There's nothing new about injecting nitrous oxide into a combustion engine to increase its output. Sure, the technology has been refined over the years, but the concept has been viable for more than two decades. What is new is GM's LS1 engine, currently used in Corvettes, Camaros, Firebirds, and the all-new c/k fullsize trucks. It was only a matter of time before someone "sprayed" one with a healthy dose of laughing gas.

Pat Musi is widely known for his Pro Street exploits in the NMCA/Comp Cams World's Fastest Street Car series, as well as his race-engine business and his experience with race-tuning nitrous-oxide systems. But one thing not typically associated with the Musi moniker is late-model, fuel-injected, computer-controlled performance.

Musi has entered the tuner wars with a '98 LS1 Pontiac Trans Am (donated by Pontiac Motor Division) and has boosted its output dramatically. The purpose of his experiments was to develop practical packages for use on near-stock street cars.

The Approach Rather than digging into the motor or trying to engineer a forced-induction setup for the 'Bird, Team Musi resorted to their favorite power-adder. With the criteria being smog legality, relatively simple installation, and good value for the buck, nitrous seemed the obvious choice. Such enhancement provides huge gains while remaining fairly simple and is quite compatible with EFI systems.

During a night test-and-tune at Englishtown, New Jersey's Raceway Park, a very stock-looking '98 Pontiac Trans Am rolled to the line in preparation for a blast down the quarter-mile. Many of those in attendance took a moment to observe the 'Bird, presumably out of curiosity over the abilities of the new LS1 engine. More than a few were astounded when the scoreboard lit up with 12.41 at 118 mph. They were among the first to be caught off guard by Pat Musi's LS1 nitrous system.

During a night test-and-tune at Englishtown, New Jersey's Raceway Park, a very stock-looking '98 Pontiac Trans Am rolled to the line in preparation for a blast down the quarter-mile. Many of those in attendance took a moment to observe the 'Bird, presumably out of curiosity over the abilities of the new LS1 engine. More than a few were astounded when the scoreboard lit up with 12.41 at 118 mph. They were among the first to be caught off guard by Pat Musi's LS1 nitrous system.

Injecting nitrous oxide directly into the intake tract introduces additional oxygen to the combustion mixture. In doing so, the nitrous-oxide injection system hurdles perhaps the biggest obstacle in producing horsepower-the ability of the engine to breathe. All that remains is to maintain the proper air/fuel ratio throughout (to support the additional O2 with the right amount of additional fuel), and suddenly your engine thinks it's a lot bigger than it really is.

The Trouble With The LS1 In recent years, the hot ticket for spraying late-model EFI-equipped engines has been the "dry" nitrous system, so-called because additional fuel plumbing is not required. The nitrous is injected through a small nozzle, usually positioned forward of the throttle-body blade(s). A regulator feeds a measured amount of N2O to the OE fuel-pressure regulator via a T-fitting in the fuel regulator's manifold vacuum line. This fools the regulator into thinking that there is a high-pressure condition in the intake system, thus fuel pressure is raised by a specific amount. The increase in fuel pressure translates directly to more fuel delivery at the injectors and serves as the proper accompaniment to the nitrous oxide.

The problem with this type of system on the LS1 is the "demand" fuel system; there is no vacuum-controlled fuel-pressure regulator on the fuel rail and no return line to the tank. Instead, an electronic regulator is integrated with the fuel-pump assembly located in the fuel tank. This makes it difficult to manipulate fuel pressure in the presence of nitrous oxide.

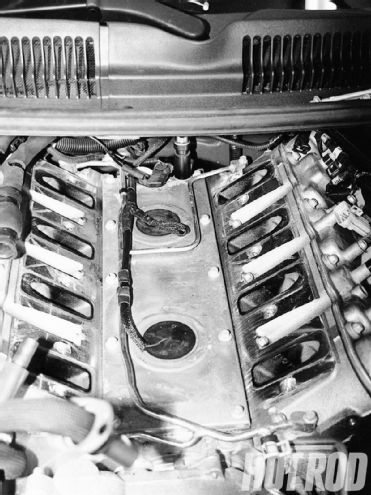

Don't be afraid to pull the intake from your LS1 for the nitrous install; it may be the cleanest V-8 manifold swap you'll ever do. The composite manifold is held by eight bolts which thread straight into the heads. The lifter valley is covered with an aluminum plate; there are no coolant passages through the manifold, and each intake port is sealed with an O-ring, not a gasket.

Don't be afraid to pull the intake from your LS1 for the nitrous install; it may be the cleanest V-8 manifold swap you'll ever do. The composite manifold is held by eight bolts which thread straight into the heads. The lifter valley is covered with an aluminum plate; there are no coolant passages through the manifold, and each intake port is sealed with an O-ring, not a gasket.

A simple alternative would seem to be a plate system, but this also poses problems. Some port-injected engines (like the 5.0L Ford) feature a two-piece manifold, which can easily and effectively accommodate a plate between its upper and lower halves. Positioning the nozzles at this point in the runners allows a relatively straight shot of fuel to the intake port. But because the LS1 utilizes a one-piece composite plastic intake manifold, the only place to position the plate would be between the throttle body and the manifold, but due to the design of the LS1's plenum and runners, fuel distribution would be extremely poor. The "dry" LS1 intake, like most port fuel-injected engines, only carries air, not fuel and air.

Typically, port-nitrous systems are regarded as race-only setups and are often considered too exotic for the average street freak. But Team Musi intends to eradicate this myth. By combining hardware from Nitrous Oxide Systems (NOS) with the experience of former NOS technician, Jeff Prock, Musi has developed an effective and user-friendly port system for the LS1.

One of the potential obstacles to installing a port-nitrous system on an LS1 was the plastic manifold. According to nitrous guru Jeff Prock of Musi's, extra care during the tapping process and while threading in the nozzles is all that is required.

One of the potential obstacles to installing a port-nitrous system on an LS1 was the plastic manifold. According to nitrous guru Jeff Prock of Musi's, extra care during the tapping process and while threading in the nozzles is all that is required.

How They Did It With a conventional intake casting, the installer would simply drill into the aluminum and tap a hole for the nozzles. Prock says that the procedure for the plastic LS1 intake manifold requires a bit more finesse. Once the holes are drilled, he keeps the tap as straight as possible, and when he installs the nozzles he takes extreme caution to prevent cross-threading.

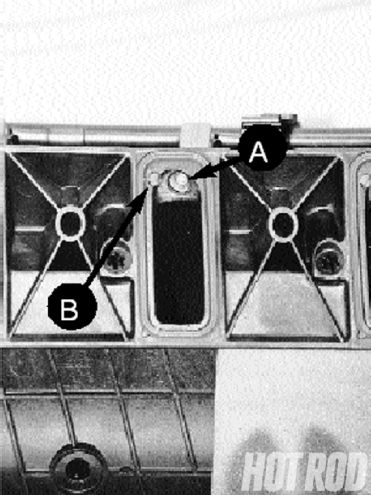

Since the spray pattern of the NOS annular discharge nozzles emits straight from the tips, Prock positioned them adjacent to the factory fuel injectors. Annular nozzles also maintain more efficient flow and more complete atomization of the fuel. Prock took advantage of the LS1's tall intake ports, which were designed to allow the fuel injectors to spray directly at the back of the intake valves. Musi's nitrous oxide is administered in precisely the same way.

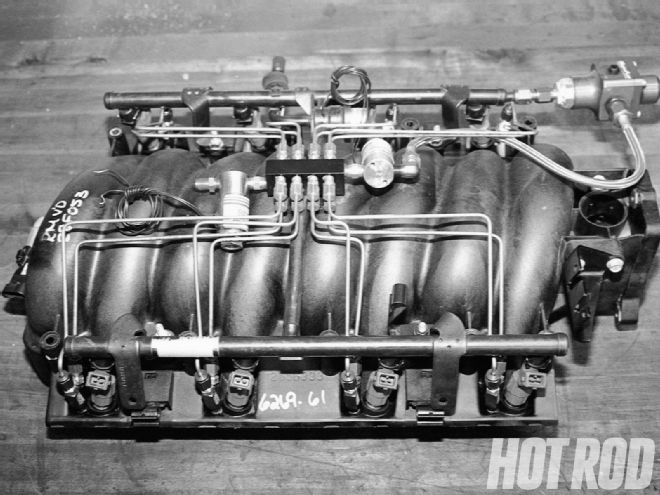

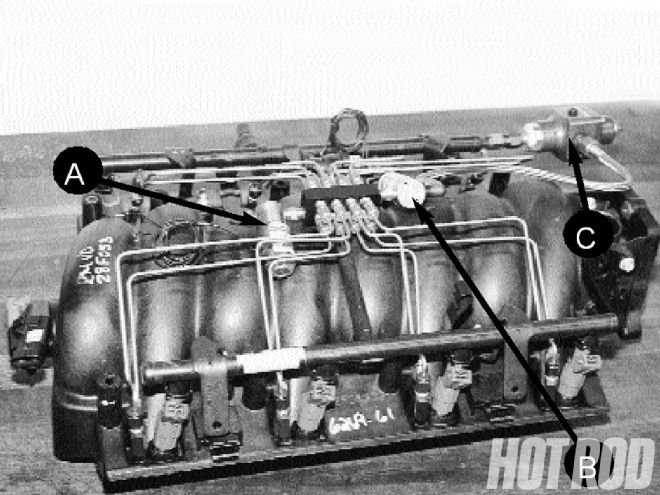

All the plumbing is top-side, and the junction block is positioned over the center of the intake and held stationary by 1/8-inch feed lines. Replacing the Schraeder valve in the end of the factory fuel rail with a MagnaFlow fuel-pressure regulator enabled Prock to draw additional fuel; the MagnaFlow steps down pressure from the rail to 6.5 psi before feeding it to the fuel nozzles in the nitrous setup. The only line that must be run from the rear of the car is for the nitrous.

The modified manifold, ready for installation, shows each of the eight nitrous nozzles plumbed to the junction block above the center of the manifold via 1/8-inch tubing. The junction block also houses the nitrous solenoid (A) and the fuel solenoid (B) (which receives its fuel supply from the factory fuel rail). A MagnaFlow regulator (C) steps rail pressure down to 6.5 psi for the nitrous system.

The modified manifold, ready for installation, shows each of the eight nitrous nozzles plumbed to the junction block above the center of the manifold via 1/8-inch tubing. The junction block also houses the nitrous solenoid (A) and the fuel solenoid (B) (which receives its fuel supply from the factory fuel rail). A MagnaFlow regulator (C) steps rail pressure down to 6.5 psi for the nitrous system.

Team Musi feels that a 125hp shot of juice is just about right for this application; it is more than enough to lower elapsed times by at least a second and a half, yet not enough to jeopardize the engine's well-being. Although the rigging may look complex hovering above the intake, operating it is nearly a no-brainer. A toggle in the cockpit arms the single-stage system, and the fast gas is administered when a switch is tripped by wide-open throttle. All wiring was handled by Julio Hormilla of Carter in Garwood, New Jersey.

How Does It Run? Upon delivery, Musi strapped the Trans Am to his DynoJet chassis dynamometer. A series of pulls established approximately 275 hp, and dragstrip testing provided a handful of low 14-second timeslips, all of them a shade over 100 mph. In preparation for the increased power, Musi bolted a Borla exhaust system to the cats and found another 24 hp.

Prior to the nitrous tests, they lashed the Pontiac to the DynoJet for another round of baseline pulls (all within 3 to 4 hp of the 300 figure obtained after the Borla system had been installed). For the nitrous exhibition, the Musi crew ran up the LS1 in Fourth and mashed the throttle. The computer verified a maximum hp reading of 451 at 5,400 rpm. Peak torque still occurs at 4,000 rpm, but now it's a smack-your-lips 509 lb-ft. Several back-up pulls posted numbers within 2 to 3 hp of the initial one. The Musi crew was thrilled with the power output and overjoyed that the OBD-II checker had not been awakened, and that the "check engine" light had not been triggered.

The new Foggerr annular discharge nozzles from NOS were helpful in creating the LS1 system. With them, the nitrous and fuel are sprayed from the tip of the nozzle. This allowed Prock to position the nozzles right alongside the factory fuel injectors, which would have been impossible with a conventional nozzle design.

The new Foggerr annular discharge nozzles from NOS were helpful in creating the LS1 system. With them, the nitrous and fuel are sprayed from the tip of the nozzle. This allowed Prock to position the nozzles right alongside the factory fuel injectors, which would have been impossible with a conventional nozzle design.

At The Track Dyno numbers may be enough for some people, but not for hard-core drag racers. As soon as Musi's guys rolled the Trans Am off the DynoJet, they pointed the swoopy, red missile toward Old Bridge Raceway Park (Englishtown, New Jersey) to see what effect their output would have in the real world. They ran with factory-issue radials, which created a rather large traction problem. The e.t. came in at 12.41, but trap speed was 118.36 mph! With the right bite, that's fast enough to support a genuine 11-second elapsed time.

There was nothing proper about the traction the 'Bird realized that night, but it was still enough to smoke the clutch. Centerforce was summoned for one of its just-released LS1 clutches. Deadlines prevented us from reporting on the return to E-Town. Once the new clutch and BFGoodrich Drag Radials are in place, Musi will invade the 11s. The power is already there, all team Musi needs to do is put it to the ground.

The tall, narrow intake ports of the LS1 provide the factory fuel injectors (A) with a straight shot at the back of the intake valves. Prock's positioning of the nitrous nozzles (B) allows the juice to be administered with the same efficiency.

The tall, narrow intake ports of the LS1 provide the factory fuel injectors (A) with a straight shot at the back of the intake valves. Prock's positioning of the nitrous nozzles (B) allows the juice to be administered with the same efficiency.

How to Get One Musi's manifolds are pre-plumbed and available on an exchange basis. Remove your car's manifold, send it to Musi, and receive a fully plumbed intake, a MagnaFlow fuel-pressure regulator (already installed), the proper jets and solenoids, a bottle (with warmer), and the necessary line and fittings for approximately $2,000.

For a modest investment of cash and time, you boost the performance of your F-car to a level that requires a rollbar without even lifting a valve cover-all the while maintaining absolute driveability and factory-promised fuel economy. Could getting into the 11s get any easier?

The '98 Trans Am made 275 hp and 294 lb-ft of torque on the DynoJet in stock form. After the addition of a Borla Cat-Back exhaust system, those figures jumped to 300 hp and 310 lb-ft Once the nitrous system was up and running, Musi recorded 451 hp and 509 lb-ft of twist. These numbers were repeatable, and not once did the "check engine" beacon illuminate.

The '98 Trans Am made 275 hp and 294 lb-ft of torque on the DynoJet in stock form. After the addition of a Borla Cat-Back exhaust system, those figures jumped to 300 hp and 310 lb-ft Once the nitrous system was up and running, Musi recorded 451 hp and 509 lb-ft of twist. These numbers were repeatable, and not once did the "check engine" beacon illuminate.