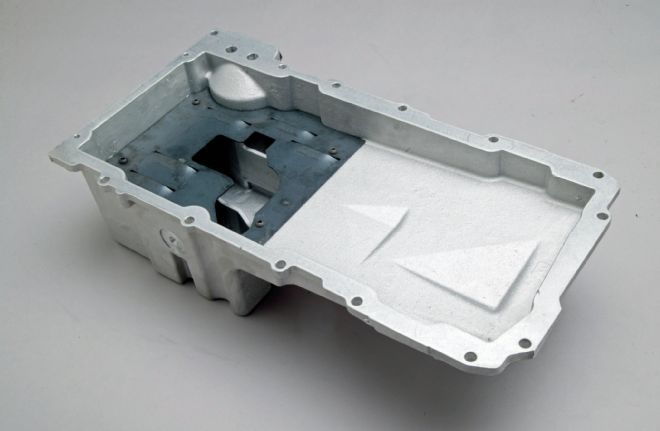

23. Shaver also decided on a Mast Motorsports oil pan that would work well with the RHS block and also clear the crossmember on the Roadster Shop chassis. The pan is cast aluminum and is intended for use in autocross or road racing applications. Plus, it has a cast-in filter boss, eliminating the need for an external filter.

24. Rather than go with a mundane carburetor or factory intake for the 427, we chose an Inglese 8-Stack Induction System. The eight individual 50mm IDA-style throttle bodies each fitted with a 50-lb/hr FAST fuel injector. In addition, the fully assembled manifold is complete with installed fuel rails and an extremely precise throttle linkage system. Intake bells and filters were also part of our assembly.

25. Controlling the Inglese 8-Stack is a FAST EZ-EFI 2.0 self-learning EFI. The beauty of this system is that with just a few keystrokes, the system establishes the necessary parameters and the engine runs and quickly settles into the proper air/fuel ratios.

26. Clapp test-fit the intake on the engine to ensure everything bolted up properly. The Inglese 8-Stack intake uses O-rings instead of gaskets, which makes the installation on an LS engine nearly foolproof. The Inglese manifold also integrates a common chamber for the MAP sensor and idle airspeed controls that make running an individual runner manifold like this much easier. No more balancing throttle blades with a Uni-Syn!

27. The Vintage Air Front Runner accessory drive assembly comes with everything you need to install, including the water pump, alternator, power steering pump, A/C compressor, and all the brackets and hardware.

28. Installed on the dyno, the EZ-EFI 2.0 system fired the engine immediately and after a short engine break-in period, the engine was ready to impress. It only took a couple of runs for the EZ-EFI 2.0 system to dial-in the air/fuel ratio for peak power, making a best of 622 hp at 6,000 rpm.

29. Speedway Motors provided the LS finned valve covers while Lokar supplied the engine oil and the trans dipsticks.

30. During the assembly of any engine a great choice for engine assembly lube is AMSOIL INC. It will stick to components and provide rust and corrosion protection, will dissolve in engine oil, and contains antiwear additives all during the assembly and “storage” cycle before the engine is put into service.

31. Flowmaster LS block hugger-style headers (PN 814121) were used, giving plenty of clearance to the Flaming River steering and the Wilwood brake components.