Forget things like nuclear power, lasers, and freeze-dried ice cream. When it comes to back-engineered alien technology, the automatic transmission is a marvel of seemingly otherworldly intelligence. General Motors introduced the first Hydramatic transmission in the 1940 Oldsmobile. That was seven years before the Roswell incident, but who knows? Maybe flying saucers had been buzzing around Detroit the previous decade and the one that supposedly crashed in New Mexico simply burned up a couple of clutch bands in its intergalactic slushbox.

Amazingly, the basic design of the modern automatic transmission hasn’t changed much from the early Hydramatics introduced 75 years ago – and they’re still the source of confusion and apprehension among enthusiasts who view their workings and performance nuances as a black art.

There’s not enough room here to explain everything about the design, operation, and performance capabilities of automatic transmissions, but in this second in a series of explanatory features, we answer some of the most common questions and explain the more misunderstood aspects of GM automatic transmissions and related performance features.

Don’t worry. There are no alien probes involved.

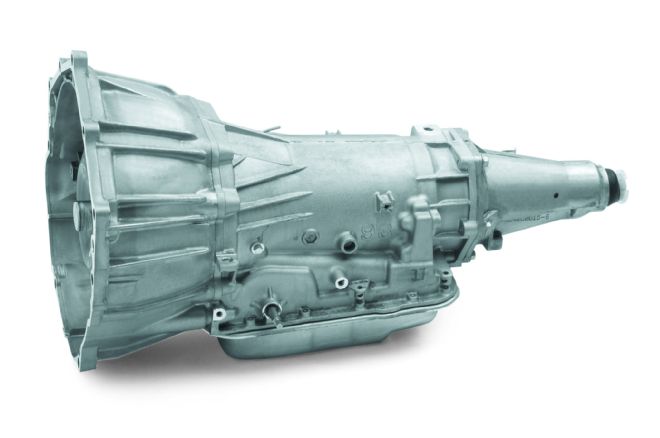

The Turbo 350 (top) and the Turbo 400 (bottom) are the quintessential GM automatic transmissions. Both are three-speeds, but the Turbo 400 is physically larger and designed more for the torque capacity of big-block engines.

1. Is there a big difference between a Turbo 350 and Turbo 400 – and which one do I want?

They are completely different transmissions. The Turbo 400 is larger, longer, and heavier than the Turbo 350 and was designed to live behind higher-torque applications such as big-blocks. That doesn’t mean the Turbo 350 is weak in comparison. In fact, with all of the enhancements from companies such as TCI Automotive, Performance Automatic, and Hughes Performance, both transmissions can be built to match very high power levels. When it comes to picking one for your vehicle, we’ll always side with lighter and smaller whenever possible. You’ll also want to consider what type came originally equipped in the car. Changing to a Turbo 400 in an original Turbo 350 car will require mounting/crossmember modifications and likely a shorter driveshaft. If you’re worried about the ultimate strength of the transmission, consult one of the transmission specialists for upgrades.

A mainstay of drag racers decades after it went out of production; the simple, durable two-speed Powerglide continues to send drag racers down the strip.

2. Why is the Powerglide transmission so popular in drag racing?

In the high-tech 21st century, it seems antithetical that racers would rely on an archaic, two-speed automatic gearbox, but there are several good reasons: simplicity, low inertia, and versatility. The simplicity of the Powerglide makes it easier and faster to work on, while contributing to lower weight than three- and four-speed transmissions. Only two gears means less inertia is required to spin it, too, which translates into more power getting to the pavement. As for versatility, there are tons of available First gear ratios that make it easy to tailor the trans to the rest of the engine and drivetrain elements – and a big-torque engine doesn’t need numerically high gear ratios to get the car launched, so the simple Low and High gears are ideal for a quick blast down the strip.

The Hydramatic 200-4R (shown) is a good swap choice, but isn’t as easy to find as a 700-R4.

3. Which is better: the 200-4R or the 700-R4?

This is one of those questions akin to asking who in your town makes the best pizza. Everybody has an opinion and they’re not necessarily wrong. The 200-4R was introduced in 1981 and its design roots lie in the Turbo 350. In fact, its overall size and length are comparable to the TH350, which makes swapping one comparatively easy into a vehicle originally equipped with the Turbo 350. The rear crossmember has to be relocated, but the original driveshaft can be retained. The 700-R4 debuted in 1982 and was renamed 4L60 in 1990. It offers comparable performance characteristics to the 200-4R, but it’s a longer transmission and a swap into an older vehicle requires a new crossmember and a shorter driveshaft. In the 700-R4/4L60’s favor is economy of scale. They were made in the millions and for much longer than the 200-4R, so used examples are plentiful and cheap. The 200-4R is getting a little harder to find these days.

The 4L60 series is the 350 small-block of overdrive transmissions – it fits everything and is durable and economical.

4. What about the 4L60 series overdrive transmissions? Are they better than a 700-R4?

See #3 above. The 4L60 and the 700-R4 are the same transmission. General Motors changed the name in 1990 to 4L60 as part of a new naming convention that continues today. The 4 stands for four-speed, the L stands for longitudinal (i.e., the north/south orientation of the powertrain in a rear-drive vehicle), and 60 stands for the relative torque capacity. Some suggest pre-1987 700-R4 transmissions are more problematic than later editions, but that’s not a universal belief. Higher-torque versions of the family include the 4L65E and 4L70E, which have five-pinion gearsets versus the 4L60’s four-pinion design, for enhanced strength.

The 4L80 family is the choice for big-block engines and has its roots in the Turbo 400.

5. What about the 4L80 series? Just as the 200-4R was an extension of the Turbo 350, the 4L80, which was introduced in 1991, was developed on the Turbo 400 architecture. That means it has a different case design and dimensions and is not simply a high-torque extension of the 4L60 – although the families are surprisingly close in overall length and width. And like the Turbo 400, the 4L80 was designed for higher-torque applications. Consequently, it is heavier than the 4L60.

GM’s electronically controlled transmissions take their gear-change commands from a stand-alone controller and require a separate, aftermarket converter to work with mechanical speedometers.

6. What’s the difference between the 4L60 and 4L60E – and 4L80 and 4L80E?

The “E” versions of the 4L60 and 4L80 series transmissions are electronically controlled, meaning a powertrain control module directs solenoids inside the valvebody to activate the valves, compared to the completely mechanical operation of the non-E versions. Using the E versions in an older car requires a complementing controller. The E versions also use an electronic speed sensor to relay information to the speedometer. Signal converters are available to adapt the electronic output for use with conventional mechanical speedometers.

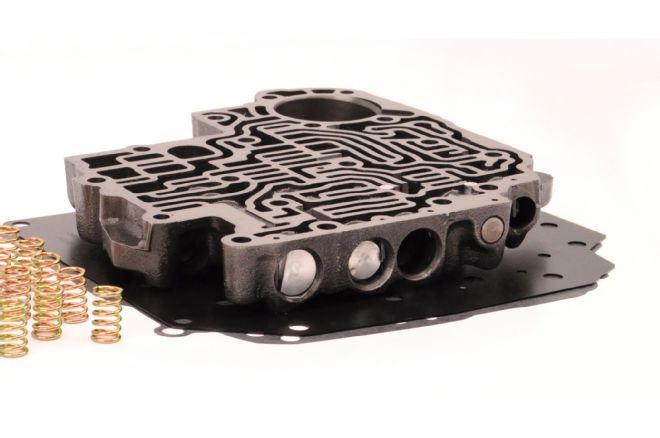

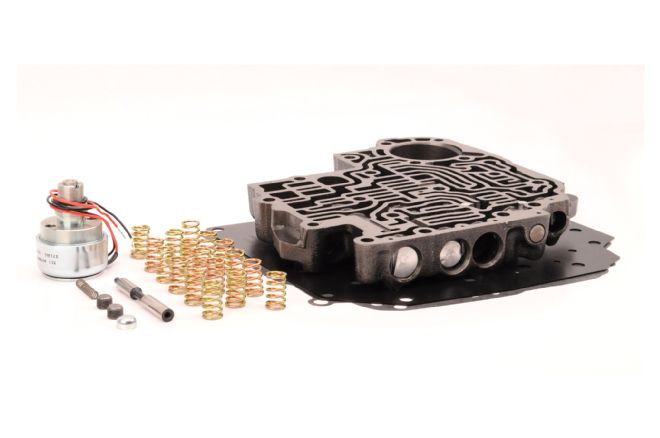

The maze of channels in a valvebody directs fluid that controls the valve actuation for each gear change.

7. What is the transmission’s valvebody?

It is the nerve center of an automatic transmission. It’s basically a maze of channels and passages that funnel hydraulic fluid to various valves that, in turn, activate the appropriate clutch pack or band servo. Each valve has a specific job, such as activating the upshift from Second gear to Third gear, while another valve controls the downshift from Third to Second. With a computer-controlled transmission such as the 4L60E, electronically activated solenoids are mounted in the valvebody and direct fluid to the clutch packs or bands.

Shift kits basically reduce the mushy feeling built into a production transmission for smoothness, adding snap to the gear changes for a firmer, more positive feel. Reducing slippage can also prolong the transmission’s life.

8. What does a shift kit do for performance?

Different types of shift kits are designed for different tasks, but generally speaking, a performance-type shift kit is designed to provide firmer-feeling shifts by altering the fluid flow and other elements in the valvebody. While actual vehicle performance (i.e., acceleration) may not be significantly affected, the result is typically a greater feeling of precision. A shift kit can also help reduce wear by reducing the slippage and shift overlap built into many transmissions to give them smoother-feeling shifting. And while it is technically a bolt-on project, it can be an involved one, including spring replacement and even drilling out fluid passages in the valvebody.

A manual-control valvebody eliminates the automatic gear changes in an automatic transmission – and it’s really designed for the strip, not the street.

9. Is a manual valvebody what I think it is?

If you believe it allows the driver to shift an automatic transmission manually, you’re correct. But unlike clicking up through the low gears in your street car, a manual valvebody totally eliminates the automatic shifting function and puts full gear-change control in the driver’s hand. That means the transmission won’t automatically shift at all. It’s designed for racing, allowing much greater line pressure that makes it harder for the clutches to slip under high loads. Although some hard-core enthusiasts run manual valvebodies on the street, they’re really best left to the dragstrip, off-road course, or perhaps the monster truck you’ve been dreaming of building since fifth grade.

When clicking through the gears with manual control, a reverse-pattern valvebody can be more intuitive and prevent inadvertently shifting into Neutral.

10. What, then, is a reverse-pattern valvebody?

It’s a modification that reverses the shift pattern for a manual-control automatic, meaning First gear is right below Neutral and the high gear is the farthest from it. The idea is for a more natural-feeling shift pattern on the dragstrip, while preventing inadvertently shifting into Neutral — or worse, Reverse — when clicking up through the conventional automatic shift pattern.

A transbrake allows a vehicle to achieve the maximum converter stall for higher-rpm launches – much like a high-rpm clutch-dump launch with a manual transmission. This one is from TCI Auto.

11. What is a transbrake and how does it work?

A transmission brake valvebody is designed for hard, optimal-rpm launches at the dragstrip. It’s an electrically controlled device that, when activated, simultaneously holds the transmission in First and Reverse gears, “locking” the transmission and allowing the driver to bring up the engine rpm without holding his or her foot on the brake pedal. When the transbrake is engaged, there’s no torque sent to the driveshaft, so the suspension remains unloaded, which is also better for the launch, and without the need to hold the brake it prevents the car from inadvertently creeping forward through the staging lights. The driver releases the transbrake as the lights come down on the Christmas Tree, disengaging Reverse and launching the vehicle forcefully and at the optimal rpm. Think of it as the automatic transmission equivalent of revving the engine and dumping the clutch.

Using a delay box can make a car deadly consistent, with near-perfect launches, but some believe it minimizes the human element in racing.

12. So, what then is a delay box?

Essentially, a delay box is a timer partnered with a transbrake, designed to help the driver launch with a better reaction time. Without a delay box, the car launches as soon as the driver releases the trans brake. With a delay box, the driver can dial in a countdown before the trans brake releases. If the delay is timed just right, the car will launch with a perfect or near-perfect reaction time. This is a simplified explanation, because there’s quite a bit of math involved with determining the optimal delay timing. There are even crossover boxes that enable bracket racers to factor in their opponent’s dial-in – more math there. Delay boxes have always been controversial, because of the perception they take much of the human factor out of racing. We tend to agree, but the devices are here to stay.