Most gearheads will give their engine buildup plenty of thought and planning, but very little goes toward the driveshaft. In that department, it's usually about beefier universal joints. Today's technology enables us to build an engine that will develop two or three times the power of the so-called "good old days." With 600-plus horsepower now being commonplace, more attention is needed toward that tube between the U-joints and the drivetrain. We've suffered a broken driveshaft at the track and the result wasn't pretty. Fortunately, no injuries occurred, but the mufflers and X-pipe handled the brunt of the damage while the floorpan was scorched-up.

There are three types of driveshafts manufactured: steel, aluminum, and carbon fiber. After use and testing of those three types though the years, a carbon-fiber shaft is the best and safest way to go. When a steel or aluminum driveshaft fails, damage can be costly (motor, trans, rear axle, exhaust, body) and injuries to the driver can occur. If a carbon-fiber driveshaft fails, its fibers will only shred apart to look like a broomstick. Therefore, zero, or maybe minimal damage is done to your pride and joy. In our case (see pix) it would have been more cost effective at first to get the more expensive and stronger QA1 carbon-fiber driveshaft. Sure, a quality carbon-fiber shaft is more costly, but it offers better strength, high-speed dynamics, and obviously less rotational weight for quicker acceleration.

QA1 spent a considerable amount of R&D to produce the highest-quality carbon-fiber driveshaft available for your street or race car. They worked with 3M's Aerospace and Transportation Group to develop a nano-silica matrix resin (3M Matrix Resin) for its part. The fiber is wound with the 3M Matrix Resin in several directions at specific angles to provide torsional strength (stiffness) that curtails flex at high driveshaft speeds to reduce resonant vibration. At each end of the shaft the yokes are secured by a proprietary 11-step bonding procedure. The yokes are 7075 forged aluminum, CNC machined to ensure proper axial alignment and prevent high-rpm unbalance. QA1's new REV Series carbon-fiber shafts are available in 3.2- and 3.7-inch diameter. The 3.2-inch shaft is rated to 700 hp and 500 lb-ft with choices of 1310, 1330, and 1350 U-joints. The 3.7-inch brute is designed to handle up to 2,000 hp and 1,500 lb-ft torque and features beefy 1350 yokes and high-strength alloy U-joints. At the time of this writing, only the fatter 3.7-inch shaft is applicable for the Mopar user with the 30-spline slip yoke common to the 727 TorqueFlite and A833 four-speed.

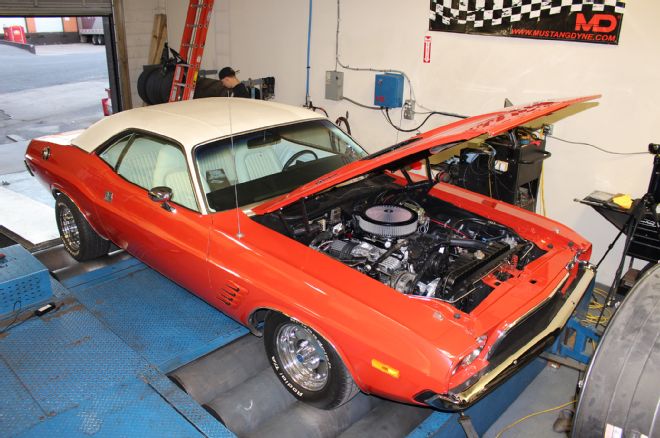

So you're interested, right? To order a custom QA1 REV Series carbon-fiber driveshaft, you'll need to fill out the custom order form. The order form is available from the QA1 website or just a phone call away. The form illustrates where all the measurements should be taken from. Be sure measurements are correct for the slip yoke to have the proper amount of play during rear suspension movement. We recently ordered and installed a QA1 driveshaft in our '73 Challenger project, and we're glad we did. During normal stop-and-go driving it's easier to get rolling with less throttle depression and riding the clutch. You can actually feel the power going to the rear tires more freely and smoothly. Then there's no vibration and less noise at high driveshaft speeds (3.55 gearing and 25-inch diameter 245/60R14 tires) when out on the highway. After realizing the aforementioned benefits, we also felt the need to chassis dyno test the effects of less rotational weight. Follow along for more of the facts, installation, and performance gains a carbon-fiber driveshaft can deliver.

1. Every QA1 carbon-fiber driveshaft is designed and manufactured at its Lakeville, Minnesota, facility. During the filament winding process, 3M Matrix Resin is used to produce a driveshaft with extra strength and torsion stiffness. The fiber is wound in several directions at specific angles to provide strength and stiffness to prevent flex at high driveshaft speeds (essential to reduce resonant vibration).

2. Next, the shaft is placed into a special oven for the curing process. The oven will ramp up, dwell, and ramp down for a precise cure. After the shaft is cured, it is cut to the desired length. There's also an example "test" ring cut from every shaft for imaging, inspection, and quality control. Then the ends of the cut-to-length shaft are prepped for yoke fitment.

3. A QA1 technician prepares the 7075 forged aluminum, CNC-machined yokes for the confidential 11-step bonding process. These light and strong aluminum yokes extend five-times further into the carbon-fiber tubing than a driveshaft built of steel or aluminum.

4. After the shaft is built, it is tested for quality and strength on a torsion tester. Once passing the torsion test, each shaft is serialized. Here's an example of failure to a carbon-fiber shaft. It will shred like a broomstick causing no damage to the underside of your ride. QA1's REV Series 3.2- and 3.7-inch shafts are rated at 700 and 2,000 hp with a wall thickness of .080 and .125 inch, respectively.

5. Here's our steel shaft that twisted and snapped. It was locally made with 3 1/4-inch tubing, .063-inch wall we were told was good for over 700 hp. Our 577 hp 340/416ci LA small-block destroyed it the first time we power-shifted Second gear. It was an unexpected, scary experience having only 245/60R14 BFG T/A Radial rear tires.

6. We were fortunate the exploding steel driveshaft did not go through the floor and injure us. It has been known to happen. Luckily, the DynoMax Super Turbo mufflers and the TTi X-pipe took the brunt of the damage. Above the mufflers is where the floor pan took its beating. We ordered a new TTi X-pipe and Dynomax Ultra Flo's from TTi Exhaust.

7. When stepping-up to beefier 1350-series U-joints, the stock smaller-size (7260 in our case) pinion yoke will need to be swapped out. Here we used our old Snap On harmonic balancer puller to properly do the job. Do not torque the new yoke to more than spec (100 ft-lb for our 489 housing) or the pinion pre-load could be upset and cause rearend noise.

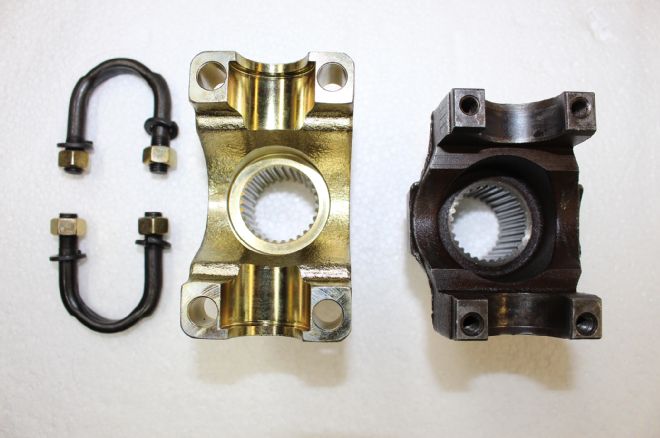

8. Left to right: From Randy’s Worldwide we ordered a 1350 U-bolt kit (PN YY UB-004, $9.29). The 489-case 8 3/4 rear also needed a 1350 Extra HD 29-Spline Yoke (PN YY C8.75-1359-F, $126.14). Not shown, is the pinion seal (PN YMS 5126, $15.98). To the right is the stock, smaller 7260 yoke that offers less strength.

9. To be sure improper pinion and/or driveshaft angle wasn't the cause of breakage and vibration, we checked it at rest with an angle meter. Our pinion angle was 1 degree and the driveshaft angle 2 degrees. Ideally there should be a 2-degree difference between pinion and driveshaft angle. Pinion and driveshaft angle should not exceed 5 degrees.

10. QA1's well-designed packaging protects your carbon-fiber driveshaft during shipment. The box can also serve for safe storage when not in use. Our REV Series carbon-fiber driveshaft ($1,595.00) is a 3.7-inch unit with 1350 high-strength U-joints. It features a heavy-duty 30-spline slip yoke that fits the Chrysler 727 or A-833 transmission.

11 & 12. There should be at least a half-inch of clearance for the driveshaft not to rub during rotation and suspension movement. We hammered-in the inlet edge body of the DynoMax Ultra Flo's for sufficient clearance. You don't want to ruin your new driveshaft.

13. QA1 informed us the bonding area of the driveshaft yokes should not exceed 200 degrees. X-pipes will produce more heat than H-pipes, so we used exhaust heat wrap we had laying around. Testing with a temperature gun was performed many times. The hottest readings we recorded were 185 degrees after a few full throttle blasts.

14. At the time of our steel driveshaft fatality, the QA1 carbon-fiber shaft would not be available for our application for two months. In the meantime we ordered another steel shaft with .083-inch wall thickness and 1350 series U-joints. Money wasted for the two steel shafts and TTi exhaust parts was more costly than if we first ordered the QA1 shaft—plus no damage.

15. A carbon fiber driveshaft accelerates faster than a steel driveshaft due to its lower mass and lower inertia. Our friends at Tune Time Performance welcomed us to test the two driveshafts on their chassis dyno. The steel shaft showed us 367 lb-ft and 413 hp. Swapping to the carbon fiber shaft showed us 373 lb-ft and 424 hp. Gains like that should be worth over a tenth at the strip and some piece of mind knowing we have a safer ride and smoother running.