Painting cars has changed since the early days of automotive production. In the ’20s paint was about one step away from varnish and was applied with a brush or flooded as it was on Model Ts (Ford applied paint at the top of the body with something akin to a wide sprinkler head, it literally ran down the sides like one continuous run and was captured at the bottom in trays to be reused). It wasn’t until 1924 that Oakland automobiles became the first to be painted with a spray gun, thanks to a dentist named Dr. Allen DeVilbiss. In 1888 he created an atomizer to spray medicine into patients’ throats. The doctor’s son, Thomas, expanded on the idea and created what is acknowledged as the first spray gun for paint.

During the ’30s, paints improved and alkyd enamel and nitrocellulose lacquer were commonly used. Enamel was tough, but it oxidized rapidly and became dull. Lacquer had more gloss but was susceptible to chipping. In some cases both finishes could be found on the same car—enamel covered the fenders and frame for durability and lacquer was on the bodies for greater gloss. Through the ’50s nitrocellulose lacquers remained a favorite of custom painters and continued to be used on some passenger cars until acrylic lacquers were introduced. Another improvement in automotive paints came in the early ’60s with the introduction of durable acrylic enamels.

While acrylic enamel and acrylic lacquer were popular, there were significant differences between them. Enamel was tougher, but was far more difficult to apply. It was not possible to color-sand and polish enamel, so what came out of the paint booth was what you lived with. Lacquer was certainly easier to work with but it required polishing, which took time but the results were worth the effort. As a result of these characteristics most repair shops chose enamel, while custom painters continued to use lacquer.

An interesting development came with the advent of hardeners for acrylic enamel. Appearing to have the best attributes of both lacquer and enamel, many painters believe that if a little hardener was good, a bunch would be great. The end result was often crazing and paint that came off in chunks.

With a mixing bank like this just about any color can be created in conventional enamel and urethane coatings, such as Delstar and Deltron. Drips of color here and there are good signs, lots of paint has been mixed, which means plenty of experience.

With a mixing bank like this just about any color can be created in conventional enamel and urethane coatings, such as Delstar and Deltron. Drips of color here and there are good signs, lots of paint has been mixed, which means plenty of experience.

Another gigantic improvement in the appearance and durability of automotive paints came in the late ’70s with the introduction of two-stage, or basecoat/clearcoat finishes. At first expense was an issue, but it didn’t take long for automobile manufacturers and repair shops to recognize the benefits of these better-looking, higher gloss, more durable finishes.

While paints continued to improve they also became more toxic. Better personal protection gear was needed, improved booths and the federal government got more involved because of something called Volatile Organic Compounds (VOC). VOCs are unstable, carbon-containing compounds that are released when solvent-based paints are sprayed and as they dry. When VOCs enter the air, they react with other elements to produce ozone, which causes air pollution and a host of health issues. One method of reducing VOCs was with the introduction of High Volume Low Pressure, or an HVLP spray gun. More material makes it to the surface and less is lost to the atmosphere during application. Of course the real change came with how materials are formulated.

VOC emissions are established by pounds per gallon of material. And while there are federal regulations that apply, VOC limits vary from state to state. California’s South Coast Air Management District has strict guidelines and some of the products available to the rest of the country are not sold there.

When deciding what paint products to use, the number of choices can be confusing. To make sense of it all we turned to the pros at PPG.

PPG has a long history in the paint business, going back 1928 when it purchased Ditzler Inc.—the leading OEM supplier for automobiles at the time. Today, PPG offers products for industrial applications, fleet owners, body shops, as well as specialty and custom painters. PPG’s brands include the Global Refinish System, Deltron, Nexa Autocolor 2K, Delfleet Evolution, Envirobase High Performance, the Vibrance Collection, and Commercial Performance Coatings.

To produce a quality paintjob a variety of products are required. Here is a look at the common materials used:

Primer

The function of any primer is to provide a surface for paint to adhere to. Primers by nature are thin and do little to fill imperfections. There is no advantage to heavy coats of primer; in fact it should be avoided.

The DPLF epoxy primers are applied direct to prepared metal. They have excellent corrosion resistance and are unique as they can be used as a primer and a sealer. Available in a variety of colors, the LF stands for lead free.

The DPLF epoxy primers are applied direct to prepared metal. They have excellent corrosion resistance and are unique as they can be used as a primer and a sealer. Available in a variety of colors, the LF stands for lead free.

Primer-Surfacers

These products are a foundation for the paint, plus they fill imperfections. Multiple coats of primer-surfacer will build a thick film quickly and allow for block sanding to get rid of surface irregularities and provide a superstraight base for the topcoat. Always keep this in mind—if the car is not straight in primer, it won’t get any better with paint. That’s the reason bodies are often block-sanded several times.

Contemporary primer-surfacers, such as those available from PPG, are catalyzed, which eliminates shrinkage and the sand scratches that used to result from the solvent evaporating from lacquer-based products. Additionally, primer-surfacers provide excellent corrosion resistance and a chip-resistance base for color coats.

ECP is a line of low-VOC primer/surfacers specifically designed to be used under Envirobase waterborne basecoat.

ECP is a line of low-VOC primer/surfacers specifically designed to be used under Envirobase waterborne basecoat.

Primer-surfacer is often the secret behind perfectly smooth bodywork. D839 dries quickly and is easy to sand surface leveling and gloss holdout over a wide range of substrates. By adjusting the thinning ratio, it may be applied as a conventional primer-surfacer, as high build spray filler, or as a wet-on-wet surfacer.

Primer-surfacer is often the secret behind perfectly smooth bodywork. D839 dries quickly and is easy to sand surface leveling and gloss holdout over a wide range of substrates. By adjusting the thinning ratio, it may be applied as a conventional primer-surfacer, as high build spray filler, or as a wet-on-wet surfacer.

Sealers

These products are intended to keep the solvents in the topcoat materials from penetrating what’s underneath, as well as preventing undercoats from bleeding through. If you’ve ever shot lacquer over enamel and watched the surface wrinkle like a prune, you understand the need for a sealer.

ECS 60-series sealers are acrylic urethane that can be mixed using compliant thinners to reduce VOCs.

ECS 60-series sealers are acrylic urethane that can be mixed using compliant thinners to reduce VOCs.

Deltron NCS sealers are isocyanine-free and are available in three colors. They can also be tinted with DMC mixing bases.

Deltron NCS sealers are isocyanine-free and are available in three colors. They can also be tinted with DMC mixing bases.

Primer-Sealers

PPG’s epoxy sealers are unique in that they serve a dual function, acting as both a primer and a sealer, in some instances they will also take one step out of the finishing procedure.

Again, primer-sealers are not designed to fill imperfections, so heavy, multiple coats are a waste of material. One light coat is all that’s necessary.

Acrylic Enamel

At one time acrylic enamel was very popular, but it’s seldom used today and will be phased out eventually due to tightening VOC regulations.

Still with us is the Delstar line of acrylic enamel. Once commonly used for repair work in body shops, it is still seen as affordable single-stage paint on street rod chassis and components.

Still with us is the Delstar line of acrylic enamel. Once commonly used for repair work in body shops, it is still seen as affordable single-stage paint on street rod chassis and components.

Single-Stage Deltron

Modern paint materials are available in different packages. There are single-stage urethanes that are applied very much like the once-popular acrylic enamel—shoot on the color and you’re done. PPG’s Concept DCC is Deltron’s direct gloss system, meaning no clearcoat is required.

Basecoat/Clearcoat

Another option is PPG’s Deltron 2000 (DBC) system. With these two-stage paints, a highly pigmented base is applied that looks flat when cured. A second stage, or clearcoat, provides the gloss as well as a durable, chip-resistant surface. When used with a basecoat system the clearcoat provides the gloss as well as a durable, chip-resistant surface.

Deltron DBC is the basecoat used in PPG’s two-part basecoat/clearcoat system. It’s combined with DT series reducer and can be used with a wide variety of clears.

Deltron DBC is the basecoat used in PPG’s two-part basecoat/clearcoat system. It’s combined with DT series reducer and can be used with a wide variety of clears.

DCH is hardener to be used with Deltron DC clears. It’s available in for use in low, medium, and high temperature environments.

DCH is hardener to be used with Deltron DC clears. It’s available in for use in low, medium, and high temperature environments.

Envirobase: The Latest in Top Coats

When solvent-based paint is applied a certain amount of VOCs are released. Interestingly, while the highest level of VOC release is during painting it continues while the paint cures. To comply with mandated VOC reductions waterborne paints were developed.

For some street rodders the mention of waterborne paint is a reminder of the first OEM attempts at using water-based materials and what a disaster it was; not only did it turn dull but it peeled off in sheets. However, today’s waterborne paint uses totally different and vastly improved technology to reduce the release of VOCs while offering unmatched gloss and service life; today the technology is used in about 70 percent of OEM colors. PPG’s waterborne products use high-tech latex resin pigments in a special acrylic waterborne latex resin. Interestingly one of the advantages to waterborne paint is the way the pigment stays in suspension—mixing machines and mechanical paint shakers are no longer necessary just shake the containers by hand and combine the required materials.

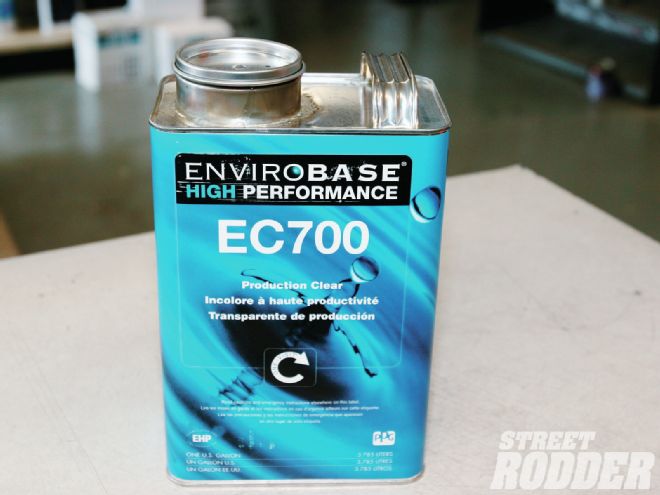

EC700 clear is designed to be used over Envirobase basecoat. Intended for high production body shops, this product is referred to as one-visit technology, which means there is no flash time between coats.

EC700 clear is designed to be used over Envirobase basecoat. Intended for high production body shops, this product is referred to as one-visit technology, which means there is no flash time between coats.

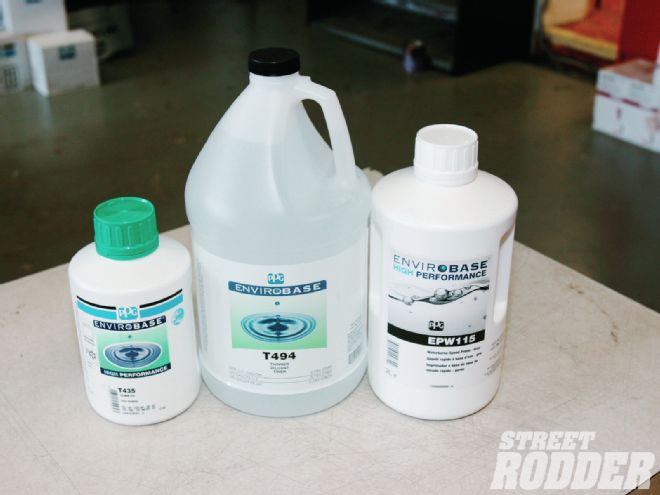

Enviorbase basecoat (left) is PPG’s third-generation waterborne technology, T494 is waterborne thinner, and EPW is waterborne speed prime.

Enviorbase basecoat (left) is PPG’s third-generation waterborne technology, T494 is waterborne thinner, and EPW is waterborne speed prime.

Vibrance Collection

The Vibrance Collection from PPG offers the latest in custom colors using unique micas and innovative pigments to create a truly custom finish. Ditzler Big Flake and Liquid Crystal are designed to create a three-dimensional effect. Harlequin’s six color-shifting pigments can create colors that change completely when viewed from different angles. And of course there are pearls, candies, and “standard” metalflake. Luminescence II can be mixed with Deltron DBC basecoat to create a color travel effect on basecoat and tri-coat finishes and Flamboyance offers six custom shades that can be formulated to produce one-of-a-kind tri-coat effects.

Along with the basecoat products, there are Vibrance clears. Designed for custom applications, VC5225 Soft Touch Clear is a high-solid, two-component urethane topcoat that provides a very low sheen for trim accents and interiors. VC5200 Custom Clear is a high-solid, urethane clearcoat with superior gloss.

The Systems Approach

Regardless of the type of products used, something crucial to a bright, long-lasting paintjob is that they are all compatible. Don’t get creative—mixing and matching products is a formula for failure. When in doubt, always refer to PPG’s website, or the paint store reps.

PPG offers a variety of clears in the Concept and Deltron lines. Not shown is Vibrance clear, a favorite of custom painters, and the new Envirobase clears.

PPG offers a variety of clears in the Concept and Deltron lines. Not shown is Vibrance clear, a favorite of custom painters, and the new Envirobase clears.

Here are examples of popular PPG systems:

Maximum Performance System

Self Etching Wash Primer (DX1791): Fast-drying, self-etching wash primer with excellent adhesion and corrosion resistance. In VOC-compliant areas it serves as a pretreatment coating.

V-Prime Acrylic Urethane Surfacer (DPS3055): Premium quality, high-build, fast-drying, easy to apply and sand—available in white, gray, and dark gray.

V-Seal Acrylic Urethane Sealer (DAS3025): Premium quality, fast-drying sealer with superior flow properties and excellent gloss holdout. Can be applied directly over unsanded OEM e-coat. Available in white, gray, and dark gray.

Deltron 2000 Basecoat (DBC): State-of-the-art, basecoat/clearcoat system designed to reproduce the high-tech OEM finishes.

Deltron High Velocity Clearcoats (DC3000/ DC4000): High velocity, high-quality clearcoats.

Performance System

Self-Etching Wash Primer (DX1791): Fast drying, self-etching wash primer with excellent adhesion and corrosion resistance.

PRIMA Acrylic Urethane Primer (K36): High-build, fast drying with superior color hideout and sanding qualities.

Deltron 2000 Basecoat (DBC): High-performance quality designed to reproduce today’s OEM finishes.

CONCEPT Clears (DCU2042, DCU2021): Mid-tier clears capable of matching OEM gloss with a minimum of time and effort.

Single-Stage System

Self-Etching Wash Primer (DX1791): Fast drying, self-etching wash primer with excellent adhesion and corrosion resistance.

Corrosion-Resistant Primers (NCP270, NCP271): Premium quality, corrosion-resistant primer developed for today’s advanced technology finishes—free of chrome, lead, and isocyanides.

Tintable Primer Surfacer/Sealer (K93): A translucent, premium quality primer/sealer designed to be tinted with DCC color base.

Concept Acrylic Urethane (DCC): Premium quality, single-stage topcoat with exceptional gloss. Available in solid and metallic colors.

Paint Additives

Catalyst: A catalyst causes a chemical reaction without becoming part of the material. Just like mixing catalyst with fiberglass resin, it serves the same purpose with paint products

DPLF primers must be mixed in a 2:1 ratio with DP401LF or DP402LF catalyst. DP401LF requires a 30-minute induction period (the primer and catalyst must sit after mixed), DP402LF does not.

DPLF primers must be mixed in a 2:1 ratio with DP401LF or DP402LF catalyst. DP401LF requires a 30-minute induction period (the primer and catalyst must sit after mixed), DP402LF does not.

Reducer/Thinner: These change the viscosity of the paint so it sprays properly. Reducers are normally selected based on the ambient air temperature.

Accelerators: speed up drying time.

Retarder: slows the drying time.

Flex additive: Added to undercoats or clearcoats when painting plastic parts, it helps the paint to remain flexible

DX 330 cleaners are used to remove surface contaminants such as wax, grease, silicones, and others—it should be used before and after sanding. DX320 should be used as a final cleaner before applying paint.

DX 330 cleaners are used to remove surface contaminants such as wax, grease, silicones, and others—it should be used before and after sanding. DX320 should be used as a final cleaner before applying paint.

Next We Get To Work

We spent a number of hours looking at paint products, asking questions and generally disrupting the normal operations at Automotive Specialties in North Bend, Oregon. Thanks to Deborah McDermott we came away knowing much more than we did when we walked through the door.

We decided on a PPG system that we will begin applying in our next installment. If you’re painting a car yourself we can’t over emphasize the importance of checking local regulations to make sure the products are appropriate. If you’re relying on a professional shop, now you’ll know what questions to ask. In any case, choosing the correct products is the first step to a great paintjob.