When you hit the throttle, the engine spins the flywheel. The flywheel transfers energy to the transmission that is transferred to the differential, spinning the tires and putting the power to the ground. That's all there is to it, right? The driveshaft is only a link between the tranny and the rearend. The problem is this is the common view about the driveshaft-it's a simple link. The fact is, while you can't gain horsepower through the driveshaft, you can certainly lose it.

Balance

Anytime you increase the power output of a stock engine and subsequently increase the speed at which the engine operates, you need to look at driveshaft balance. Most factory driveshafts are balanced between 3,000 and 3,500 rpm. Spinning the driveshaft past that range can have a parasitic effect. Steve Raymond from DynoTech Engineering tells us, "We have had several NASCAR teams tell us our driveshaft saves them 3 to 7 hp at the wheels of their race cars. That's why balance and design are important and why we manufacture shafts for about 85 to 90 percent of the NASCAR teams."

DynoTech Engineering uses Balance Engineering driveshaft balancers, which are considered the best in balancing accuracy. DynoTech suggests balancing a performance driveshaft at a minimum of 5,000 rpm and as high as 7,500 rpm. This ensures a properly tuned driveshaft that reduces vibration and efficiently transmits power to the wheels.

Length And Diameter

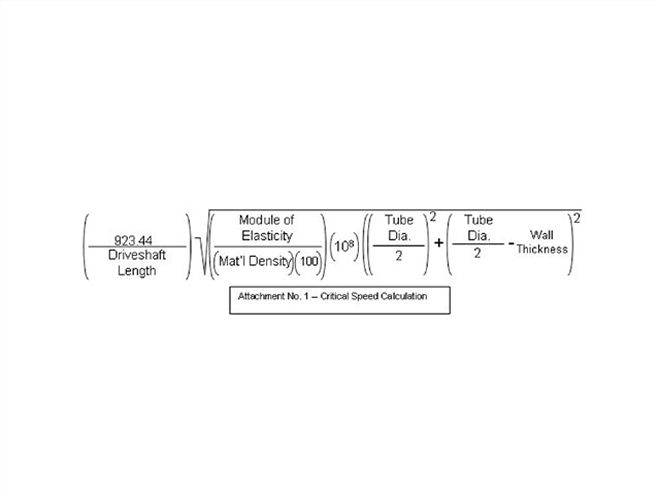

Other than balance, the length and diameter of the driveshaft directly affect the performance of the unit. Critical speed is the rpm at which the driveshaft becomes unstable and begins to bend into an S shape. The longer and smaller (diameter) a driveshaft is, the lower its critical speed. Critical speed is felt as excessive vibration that could cause the unit to fail. To calculate the critical speed, the length, diameter, wall thickness, and material module of elasticity must be known. Then using the critical speed calculation formula (see the Speed sidebar), the numbers are plugged in and you will know the driveshaft's critical speed.

Materials

What the driveshaft is made of is just as important as its length and diameter. An OEM steel shaft is rated for no more than 350 lb-ft or 350 to 400 hp. For high-performance use, there are two types of steel used: DOM or drawn over mandrel seamless tubing and chrome-moly steel. DOM steel is better than OEM steel, handling up to 1,300 lb-ft and 1,000 to 1,300 hp and also has a higher critical speed. This is a good choice for any car that does not need a lightweight unit.

The step up from DOM steel would be chrome-moly, which is the strongest possible material and usually seen in Pro Stock cars. Chrome-moly steel tubing can be heat-treated as well, raising the torsional strength 22 percent and increasing the critical speed 19 percent. The problem with steel is it is heavy, which increases the load on the drivetrain.

Aluminum is probably the most common performance driveshaft material. The lightweight aluminum shaft reduces rotational mass, freeing up horsepower from the engine and reducing parasitic loss.

An aluminum driveshaft will support up to 900 lb-ft or 900 to 1,000 hp, making it a great lightweight choice for most muscle cars. However, it is not as strong as steel, so some custom driveshaft shops do not have twist guarantees on aluminum driveshafts.

The chances of breaking the pinion-yoke are small, and the compact design means more meat in the important places, yielding a strong component. That is not to say a cast yoke is bulletproof. When the slip-yoke broke in our '71 Buick GS, it egged out the pinion-yoke saddles. We replaced it with a billet steel yoke from Mark Williams. New yokes usually come with the better joint caps instead of the lighter-weight stock-style U-bolts, which are prone to distorting the U-joint bearing caps.

The chances of breaking the pinion-yoke are small, and the compact design means more meat in the important places, yielding a strong component. That is not to say a cast yoke is bulletproof. When the slip-yoke broke in our '71 Buick GS, it egged out the pinion-yoke saddles. We replaced it with a billet steel yoke from Mark Williams. New yokes usually come with the better joint caps instead of the lighter-weight stock-style U-bolts, which are prone to distorting the U-joint bearing caps.

Carbon-fiber tubes are the most expensive, but they are also the most efficient. When you are looking at power figures up to 1,200 lb-ft or 900 to 1,500 hp, carbon fiber is a great choice. Carbon-fiber driveshafts are not only strong, but they also have a surprisingly high torsional strength, resisting twisting and reducing the shock factor on the rearend. Carbon fiber also has the highest critical speed module of elasticity, meaning the shaft won't flex at slower speeds, unlike other material components. Coupled with the highest critical speed and the light weight, a carbon-fiber driveshaft can free up as much as 5 hp over a stock steel driveshaft. When winning is everything, that might make the difference.

U-Joints

Once the driveshaft is measured and ready to build, there are a few other issues to contend with. Phasing the U-joints with the weld-in yokes is an important part of the equation. With every rotation of a U-joint at any degree other than zero, a vibration is generated. This shows up as a torsional pulse, which is felt as a significant vibration. By phasing the weld-in yokes to minimize the combined degrees of rotation, the vibration will be drastically reduced.

Which U-joints you use makes a difference-and not just the brand. A U-joint should be looked at in terms beyond load capacity. For most cars, 1310-series U-joints are common. For performance applications, 1350-series joints are the better choice. The larger the series number, the larger the trunnion (the protruding shafts the caps ride over) diameter, which equates to more torsional strength. Torsional forces are those exerted in a twisting motion. Changing to a larger-series U-joint is not a simple task; you can't just buy bigger joints. All the yokes-slip, bolt-on, and weld-in-must match the desired joint size. Crossover U-joints allow you to mate a larger (or smaller) U-joint to the other. For example, you buy a new driveshaft that comes with 1350 weld-in yokes, but your car has 1310-sized yokes for the tranny and rear differential. A 1350-to-1310 joint would have a 1350 on one plane and a 1310 on the other, allowing you to install the driveshaft until you replaced the slip- and bolt-on yokes. While it can be done, using crossover U-joints is not suggested as a long-term solution. The smaller size basically becomes a fuse, and it will eventually fail.

The type of joint, solid-body versus greaseable, is important as well. The Spicer-style solid-body U-joints come lubed for life and do not have grease zerk fittings. This makes them a little stronger, as they do not have the stress risers created by the opening for the zerk fitting in a greaseable U-joint.

Yokes

The slip-yoke and the pinion-yoke also take a lot of abuse in a high-performance application. These are the physical connectors to the transmission, driveshaft, and differential. When the slip-yoke failed on our Buick GS, it wiped out just about everything it could, including damaging the pinion-yoke saddles. In most applications a cast pinion-yoke is usually strong enough to handle up to 800 hp. That number has some fudge room, though, as a lightweight car with street tires and 800 hp will put less strain on the yokes than a 4,000-pound Chevelle with slick and 500 horses. Another option when using a cast pinion-yoke is using U-joint caps instead of the weaker stock-style U-bolt retainers. This will increase the holding power and eliminate the possibility of distorting the caps. New billet yokes typically come with the proper retaining caps.

How To Measure A Drive Shaft

If you have changed transmissions and need to measure for a new one, it is important to measure from the face of the seal on the tailshaft to the flat surface on the pinion-yoke with the pinion-yoke installed and the car sitting at ride height. Changing to a billet pinion-yoke can alter the length by as much as 3/4 inch. maintenance

With this measurement, the driveshaft shop can create the complete shaft with the required slip-yoke and predetermined play for the slip-yoke. For most applications, 1 inch is more than enough for suspension travel. Do not let a shop talk you into leaving more play than that. Some transmission shops will insist on running 1.5 inches, which would be disastrous. With that much of the slip-yoke hanging out of the tranny, there could be less than 3 inches of splined yoke in the tranny, thus creating a wobble in the yoke, which would cause a heavy vibration at various rpm. Stick with the 1-inch rule and you will be good to go.

Speed

What causes driveshaft failure is reaching critical speed. This complex formula is used to calculate the critical speed for every driveshaft. All driveshafts have a critical speed; it depends on the length and diameter. The module of elasticity of the shaft material is an important part of the equation. Getting these numbers can be a little tricky, as most shops keep the specific numbers close to the vest. For steel, the basic MOE is 30, aluminum is 10, and carbon fiber depends on the manufacturing processes used, so no numbers are available.