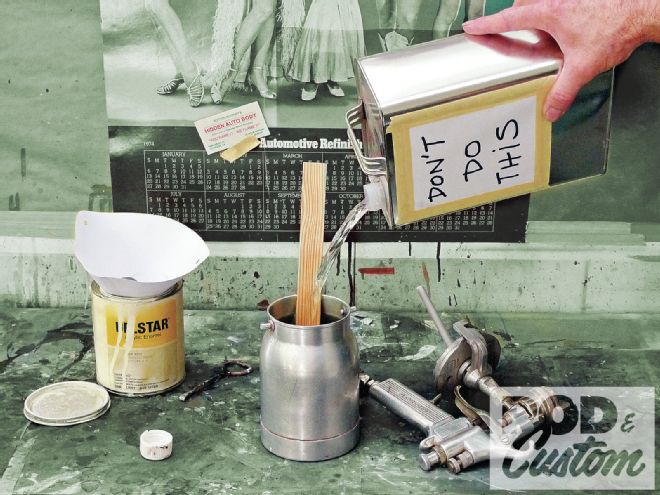

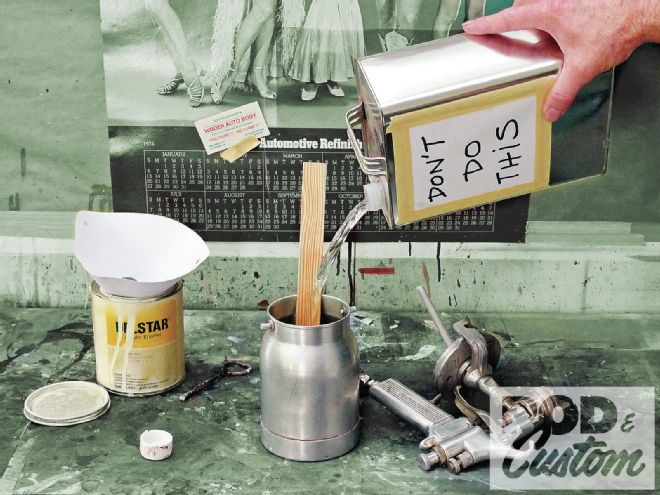

For over 35 years I’ve made a career of refinishing various forms of motor vehicles, including rods and customs. Over that span I’ve had opportunities to shoot everything from nitrocellulose lacquer (which was even older than me) to PPG’s up-to-date waterborne Envirobase. Back in the ’70s when I became involved in the trade, an acrylic lacquer job was still the top-of-the-line finish. For the in-and-out jobs, acrylic and synthetic enamels were—well, they were what we had. Unlike the modern finishes we use today, the aforementioned were forgiving in that mixing proportions weren’t so critical. In fact, many mixers of that era relied on a measuring method that took its name from the sound a reducer can makes when it’s opened and turned upside-down, “the glub system.” Here’s an example of how it worked: 3 glubs of color to 1 1/2 glubs of reducer, give or take a few glubs. Don’t try that with today’s primers, basecoats, or acrylic urethane clears. Along with our current material’s superior durability comes magnified sensitivity to loosey-goosey mixing mistakes. Now more than ever, the mixer had best be part chemist—and chemical components must be mixed in exact accordance to the manufacturer’s recommendations.

To some it may seem trivial to expound upon mundane methods of mixing. If that’s your feeling, I beg to differ and I’ll warn you that you’re likely headed for trouble. Any professional mixer worth his or her salt will tell you that mixing should be taken seriously. Nowadays it’s either get it right or suffer the consequences. And if you’re like me, perhaps you could use a little help in seeing what you’re doing. Here’s a brief overview of standard mixing procedures, followed-up with a harder squint at an alternative method developed through personal necessity, by and for the shy-of-sight.