TCI Automotive has years of experience building GM's 700-R4s and all the variants. The company can build one from the ground up and include its new Constant Pressure Valve Body.

TCI Automotive has years of experience building GM's 700-R4s and all the variants. The company can build one from the ground up and include its new Constant Pressure Valve Body.

The GM 700-R4 is one of the most popular overdrive automatic transmissions used in street rods. And why not, you might ask-they have a 3.06:1 First gear for launching from a standstill, a .70:1 overdrive Fourth for low-rpm highway cruising, and they can be built to withstand a tremendous amount of horsepower. But then if you've had one burn-up or fought with adjusting shift points until you were blue in the face, you just might have plenty to say about the 700-R4-and most likely not much of it would be printable.

When first introduced, the 700-R4 got off to a rather rocky start. GM had not done its homework, and much like the company's first foray into diesel engines in passenger cars, research and development was left up to the consumer. Lots of those early transmissions quit before the payments on the cars they came in were completed and warranty repairs quickly established the transmission's weak points. But, eventually-after a list of updates that were about the size of an L.A phone book when printed out-Generous Motors corrected the 700-R4.

While the 700-R4 ultimately became a pretty bulletproof transmission in production automobiles, the same couldn't always be said when they found their way into a street rod. And while it seems ludicrous to say, it wasn't always the fault of the transmission, but rather the induction system that was in use. Now before you demand that STREET RODDER staffers be subjected to random drug testing, let us explain.

For those who have a properly operating transmission in a street rod and want to keep it that way, TCI offers its replacement Constant Pressure Valve Body in kit form.

For those who have a properly operating transmission in a street rod and want to keep it that way, TCI offers its replacement Constant Pressure Valve Body in kit form.

All automatic transmissions use hydraulic pressure to apply friction components; either bands or clutches shift into each gear. The 700-R4 (as well as the 200-4R and the 4L60) uses a cable (called the throttle valve, or TV cable) connected to the throttle linkage to establish that pressure. On these factory induction systems, the linkage arm where the TV cable attaches has very specific geometry that moves the cable a precise distance in relation to the throttle opening to ensure the transmission's hydraulic pressure is appropriate. That's why 700-R4s behind engines with GM TPI don't seem to have nearly as many problems-the TV cable geometry is correct. On the other hand, most carburetors don't have the proper lever geometry; they may work just fine with a Turbo 350, but they won't work with a 700-R4. This condition has become so well recognized that many new aftermarket carburetors now come with a warning that they are not to be used with an overdrive automatic equipped with a TV cable (with computer-controlled transmissions, it doesn't matter).

A 700-4R's shifting can be erratic as a result of improper TV cable lever geometry. In many cases, the shifts are poorly timed and may be early and soft, late and harsh, or a combination of both. Downshifts often fall into their own category of weird, and no amount of fooling with the TV cable adjustment seems to make things right. But then why would it-the cable isn't at fault.

While odd shifting characteristics are annoying, transmission failure is even more so, and it's expensive to repair to boot. And although there are other scenarios that cause damage to a 700-R4, what happens in many cases is basically this: The engine begins producing increased torque before the transmission is ready for it. What's supposed to happen as the throttle opens and the engine produces more power is that the hydraulic pressure in the transmission increases to handle it. However, slippage can occur if that pressure increase lags behind the power increase because the relationship between the throttle and TV cable movement isn't properly coordinated. Sometimes the slippage is noticeable, but often it's not. In any case, it's the kiss of death for an automatic transmission and allowing it to continue ultimately results in total transmission failure.

TCI's valvebody kit does not fit in pre-1987 700-R4 transmissions. A simple way to tell if yours is a candidate once the pan is off is by the presence of auxiliary valvebody shown here being removed. Earlier transmissions don't have them.

TCI's valvebody kit does not fit in pre-1987 700-R4 transmissions. A simple way to tell if yours is a candidate once the pan is off is by the presence of auxiliary valvebody shown here being removed. Earlier transmissions don't have them.

Driving With The CPVB

Our test case for the TCI Constant Pressure Valve Body was our own associate publisher, John Barkley's pick-'em-up with a fairly stout SBC. A former drag racer who looks at green lights as indicators to launch, we know it's good to go if anything mechanical can live with John. Here are his comments on a new and improved 700-R4.

My truck is really sweet to drive now, and it's basically a five-speed with the lockup converter. I'm an aggressive driver, so I have it set up to downshift without having to put the pedal to the floor. The result: My truck gets 15 mpg going back and forth to work, which is huge, considering the way I drive and that it's got a 435hp, 355ci small-block with a big hydraulic roller cam.

Line pressure stays between 130 and 230 depending on oil temp and throttle position. At warm idle, 800 rpm in gear, it drops to 100 lbs. Line pressure fluctuates due to engine speed and transmission pump rotor speed, which controls oil volume and pressure. The line pressure increases as soon as you crack the throttle and the pump rotor speeds up. Trans temp so far (just did it over the weekend and it's been cool) hasn't exceeded 165 degrees.

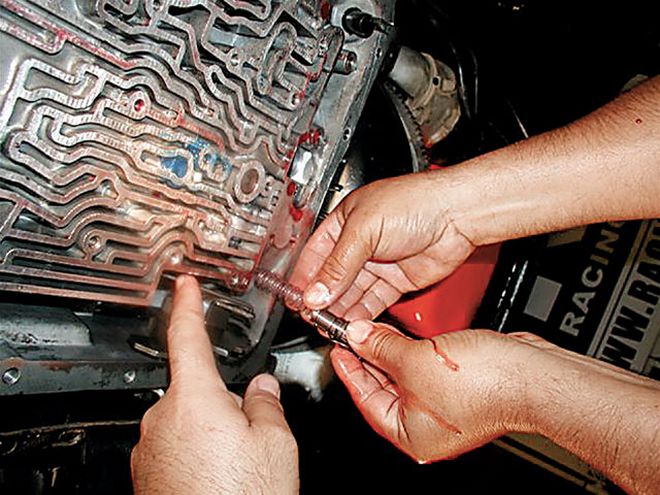

If you do this in the car when removing the valvebody, prepare yourself for parts falling out and fluid running down your arms.

If you do this in the car when removing the valvebody, prepare yourself for parts falling out and fluid running down your arms.

Basically, the TV cable is only used to tailor shift points with the Constant Pressure Valve Body. This allows me to back it off a little and tone down the 1-2 shift. When using a lockup converter, the vacuum switch can be adjusted to keep the lockup from "hunting" back and forth. The switch has a tiny (5/64-inch) socket head screw in the side that is used to adjust vacuum sensitivity. The governor uses weights and springs and centrifugal force to control full-throttle shift points and kick-downs. In the 700-R4, it's basically the same governor as a Turbo 350 or 400, by changing to lighter weights, the shift is delayed; different springs can also be used to tailor shift duration (hard and quick, or softer and slower).

When installing the TV cable, set the initial adjustment in the middle of the range so you can easily fine-tune one click at a time in either direction.

The TCI kit includes everything you need for installation, including the valvebody, gaskets, O-rings, check balls, valvebody separator plate (not shown), and 2/4 Servo (PN 376003). Don't worry-the instructions make it clear where all this stuff goes.

The TCI kit includes everything you need for installation, including the valvebody, gaskets, O-rings, check balls, valvebody separator plate (not shown), and 2/4 Servo (PN 376003). Don't worry-the instructions make it clear where all this stuff goes.

The Fix

One of the most experienced companies specializing in high-performance automatic transmissions is TCI Automotive. When TCI went looking for a cure for 700-R4 TV cable issues, the company cut to the chase and came up with what is called the TCI Constant Pressure Valve Body. And while the TV cable is still used to establish part-throttle shift points, the line pressure has a fixed minimum, which, according to TCI, eliminates the possibility of the transmission burning up from an improperly or misadjusted TV cable and the low line pressure that normally results.

Installation

We're not going to do a blow-by installation of the valvebody, primarily because TCI's instructions are excellent and complete, so we'll let you get oily fingerprints on the company's paperwork rather than your magazine. Instead, we're going to save some space by not being redundant and just touch on the high points.

First off, if you're scared of tearing into an automatic transmission, you don't need to be; this installation is within your capabilities if you can handle routine maintenance on your street rod. And if you do get stuck, TCI has excellent tech support-just pick up your phone. Second, this kit won't cure the ills of a malfunctioning or slipping 700-R4; it is intended to prevent those things from happening and should only be installed in a transmission that is in top-notch condition. Finally, this kit is only for 1987 to 1992 transmissions.

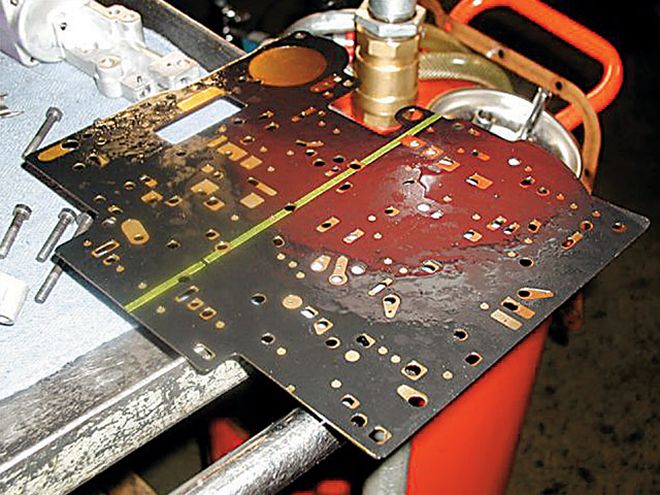

This is the separator plate that goes between the transmission case and the valvebody.

This is the separator plate that goes between the transmission case and the valvebody.

One of the interesting features of this kit is that the parts are provided to allow the installer to choose from three levels of performance: Heavy Duty, for towing, and for motorhomes and similar vehicles-the shift is firm but not harsh; Street, a step above the stock shift feel; and Street Plus, TCI's Street Fighter configuration with a very positive and sharp shift.

Installation begins by removing the pan, the filter, the 1-2 accumulator, auxiliary and main valve bodies, and separator plate (all these are identified in the instructions). Be forewarned, if you do this with the transmission in the car, some of the accumulator parts and some check balls are going to fall out, but don't panic. TCI includes six new check balls, and you only need four, so you can even lose some new stuff and be OK.

Reassembly consists of choosing which new parts to install to achieve the level of performance you're after. The most challenging part may be keeping the check balls in the right spot, but a little petroleum jelly will help with that chore. The other precaution is not to over-tighten anything; use a torque wrench and follow the instructions for specs.

A new pressure regulator spring and boost-valve are supplied with the kit. Installation is simple with a pair of snap ring pliers.

A new pressure regulator spring and boost-valve are supplied with the kit. Installation is simple with a pair of snap ring pliers.

With the transmission buttoned up and full of fluid, the final step is to adjust the TV cable. Again, TCI's instructions describe the procedure. We will say that, when properly adjusted, the First-to-Second shift should occur at 15-20 mph; Second-to-Third shift at 25-30 mph; and Third-to-Fourth shift at 40-45 mph. Readjust the cable if the transmission shifts into First, Second, and Third within seconds.

Great Expectations

Over the years, we've talked to many street rodders who were bewildered by the poor operation and often the complete failure of a 700-R4 and blamed it on everything from the basic design of the transmission to whoever rebuilt it. As we've pointed out, the actual cause of many of these problems often comes from something as simple as TV cable geometry. But, thanks to TCI's Constant Pressure Valve Body, all those ills are in the past. Now stock or aftermarket TV cables can be used with virtually any induction system without fear of failure because the pressure is on, and that's a good thing in this case.

Late-Breaking News

As we go to press, TCI has announced the expansion of its line of Constant Pressure Valve Bodies, now available for '82-86 700-R4s, '81-90 200-4Rs, and '80-93 Ford AODs. Now those transmissions can benefit from this technology as well.