It is interesting how things change. In the '70s the rebirth of street rodding was in full swing and much of it was based on the reproduction fiberglass T-bucket body and associated box tubing chassis. It was the 1-800 rod that was invented about the same time as the 1-800 number (which, should you be wondering, was first established in 1967). Go to a rod run in the '70s and you were sure to see a swarm of T-buckets of every description, some of them were original bodies, most were not. Ai Fiberglass, Speedway Motors, Total Performance, and others were leading the charge on the T-bucket brigade and while most hot rodders tend to think the T-bucket was the first fiberglass body, there were actually a number of companies and individuals making competition fiberglass bodies before the street-going T-bucket.

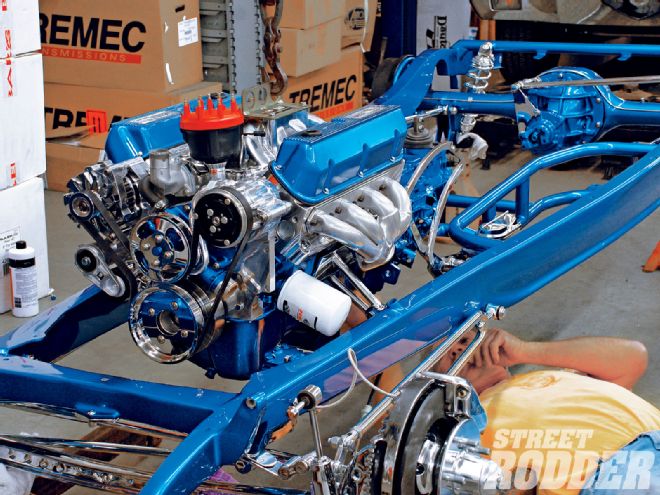

The fiberglass body and reproduction frame has enabled a lot of street rodders to drive their dream Deuce. Bobby Alloway has the rolling chassis and Rats Glass body fully prepared to reunite for the last time.

The fiberglass body and reproduction frame has enabled a lot of street rodders to drive their dream Deuce. Bobby Alloway has the rolling chassis and Rats Glass body fully prepared to reunite for the last time.

When Dave Anderson started Ai Fiberglass in 1962, they built lightweight bodies, doors, hoods, fenders, and decklids for drag racers. Lightweight was the name of the game so panel fit and finish was not a big priority. Willy, Anglia, and Austin owners were all looking for lightweight components for their gassers so this was the focus, along with a lightweight T-roadster and Bantam body for the altered classes. When street rodders began clamoring for reproduction bodies, companies like Ai Fiberglass answered the call with "street weight" fiberglass bodies and fenders. The oldest known '32 fiberglass roadster body that we can document was built by drag racer and street rodder Jerry Cogswell who made his own molds and built the body in 1959 for his Deuce race car. (Editor's Note: Jerry is a longtime, we mean longtime, L.A. Roadster member and retired airline pilot who now spends his time enjoying his hot rods. -B.B.)

Around the same time, the late-Dee Wescott was making top-quality reproduction fenders from his Wescott's Auto Restyling shop. While the Cogswell roadster was completed in 1959, the first commercially available Deuce roadster that we can document went on sale around 1971, built by John Brown in Illinois. Marten's Fabrication was also building a reproduction chassis for that body, but it lacked the iconic Deuce reveal in the side of the framerail. Dwight Bond was building fenders in Gibbon, Nebraska, in 1971, and in 1972 he introduced a complete Model A roadster and pickup body; by 1976 he was advertising '34 Ford roadster bodies. These were just some of the pioneers of the reproduction body, and since glass bodies have been around since the late-'50s it seems apparent that you can build a true nostalgia rod based on a fiberglass body-now that should stir up some conversation!

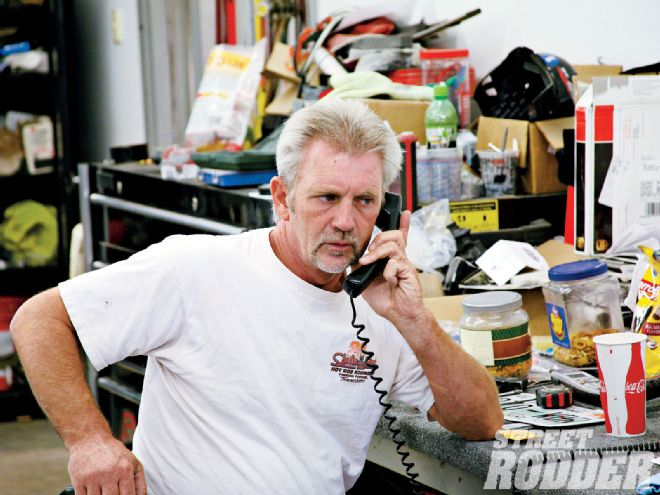

"You want it when?" Bobby Alloway deep in discussion with Editor Brennan on how much work had to be completed to get the car to the NSRA Street Rod Nationals. They made it with at least a few hours to spare.

"You want it when?" Bobby Alloway deep in discussion with Editor Brennan on how much work had to be completed to get the car to the NSRA Street Rod Nationals. They made it with at least a few hours to spare.

As street rodding progressed, the hobby embraced each new reproduction part, after all, these very parts enabled street rodding to grow and people to own cars they could not otherwise afford or find in their original state. Not long after the T-bucket, the Model A and Deuce roadster bodies were being manufactured in fiberglass by companies like Wescott's and Gibbon Fiberglass. While there were flat side reproduction framerails on the market, when the Deuce Factory introduced accurate, stamped '32 framerails everything changed. Suddenly a great street rod could be built using entirely new parts. The cost was more, but the end product was predictable, good looking, and the process generally saved a lot of time and labor. Pete & Jakes, Super Bell, and the Deuce Factory supplied everything from complete chassis to shock brackets, and suddenly building a street rod was a lot easier.

By the '80s fiberglass bodies were being produced to cover the Ford, Chevy, Willys, and Mopar lines of cars and even "phantom" bodies were being produced, cars that never existed but resembled cars of the '30s. We'll be kind here and say there was a vast range of design talent in the phantom body world and one need only attend a rod run to realize many of them were not particularly successful. But the fiberglass bodies of established cars like the '32-34 Ford three-window, roadster, and Victoria were a huge hit and most of them remain on the road today. Outlaw Performance had the Chevy market covered with their '34 three-window coupe and sedan. They also produce a very nice '40-41 Willys. The fiberglass bodies proved to be so popular that many owners of original bodies would affix decals or badges to their cars with the slogan, "Steel is Real," which at the time seemed reasonable enough since they wanted the world to know they had started their project with an original, 50-something-year-old body.

Patience is a virtue, and when it comes to building great hot rods it is super important. Josh Bailey is running the stainless brake lines, keeping everything neat and straight is the name of the game.

Patience is a virtue, and when it comes to building great hot rods it is super important. Josh Bailey is running the stainless brake lines, keeping everything neat and straight is the name of the game.

Around this same time, rumors spread of reproduction steel bodies and frankly it seemed unbelievable at the time. It began slowly with the Model A roadster body in 1982, followed by the Model A roadster pickup, both from Brookville Roadsters. Then a company called Experi-Metal produced a reproduction '32 Chevrolet roadster complete with fenders, running boards, and a hood and grille shell. These cars were not cheap, but they were brand-new metal and the argument was a simple one. By the time you find an original '32 Chevy and pay to have it repaired, it will cost you the same or more as simply buying a new steel body. Of course this same argument applied to the reproduction fiberglass body as well, only the savings were more dramatic due to the lower cost of the fiberglass body.

The steel reproduction floodgates really opened when the steel Deuce roadster body was introduced. Some of the most popular steel reproduction cars, like the Dearborn Deuce, are not faithful to the original car (which technically would put them in the "phantom" category) but the liberties taken on the body were so discreet it is difficult to tell the differences between this car and the original Deuce. Then Brookville introduced their steel Deuce roadster and three-window coupe bodies that have some structural differences and improvements, but the body panels are all faithful reproductions of the original Ford cars. Steve's Auto Restorations offers '33-34 coupes and roadsters and Kelvin Waddington's Australian Ute company builds beautiful '33-34 Ford phaetons and '28-29 Ford closed cab pickups, all in steel. And finally this year Bob Drake introduced the all-new, all-steel '40 coupe; a mammoth undertaking that has produced yet another great steel body. (At the time of this writing United Pacific Industries is preparing for the introduction of a '32 five-window.)

Installing a master cylinder with the proper exit side is imperative if you want clean brake lines; this unit is from Pete & Jakes.

Installing a master cylinder with the proper exit side is imperative if you want clean brake lines; this unit is from Pete & Jakes.

Remember that little badge on the dashboard of that steel Deuce roadster in 1982, "Steel is Real"? Well, that same moniker is now attached to hundreds of steel cars that, well, are not actually "real." While we applaud the advent of the steel body and feel that it has contributed to the street rodding and restoration hobby in much the same way as the fiberglass body, the fact remains that both the new steel and the fiberglass cars are reproduction bodies, the only thing that differs is the material. The "Steel is Real" battle cry is a bit of a stretch for repro-bodies but there is no denying that reproduction steel has become the body of choice for those who can afford the initial buy-in price.

Now, we are not saying one type of reproduction body is better than the other, rather we want to point out that both bodies are viable approaches to building a very cool hot rod. While the new line of steel bodies is incredible, the fiberglass alternative still provides an approach to street rodding on a slightly lower economic level. Nor are we suggesting a fiberglass body, reproduction frame crate motor is the low-buck way to build a street rod, but we will suggest that it is the midrange approach to street rodding and it will produce a car with predictable performance, great looks, along with many years of enjoyment. Add in timesavings and it is easy to see why the 1-800 rod is still a great way to go. The very term 1-800 rod has taken on a bit of a negative connotation lately but frankly if you want to build a really neat hot rod in about of year of weekend work let your fingers do the walking. To prove the point we decided it would be interesting to assemble just such a car today and see exactly what an all-new, mid-price range street rod costs and how it performs.

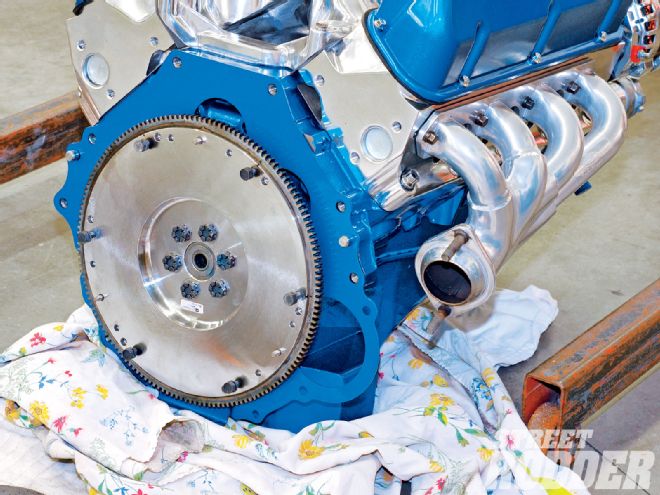

The Sanderson headers are installed along with the Ford Racing flywheel. Taking the time to chase all threaded holes with a tap makes final assembly easier and torque specs more accurate.

The Sanderson headers are installed along with the Ford Racing flywheel. Taking the time to chase all threaded holes with a tap makes final assembly easier and torque specs more accurate.

To accomplish this we enlisted the considerable talents of Bobby Alloway. We'll admit that many of us, OK make that most of us, are unable to build a hot rod in our home garage to the same level as the Alloway team, but many of us can come close enough. Beginning with a Stage III chassis from Pete & Jakes is a good first step, then topping it off with a quality fiberglass body goes a long way to speeding the process. This particular '32 Ford five-window coupe body is from Rats Glass and comes complete with dashboard, garnish moldings and wood and steel reinforcing for a price of $6,500, add stock-style exposed hinges and the price goes to $7,000, while the Rats Glass chopped top three-window coupe is $200 less.

Comparing the steel body to the fiberglass body is truly comparing apples to oranges, but that's precisely the point, there are two different ways to build a fun hot rod here. The Brookville all-steel reproduction Deuce three-window sells for a $24,000, stock top, open roof insert. It is a beautiful piece and their steel bodies have proven to maintain higher selling prices years later than comparable fiberglass bodies. But, like many things, some of that is a function of "money in money out." If you can afford the steel body by all means use one, they are great, but for many people the budget is just not up to the price of steel, and for those people fiberglass is the natural choice.

In this case, finding an original Deuce coupe body for $7,000 is out of the question, and steel reproduction bodies are well above our budget, so the fiberglass body and reproduction frame become the perfect solution for fulfilling that dream of owning a Deuce. Since the Pete & Jakes Stage III chassis will cost approximately $8,000 and a crate motor and new transmission will cost approximately $6,000. So, with a new body, chassis, engine, and transmission rolling around the floor the cost is around $22,000, once again, hardly low-buck, but not big buck either. Plus every piece from the Currie rearend to the Ford motor is new, ensuring maximum pleasure on trips long and short. There is still money to be spent finishing the body and interior and selecting things like radiators, steering column and wheel, wiring, A/C, gauges, seats, and upholstery, and costs can and will vary dramatically based on where you live, the quality of workmanship desired, and how much of the job you can perform yourself. If you do the body prep and painting yourself you are a long way toward saving money. As a homebuilt car with some of the work contracted out and much of it done at home, the car should be able to be completed for under $50,000, and you should have one very nice hot rod when it is over. Needless to say if you are having all work performed by skilled professionals the figure can go much higher. On the other hand, rather than buy a crate motor find a good used engine or build your own, ditto the tranny and if primer and an Indian blanket define your tastes you could build a Deuce for around $35,000 or less. Not bad, it pays to scrounge around a bit.

Don't think for a minute that Bobbay Alloway isn't a hands-on guy when it comes to building these hot rods. Running the business is a big part of his day, but so is building hot rods.

Don't think for a minute that Bobbay Alloway isn't a hands-on guy when it comes to building these hot rods. Running the business is a big part of his day, but so is building hot rods.

So back to Alloway's Hot Rod Shop where the Rat's Glass five-window coupe body has been delivered and a very nice Stage III Pete & Jakes chassis has been rolled into the shop. Bobby Alloway has long been a fan of Ford Racing motors and so a Blue Oval crate motor is sitting on a motor stand with a Tremec five-speed manual gearbox still in the crate. For the most part this car becomes a study in detailing and assembly and anyone who has ever tried to assemble a flawless car will tell you, this is much more difficult than it looks. The assembly is fairly straightforward, doing it with perfect panel fit, a flawless finish, and no chips, runs, or errors is the real challenge.

Of course for team Alloway this is just another day at the office, this is what they do on a daily basis, and actually this is the most uncomplicated project in the entire shop. Because fabrication is kept to a minimum, time is channeled into detailing every piece prior to assembly. Then to personalize the car, brackets and subtle modifications are added along the way and special attention is spent on color selection and interior design.

We made several stops at Alloway's as he assembled this brilliant blue (PPG basecoat/clearcoat in a Toyota Tundra blue) hot rod (and you thought it would be black right?). While Bobby Alloway has built his reputation by creating many one-off creations, they build basic hot rods like this too. Other than the one-off wheels Alloway commissioned Team III/ET Wheels to create, all of these pieces are available to you right now. Let's take a look at how a professional team tackles the job; hopefully it will help you to assemble your own great street rod at home.