What can you say about bumpers? They started out as strictly utilitarian features on the first cars because, well, drivers kept running into things. They were sacrificial components-bend the bumper, save the radiator. By the '50s, they had evolved into a major styling component of new car design, but bumpers still had only one purpose-save the more expensive sheetmetal in the event of a minor accident.

Besides being used as fence post deflectors, bumpers were (and are) often employed as "Park by Braille" bump stops, impromptu tow chain anchors, and lift points used to support the entire weight of the vehicle during tire changes and brake jobs. Is it any wonder that by the time your name is added to the vehicle's title, the bumpers often look like they came off a stunt car from the Mad Max movies?

Chromed and polished metal trim are very unforgiving during the restoration process. Unless you paint the pieces, and can therefore hide any flaws with a layer of filler, they must be absolutely perfect or they look terrible. Pits, waves, and scratches are common sights on rechromed bumpers. Because the metal work underneath the layer of chrome has to be free of flaws and perfectly straight, restorers are often faced with imperfect bumpers or a second mortgage.

John Balow, owner of Muscle Car Restorations in Au Claire, Wisconsin, has turned out several cars that have taken Best Of Show and OE Certified awards at the Mopar Nationals. One of his current projects is the Holley Road Runner, which we've been following along with on these pages. John turns out cars that are perfect-plain and simple. To do this, he's had to find a network of competent restoration specialists to handle the things his shop isn't equipped to do, such as bumper rechroming. John uses North Star Plating Company in Brainerd, Minnesota, exclusively.

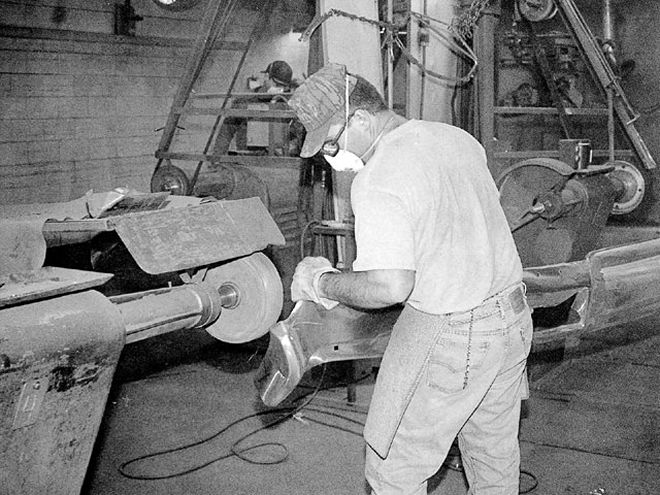

What sets a shop like North Star apart from your local chrome plater? Specialization. North Star does nothing but bumpers. It runs 24 hours a day, five days a week, and often runs on weekends. North Star employees are trained in specific areas of bumper restoration, such as straightening, grinding, polishing, etc., and they master their facet of the restoration process. "We've got guys who have been straightening bumpers for 20 years," said Richard Monson, North Star's plant manager. North Star has made the investment in equipment to straighten, grind, and buff bumpers from every angle, and they have the guys who know how to use that equipment. They've also invested in templates for any car you'd care to name, which they match up to every bumper that goes through the restoration process, ensuring each piece is exactly as it rolled out of Chrysler's factories.

Because they've chosen to specialize in bumpers, they're equipped to handle the big, cumbersome pieces of metal, and do it on a daily basis. Your local plater can probably handle a bumper adequately, but chances are they'd rather deal with headlight bezels and door handles. As a result, not only might the quality not be what it could, but the price will probably be pretty steep. North Star's sheer volume and specialization help keep the cost surprisingly low, and the quality is excellent. We were shown a couple of bumpers that had gone through the entire straightening, chroming and polishing process, only to fail the final quality inspection. We've seen bumpers that weren't this nice shipped out to customers-the examples we were shown weren't perfect, so they weren't shipped. All North Star bumpers are guaranteed for fit and finish. After watching the work North Star does, it's easy to see why a concours-quality shop like Muscle Car Restorations uses them exclusively. We thought you'd be interested in seeing the process, too.