Automatic transmissions have been with us for a long, long time. In fact, the basics can be found in the Model T Ford. At the heart of an automatic transmission are the planetary gearsets. As gears go, planetaries could be considered the most sophisticated. Made up of three elements—a sun gear, ring gear, and planet pinion gears—planetary gear assemblies can provide forward or reverse rotation, a speed increase, constant speed, or a speed reduction (to provide a variety of gear ratios multiple gearsets are used).

In operation, a planetary gearset requires an input (power from the engine), an output (power going out), and a reactor (one of the elements that is held stationary). The gear ratio and the direction of travel depend on which element is performing each function; when none of the elements are held, the transmission is in neutral. To keep the reactors stationary, bands are used to hold the ring gear to the transmission case, clutch plates and one-way roller clutches are used to hold the planetary elements. In the Tin Lizzie, bands were applied mechanically when the driver stepped on a pedal—modern automatic transmissions use hydraulic pressure.

The valvebody is the “brain” of the transmission. It controls shifting by controlling which reactor is applied to what gearset and when. Historically, automatic transmissions used hydraulic pressure from a governor, throttle valve, or vacuum modulator to determine shift points, but today they use computer-controlled electromechanical servos.

While computer controls have improved the performance and efficiency of modern automatic transmissions, without a Transmission Control Unit, or TCU, they're a big, dumb aluminum container full of parts. That means that stuffing one under the floorboards of your custom classic truck has some challenges. But for every problem there is a solution, and in this case it comes from the appropriately named Powertrain Control Solutions.

As the brain trust at PCS explains it, “The primary factor separating the modern electronic automatic transmission from yesterday's hydro-mechanical automatic transmission is the speed and complexity of the logic used for transmission behavior. The hydro-mechanical automatic transmission of yesterday could only make its decisions based on throttle position, engine load, and driveshaft speed. Whereas the TCU can use these inputs as well as torque converter speed, engine speed, wheel speeds, traction control parameters, electronic throttle position, fluid temperature, engine temperature, brake pedal actuation, forward and lateral acceleration, as well as several other parameters. The TCU can also utilize manual shifting operation and provide altered transmission behavior for special conditions (road race, drag race, dynamometer, snow, towing, etc.).” Translated, that means the PCS TCU is definitely OK.

For those looking for a straightforward, easy-to-live-with transmission controller, PCS offers the Simple Shift. Neither a laptop, nor a technician in a lab coat are required to install the Simple Shift and it will completely control shift points, shift firmness, and torque converter lockup. Transmission shift points are adjusted by dials on the end of the control unit and diagnostic capabilities are communicated by flashing LEDs that also indicate what gear the transmission is in and whether or not the torque converter is locked. For those who want more adjustment options, the Simple Shift Tuner is also available. The handheld tuner can remain connected to the Simple Shift or be removed when programming is complete.

Also available from PCS is the TCM-2000. Similar to all their controllers, the TCM-2000 features dual calibrations that allow the driver to pick from two distinctly different transmission operating modes (sport mode, tow-haul mode, etc.), with programmable shift points, shift firmness, and torque converter lockup tailored to each application. Unique to the TCM-2000, it's capable of supporting a wide range of transmissions from GM, Ford, Chrysler, and a variety of imports. A CAN interface (controller area network, which lets multiple computers talk to one another) allows the TCM-2000 to be seamlessly used with CAN-based vehicles or ECUs and also simplifies the connection to a PCS Paddle Shifter or GSM-5000 Gear Select Module.

To put shifting at your fingertips, PCS offers the GSM Push Button Shifter that replaces the shift lever and linkage with a small touch-pad control module and sealed actuator. Thanks to its design the GSM control module can be surface or flush-mounted and is small enough to fit in consoles, dashes, door panels, or even armrests. Each button is recessed to avoid inadvertent touches and brightly backlit for darker environments. An easy-to-read display shows you what gear you're in. Standard control modules utilize a PRND configuration along with plus and minus buttons for shifting up or down.

Another unique shifting option is the PCS Paddle Shifter. Designed to provide the look and feel of an OEM system, it will bring out the Ferrari F-1 driver in anyone—it's that cool. Easily installing behind any aftermarket 5-, 6-, or 9-bolt steering wheel, the Paddle Shifter communicates with the transmission control unit via a wireless receiver module that plugs into the PCS transmission control units wiring harness.

1.The Simple Shift from PCS is the perfect solution for those who want an overdrive electronic transmission in their truck without a complicated control system. Set the knobs that control the shift points, shift firmness, when the converter locks and unlocks, as well as the number of cylinders the engine has and you’re done—it’s that simple.

1.The Simple Shift from PCS is the perfect solution for those who want an overdrive electronic transmission in their truck without a complicated control system. Set the knobs that control the shift points, shift firmness, when the converter locks and unlocks, as well as the number of cylinders the engine has and you’re done—it’s that simple.

2. For the ultimate in flexibility, PCS offers the TCM-2000. This user-friendly TCU provides complete control over an electronic transmission’s operation in two separate modes such as street and sport.

2. For the ultimate in flexibility, PCS offers the TCM-2000. This user-friendly TCU provides complete control over an electronic transmission’s operation in two separate modes such as street and sport.

3. The PCS transmission control units require input from several senders, one is the throttle position sensor found on electronic fuel injection systems.

3. The PCS transmission control units require input from several senders, one is the throttle position sensor found on electronic fuel injection systems.

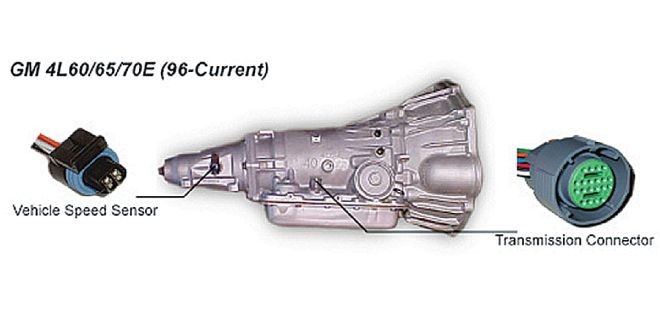

4. Computer controlled transmissions will have a Vehicle Speed Sensor and a plug for wiring from the computer. The PCS harness plugs into the factory connectors.

4. Computer controlled transmissions will have a Vehicle Speed Sensor and a plug for wiring from the computer. The PCS harness plugs into the factory connectors.

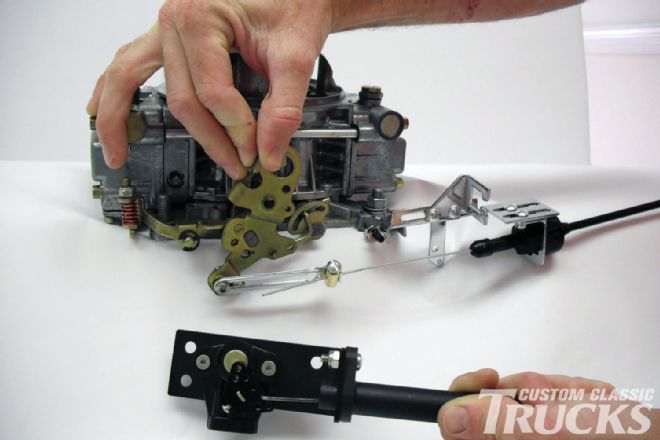

5. For carbureted applications, PCS offers a TPS conversion that uses a cable.

5. For carbureted applications, PCS offers a TPS conversion that uses a cable.

6. The TPS conversion includes the hardware to connect to the throttle valve lever on the carburetor.

6. The TPS conversion includes the hardware to connect to the throttle valve lever on the carburetor.

As if the paddle shifters weren't cool enough, the optional display allows the driver to view an array of data including:

•Current gear

•Vehicle speed

•Coolant temperature

•Converter lockup

•Engine rpm

•Turbine rpm

•Transmission slip

•Manifold pressure

•Transmission temperature

•Line pressure

•Driveshaft rpm

Installation of the Simple Shift is Uncomplicated

Mount the unit, hook up the wires, and you're ready to go. The output from the TCU plugs into the factory socket on the transmission; the remaining wires are for signals to the TCU—some are not used while others are.

Output Shaft Speed Sensor (also called the VSS or Vehicle Speed Sensor)

For transmissions with an Output Shaft Speed Sensor PCS has added a ‘Y' to the wiring harness, which allows the Simple-Shift harness to plug directly into the transmission and still leave an access plug for aftermarket speedometers or factory connectors that require a VSS signal.

Input Shaft Speed Sensor

If the transmission is equipped with it, this connector is required for operation.

Throttle Position Sensor

For cable-driven type throttle bodies it's simply a matter of splicing into the existing throttle position sensor wiring. Proper wiring techniques can be found on the support page at powertraincontrolsolutions.com. For carbureted applications, a Remote Mount TPS Adapter Kit is included in the Simple Shift Carb kit or available from PCS, part number TCM-6000.

Brake Lamp Input

This is required to unlock the torque converter when the brakes are applied.

Speedometer

This wire is not required for operation of the Simple Shift unit. Its purpose is to deliver a signal to early, older versions of electronic speedometers. Most aftermarket speedometers will use the Output Shaft Speed Signal.

Tachometer

Not required for operation of the Simple Shift unit, but it is recommended to offer comprehensive diagnostic capabilities. To utilize the full diagnostic function of your Simple Shift, connect this wire to the tachometer output wire of your ignition system. The tachometer ground wire must also be connected.

PCS Expansion

Not required for operation of the Simple Shift unit, it allows optional equipment, such as the Paddle Shifter or the D200 Touchscreen Dash logger, to be connected to the Simple Shift system. Instructions on how to utilize this connector will be included in the instructions for the optional expansion kits.

+12V Battery

Required for operation of the Simple Shift unit, it must be connected to the positive terminal of the vehicle's battery. Improper wiring will cause the unit to lose its TPS calibration and will not store diagnostic codes.

Switched +12V

Required for operation it is connected to the ignition/start system of your vehicle. It must have +12 volts while in both the start and run positions and no power while in the off position.

Chassis Ground

This wire is required; it is connected to the vehicle's chassis. During the initial installation and before driving the vehicle, the Simple Shift knobs must be set to a baseline configuration described in the instructions, then further adjustments can be made.

Full-Throttle Shift Points

PCS recommends this must be done under a controlled environment such as a dragstrip or a chassis dyno so no speed limits are exceeded. Shifts are going to occur at approximately the same rpm for each shift; therefore you may only need to make adjustments using the 1st to 2nd shift as a test. To lower the shift point, turn the knob counterclockwise toward the negative numbers. To raise the shift point the knob is turned clockwise toward the positive numbers.

Full-Throttle Shift Firmness

If the full-throttle shift firmness needs to be decreased, rotate the knob counterclockwise. If the full-throttle shifts need to be firmed up, increase the shift firmness by rotating the knob clockwise.

When making adjustments, turn the knob by one position then retest. Repeat as necessary. Keep in mind that a softer shift may result in higher engine rpm during the shift, therefore you may have to adjust your high throttle shift point selected in the previous step.

Low/Light Throttle Shift Points

Drive the vehicle at light throttle and adjust the low-throttle shift points as necessary. Rotate the knob clockwise to make the shifts occur at a higher rpm. Rotate the knobs counterclockwise to make the shifts happen at a lower rpm.

Installation of the TCM-2000 is similar to the Simple Shift; the TCU is mounted and the wiring harnesses are connected. Next, a PC is used to start the TCU software, it will auto-detect the presence of the transmission controller and the current operating parameters of the TCU will appear on the screen. At that point the transmission's functions can be tailored to its intended use. Detailed instructions on tuning the TCU will be found in the user's manual.

Modern automatics are far superior to their predecessors, but along with the advantages these new transmissions offer comes the requirement of a standalone management system when they are transplanted into an older environment. Not long ago installing a contemporary, computer-controlled automatic transmission in a custom classic truck was considered too complicated to contemplate, but PCS has made it easy with the Simple Shift and the TCM 2000. It's a great way to transform your truck.

7. An adjustable cable allow the conversion TPS to be mounted away from the carburetor.

7. An adjustable cable allow the conversion TPS to be mounted away from the carburetor.

8. For those who want to do away with the shift lever, PCS offers the GSM push-button shifter. A proven device, it has been thoroughly tested in automotive, military, commercial, and agricultural applications.

8. For those who want to do away with the shift lever, PCS offers the GSM push-button shifter. A proven device, it has been thoroughly tested in automotive, military, commercial, and agricultural applications.

9. Changing gears can be done with your fingertips with the PCS Paddle Shifter. The unit is connected to the horn button wire, eliminating any external wiring on the column.

9. Changing gears can be done with your fingertips with the PCS Paddle Shifter. The unit is connected to the horn button wire, eliminating any external wiring on the column.

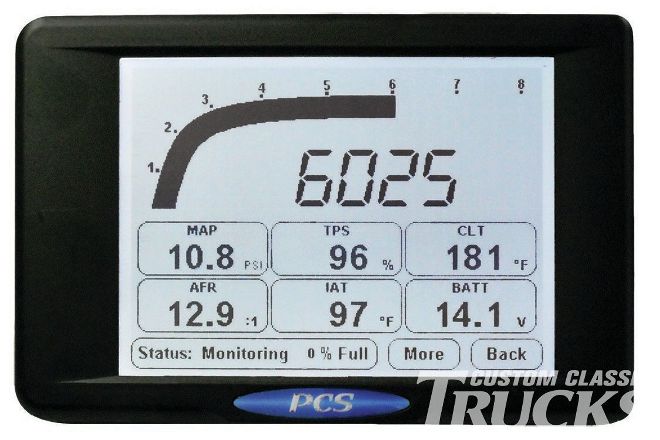

10. The PCS D200 Dashlogger is a fully programmable monitoring, data logging, and analysis system for drag race, circle track, road race, and even street trucks. The D200 can bring together information from a Lambda meter, aftermarket ECU, and transmission controller or act as a standalone data acquisition system.

10. The PCS D200 Dashlogger is a fully programmable monitoring, data logging, and analysis system for drag race, circle track, road race, and even street trucks. The D200 can bring together information from a Lambda meter, aftermarket ECU, and transmission controller or act as a standalone data acquisition system.

11. PCS wiring harnesses come with weather-tight plugs, factory-style connectors, and the wires are labeled for easy installation.

11. PCS wiring harnesses come with weather-tight plugs, factory-style connectors, and the wires are labeled for easy installation.

12. It goes without saying the all wires must be carefully routed and the included protective grommets should be used wherever the harness passes through holes in the body.

12. It goes without saying the all wires must be carefully routed and the included protective grommets should be used wherever the harness passes through holes in the body.